Comprehensive Guide to Ford 3000 Tractor Repair Manual

Ensuring the optimal performance of heavy-duty agricultural equipment is essential for maximizing productivity on the farm. This guide offers comprehensive insights into the essential practices and troubleshooting techniques necessary for maintaining your machinery. Understanding the intricacies of your equipment can lead to enhanced efficiency and longevity, ultimately benefiting your agricultural operations.

In the following sections, we will delve into various aspects of upkeep, from routine inspections to detailed diagnostic procedures. Whether you are a seasoned operator or a newcomer to the field, mastering these techniques will empower you to address issues proactively and maintain peak performance. Emphasizing the importance of regular attention and care, this resource serves as a valuable reference for all your mechanical needs.

With a focus on practical advice and step-by-step instructions, you will learn how to identify common problems, perform necessary adjustments, and implement preventive measures. The aim is to equip you with the knowledge required to handle challenges effectively, ensuring that your machinery remains reliable and ready for any task. Embrace the journey of maintenance and discover how proper care can lead to successful agricultural endeavors.

Essential Tools for Tractor Repairs

When maintaining and fixing heavy machinery, having the right equipment is crucial for efficiency and effectiveness. A well-equipped workspace can make all the difference in tackling various mechanical challenges. Understanding which tools are necessary helps streamline the maintenance process and ensures that tasks are completed safely and effectively.

Basic Hand Tools

Every mechanic should have a solid foundation of hand tools. These tools are indispensable for performing a wide range of tasks, from simple adjustments to more complex procedures. Below is a list of essential hand tools that every workshop should include:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening bolts and nuts. |

| Screwdrivers | Essential for driving screws in various applications. |

| Pliers | Helpful for gripping, bending, and cutting wire. |

| Socket Set | Provides a range of sizes for easier access to fasteners. |

Power Tools

In addition to hand tools, power tools significantly enhance efficiency and precision in mechanical tasks. These tools can reduce manual effort and increase productivity. Here are some power tools that are beneficial for any machinery maintenance:

| Tool | Purpose |

|---|---|

| Impact Wrench | Offers high torque output for fastener removal. |

| Drill | Used for making holes and driving screws quickly. |

| Grinder | Useful for cutting, grinding, and polishing metal parts. |

| Air Compressor | Powers pneumatic tools and assists in various tasks. |

Understanding the Ford 3000 Model

This section explores a specific agricultural machine, known for its reliability and efficiency in various farming tasks. Designed for optimal performance, it has gained popularity among users for its robust features and versatility.

Key characteristics of this model include:

- Durable construction materials that enhance longevity.

- Powerful engine options tailored for different needs.

- Intuitive controls that facilitate ease of use.

- Versatile attachments that expand functionality.

Its compact design allows for maneuverability in tight spaces, making it suitable for diverse agricultural environments. Additionally, the maintenance requirements are straightforward, contributing to a lower total cost of ownership.

Users often appreciate:

- Fuel efficiency, which minimizes operational costs.

- Strong aftermarket support, ensuring parts availability.

- A supportive community of owners sharing tips and experiences.

Overall, this machine remains a valuable asset in modern farming, combining practicality with performance to meet the demands of today’s agricultural landscape.

Common Issues with Ford 3000 Tractors

Many owners encounter a variety of challenges with their agricultural machinery over time. Understanding these prevalent problems can facilitate better maintenance and enhance the longevity of the equipment. Addressing these issues promptly is crucial for ensuring optimal performance and efficiency in the field.

One frequent concern involves engine performance, where operators may notice irregularities in power output or difficulty starting the machine. These symptoms can often stem from fuel system complications, such as clogged filters or injector malfunctions.

Another common issue relates to the hydraulic system. Users may experience inadequate lifting capacity or slow response times, which can be attributed to leaks, low fluid levels, or worn-out components within the hydraulic circuit.

Transmission difficulties are also reported, with challenges including slipping gears or difficulty shifting. These issues often result from inadequate lubrication or wear and tear on the transmission parts.

Electrical problems, such as faulty wiring or battery failures, can hinder operation as well. Regular checks on the electrical system can prevent unexpected breakdowns.

Lastly, tire wear and alignment issues can affect traction and maneuverability, leading to uneven wear patterns and reduced efficiency. Regular inspections and timely replacements are essential to maintain proper functionality.

