Comprehensive Guide to Ford 4500 Repair Manual

In the realm of automotive care, understanding the nuances of a specific vehicle can significantly enhance its performance and longevity. This section aims to provide a thorough exploration of essential techniques and procedures that ensure optimal functioning of a robust machine. Whether you’re a seasoned technician or a curious enthusiast, having access to detailed information can empower you to tackle various challenges with confidence.

From basic upkeep to more complex interventions, this guide serves as a valuable resource for individuals seeking to deepen their knowledge. With a focus on systematic approaches and practical tips, you’ll discover how to efficiently diagnose issues, implement solutions, and perform necessary adjustments. Each topic is designed to equip you with the skills required to maintain peak operational standards.

Emphasizing the importance of regular inspection and timely interventions, this compilation highlights critical components that demand attention. By familiarizing yourself with these aspects, you’ll not only enhance the reliability of your vehicle but also develop a greater appreciation for its intricate design. Join us on this journey of discovery as we delve into the vital practices that keep your automotive investment in prime condition.

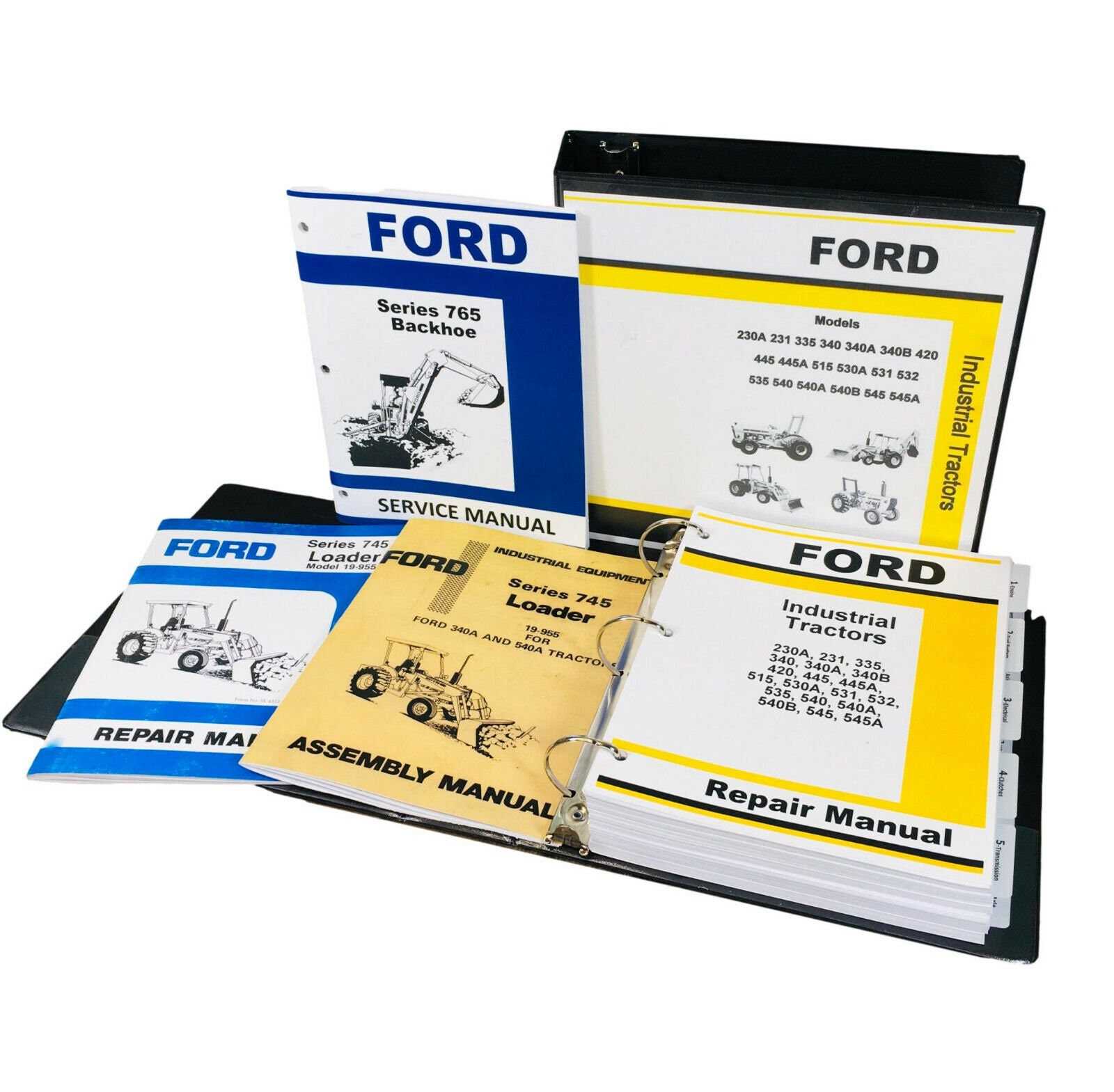

Overview of Ford 4500 Repair Manual

This section provides a comprehensive introduction to a crucial resource designed for maintenance and troubleshooting of specific machinery. It aims to equip users with essential information and guidance, ensuring efficient operation and longevity of the equipment.

Key Features

- Detailed instructions for routine maintenance

- Step-by-step troubleshooting guides

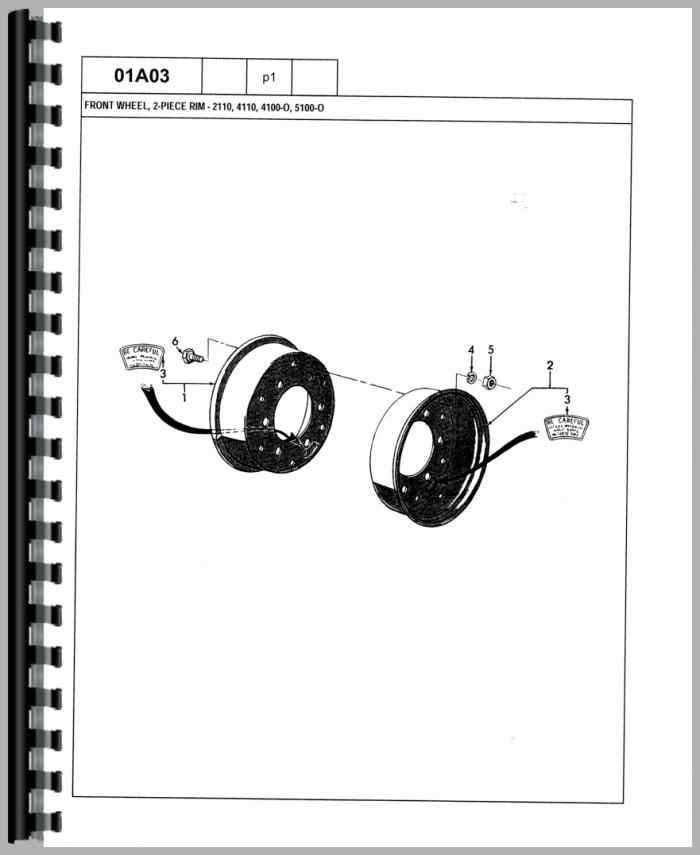

- Illustrative diagrams for clarity

- Parts lists and specifications

- Safety guidelines and precautions

Benefits of Using the Guide

- Enhances understanding of equipment functionality

- Reduces downtime through effective problem-solving

- Promotes DIY repairs, saving time and money

- Facilitates proper maintenance practices

Utilizing this resource effectively can lead to improved performance and reduced operational costs, making it an indispensable tool for owners and operators alike.

