Complete Guide to Repairing the 1974 Honda CB360

For enthusiasts and riders alike, maintaining a classic two-wheeler is a fulfilling endeavor that combines technical skill with a passion for the open road. This section offers essential insights into the care and upkeep of vintage models, ensuring longevity and optimal performance. From routine checks to intricate fixes, understanding the inner workings of your machine is crucial.

Detailed documentation serves as a vital resource, providing clear instructions and specifications tailored to various components. Whether you’re troubleshooting an issue or performing regular service tasks, having access to a well-organized reference can make all the difference. Emphasizing clarity and thoroughness, these guidelines empower owners to tackle repairs with confidence.

Additionally, learning the nuances of your vehicle not only enhances your riding experience but also deepens your appreciation for its engineering. By engaging with every aspect of maintenance, you cultivate a relationship with your motorcycle that goes beyond mere transportation. This journey of discovery will ultimately lead to greater satisfaction and pride in your prized possession.

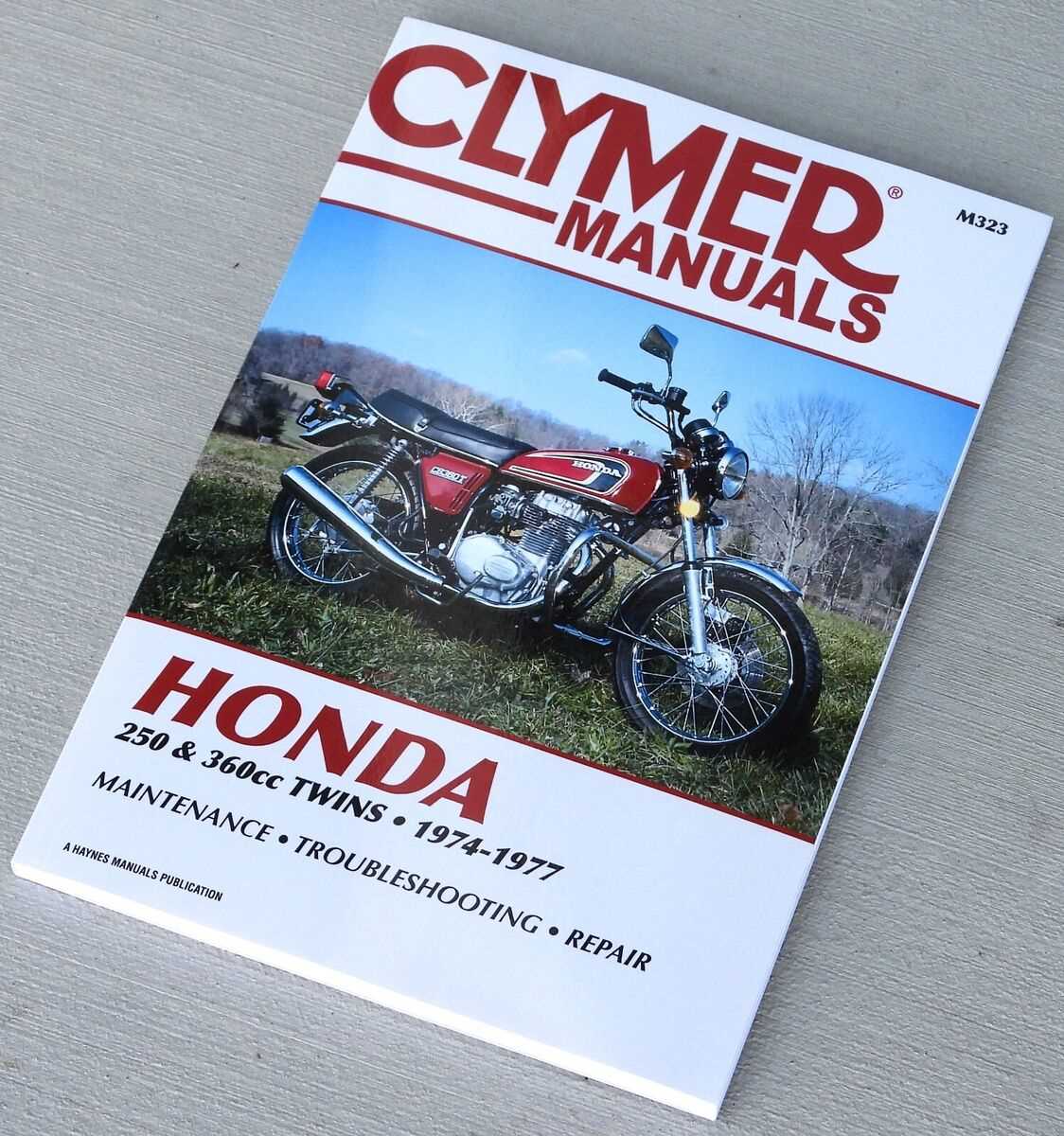

Overview of the 1974 Honda CB360

This section provides a comprehensive look at a classic motorcycle model that has garnered attention for its unique blend of style and performance. Known for its engaging riding experience and reliable engineering, this two-wheeled machine appeals to enthusiasts and casual riders alike.

Key features that define this model include:

- Engine: A well-balanced powerplant that delivers a smooth ride.

- Design: A sleek and timeless aesthetic that stands out on the road.

- Handling: Agile maneuverability that enhances the overall riding experience.

The motorcycle is celebrated for its:

- Efficient fuel consumption, making it a practical choice for daily use.

- Durability, which has allowed many units to remain operational for decades.

- Community support, with a dedicated following that shares knowledge and resources.

Overall, this iconic model represents a significant era in motorcycle history, offering a perfect combination of form and function that continues to captivate riders around the world.

Common Issues with CB360 Motorcycles

Motorcycles of this vintage often encounter a variety of challenges due to their age and the wear and tear from years of use. Understanding these common problems can help enthusiasts maintain and restore their beloved machines effectively.