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. Following a systematic approach to maintenance not only prevents unexpected failures but also enhances overall efficiency. Below are detailed procedures that will guide you through essential maintenance tasks.

Routine Checks

- Inspect fluid levels (oil, coolant, hydraulic fluid) regularly.

- Examine belts and hoses for signs of wear and tear.

- Check air filters and clean or replace them as needed.

Scheduled Servicing

- Change engine oil and replace the oil filter at recommended intervals.

- Lubricate pivot points and grease fittings to prevent rust and ensure smooth operation.

- Adjust brake systems and test functionality to ensure safety.

- Inspect tires for pressure and tread wear, adjusting as necessary.

Implementing these procedures consistently will contribute to the reliable functioning of your machinery and minimize the risk of costly repairs.

Engine Troubleshooting Tips

When encountering issues with your machinery, understanding the root causes of engine problems can significantly enhance performance and longevity. This section offers valuable insights to help you diagnose common complications, ensuring efficient operation and reducing downtime.

Common Symptoms and Solutions

Identifying the symptoms of engine malfunctions is crucial. Below is a table that outlines frequent issues along with possible solutions:

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Difficulty starting | Weak battery or faulty starter | Check battery charge and connections; replace starter if needed. |

| Overheating | Coolant leak or blocked radiator | Inspect hoses for leaks; clean or replace radiator. |

| Poor acceleration | Clogged fuel filter | Replace fuel filter and check fuel lines. |

| Excessive smoke | Oil contamination or fuel issue | Check oil levels and quality; examine fuel type used. |

Preventive Measures

Regular maintenance can prevent many engine issues. Ensure to perform routine checks on fluid levels, filters, and belts. Additionally, adhering to the manufacturer’s recommendations for service intervals can greatly extend the lifespan of your equipment.

Hydraulic System Diagnostics Explained

The functionality of a hydraulic system is crucial for optimal performance in various machinery applications. Understanding the diagnostic processes involved can help identify issues that may hinder efficiency and productivity. This section delves into essential techniques for evaluating hydraulic systems, ensuring that any malfunctions are addressed promptly and effectively.

Common Symptoms of Hydraulic Issues

When a hydraulic system is not operating as intended, several indicators may arise. These can include unusual noises, inconsistent pressure readings, or a noticeable decrease in operational speed. Fluid leaks are also a significant red flag, as they often point to compromised components within the system. Regular observation and awareness of these signs can facilitate early detection and mitigate further damage.

Diagnostic Procedures

To effectively diagnose hydraulic problems, technicians typically follow a systematic approach. Initial steps often involve visual inspections to check for leaks and assess fluid levels. Following this, pressure tests can be conducted to determine whether the system is maintaining appropriate levels. Utilizing diagnostic tools such as flow meters and pressure gauges is essential for gathering accurate data, allowing for informed decisions on necessary repairs or replacements.

Replacing Ford 3000 Parts Safely

Ensuring the longevity and efficiency of your machinery requires careful attention when changing components. Proper procedures and safety measures are essential to prevent accidents and damage during the replacement process. Understanding how to effectively handle each part not only safeguards the equipment but also promotes a secure working environment.

Preparation and Safety Gear

Before starting any work, gather the necessary tools and wear appropriate safety equipment. This includes gloves, goggles, and steel-toed boots. Make sure the machine is turned off and cooled down to avoid burns or injuries. Additionally, consult any available documentation to familiarize yourself with the specific components being replaced, ensuring you have all necessary information at hand.

Step-by-Step Replacement Process

Begin by carefully removing the old part, taking note of how it is connected. Documenting the process with photos can be helpful for reference during reinstallation. When installing the new component, ensure that it fits correctly and is securely fastened. Double-check all connections and settings before testing the machinery to confirm everything operates smoothly. Regular maintenance checks can further enhance the performance and lifespan of the equipment.

Electrical System Repair Techniques

Maintaining the electrical components of machinery is crucial for ensuring optimal performance and longevity. A thorough understanding of the system’s structure and function allows for effective troubleshooting and restoration of functionality. This section provides essential methods for diagnosing and resolving common issues within the electrical network.

