Comprehensive Guide to Repairing Ridgeway Grandfather Clocks

Maintaining the intricate mechanisms of traditional timekeeping devices is essential for preserving their beauty and functionality. This guide offers insights into the essential techniques and considerations necessary for ensuring the longevity of these cherished pieces. Through careful examination and methodical approaches, enthusiasts can successfully navigate the challenges of rejuvenating their treasured items.

Understanding the Mechanics is crucial for any enthusiast. Each component plays a significant role in the overall performance, making it vital to familiarize oneself with the various parts and their interactions. Knowledge of how these mechanisms operate will empower individuals to tackle common issues effectively.

In addition, preserving the Aesthetic Appeal is just as important as maintaining functionality. A well-cared-for timepiece not only serves its purpose but also stands as a testament to craftsmanship. This guide will explore methods to restore and enhance the visual charm of these stunning artifacts, ensuring they remain as captivating as the day they were created.

Understanding Ridgeway Grandfather Clocks

This section delves into the intricacies and charm of a timeless timekeeping piece that has graced homes for generations. These intricate mechanisms are not only functional but also serve as stunning decorative elements. The craftsmanship and artistry involved in their creation reflect a rich history, making them prized possessions for many enthusiasts.

Many of these elegant timepieces feature distinctive characteristics that set them apart from other types of timekeepers. From ornate designs to the unique sound of their chimes, each piece tells a story of its own.

| Feature | Description |

|---|---|

| Design | Typically crafted from high-quality wood with intricate carvings and finishes. |

| Movement | Often powered by a pendulum mechanism that enhances accuracy and stability. |

| Chimes | Emitting soothing melodies that mark the passage of time, adding to the ambiance of the space. |

| Maintenance | Requires regular upkeep to ensure longevity and proper functionality. |

Understanding these unique characteristics is essential for any collector or admirer. Knowledge of their features and requirements can greatly enhance the appreciation of these exquisite timekeeping masterpieces.

Common Issues with Ridgeway Models

Many individuals encounter typical challenges when maintaining their intricate timepieces. Understanding these issues can lead to more effective solutions and prolonged enjoyment of these beautifully crafted items.

Mechanical Malfunctions

One of the most frequent problems involves mechanical components that may become misaligned or wear over time. This can result in inaccurate timekeeping or an inability to function altogether. Regular inspections can help identify these concerns before they escalate, allowing for timely adjustments or replacements.

Chiming Problems

Another common issue pertains to the chime mechanism. Sometimes, the delightful melodies can become irregular or fail to sound entirely. This could be due to a variety of factors, including misalignment of the chime rods or a malfunctioning movement. Ensuring proper lubrication and alignment can often restore these charming features.

By addressing these typical concerns, owners can enhance the longevity and performance of their cherished timepieces, ensuring they remain a treasured part of their homes for years to come.

Essential Tools for Clock Repair

Maintaining and restoring intricate timekeeping devices requires a specific set of instruments. These tools not only facilitate precision but also ensure the longevity of the mechanisms involved. Familiarity with the appropriate equipment can greatly enhance the efficiency of the process and yield impressive results.

Basic Tools

Among the primary instruments, a variety of hand tools play a critical role in the upkeep of these delicate machines. Below is a list of essential items that every enthusiast should have on hand.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws on various components. |

| Pliers | Used for gripping and bending small parts. |

| Tweezers | Ideal for handling tiny components with precision. |

| Magnifying Glass | Assists in examining intricate details and mechanisms. |

| Oil Can | For applying lubricants to moving parts to ensure smooth operation. |

Advanced Equipment

For those who wish to delve deeper into the art of restoration, certain advanced instruments can prove invaluable. Utilizing these specialized tools allows for a more comprehensive approach to maintenance and enhancement.

| Tool | Purpose |

|---|---|

| Time Grapher | Measures the accuracy and rate of the device. |

| Drill Set | Used for creating precise holes in wood or metal components. |

| Caliper | Helps in measuring the thickness and dimensions of parts. |

| Vise | Secures components during intricate tasks. |

| Cleaning Kit | Ensures all parts are free from dust and grime, promoting functionality. |

Step-by-Step Maintenance Guide

Proper upkeep of intricate timekeeping devices is essential to ensure their longevity and accurate performance. This guide provides a systematic approach to maintaining these remarkable pieces, allowing you to enjoy their beauty and functionality for years to come.

-

Gather Necessary Tools:

- Screwdriver set

- Soft cloth

- Lubrication oil

- Feeler gauge

- Cleaning solution

-

Initial Inspection:

Begin by examining the exterior for any visible damage or wear. Check the glass, wood, and any decorative elements for cracks or scratches.

-

Dust and Clean:

Use a soft cloth to gently remove dust from all surfaces. For more stubborn grime, apply a suitable cleaning solution, taking care not to damage the finish.

-

Check Mechanism:

Carefully open the access panel to examine the internal mechanism. Look for any signs of rust or dirt accumulation that may impede function.

