Ford Tractor Repair Guide

Ensuring the longevity and optimal performance of agricultural machinery is crucial for those who rely on it for daily operations. A thorough understanding of how to keep these machines in peak condition can prevent downtime and extend the equipment’s lifespan, leading to more efficient work on the field.

This resource offers detailed instructions and insights on addressing common issues that may arise with various machines used in farming. From basic maintenance tasks to more involved procedures, following these guidelines will help maintain the functionality of your equipment and avoid costly breakdowns.

By following these practical tips, you’ll be equipped to handle routine upkeep and tackle more complex challenges with confidence. This guide aims to simplify the process, making it easier to keep your machinery running smoothly for years to come.

Maintenance Guidelines for Agricultural Equipment

Regular upkeep of machinery is crucial to ensure its optimal performance and longevity. By following a few essential practices, you can prevent common issues and extend the working life of your equipment. Proper care includes monitoring various components and conducting periodic inspections to identify any potential problems before they escalate.

Lubrication plays a vital role in maintaining the smooth operation of moving parts. It’s important to keep all relevant areas well-oiled, as this reduces wear and tear, ensuring efficient functionality.

Another critical aspect is to check fluid levels regularly. This includes monitoring the hydraulic systems, coolant, and fuel levels. Inadequate fluid levels can lead to overheating or decreased efficiency, so timely refills are essential.

In addition, routine cleaning helps to prevent the accumulation of dirt and debris, which can interfere with sensitive components. Keeping your machinery clean will help preserve its condition and minimize unexpected breakdowns.

Engine Troubleshooting for Agricultural Machines

Identifying and resolving engine issues is essential to maintaining the performance of any agricultural machinery. This section provides a detailed approach to recognizing common problems that may arise in engines and offers practical solutions to keep the machine running efficiently.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel system blockage or ignition failure | Check fuel lines for blockages and ensure the ignition system is functioning correctly. |

| Overheating | Coolant level low or radiator malfunction | Refill coolant and inspect the radiator for leaks or blockages. |

| Excessive smoke | Oil leakage or incorrect fuel mix | Inspect for oil leaks and adjust the fuel mixture accordingly. |

By diagnosing and addressing these issues, you can extend the engine’s life and avoid costly breakdowns. Regular maintenance is key to ensuring the smooth operation of machinery in the field.

Replacing Hydraulic Components on Ford Tractors

Hydraulic systems play a crucial role in the overall functionality of agricultural machinery. Over time, these systems may experience wear, requiring some parts to be replaced. Understanding how to correctly replace key components ensures smooth operation and prevents future issues. Below is a detailed guide for changing essential parts within the hydraulic assembly.

- Start by ensuring that the equipment is safely secured and all power sources are disconnected.

- Drain the hydraulic fluid to prevent spillage when removing components. Use appropriate containers to catch the fluid.

- Identify the part of the system that needs replacement. This could be a pump, hose, or valve, depending on the issue encountered.

- Loosen and remove any bolts or connectors securing the faulty part in place.

- Install the new component, ensuring all fittings are tightened properly to avoid leaks.

- Refill the system with fresh hydraulic fluid, following the manufacturer’s recommendations for fluid type and quantity.

- Test the system for any irregularities by operating it under normal conditions. Check for leaks or unusual noises.

By following these steps, you can efficiently replace hydraulic components and maintain the smooth functioning of your equipment. Regular inspections and timely part replacement will extend the life of the machinery and reduce downtime.

Electrical System Repairs for Ford Models

Maintaining the electrical system is essential for ensuring smooth functionality and preventing issues with the performance of machinery. Regular checks and adjustments can help keep all components running efficiently, minimizing the risk of malfunctions.

Common Issues in the Electrical Setup

Various electrical components may encounter issues over time, especially due to wear or exposure to harsh conditions. Identifying these problems early can prevent more serious complications down the road.

- Battery connections becoming loose or corroded.

- Wiring faults leading to intermittent failures.