When addressing problems, start by conducting a systematic inspection of the wiring and connectors. Look for signs of wear, corrosion, or loose connections that could lead to intermittent faults. Utilize a multimeter to measure voltage and continuity, ensuring that power is flowing correctly throughout the system.

| Issue | Possible Cause | Solution |

|---|---|---|

| No power | Faulty battery or connections | Check and replace battery; clean connections |

| Dim lights | Weak battery or bad alternator | Test battery voltage; replace alternator if necessary |

| Intermittent starting | Worn starter or ignition switch | Inspect and replace starter or switch |

After identifying the issue, ensure all components are correctly installed and aligned. Regular maintenance, such as cleaning contacts and ensuring proper voltage levels, can prevent future failures and enhance the overall reliability of the system.

Importance of Regular Servicing

Consistent maintenance of machinery is essential for ensuring optimal performance and longevity. By adhering to a structured service schedule, owners can prevent minor issues from escalating into major problems, ultimately saving time and costs associated with repairs. Regular attention to equipment not only enhances functionality but also guarantees safety during operation.

Benefits of Preventive Care

Engaging in routine inspections and adjustments helps identify wear and tear before it leads to breakdowns. This proactive approach minimizes downtime and maximizes productivity. Additionally, maintaining clean and well-functioning components contributes to efficient fuel usage, reducing operational expenses over time.

Enhancing Resale Value

Well-maintained machinery tends to retain its value better than neglected counterparts. A documented history of regular servicing can be a strong selling point when it comes time to upgrade or sell. Prospective buyers often seek assurance that equipment has been properly cared for, making a detailed service record an asset.

Finding Quality Replacement Parts

When it comes to maintaining machinery, sourcing high-quality components is essential for ensuring longevity and optimal performance. Whether you are undertaking a minor fix or a major overhaul, selecting the right pieces can make a significant difference in your equipment’s reliability.

Research and Verification

Start by identifying reputable suppliers who specialize in machinery parts. Online reviews, forums, and recommendations from fellow operators can provide valuable insights. Look for vendors that offer a warranty or guarantee on their products, as this often indicates a commitment to quality.

Compatibility and Specifications

Always verify that the replacement parts match the specifications of your machinery. Using components that are designed for your specific model will help prevent compatibility issues and ensure smooth operation. Keep a record of part numbers and specifications for future reference.

| Criteria | Importance |

|---|---|

| Quality Assurance | High |

| Supplier Reputation | Medium |

| Warranty Options | High |

| Compatibility Checks | Critical |

Upgrading Your Ford 3000 Tractor

Enhancing the performance and efficiency of your agricultural machine can significantly impact productivity. Whether you’re looking to boost power, improve comfort, or increase versatility, a few strategic upgrades can make a world of difference.

Here are some key areas to consider for enhancements:

- Engine Performance:

- Install a high-performance air filter for better airflow.

- Upgrade the fuel system to ensure optimal fuel delivery.

- Consider an aftermarket exhaust system for improved engine breathability.

- Hydraulic System:

- Upgrade hydraulic hoses and fittings for enhanced durability.

- Install a hydraulic cooler to maintain optimal operating temperatures.

- Consider adding additional hydraulic remotes for increased functionality.

- Comfort Enhancements:

- Add a better seat with improved cushioning and support.

- Install a cab or canopy for protection against weather conditions.

- Integrate ergonomic controls to reduce operator fatigue.

- Technology Upgrades:

- Implement GPS guidance systems for precision farming.

- Add a digital display for monitoring vital machine parameters.

- Consider telematics systems for real-time data tracking and diagnostics.

Before starting any upgrades, assess your needs and budget. Prioritize enhancements that align with your operational goals, and ensure compatibility with existing components to achieve the best results.

Resources for DIY Repairs

Engaging in hands-on maintenance can be both rewarding and cost-effective. By utilizing the right materials and information, enthusiasts can effectively tackle various tasks, ensuring optimal performance and longevity of their machinery. This section explores various avenues to empower individuals in their DIY endeavors.

Online forums and communities provide a wealth of shared experiences and knowledge. Members often discuss common issues, troubleshooting techniques, and solutions that have worked for them. Participating in these discussions can offer valuable insights and support.

Video tutorials have become an essential resource for visual learners. Platforms dedicated to educational content showcase step-by-step guides, making complex processes more approachable. Watching professionals and fellow enthusiasts can demystify repairs and inspire confidence.

