Repair Guide for Urgos Grandfather Clock Movement

Maintaining and enhancing intricate timekeeping devices requires a comprehensive understanding of their various components and functions. This guide is designed to assist enthusiasts and caretakers in ensuring the longevity and accuracy of these cherished artifacts.

In the world of horology, the importance of regular upkeep cannot be overstated. Engaging with these mechanisms not only preserves their beauty but also allows for a deeper appreciation of the craftsmanship involved. By following the outlined steps and techniques, users can navigate the complexities of maintaining these elegant devices.

Through careful examination and thoughtful intervention, one can restore the precision and reliability of these timepieces. This resource aims to provide clear instructions and valuable insights, empowering individuals to undertake the necessary actions with confidence.

Many timekeeping devices can experience various challenges that affect their functionality. Understanding these typical problems is essential for effective maintenance and troubleshooting. Below are some frequent concerns encountered in such mechanisms.

Mechanical Failures

Mechanical failures are among the most prevalent issues, often resulting from wear and tear over time. Key factors contributing to these problems include:

- Lubrication breakdown

- Worn gears

- Misalignment of components

Accuracy and Timing Issues

Another common concern involves inaccuracies in timekeeping. This can stem from several factors, including:

- Environmental changes affecting the mechanism

- Debris accumulation in sensitive parts

- Faulty escapements or regulators

Essential Tools for Repairs

Successful restoration of intricate timekeeping devices requires a specific set of instruments. Each tool plays a crucial role in ensuring precision and efficiency throughout the process. Understanding these essentials is vital for achieving optimal results in any undertaking.

Basic Instrumentation

The foundation of any repair task lies in basic tools that allow for effective manipulation and adjustment. A few key instruments include:

- Screwdrivers of various sizes

- Precision tweezers

- Magnifying glass

- Brass brushes for cleaning

Specialized Equipment

In addition to basic tools, specialized equipment can enhance the repair experience. These instruments enable more complex procedures to be executed with ease:

