Thetford Aqua Magic IV Repair Guide

Maintaining a high-performance sanitation system is crucial for ensuring a comfortable and functional experience. This guide aims to provide insights into troubleshooting common issues and enhancing the longevity of your equipment. Understanding the components and their operations can significantly improve your maintenance routine.

In this section, we will explore various techniques for diagnosing problems and implementing effective solutions. By following straightforward steps, users can easily address concerns and keep their systems in optimal condition. Armed with knowledge and practical tips, anyone can ensure reliable performance and extend the lifespan of their fixtures.

This section addresses frequently encountered problems associated with a particular model of portable sanitation devices. Understanding these common challenges can aid users in identifying issues quickly and implementing effective solutions, ensuring optimal functionality.

| Issue | Description | Possible Solution |

|---|---|---|

| Flushing Problems | Inconsistent or weak flushing action. | Check for blockages in the system and ensure adequate water supply. |

| Leaks | Water leaking from the base or connections. | Inspect seals and tighten connections; replace worn components as needed. |

| Odor Issues | Unpleasant smells emanating from the unit. | Ensure proper sealing and regular maintenance; consider using odor control products. |

| Valve Malfunctions | Difficulty in operating the flushing mechanism. | Clean or replace the valve assembly to restore functionality. |

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to identifying and resolving common issues with your toilet system. By following the steps outlined below, you can efficiently diagnose the problem and implement effective solutions.

1. Check for Blockages: Begin by inspecting the toilet for any visible obstructions. Clear any debris that may be hindering the proper flow. A clogged system can lead to various malfunctions.

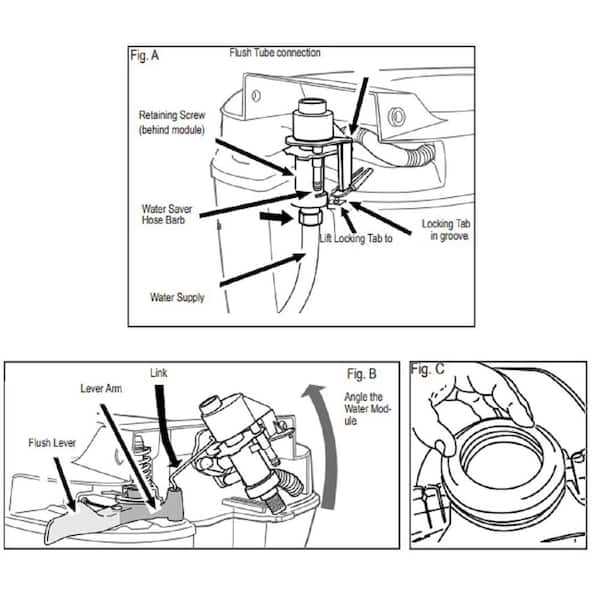

2. Inspect Water Supply: Ensure that the water supply is adequately connected and functioning. Verify that the valve is open and there are no leaks in the hoses. Insufficient water flow can cause flushing problems.

3. Test the Flush Mechanism: Examine the flushing mechanism to confirm it is operating correctly. If the flush lever feels loose or unresponsive, it may need adjustment or replacement.

4. Examine Seals and Gaskets: Check the seals and gaskets for any signs of wear or damage. Worn components can lead to leaks and inefficient operation, necessitating replacement.

5. Look for Signs of Wear: Assess the overall condition of the unit, including any cracks or degradation. Any noticeable damage should be addressed promptly to prevent further issues.

6. Consult Manufacturer Resources: If problems persist, refer to the manufacturer’s documentation for additional guidance. These resources often include detailed troubleshooting tips and maintenance advice.

By systematically following these steps, you can effectively troubleshoot and resolve many common issues encountered with your toilet system.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your sanitation system, regular care and attention are essential. Implementing simple maintenance practices can greatly enhance the lifespan of your equipment and prevent potential issues.

- Regular Cleaning: Keep surfaces clean and free from debris. Use mild detergents and avoid harsh chemicals that could damage components.

- Check Seals: Inspect rubber seals and gaskets for wear and tear. Replace any that appear cracked or brittle to prevent leaks.

- Flush System: Periodically flush the system to remove buildup and ensure smooth operation. This is especially important after prolonged use.

- Avoid Overloading: Do not exceed the recommended usage limits to prevent strain on the system. Follow manufacturer guidelines for safe operation.

- Store Properly: If storing for an extended period, ensure the unit is emptied and cleaned to prevent odors and damage.

By following these straightforward maintenance tips, you can promote the longevity of your sanitation equipment and ensure it remains in good working condition for years to come.