-

Lubricate Moving Parts:

Apply a small amount of lubrication oil to the moving components as recommended. This helps reduce friction and wear over time.

-

Adjust Timing:

Utilize the feeler gauge to check the escapement and make necessary adjustments to ensure accurate timekeeping.

-

Final Assembly:

Carefully reassemble all parts, ensuring everything is securely fastened. Double-check that the access panel is closed properly.

-

Regular Maintenance Schedule:

Establish a routine maintenance schedule, ideally every six months, to keep your timepiece in optimal condition.

By following these steps, you can help preserve the craftsmanship and elegance of your cherished timepiece, ensuring it remains a focal point in your home.

Identifying Movement Types in Clocks

Understanding the various mechanisms that drive timepieces is essential for enthusiasts and technicians alike. Each system has unique characteristics, making it important to recognize these distinctions for effective maintenance and evaluation.

Generally, mechanisms can be classified into three primary categories:

- Quartz Movements: These are battery-operated and rely on a quartz crystal to maintain accurate time. They are known for their precision and low maintenance needs.

- Mechanical Movements: These can be further divided into two subtypes:

- Manual: Wound by hand, requiring regular interaction to maintain operation.

- Automatic: These harness energy from the motion of the wearer, providing a self-winding mechanism.

- Hybrid Movements: Combining features of both quartz and mechanical systems, these offer the best of both worlds in terms of performance and aesthetics.

Recognizing the type of mechanism not only aids in understanding the timepiece’s function but also informs the approach to its upkeep and care.

Disassembling Your Grandfather Clock

Taking apart an intricate timepiece can seem daunting, but with careful attention and methodical steps, it becomes a manageable task. This process allows for thorough cleaning, part replacement, or restoration of the mechanism. Understanding the various components and their interconnections is crucial for a successful disassembly.

Essential Tools and Preparation

Before beginning, ensure you have the right tools at hand. A clean workspace is essential for organizing parts as they are removed. Here’s a quick overview of what you’ll need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening screws on the casing and mechanism. |

| Wrenches | To detach any nuts or bolts securing the mechanism. |

| Pliers | Useful for gripping and removing tight components. |

| Magnetic Tray | To keep small parts organized and prevent loss. |

Step-by-Step Disassembly Process

Follow these steps to effectively take apart your timekeeping device:

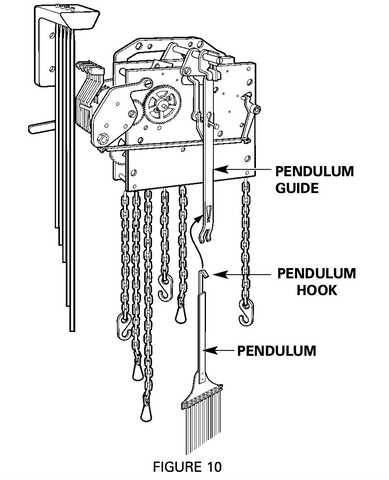

- Remove the pendulum carefully, noting its position for reassembly.

- Take off the face plate, ensuring to keep screws organized.

- Detach the mechanism from the casing, documenting wire placements.

- Inspect and catalog all parts as they are removed to facilitate reassembly.

Cleaning Techniques for Clock Components

Maintaining the beauty and functionality of intricate timekeeping devices involves a careful approach to cleaning their delicate parts. Regular maintenance not only preserves their appearance but also ensures accurate performance. Understanding the appropriate methods and tools for cleaning various components is essential for any enthusiast or technician.

Different materials require specific techniques to avoid damage. Below is a summary of effective cleaning methods tailored to various parts of the mechanism.

| Component | Cleaning Method | Recommended Tools |

|---|---|---|

| Metal Gears | Soak in a solvent, then scrub gently with a soft brush | Non-abrasive brush, solvent (e.g., isopropyl alcohol) |

| Glass Face | Wipe with a microfiber cloth and glass cleaner | Microfiber cloth, glass cleaner |

| Wooden Case | Dust with a soft cloth, polish with furniture polish | Soft cloth, furniture polish |

| Chime Rods | Wipe with a damp cloth, dry thoroughly | Damp cloth, dry cloth |

| Escapement Mechanism | Carefully brush with a fine, dry brush | Fine brush |

Using the right technique ensures that each component retains its integrity and operates smoothly. Regular cleaning not only enhances the visual appeal but also contributes to the longevity of the intricate system.

Lubrication Methods for Smooth Operation

Ensuring optimal performance of intricate mechanisms requires a careful approach to lubrication. Properly applied substances not only minimize friction but also enhance longevity and precision in functionality. Here, we explore various techniques and considerations for maintaining smooth operation.

Effective lubrication can be achieved through several methods, each with its own advantages:

- Oil Application: This involves using a suitable oil designed for mechanical parts. It penetrates tight spaces and reduces wear.

- Grease Usage: Grease is thicker than oil, making it ideal for parts that experience heavy loads or are exposed to moisture. It stays in place longer.

