Comprehensive Guide for Repairing the 1999 Pontiac Grand Prix

This section serves as an essential resource for individuals seeking to understand the intricacies of automotive upkeep. It emphasizes the importance of systematic maintenance practices to ensure longevity and optimal performance of your vehicle.

Here, you’ll find detailed information covering various aspects of vehicle care, including troubleshooting techniques, component replacements, and routine checks. By following these guidelines, you can enhance your understanding and skills in managing your automobile effectively.

In addition to general maintenance tips, this guide addresses common issues that drivers may encounter, offering solutions and preventative measures. Whether you are a seasoned enthusiast or a novice, the insights provided will equip you with the knowledge needed to tackle any challenge with confidence.

Essential Tools for Auto Repair

Having the right instruments is crucial for anyone looking to maintain or fix a vehicle effectively. A well-equipped toolkit not only streamlines the process but also enhances safety and accuracy during tasks. From basic hand tools to specialized equipment, understanding what to have on hand can make a significant difference in any automotive project.

Basic Hand Tools

Starting with the fundamentals, a set of wrenches, screwdrivers, and pliers forms the backbone of any toolkit. These instruments are essential for loosening and tightening various components, ensuring that everything remains securely fastened. Additionally, a reliable ratchet set allows for quicker adjustments in tight spaces, saving both time and effort.

Diagnostic Equipment

In modern automobiles, the integration of technology necessitates the use of diagnostic tools. An OBD-II scanner helps identify issues by reading error codes from the vehicle’s computer. This equipment can significantly aid in troubleshooting, providing valuable insights that facilitate more efficient repairs.

Understanding Common Mechanical Issues

Vehicles can experience a variety of mechanical challenges that impact performance and safety. Identifying these issues early is crucial for maintaining reliability and efficiency. This section highlights some prevalent problems encountered in automobiles, providing insight into their causes and potential solutions.

- Engine Performance:

- Decreased power and acceleration

- Unusual noises, such as knocking or tapping

- Frequent stalling or rough idling

- Transmission Issues:

- Slipping gears or difficulty shifting

- Unresponsive or delayed engagement

- Fluid leaks or unusual odors

- Suspension Problems:

- Excessive bouncing or swaying during driving

- Uneven tire wear

- Steering difficulties or vibrations

- Brake System Malfunctions:

- Soft or spongy brake pedal

- Unusual sounds when braking, such as grinding

- Pulling to one side during braking

- Electrical System Failures:

- Inconsistent operation of lights and accessories

- Frequent blown fuses

- Starting issues or battery drain

Awareness of these typical concerns allows for proactive measures, ensuring a smoother driving experience. Regular maintenance and inspections can help detect these issues before they escalate into more significant problems.

Step-by-Step Maintenance Guide

Regular upkeep is essential to ensure optimal performance and longevity of your vehicle. This guide offers a systematic approach to help you manage routine tasks effectively, preventing potential issues and enhancing overall reliability.

Essential Checks and Services

Begin with routine inspections, focusing on key components such as fluid levels, tire pressure, and brake functionality. Fluids should be checked regularly; make sure to top up engine oil, coolant, and transmission fluid as necessary. Additionally, tire maintenance is crucial–monitor tread wear and adjust pressure according to specifications.

Scheduled Replacements

Establish a schedule for replacing essential parts like air filters and spark plugs. Air filters should typically be changed every 12,000 to 15,000 miles, while spark plugs may require replacement every 30,000 miles. Following these intervals will promote efficient engine operation and fuel economy.

Electrical System Troubleshooting Techniques

Diagnosing issues within a vehicle’s electrical framework can be a complex process that requires a systematic approach. Understanding the components and their interactions is essential for effective problem-solving. By employing specific techniques, one can identify malfunctions and restore functionality efficiently.

Common Symptoms of Electrical Issues

- Dim or flickering lights

- Unresponsive electronic devices

- Unexpected battery drain

- Difficulty starting the engine

Steps for Effective Troubleshooting

- Begin with a thorough visual inspection of wiring and connections for signs of wear or damage.