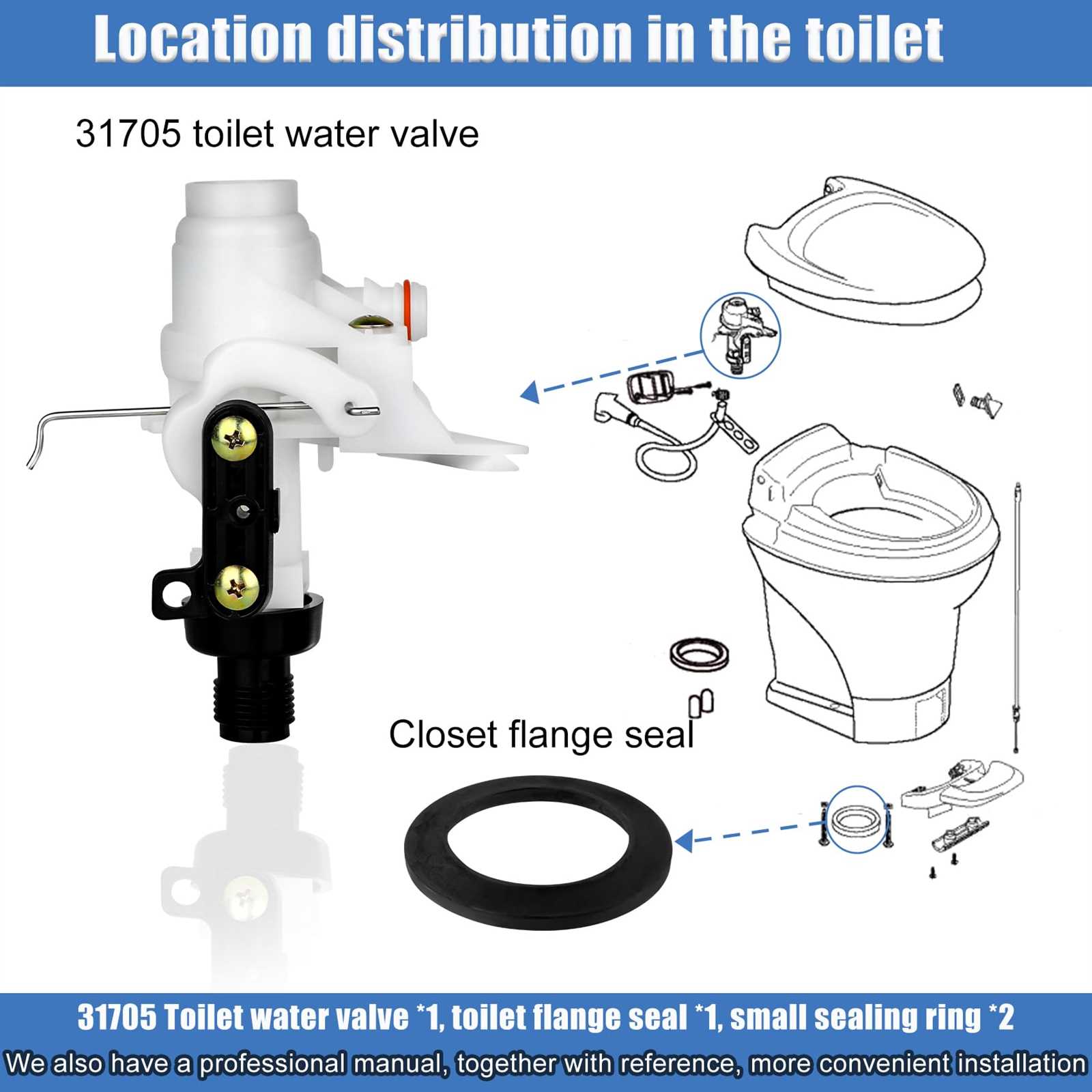

Parts Replacement and Upgrades

Maintaining and enhancing the functionality of your sanitation unit involves understanding when and how to replace components. Upgrading specific parts can improve performance and extend the lifespan of the system, ensuring reliable operation during use.