- Lubrication oils

- Calipers for measurement

- Workbenches with vises

- Safety goggles for protection

| Tool Type | Purpose |

|---|---|

| Fine Screwdrivers | Adjust small screws and components |

| Calipers | Measure distances and dimensions accurately |

| Lubricants | Ensure smooth operation of moving parts |

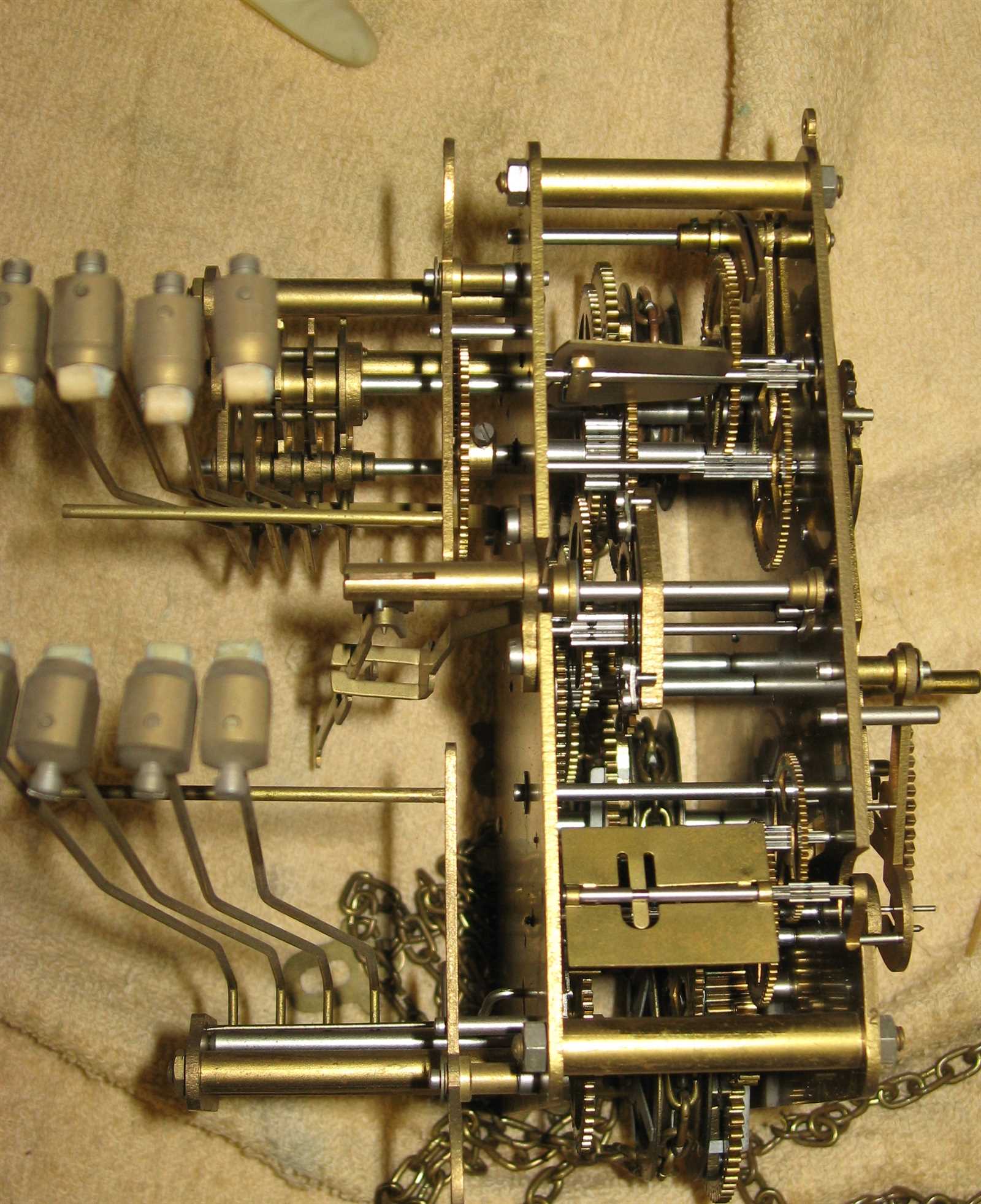

Step-by-Step Repair Process

This section outlines a comprehensive guide for addressing common issues related to intricate timekeeping mechanisms. Following a systematic approach can help ensure successful restoration and functionality.

Begin by gathering essential tools and materials:

- Screwdrivers of various sizes

- Lubricants suitable for delicate mechanisms

- Cotton swabs and cloths for cleaning

- Magnifying glass for detailed inspection

Next, follow these key steps to troubleshoot and fix the issues:

- Disassemble the unit carefully, noting the arrangement of components.

- Inspect each part for signs of wear or damage.

- Clean the components thoroughly to remove any dirt or old lubricant.

- Apply fresh lubricant to moving parts, ensuring not to overapply.

- Reassemble the unit in the reverse order, paying close attention to alignment.

- Test the mechanism to confirm proper function and make adjustments as needed.

By adhering to this structured approach, one can enhance the longevity and performance of intricate timekeeping devices.

Maintaining Clock Accuracy

Ensuring precise timekeeping is essential for any timepiece. Regular attention to various components can significantly enhance performance and reliability. This involves monitoring and adjusting mechanisms to prevent deviations from the correct time.

Periodic Lubrication is crucial for smooth operation. Apply appropriate oils to gears and pivots, reducing friction and wear. This practice prolongs the lifespan of internal parts and maintains consistent movement.

Environmental Considerations also play a role in accuracy. Place the timepiece in a stable environment, avoiding direct sunlight and extreme temperatures. Humidity control is essential, as excessive moisture can lead to rust and damage.

Lastly, regular checks for misalignment and loose components are vital. Inspect the structure to ensure all parts function harmoniously. Addressing minor issues promptly prevents larger problems, safeguarding the precision of the timekeeping instrument.

Cleaning and Lubrication Techniques

Maintaining the functionality of intricate timekeeping devices involves systematic cleaning and appropriate application of lubricants. These processes ensure smooth operation and longevity of the internal components, preventing wear and tear that can lead to performance issues.

Essential Cleaning Methods

Effective cleaning requires careful removal of dust and grime from various parts. Use soft brushes and lint-free cloths to gently wipe surfaces. A mixture of isopropyl alcohol and distilled water can be applied to a cloth for deeper cleaning, ensuring no residue remains.

Proper Lubrication Practices

Applying the right type of lubricant is crucial for optimal performance. Use lightweight oils specifically designed for mechanical devices. Apply a small amount to pivot points and moving parts, taking care not to over-lubricate, which can attract dirt and debris.

Identifying Wear and Tear

Understanding the signs of deterioration in intricate timekeeping devices is essential for maintaining their functionality. Regular inspection can help detect issues that may affect accuracy and performance over time.