- Utilize a multimeter to measure voltage levels across various components.

- Test fuses and relays to ensure they are functioning properly.

- Isolate individual circuits to pinpoint the source of the problem.

- Consult wiring diagrams to understand the electrical layout and identify potential issues.

By following these techniques, one can enhance the likelihood of successful diagnostics and repairs, ultimately leading to a more reliable electrical system.

Fluid Change Procedures Explained

Maintaining optimal performance of your vehicle requires regular attention to various liquid levels. Understanding the process of replacing these essential fluids is crucial for ensuring longevity and efficiency. This section outlines the standard procedures to follow for effective fluid changes.

Preparation is key. Before starting, gather all necessary tools and materials, including fresh fluid, a funnel, and a container for waste disposal. Ensure the engine is cool and parked on a level surface to promote safety and accuracy during the process.

Begin with draining the old fluid. Locate the appropriate drain plug or valve, typically situated at the lowest point of the reservoir. Carefully remove it, allowing the fluid to flow into the prepared container. Always follow proper disposal regulations for hazardous materials.

After draining, it is essential to clean the system. Rinse any remaining residue from the reservoir to prevent contamination of the new fluid. A thorough inspection of hoses and connections can also help identify potential leaks or wear.

Once the area is clean, proceed to fill with new fluid. Use a funnel to avoid spills and ensure an accurate fill. Check the manufacturer’s specifications for the correct type and amount of fluid needed. After filling, replace the drain plug securely.

Finally, it is advisable to run the engine for a few minutes. This allows the new fluid to circulate throughout the system. Afterward, check the fluid level again, topping off if necessary, and inspect for any leaks around the connections.

Regularly scheduled fluid changes not only enhance vehicle performance but also contribute to the overall health of the engine and its components. Following these procedures will help maintain a reliable driving experience.