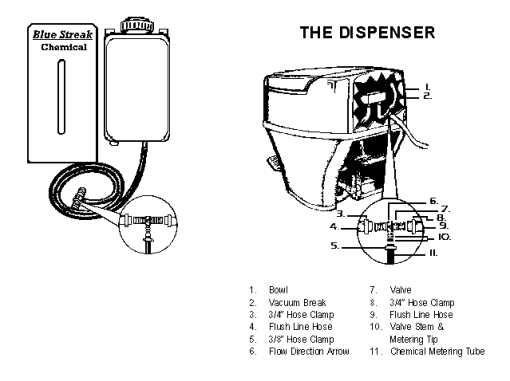

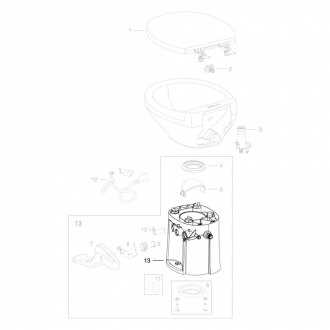

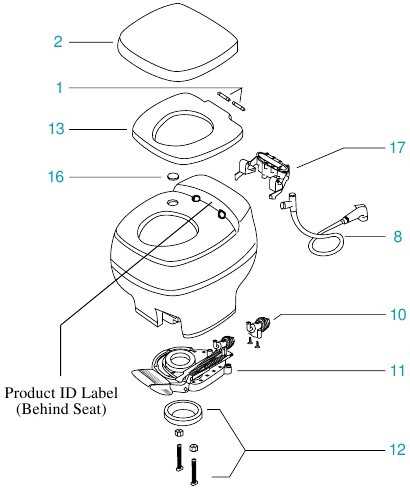

Identifying Components for Replacement

Regular inspection is essential to identify worn or malfunctioning parts. Commonly replaced items include seals, valves, and pumps. If you notice leaks, reduced flushing efficiency, or unusual noises, it may indicate the need for part replacements. Addressing these issues promptly can prevent further damage and enhance overall performance.

Upgrading for Enhanced Performance

Consider upgrading to higher-quality materials or more advanced technology to boost efficiency. Enhanced components may offer better durability, improved flushing power, or reduced maintenance needs. Research available options to find suitable upgrades that fit your specific requirements and improve the user experience.

Cleaning Procedures for Optimal Function

Maintaining cleanliness is essential for ensuring the efficient operation of your sanitation system. Regularly scheduled cleaning not only prolongs the lifespan of components but also enhances overall performance. This section outlines effective techniques to keep your system in top condition.

Daily Maintenance Tips

Implementing a daily cleaning routine can significantly reduce buildup and prevent clogs. Start by rinsing the system with clean water after each use. Additionally, using a soft cloth to wipe down surfaces helps remove any residue. Avoid harsh chemicals that could damage components.