Below are some frequent issues owners might face:

- Electrical System Failures:

- Faulty wiring can lead to shorts and malfunctioning components.

- Weak battery performance often results in starting difficulties.

- Fuel System Problems:

- Clogged carburetors can hinder performance and cause stalling.

- Leaking fuel lines pose a safety risk and require immediate attention.

- Engine Performance Issues:

- Worn piston rings may lead to poor compression and decreased power.

- Overheating engines can result from insufficient cooling or oil flow.

- Suspension and Handling:

- Worn-out shock absorbers can affect ride comfort and stability.

- Misaligned wheels may cause uneven tire wear and handling issues.

Addressing these concerns promptly can significantly enhance the longevity and reliability of these classic bikes.

Tools Needed for Basic Repairs

Having the right equipment is essential for conducting maintenance and minor fixes on your two-wheeled companion. A well-equipped workspace can greatly simplify the process, ensuring efficiency and effectiveness. Below is a list of essential items that will help you tackle a variety of tasks.

- Wrenches: A set of combination wrenches will allow you to handle various nuts and bolts.

- Sockets: A socket set with a ratchet will make loosening and tightening fasteners much easier.

- Screwdrivers: Both flathead and Phillips head screwdrivers are necessary for accessing different components.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating parts.

- Torque wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Hex keys: Also known as Allen wrenches, these are vital for many components.

- Oil filter wrench: Makes removing and installing oil filters much more straightforward.

In addition to these basic tools, consider investing in a few specialized items:

- Multimeter: Useful for diagnosing electrical issues.

- Compression tester: Helps evaluate the engine’s health.

- Service manual: While not a tool in the traditional sense, having a detailed guide will aid in understanding procedures.

By assembling this collection, you’ll be well-prepared to manage routine upkeep and address common challenges, ensuring your vehicle remains in optimal condition.

Engine Maintenance Tips for Longevity

Proper care and regular upkeep of your motorcycle’s power unit are essential for ensuring its durability and performance. By implementing a few key practices, you can significantly extend the lifespan of your engine and enjoy a smoother ride. This section outlines crucial maintenance strategies that will keep your machine in optimal condition.