Common Issues with Ford 4500

This section addresses frequently encountered problems that operators may face with their heavy-duty vehicles. Understanding these common challenges can help in proactive maintenance and effective troubleshooting.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Overheating | Engines may experience overheating due to coolant leaks or blocked radiators. | Check coolant levels and hoses; clean or replace the radiator. |

| Transmission Slippage | Transmission issues can manifest as slippage during gear shifts. | Inspect fluid levels; replace worn components as necessary. |

| Electrical Failures | Malfunctions in the electrical system can lead to starting issues or accessory failures. | Examine battery connections and fuses; replace any faulty wiring. |

| Hydraulic Problems | Hydraulic systems may fail to operate properly, causing loss of power in attachments. | Check for leaks in hoses and fittings; replace hydraulic fluid as needed. |

| Tire Wear | Uneven tire wear can affect handling and safety. | Regularly rotate tires; ensure proper alignment and inflation. |

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures safety during the process. Understanding which instruments are fundamental can make a significant difference in the overall experience.

Wrenches are indispensable for loosening or tightening bolts and nuts. A variety of sizes and types, such as adjustable and socket wrenches, can accommodate different fasteners, providing versatility for various tasks.

Screwdrivers come in various shapes, including flathead and Phillips, making them essential for assembling and disassembling components. Having a set with varying sizes allows for precise handling of different screws.

Plier sets are vital for gripping, bending, and cutting materials. Needle-nose pliers, for instance, are particularly useful for reaching tight spaces, while wire cutters facilitate clean cuts for electrical tasks.

Jack stands and a reliable floor jack are necessary for safely lifting and supporting the vehicle during maintenance. Proper use of these tools is critical for ensuring safety and stability while working underneath.

In addition to these basics, a multimeter is invaluable for diagnosing electrical issues, allowing for accurate readings of voltage, current, and resistance. Having this tool on hand can streamline troubleshooting significantly.

Lastly, a toolbox or a storage system keeps everything organized and easily accessible, promoting a smoother workflow. Investing in quality instruments will pay off in longevity and effectiveness, ensuring that any task can be handled with confidence.

Step-by-Step Repair Procedures

This section provides a comprehensive guide for troubleshooting and fixing common issues. Following these detailed instructions will ensure that the process is smooth and effective, allowing you to get the machinery back in optimal condition.

-

Preparation:

- Gather necessary tools and equipment.

- Review safety protocols to ensure a secure working environment.

- Obtain relevant documentation for reference.

-

Diagnosis:

- Identify the symptoms of the malfunction.

- Conduct a visual inspection of key components.

- Utilize diagnostic tools for a more precise assessment.

-

Disassembly:

- Carefully remove any coverings or panels.

- Detach components in the order specified in the guidelines.

- Store removed parts in an organized manner to avoid loss.

-

Repairs:

- Replace damaged or worn-out parts with new ones.

- Perform necessary adjustments to ensure proper alignment.

- Test all electrical connections for continuity.

-

Reassembly:

- Follow the reverse order of disassembly for reinstallation.

- Ensure all fasteners are tightened to specified torque settings.

- Reconnect any electrical components carefully.

-

Testing:

- Conduct a preliminary operation check to verify functionality.

- Monitor performance under load conditions.

- Make any necessary adjustments based on test results.

Following these steps meticulously will facilitate a successful restoration process, ultimately enhancing the performance and longevity of the equipment.

Electrical System Troubleshooting Tips

Tackling issues within the electrical framework of machinery requires a systematic approach. Understanding the core components and their interactions is essential for effective diagnostics. This section provides practical guidance to help identify and resolve common electrical malfunctions.

Basic Checks

Start with visual inspections of wiring and connectors. Look for signs of wear, corrosion, or loose connections that may disrupt the circuit. Utilize a multimeter to verify voltage levels and continuity, ensuring that power is reaching the necessary components. Address any discrepancies promptly to prevent further complications.

Component Testing

When basic checks don’t yield results, focus on individual parts such as relays, fuses, and switches. Test each component for functionality, replacing any that are faulty. Additionally, consult schematics to understand the layout and flow of the electrical system, which can provide insights into potential issues and their locations.

Engine Maintenance Guidelines

Proper care and upkeep of the power unit are essential for optimal performance and longevity. Regular maintenance tasks can prevent potential issues and enhance efficiency. Following a structured approach ensures that the engine operates smoothly and reliably.