Deep Cleaning Procedures

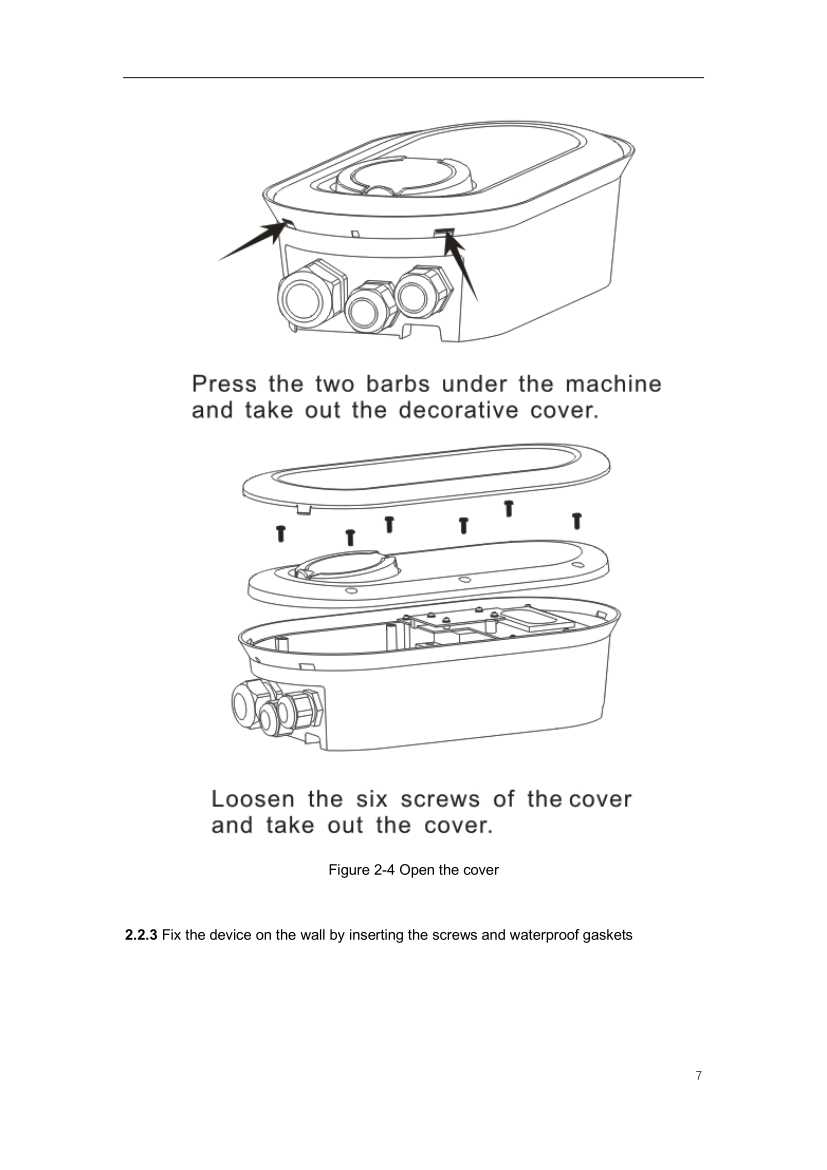

Every few weeks, conduct a more thorough cleaning. Begin by disassembling removable parts as per the guidelines provided in the manufacturer’s instructions. Use a mixture of warm water and mild soap to scrub all surfaces, paying close attention to hidden areas. Rinse thoroughly and ensure all parts are completely dry before reassembly. This practice will help maintain optimal functionality and prevent unpleasant odors.

Diagnosing Water Leakage Problems

Water leakage in portable sanitation devices can lead to significant issues if not addressed promptly. Identifying the source of the leak is essential to ensure proper functioning and maintain hygiene standards. This section provides an overview of common signs of leakage and methods for diagnosing the problem.

Identifying Symptoms of Leakage

Look for visible signs of moisture around the unit, including puddles or damp spots on the ground. Unusual odors may also indicate leaks, as they can result from waste accumulation. Additionally, a decrease in flushing efficiency or persistent low water levels can signal a problem.

Step-by-Step Diagnostic Approach

To diagnose leakage, begin by examining all connections and seals. Check hoses and fittings for cracks or wear. Inspect the holding tank for any signs of damage. If necessary, perform a water test by filling the system and observing for leaks over time. Utilizing this systematic approach can help pinpoint the issue efficiently.

Understanding the Control Mechanisms

The operation of sanitation systems relies heavily on their control features, which play a crucial role in ensuring effective functionality. These mechanisms dictate how users interact with the system, influencing performance and user experience.

Typically, these control systems consist of various components that work together to manage tasks such as flushing and water flow. Understanding how these parts communicate can enhance maintenance and troubleshooting efforts. Each component is designed to fulfill a specific function, contributing to the overall efficiency of the unit.

For instance, the actuator is responsible for initiating the flush process, while sensors monitor water levels and pressure. Recognizing the interplay between these elements allows users to identify potential issues and optimize performance, making it essential for anyone involved in system upkeep.

Tools Required for Repairs

Having the right equipment is essential for effective maintenance and troubleshooting of restroom fixtures. Proper tools can facilitate the process, making it smoother and more efficient.

Basic Hand Tools

Start with essential hand tools such as screwdrivers, pliers, and wrenches. These items will assist in loosening and tightening components as needed. Ensure to have both flathead and Phillips screwdrivers to accommodate various screws.

Specialized Equipment

In addition to standard tools, some specialized equipment may be necessary for specific tasks. For instance, a multimeter can help in diagnosing electrical issues, while sealant and adhesives are useful for preventing leaks. Always keep a clean workspace to maintain safety and organization.

Expert Advice from Users

This section compiles valuable insights and tips from experienced users who have navigated common challenges. Their shared knowledge can help others effectively troubleshoot issues and enhance their experience.

- Regular Maintenance: Users emphasize the importance of routine checks to prevent minor issues from escalating.

- Cleaning Techniques: Many recommend specific cleaning agents that ensure longevity and proper functioning.

- Common Fixes: Participants have identified several straightforward solutions for frequent problems, making repairs manageable.

- Resource Sharing: Users often share helpful resources, including videos and forums, that offer further assistance.

By following the advice from fellow users, you can effectively address issues and optimize the performance of your system.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of portable sanitation devices. Below are some typical questions and their corresponding answers to assist users in resolving issues effectively.

- What should I do if my unit is not flushing?

Check the water supply and ensure the valve is open. If the problem persists, inspect for any blockages.

- How can I clean the interior components?

Use a gentle cleanser and a soft cloth to wipe down surfaces. Avoid abrasive materials that could damage the finish.

- What are the signs of wear and tear?

Look for cracks, leaks, or any irregularities in the functionality. Regular inspections can help identify issues early.

- How often should I perform maintenance?

Routine checks are recommended every few months, but frequency may vary based on usage.

If you have further questions or need additional assistance, consider reaching out to customer support for professional guidance.