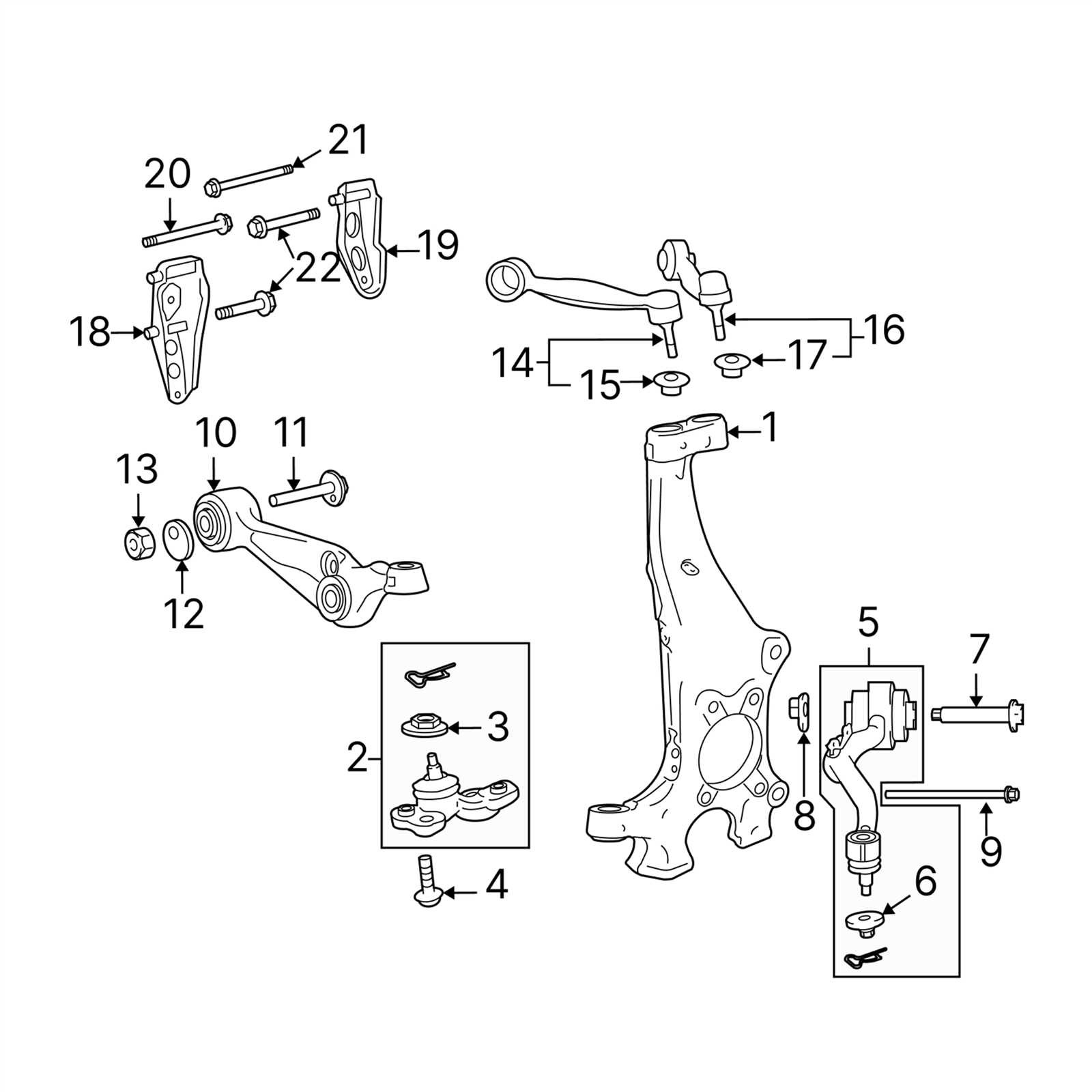

Suspension System Overview and Care

The suspension framework of a vehicle plays a crucial role in ensuring a smooth and stable ride. It serves to absorb shocks from uneven surfaces, allowing for better handling and comfort. Proper maintenance of this system is essential to prolong its lifespan and enhance overall performance.

Components and Functionality

This assembly typically consists of various elements, including springs, shock absorbers, and control arms. Each part works in unison to manage the vehicle’s weight, control body roll during turns, and maintain tire contact with the road. Regular inspections of these components can help identify wear or damage before they lead to more significant issues.

Maintenance Tips

To ensure optimal functionality, consider routine checks for any signs of leaks, unusual noises, or vibrations while driving. Keeping the suspension components clean and free from debris is also vital. Additionally, aligning the wheels and rotating tires periodically can enhance performance and extend the lifespan of the entire system.

Brake System Inspection and Repair

Ensuring the functionality of the braking mechanism is crucial for vehicle safety. Regular assessment of the components that contribute to braking performance can prevent potential issues and enhance overall reliability. This section covers essential practices for evaluating and maintaining these vital systems.

Visual Inspection: Begin with a thorough visual examination of the braking components. Look for any signs of wear, damage, or corrosion on brake pads, rotors, and calipers. Identifying irregularities early can save time and resources.

Fluid Check: The quality and level of brake fluid are critical. Ensure that the fluid is at the appropriate level and free from contaminants. If the fluid appears dark or murky, it may be necessary to replace it to maintain optimal performance.

Testing Performance: Conduct a test drive to evaluate the braking response. Pay attention to any unusual noises, vibrations, or pulling sensations when applying the brakes. These symptoms may indicate underlying issues that require immediate attention.

Component Replacement: If any components show significant wear or malfunction, replacement should be undertaken promptly. Utilizing high-quality parts is essential for ensuring durability and performance. Follow manufacturer specifications for installation to achieve the best results.

Regular inspection and maintenance of the braking system not only prolongs the lifespan of components but also significantly enhances driving safety. By staying proactive, vehicle owners can ensure that their braking systems remain effective and reliable.