Regular Oil Changes

One of the most vital aspects of engine care is maintaining clean oil. Regularly replacing the lubricant helps reduce friction and prevents the accumulation of harmful contaminants. It is advisable to follow the manufacturer’s recommendations for oil change intervals, typically every few thousand miles or after specific time frames. Always use high-quality oil that meets the engine’s specifications for best results.

Air Filter Maintenance

A clean air filter is crucial for optimal engine performance. It ensures that the power unit receives sufficient airflow, promoting efficient combustion. Check the air filter regularly, and replace or clean it as needed. A clogged filter can lead to decreased power output and increased fuel consumption, ultimately affecting the engine’s longevity.

By adhering to these maintenance practices, you can enjoy enhanced reliability and performance from your motorcycle’s engine for many miles to come.

Understanding the Electrical System

The electrical system of a motorcycle plays a crucial role in its overall functionality and performance. It encompasses various components that work together to power essential features and ensure smooth operation. Understanding these elements is vital for effective maintenance and troubleshooting.

Key components of the electrical system include:

- Battery: Stores electrical energy and provides power to start the engine and operate lights.

- Alternator: Generates electricity while the engine runs, recharging the battery and powering electrical systems.

- Regulator/Rectifier: Manages voltage and converts alternating current to direct current for the battery and electrical systems.

- Wiring Harness: A network of wires that connects all electrical components, ensuring proper communication and power distribution.

- Fuses: Protect electrical circuits from overloads by breaking the connection when excessive current flows.

Maintaining this system involves regular checks and proper care of the individual components. Here are some essential tips:

- Inspect the battery for corrosion and ensure terminals are clean and secure.

- Test the alternator output to confirm it is generating sufficient power.

- Check the regulator/rectifier for proper operation, ensuring it maintains appropriate voltage levels.

- Examine wiring for signs of wear or damage, repairing or replacing as needed.

- Replace blown fuses to maintain electrical integrity.

By understanding and maintaining the electrical system, you can enhance your motorcycle’s reliability and longevity, making every ride enjoyable and safe.

Step-by-Step Carburetor Cleaning Guide

Maintaining optimal performance in your two-wheeled companion often hinges on the cleanliness of its fuel delivery system. A thorough cleaning of the carburetor can restore efficiency and enhance overall functionality. This guide provides a systematic approach to achieving a spotless and well-functioning component.

1. Gather Your Supplies: Before starting, collect essential tools such as screwdrivers, wrenches, a cleaning solution, and a soft brush. Having everything at hand ensures a smooth process.

2. Remove the Carburetor: Carefully detach the carburetor from the engine, taking note of any connections or hoses. This step is crucial for accessing the internal components.

3. Disassemble the Unit: Gently take apart the carburetor, keeping track of each part. Use a clean workspace to avoid losing any small components.

4. Clean Each Component: Immerse the parts in a suitable cleaning solution. Use a brush to remove deposits and grime, ensuring all passages are clear. Rinse thoroughly with clean water afterward.

5. Inspect for Damage: Examine each piece for wear or damage. Replace any defective components to guarantee optimal performance.

6. Reassemble and Reinstall: Carefully put the carburetor back together, ensuring all parts fit snugly. Reattach it to the engine, making sure all connections are secure.

7. Test the System: Start the engine and listen for any irregularities. A well-cleaned carburetor should result in smoother operation and improved performance.

Following this guide will not only enhance your machine’s efficiency but also extend its lifespan, allowing you to delve deeper into the joys of riding.

How to Change the Oil Properly

Maintaining your vehicle’s engine health is crucial for optimal performance and longevity. One of the key aspects of this maintenance involves regularly changing the lubricant that keeps the internal components running smoothly. This guide will walk you through the essential steps to ensure the process is carried out effectively and safely.

Gather the Necessary Tools

Before you begin, ensure you have all the required tools and materials. You will need an oil filter, appropriate engine lubricant, a wrench set, an oil catch pan, and a funnel. Having everything ready will streamline the process and help you avoid unnecessary delays.