- Alternator malfunction affecting power distribution.

Steps for Troubleshooting

A systematic approach is required when diagnosing problems within the system. Begin by inspecting visible connections and fuses before moving on to more complex areas.

- Check all wire connections for any signs of damage.

- Test the battery to ensure it holds the correct charge.

- Inspect the alternator and voltage regulator for proper functioning.

Following these steps can help identify and resolve common electrical issues, improving overall system performance and reliability.

Transmission Issues and Solutions

Transmission problems can significantly impact the performance of heavy machinery, causing delays and inefficiencies in operation. It’s crucial to identify the root cause of any malfunctions in this system early, as prompt action can prevent further damage and reduce downtime.

Common issues often arise due to wear and tear in key components, fluid leaks, or improper adjustments. Identifying whether the problem is mechanical or related to the fluid system is essential for effective troubleshooting.

One frequent issue is difficulty in shifting gears, which could be caused by a malfunctioning clutch, low hydraulic pressure, or worn synchronizers. In such cases, inspecting the system for signs of leaks, worn parts, or improper alignment can help in diagnosing the exact cause.

Another common problem is slippage during operation. This can result from low transmission fluid levels, contamination, or degraded clutch components. Regular maintenance, including fluid checks and filter replacements, helps avoid this issue.

In conclusion, addressing transmission issues promptly with proper inspection and maintenance is vital for ensuring smooth operation and avoiding costly repairs. Monitoring key components and fluid levels can significantly extend the lifespan of the machinery’s transmission system.

Brakes and Steering Adjustments

Maintaining optimal performance of the stopping and steering systems is essential for safe and efficient operation of heavy machinery. Proper adjustments ensure that these systems respond accurately to operator inputs, enhancing control and stability. Regular checks and modifications help in identifying issues early, thereby preventing more significant problems down the line.

Brake System Calibration

Adjusting the braking mechanism involves checking the alignment and tension of various components. Ensure that the brake pads are correctly positioned and that the hydraulic fluid levels are adequate. Regular inspection of these elements will not only improve responsiveness but also extend the lifespan of the system. It is crucial to test the brakes periodically under different conditions to confirm their reliability.

Steering Mechanism Tuning

The steering system should be regularly assessed for play and responsiveness. Proper tuning can prevent excessive wear and ensure precise maneuvering. Start by examining the steering linkages for any signs of wear or looseness. Adjustments may be necessary to maintain a tight and responsive feel, providing operators with the confidence to navigate various terrains effectively.

Tire Replacement and Alignment Tips

Ensuring proper maintenance of wheels is essential for optimal performance and safety of heavy machinery. Regular attention to tire condition and alignment can enhance durability and efficiency while minimizing operational issues.

When it comes to changing tires, consider the following steps:

- Inspect the existing tires for signs of wear, such as cracks, uneven tread, or low pressure.

- Select high-quality replacements that match the specifications required for your equipment.

- Use appropriate tools and follow safety protocols during the replacement process.

- Check the valve stems and ensure they are functioning correctly to prevent air leaks.

After replacing the tires, proper alignment is crucial for optimal handling and tire longevity. Here are some alignment tips:

- Conduct a thorough inspection of the suspension and steering components for any damage or misalignment.

- Adjust the camber, caster, and toe angles according to the manufacturer’s guidelines.

- Regularly check alignment settings, especially after replacing tires or making suspension adjustments.

- Consider professional services if you’re uncertain about achieving precise alignment.

Maintaining the condition of wheels and ensuring correct alignment will not only improve performance but also contribute to overall safety during operation.

Cooling System Maintenance for Optimal Performance

Regular upkeep of the cooling mechanism is essential for ensuring peak efficiency and longevity of machinery. By maintaining the proper functioning of this system, operators can prevent overheating and reduce the likelihood of costly repairs. Understanding the key aspects of this maintenance process allows for better performance and reliability during operation.