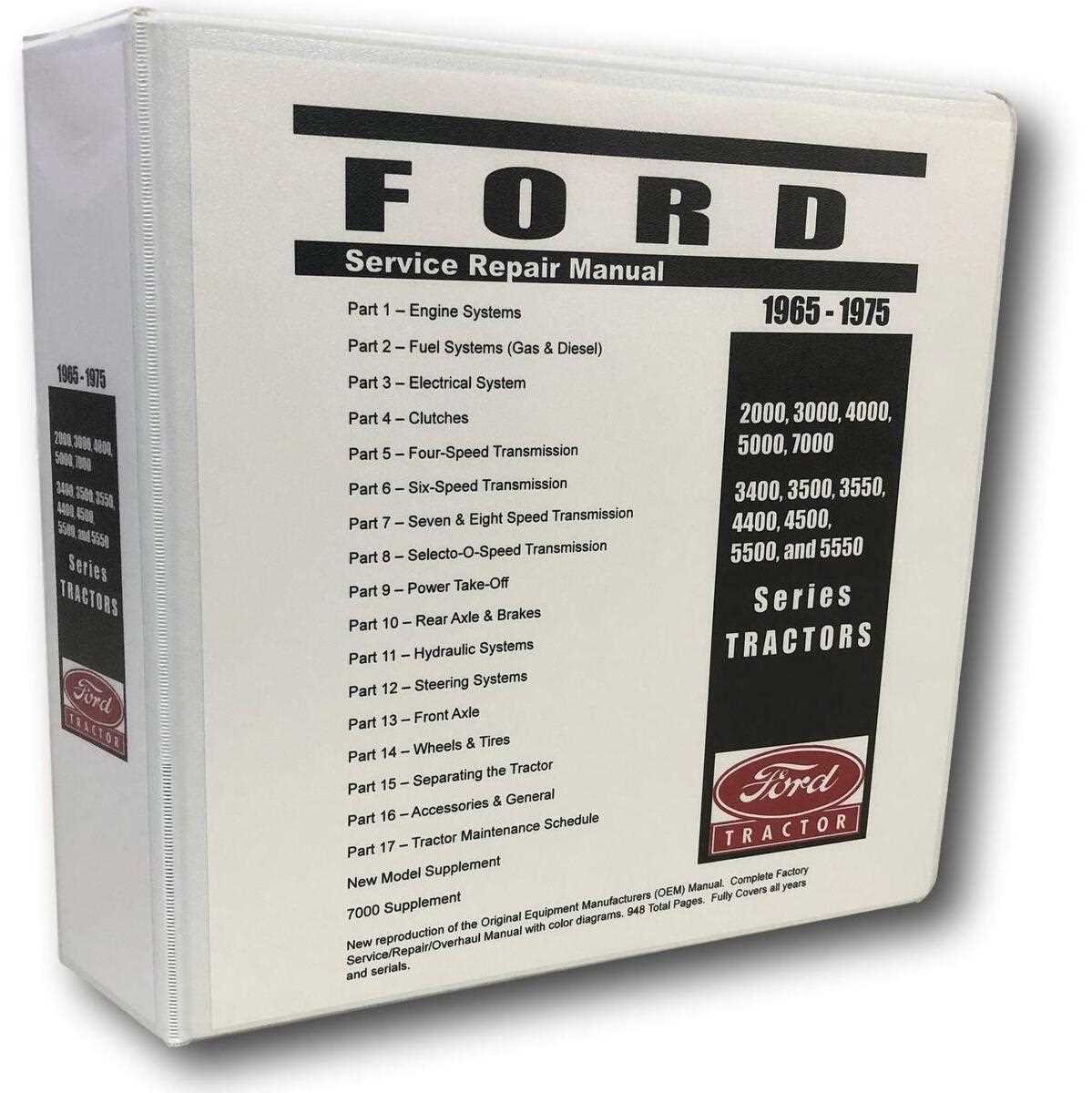

Comprehensive guides and publications can be found in bookstores and online. These texts often delve into specifics, providing detailed instructions, diagrams, and troubleshooting tips. Investing in a reliable guide can significantly enhance one’s understanding and ability to manage repairs effectively.

Additionally, local workshops and training sessions offer hands-on experience. Participating in these events allows individuals to practice techniques under expert supervision, reinforcing skills that can be applied in personal projects.

By leveraging these diverse resources, anyone can become more proficient in maintaining their equipment, ultimately leading to a deeper understanding of the machinery and an increased sense of accomplishment.