- Spray Lubricants: These provide ease of application and reach difficult areas. They often contain additives to prevent rust and corrosion.

When applying lubrication, consider the following guidelines:

- Clean Surfaces: Always start with clean surfaces to prevent dirt and debris from interfering with the lubricant’s effectiveness.

- Use Appropriate Amounts: Over-lubrication can attract dust and cause buildup, while insufficient lubrication can lead to premature wear.

- Frequency of Application: Regular checks and timely applications ensure that mechanisms remain well-lubricated and function smoothly.

Incorporating these methods into routine maintenance can significantly improve the performance and reliability of your mechanisms, ensuring they operate smoothly for years to come.

Repairing Damaged Clock Parts

Addressing issues with various components is essential for restoring functionality and aesthetics. Whether it’s a minor blemish or a significant malfunction, understanding the intricacies of each part allows for effective solutions. This section will guide you through the essential steps and techniques to mend various elements.

Identifying Common Issues

- Broken hands: Often the result of accidents, these can impede timekeeping.

- Worn gears: Over time, friction can cause significant wear, leading to misalignment.

- Deteriorated wood: Environmental factors can cause the casing to warp or crack.

Essential Tools and Materials

- Precision screwdriver set: Necessary for accessing internal mechanisms.

- Adhesives: Use wood glue or epoxy for fixing structural elements.

- Lubricants: Ensure smooth movement by applying appropriate oils to gears.

With the right approach and tools, even damaged elements can be brought back to their former glory, ensuring reliable performance for years to come.

Reassembling Your Grandfather Clock

Restoring a timekeeping masterpiece requires precision and care. This section focuses on the crucial steps for putting together your cherished timepiece after it has been disassembled for maintenance or transport. Each component must be handled with attention to detail to ensure the mechanism functions smoothly and accurately.

Begin by organizing all parts in a clear layout, making it easier to identify where each piece fits. Start with the base and work upwards, securing each section firmly yet gently to avoid any damage. Aligning gears correctly is vital; ensure that they interlock without excessive force, which could lead to wear over time.

Once the framework is complete, pay close attention to the pendulum and weights. These elements are essential for maintaining accurate timekeeping. Adjust the pendulum length as needed, and ensure that the weights are evenly distributed to prevent imbalance.

Finally, conduct a thorough check of the entire assembly. Test the movement by gently winding the mechanism and observing its operation. Make any necessary adjustments to ensure that every part works in harmony, bringing your exquisite timepiece back to life.

Calibration Tips for Accurate Timekeeping

Ensuring precise tracking of time involves careful adjustments and ongoing attention to various factors that can affect performance. This section provides essential guidance on fine-tuning mechanisms to maintain optimal accuracy and reliability.

Regular Maintenance Checks

Consistent upkeep is crucial for longevity and precision. Follow these steps:

- Inspect for dust and debris accumulation.

- Lubricate moving parts to reduce friction.

- Check the pendulum and other regulating elements for proper positioning.

Adjustment Techniques

Fine-tuning the timing device involves specific techniques:

- Utilize a timekeeping app or reference clock for accuracy comparisons.

- Make minor adjustments to the regulating mechanism as needed.

- Observe performance over a week, noting any discrepancies.

By implementing these strategies, you can enhance the precision of your timepiece, ensuring it remains a reliable instrument for years to come.

Common Mistakes to Avoid During Repairs

When undertaking the restoration of intricate timekeeping devices, enthusiasts often overlook critical aspects that can lead to further complications. Understanding these pitfalls is essential to ensure a smooth and effective process, ultimately preserving the beauty and functionality of these cherished pieces.

Neglecting Proper Tools

One of the primary errors is failing to use the appropriate instruments for the task. Relying on makeshift alternatives can result in damage to delicate components. Investing in quality tools not only simplifies the process but also safeguards against unintended harm.

Skipping Regular Maintenance

Another common misstep is disregarding the importance of routine upkeep. Over time, dust and grime can accumulate, affecting performance. Regular cleaning and lubrication can significantly enhance the longevity of the mechanism, making periodic maintenance a wise practice rather than an afterthought.

When to Seek Professional Help

Maintaining intricate timekeeping devices can be rewarding, yet certain situations may arise where expert intervention becomes essential. Understanding the signs that indicate a need for professional assistance is crucial to preserving the functionality and longevity of these sophisticated mechanisms.

If you encounter persistent issues that regular maintenance cannot resolve, such as unusual noises, erratic timekeeping, or mechanical failures, it’s advisable to consult a specialist. These symptoms may indicate underlying problems that require specialized tools and knowledge to address effectively.

Additionally, if your device has not been serviced in years, it may benefit from a comprehensive evaluation by an experienced technician. Regular inspections can prevent minor issues from escalating into significant repairs, ensuring optimal performance.

Lastly, if you feel uncertain about tackling a particular problem or lack the necessary tools, reaching out to a qualified expert can provide peace of mind. Their expertise can not only resolve existing issues but also enhance the overall reliability of your treasured timepiece.