Common Signs of Deterioration

Look for the following indicators that may suggest a decline in the device’s condition:

- Unusual sounds during operation

- Irregular timekeeping

- Visible damage to components

Importance of Timely Intervention

Addressing these symptoms promptly can prevent further complications and ensure longevity. A proactive approach is key to preserving the intricate mechanisms.

| Indicator | Possible Cause | Recommended Action |

|---|---|---|

| Unusual sounds | Friction or misalignment | Lubricate or adjust components |

| Irregular timekeeping | Wear on gears | Inspect and replace damaged parts |

| Visible damage | External impact or age | Assess and repair as necessary |

Replacing Damaged Parts

Maintaining the functionality of intricate timekeeping devices often requires the replacement of worn or broken components. Ensuring that every part operates harmoniously is essential for accurate performance. This section outlines the necessary steps and considerations involved in substituting damaged elements with new ones.

Identifying Faulty Components

Before proceeding with the replacement process, it is crucial to accurately identify which parts are malfunctioning. Symptoms such as irregular ticking or a complete lack of movement can indicate specific issues. Careful inspection and testing can help pinpoint the exact components that need attention.

Procurement and Installation

Once the defective pieces have been identified, sourcing appropriate replacements is the next step. It is advisable to choose high-quality alternatives that match the original specifications. When installing the new components, follow the manufacturer’s guidelines to ensure proper fit and functionality. Precision during installation is vital to maintain the overall integrity of the device.

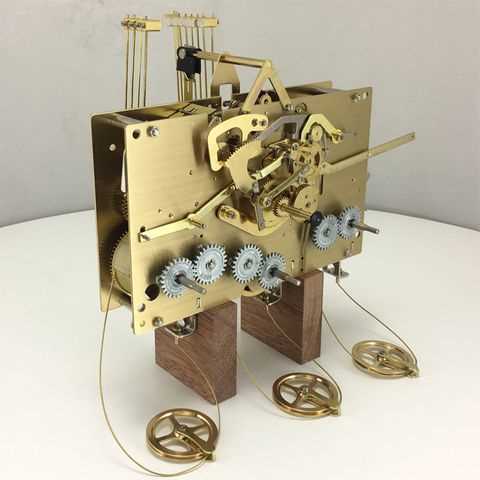

Understanding Clock Striking Mechanisms

The operation of timekeeping devices involves intricate systems that produce audible signals at designated intervals. These features not only serve a practical purpose but also enhance the aesthetic appeal of such instruments. This section delves into the various components and functions that govern these striking actions.

Key Components of Striking Systems

Several essential elements contribute to the effective functioning of striking systems:

- Strike Gear: This component regulates the timing of each sound produced.

- Hammer: Responsible for creating the sound when it strikes the bell or gong.

- Control Lever: Engages and disengages the striking mechanism based on the desired schedule.

How Striking Mechanisms Function

The mechanics behind the striking action can be summarized in the following steps:

- The gear system initiates the sequence based on the time setting.

- The control lever engages the hammer to prepare for the strike.

- The hammer strikes the bell, producing a distinct sound that indicates the hour or quarter.

Understanding these components and their interactions is crucial for maintaining the harmonious function of timekeeping devices.

Tips for Long-Lasting Performance

Ensuring optimal functionality and durability of intricate timekeeping devices requires consistent care and attention. Here are some essential guidelines to maintain peak performance over time.

- Regular Maintenance: Schedule routine inspections to identify any potential issues early.

- Cleanliness: Keep the surrounding area dust-free and regularly clean the device to prevent dirt accumulation.

- Humidity Control: Maintain a stable environment with controlled humidity levels to avoid moisture damage.

- Proper Handling: Always handle with care to prevent physical damage, especially during cleaning or adjustment.

By following these practices, you can significantly enhance the longevity and reliability of your treasured timepiece.

Resources for Further Assistance

When seeking support for issues related to timekeeping mechanisms, various resources can provide valuable guidance and insight. Engaging with experienced individuals and comprehensive materials can significantly enhance your understanding and troubleshooting skills.

Consider the following options to expand your knowledge and access assistance:

- Online Forums: Participate in communities where enthusiasts and professionals share their experiences and solutions.

- Instructional Videos: Explore visual content that demonstrates techniques and offers step-by-step guidance.

- Books and Publications: Refer to literature dedicated to timepiece maintenance for in-depth knowledge.

- Local Workshops: Attend classes or seminars to gain hands-on experience from experts in the field.

- Professional Services: Seek out specialists who can provide personalized assistance and repairs.

Utilizing these resources can help enhance your skills and confidence in addressing any challenges you may encounter.