Routine Inspection

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace oil and filter to ensure proper lubrication. |

| Coolant Check | Monthly | Inspect coolant level and condition to prevent overheating. |

| Air Filter Replacement | Every 15,000 miles | Change air filter to maintain airflow and engine efficiency. |

Performance Optimization

To enhance the overall functionality, regular tuning and adjustments may be necessary. This includes checking spark plugs, fuel injectors, and exhaust systems. Keeping these components in good condition can significantly improve power output and fuel efficiency.

Transmission Service and Repair

The maintenance and troubleshooting of a vehicle’s powertrain are crucial for ensuring optimal performance and longevity. This section covers essential procedures and best practices for addressing common issues that may arise within the transmission system. Understanding the intricacies involved in this process can help extend the lifespan of the vehicle and enhance its overall efficiency.

Common Issues

- Fluid leaks

- Unresponsive shifting

- Strange noises during operation

- Warning lights on the dashboard

Maintenance Steps

- Check and replace transmission fluid regularly.

- Inspect for leaks around seals and gaskets.

- Examine the condition of the transmission filter.

- Ensure proper operation of shift cables and linkages.

By following these guidelines, vehicle owners can proactively manage their transmission systems, reducing the likelihood of costly repairs and ensuring a smoother driving experience.

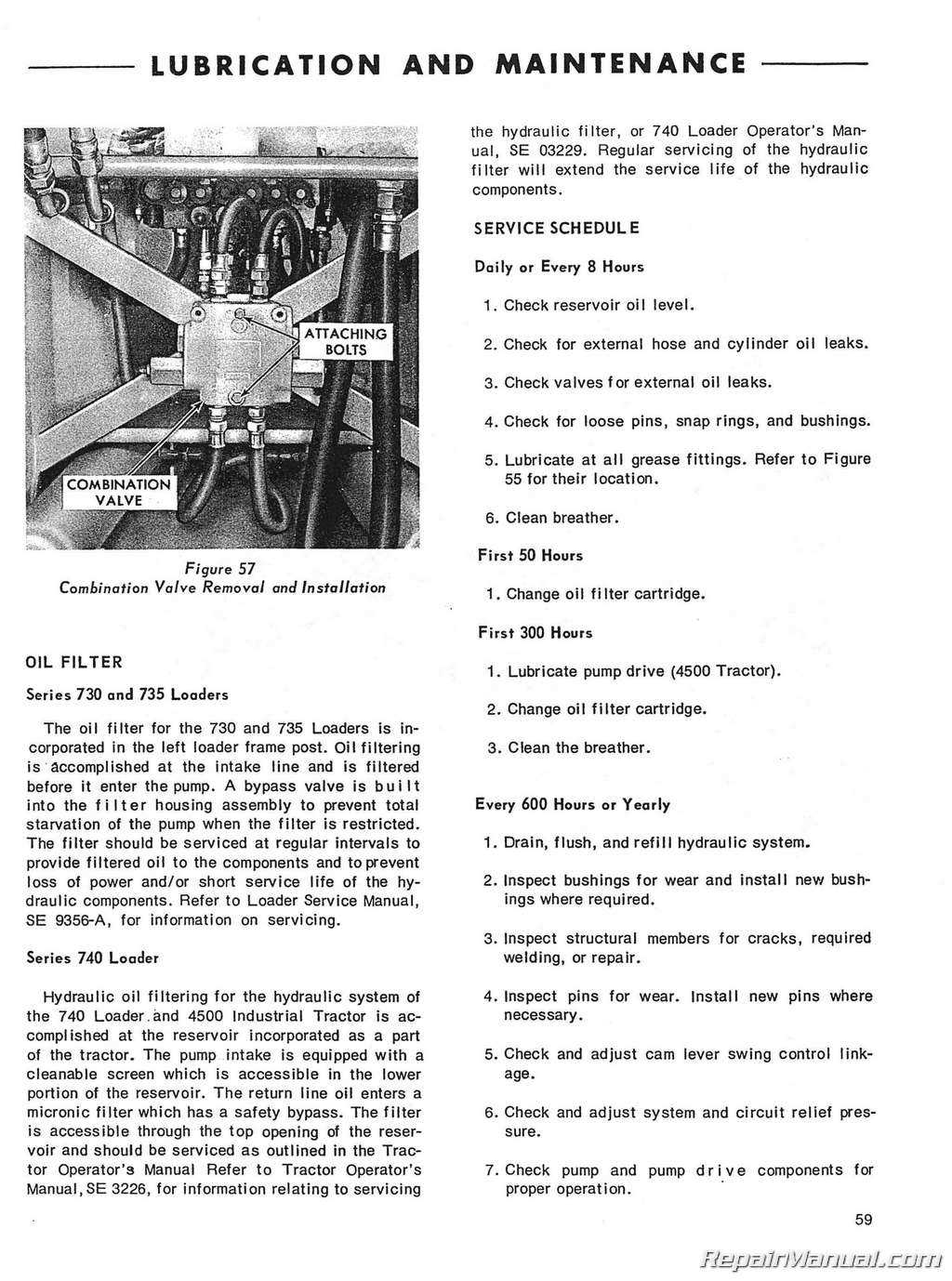

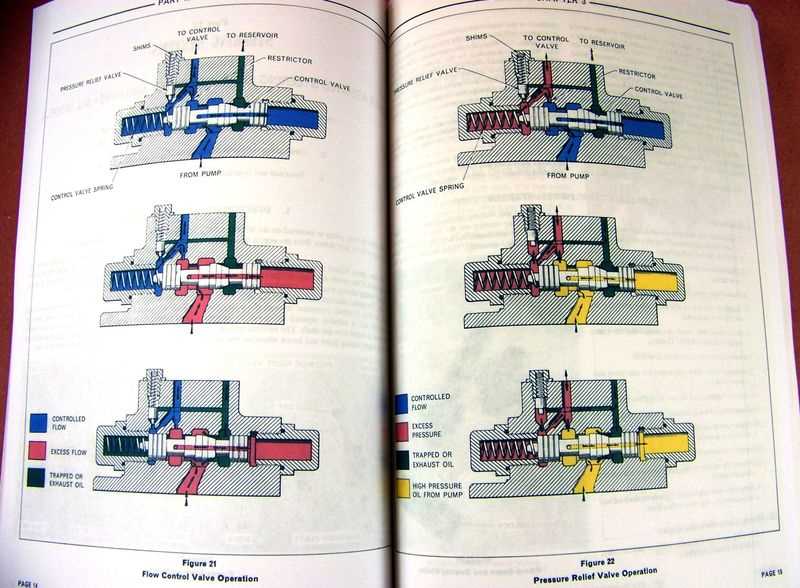

Hydraulic System Diagnostics

The efficiency of a hydraulic mechanism relies heavily on the integrity and performance of its components. Proper diagnostics are essential to identify issues that can lead to operational failures or reduced functionality. A systematic approach allows for accurate detection of anomalies, ensuring that the system operates optimally.

Common Symptoms of Hydraulic Issues

Several signs may indicate that a hydraulic system is experiencing difficulties. Recognizing these early can help prevent further damage and costly repairs.

| Symptom | Possible Cause |

|---|---|

| Slow operation | Insufficient fluid levels or contamination |

| Unusual noises | Air in the system or worn components |

| Leaks | Deteriorated seals or hoses |

| Erratic movement | Faulty valves or pump issues |

Diagnostic Procedures

To effectively troubleshoot hydraulic issues, follow a series of structured steps. Begin by visually inspecting the system for leaks or damaged components. Next, check fluid levels and quality, replacing or replenishing as necessary. Utilizing pressure gauges can provide insight into system performance, while flow tests help assess the efficiency of pumps and valves. Documenting findings will facilitate better understanding and resolution of the identified issues.