Engine Performance Enhancements

Improving the capabilities of an automotive powertrain involves a variety of strategies aimed at maximizing efficiency, responsiveness, and overall output. These enhancements not only elevate the driving experience but also contribute to the longevity and reliability of the vehicle. From tuning software to hardware modifications, there are numerous approaches that enthusiasts and owners can consider to achieve their performance goals.

Aftermarket Modifications

Upgrading components such as the air intake system and exhaust can significantly enhance engine airflow. High-performance air filters and cat-back exhaust systems are popular choices for boosting both horsepower and torque. These modifications allow the engine to breathe more freely, leading to improved performance and a more aggressive sound.

Electronic Tuning Solutions

Utilizing engine control unit (ECU) tuning is another effective method for optimizing performance. By reprogramming the ECU, drivers can adjust fuel maps, ignition timing, and boost levels, tailoring the engine’s behavior to specific preferences and driving conditions. This digital enhancement often yields noticeable gains in power and efficiency, making it a favored option among automotive enthusiasts.

Transmission Maintenance Best Practices

Proper upkeep of a vehicle’s shifting system is essential for ensuring optimal performance and longevity. By following a set of recommended practices, owners can enhance reliability and minimize the likelihood of costly repairs.

Regular Fluid Checks

One of the most crucial aspects of maintaining a shifting mechanism is monitoring fluid levels. Ensuring the fluid is clean and at the appropriate level helps to prevent wear and tear.

- Check the fluid level monthly.

- Change the fluid according to the manufacturer’s guidelines.

- Inspect for any signs of contamination or unusual odors.

Scheduled Inspections

Routine examinations can help identify potential issues before they escalate. Setting a timeline for these inspections is beneficial.

- Inspect the seals and gaskets for leaks.

- Examine the transmission for any unusual noises during operation.

- Test the shifting responsiveness and performance.

By adhering to these maintenance strategies, vehicle owners can ensure a more efficient and reliable operation of their shifting systems, ultimately prolonging their lifespan.

Identifying and Fixing Leaks

Understanding how to detect and resolve fluid leaks is crucial for maintaining the longevity and performance of any vehicle. Leaks can occur in various systems, including the cooling, fuel, and hydraulic mechanisms. Addressing these issues promptly can prevent more severe damage and costly repairs down the line.

Common Sources of Leaks

Several areas within a vehicle are prone to leakage. Hoses are often the first culprits, particularly those that transport coolant or fuel. Additionally, seals and gaskets may degrade over time, leading to fluid loss. Regular inspection of these components can help identify problems before they escalate.

Steps to Fix Leaks

Once a leak is identified, the repair process typically involves cleaning the affected area to remove any dirt or debris. Replacing damaged hoses or seals is often necessary, as attempting to patch them can result in recurring issues. After repairs, it’s essential to monitor the area for any signs of leakage to ensure the solution was effective.

Safety Measures During Repairs

When undertaking maintenance tasks on vehicles, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a secure working environment. Awareness of potential hazards and adherence to safety protocols can significantly reduce the risk of injuries.

Wear Appropriate Gear: Always use protective equipment such as gloves, goggles, and steel-toed boots. These items safeguard against injuries from sharp objects, chemicals, and heavy components.

Ensure Proper Ventilation: Working in a well-ventilated space is crucial to avoid inhaling harmful fumes or gases. If repairs are conducted in a confined area, consider using fans or opening windows to promote airflow.

Stabilize the Vehicle: Before beginning any work, ensure the vehicle is on a level surface and securely supported with jack stands. This prevents accidental movement and potential injuries while working underneath.

Disconnect the Battery: Always disconnect the power source before working on electrical systems to minimize the risk of shock or short circuits. This step is vital in maintaining safety during maintenance tasks.

Keep Tools Organized: A clutter-free workspace not only enhances efficiency but also reduces the chances of accidents. Store tools in designated areas to prevent trips and falls.

By implementing these precautions, individuals can create a safer atmosphere for themselves and others while performing vehicle maintenance tasks.