One of the primary tasks in maintaining the cooling system is checking the coolant levels. Ensuring that the fluid is at the appropriate level helps to regulate the engine temperature effectively. Low coolant levels can lead to increased temperatures, potentially causing severe damage. Regularly topping up or replacing the coolant as necessary is crucial.

Another important aspect is inspecting the radiator for any signs of corrosion or blockage. A clean radiator is vital for efficient heat dissipation. Operators should clean the radiator fins and remove any debris that may obstruct airflow. Additionally, it is advisable to check the hoses and connections for leaks or wear, as compromised hoses can lead to coolant loss and overheating.

Finally, consider the thermostat’s functionality. This component controls the flow of coolant and ensures that the engine reaches its optimal operating temperature. Regular testing of the thermostat can help identify any issues early on, allowing for timely replacements and avoiding potential overheating scenarios.

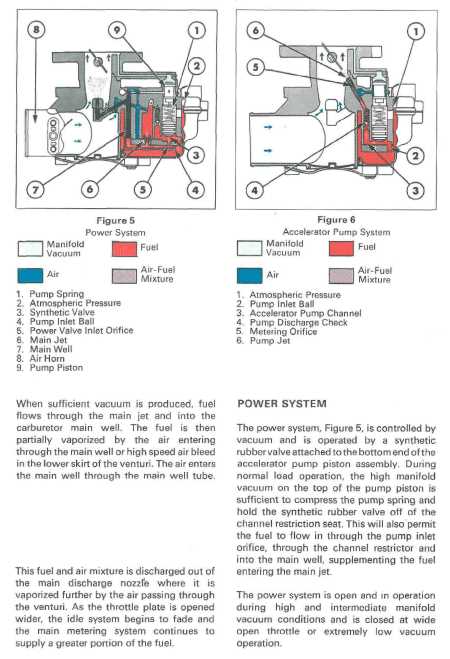

Fuel System Diagnostics and Repairs

This section focuses on identifying and resolving issues within the fuel delivery mechanism of agricultural machinery. Proper functioning of this system is essential for optimal performance and efficiency. Understanding how to diagnose common problems can lead to effective solutions and ensure longevity of the equipment.

Common Fuel System Issues

Several factors can contribute to malfunctions in the fuel delivery system. Clogged filters, faulty injectors, and leaks in fuel lines are among the most prevalent issues. Recognizing symptoms such as poor engine performance, hard starting, or excessive smoke can aid in pinpointing the source of the problem.

Diagnostic Procedures

To accurately assess fuel system health, one should conduct a series of tests. Begin with a visual inspection of all components, checking for signs of wear or damage. Utilizing diagnostic tools, such as pressure gauges and flow meters, can provide valuable insights into the system’s functionality. After identifying the root cause, appropriate measures can be taken to rectify the issue, ensuring reliable operation.

Restoring Bodywork and Paint on Ford Tractors

Bringing life back to the exterior of a heavy-duty vehicle involves a meticulous approach to address both aesthetics and durability. The process requires attention to detail, ensuring that surfaces are smooth and paint adheres properly for long-lasting results. Here are essential steps to guide you through enhancing the outer appearance of your machinery.

Preparation Steps

- Assess the Condition: Examine the surface for rust, dents, and scratches.

- Cleaning: Thoroughly wash the exterior to remove dirt, grease, and old paint.

- Sand the Surface: Use appropriate sandpaper to smooth out imperfections and prepare for painting.

- Rust Treatment: Apply rust converter or primer to prevent corrosion on affected areas.

Painting Techniques

- Choosing the Right Paint: Select high-quality paint suitable for heavy machinery.

- Applying Primer: Use a primer to ensure proper adhesion of the topcoat.

- Topcoat Application: Apply the paint in thin, even layers, allowing sufficient drying time between coats.

- Finishing Touches: Consider applying a clear coat for added protection and shine.

Following these guidelines will not only enhance the visual appeal of your equipment but also contribute to its longevity and value. A well-executed restoration can transform the appearance and extend the life of your machinery.