Body and Frame Restoration Techniques

Restoring the exterior and structural elements of a vehicle is a crucial process that enhances both its aesthetics and functionality. This involves a combination of skillful craftsmanship and the right methodologies to ensure longevity and performance. The following techniques will guide enthusiasts through the essential steps of rejuvenating a vehicle’s body and frame.

Preparation and Assessment

Before embarking on the restoration journey, it is vital to assess the current condition of the vehicle. This initial evaluation helps in identifying the areas that require attention.

- Inspect for rust and corrosion.

- Check for structural damage.

- Evaluate the alignment of the frame.

- Document existing repairs and modifications.

Restoration Techniques

Once the assessment is complete, the following techniques can be employed to restore the body and frame:

- Rust Removal: Use wire brushes, sandblasting, or chemical strippers to eliminate rust and prepare the surface for treatment.

- Welding and Fabrication: Reinforce or replace damaged sections with new metal. Ensure proper welding techniques to maintain structural integrity.

- Painting and Finishing: Apply a protective coating to prevent future corrosion. Choose quality paints that offer durability and an attractive finish.

- Alignment Adjustments: Use specialized tools to ensure the frame is properly aligned, which is crucial for handling and safety.

By following these techniques, enthusiasts can achieve a successful restoration, enhancing both the beauty and performance of their vehicle.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both the technician and the equipment. Adhering to specific guidelines minimizes the risk of accidents and enhances the overall efficiency of the work process. Proper awareness and preparation can significantly reduce potential hazards that may arise during mechanical interventions.

Essential Safety Gear

Wearing the appropriate protective equipment is vital. This includes gloves, safety glasses, and steel-toed boots. Each item plays a key role in safeguarding against injuries caused by sharp objects, chemicals, or heavy components. Make it a habit to inspect your safety gear regularly, replacing any worn or damaged items.

Work Area Organization

A well-organized workspace is fundamental to maintaining a safe environment. Ensure that tools and materials are neatly arranged, reducing the likelihood of trips or falls. Keep flammable substances away from heat sources and ensure adequate ventilation when dealing with chemicals. Clear any unnecessary items from the area to maintain focus and prevent distractions.

Understanding Manufacturer Specifications

Manufacturer specifications play a crucial role in ensuring the optimal performance and longevity of machinery. These detailed guidelines provide essential information regarding the operational standards, components, and maintenance requirements necessary for effective functioning. Adhering to these specifications helps prevent issues that can arise from improper use or inadequate servicing.

Key areas covered by manufacturer specifications include:

- Technical Data: This encompasses engine performance, torque settings, and operational limits.

- Component Requirements: Specifications often detail the types of parts suitable for replacement or repair, ensuring compatibility and efficiency.

- Maintenance Intervals: Regular servicing is outlined, including oil changes, filter replacements, and inspections, to maintain performance standards.

- Safety Guidelines: Essential safety protocols are included to minimize risks during operation and maintenance.

By understanding and following these specifications, users can significantly enhance the reliability and safety of their equipment. Neglecting these guidelines may lead to inefficient operation and potential damage, underscoring the importance of consulting the appropriate documentation regularly.

Resources for Further Assistance

When dealing with complex machinery, having access to additional resources can greatly enhance your understanding and facilitate problem-solving. Whether you are seeking specific advice, parts information, or troubleshooting tips, numerous platforms and communities can provide valuable support.

Online Communities

- Forums: Engage with fellow enthusiasts and experts on dedicated discussion boards where you can ask questions and share experiences.

- Social Media Groups: Join groups on platforms like Facebook or Reddit that focus on your equipment type, allowing for real-time advice and support.

- YouTube Channels: Explore video tutorials and walkthroughs that visually demonstrate repair techniques and maintenance tips.

Official Resources

- Manufacturer Websites: Visit the official site for comprehensive information about parts, service bulletins, and updates.

- Local Dealers: Reach out to authorized dealers for expert advice, parts availability, and maintenance services.

- Workshops and Training Programs: Consider enrolling in courses that offer hands-on experience and professional insights.