Prepare Your Vehicle

Start by warming up the engine for a few minutes. This helps to thin the lubricant, allowing it to drain out more easily. After warming, turn off the engine and let it cool slightly before proceeding. Place the vehicle on a flat surface and engage the parking brake for safety.

Drain the Old Lubricant

Locate the oil drain plug underneath the engine and position your catch pan beneath it. Carefully remove the plug using the appropriate wrench, allowing the used lubricant to flow into the pan. Be cautious as it may be hot. Once fully drained, replace the drain plug and tighten it securely.

Replace the Oil Filter

Next, locate the oil filter. Use an oil filter wrench to unscrew the old filter. Before installing the new filter, apply a small amount of fresh lubricant to the rubber gasket to ensure a proper seal. Install the new filter by hand, tightening it securely but not excessively.

Refill with Fresh Lubricant

Remove the oil filler cap on top of the engine and use a funnel to pour in the new lubricant. Refer to your owner’s specifications for the correct type and amount. After adding the oil, replace the filler cap and start the engine, allowing it to run for a few minutes. Check for leaks around the drain plug and oil filter.

Check the Oil Level

After running the engine, turn it off and wait a moment for the lubricant to settle. Use the dipstick to check the oil level, adding more if necessary to reach the recommended level. This simple check ensures that your engine has adequate protection.

By following these steps, you will help maintain your vehicle’s engine health, ensuring it runs smoothly for years to come.

Adjusting the Valves: A How-To

Proper valve adjustment is essential for optimal engine performance and longevity. This process ensures that the valves open and close at the correct times, which is crucial for efficient combustion and overall functionality. Regular maintenance can help avoid issues such as poor fuel efficiency and excessive engine noise.

Before starting the adjustment, gather the necessary tools:

- Socket set

- Torque wrench

- Feeler gauges

- Screwdriver set

- Clean rags

Follow these steps for successful valve adjustment:

- Prepare the Engine: Ensure the engine is cold to avoid injury and ensure accurate measurements.

- Access the Valve Covers: Remove any components obstructing access to the valve covers, including seats or side panels.

- Remove the Valve Covers: Carefully unscrew the covers and set them aside, keeping track of the hardware.

- Locate the Timing Marks: Rotate the engine manually using the crankshaft until the timing marks align with the specifications in your reference.

- Check Valve Clearances: Use feeler gauges to measure the gap between the rocker arm and the valve stem for both intake and exhaust valves.

- Adjust the Clearances: If gaps are not within the specified range, loosen the locknut and turn the adjustment screw to achieve the correct clearance, then retighten the locknut.

- Recheck Measurements: After adjustments, double-check the clearances to ensure accuracy.

- Reassemble: Replace the valve covers and any other components removed during the process. Ensure everything is securely fastened.

Regularly checking and adjusting the valves can significantly enhance engine performance and reliability. Make it a part of your routine maintenance schedule for the best results.

Tire Maintenance and Replacement Tips

Proper care and timely replacement of your vehicle’s tires are crucial for ensuring safety and enhancing performance. Regular checks and maintenance can prevent unexpected issues and extend the lifespan of your tires, leading to a smoother and safer ride.

Regular Inspection

Routine inspections are vital. Look for signs of wear, such as uneven tread patterns or visible damage. Checking tire pressure is equally important, as both under-inflation and over-inflation can adversely affect handling and fuel efficiency.

Replacement Guidelines

Knowing when to replace your tires can prevent hazardous situations. A good rule of thumb is to replace tires every six years, but this can vary based on usage and conditions. Pay attention to tread depth, and consider replacing tires when they reach 2/32 of an inch.

| Indicator | Action |

|---|---|

| Visible Damage | Replace immediately |

| Uneven Wear | Inspect alignment and replace if necessary |

| Tread Depth | Replace tires |

| Aging (6+ years) | Consider replacing regardless of tread |

Brake System Troubleshooting Techniques

Effective diagnosis of braking issues is crucial for ensuring safety and optimal performance. By employing systematic methods, one can identify problems and implement solutions efficiently.

- Visual Inspection: Begin by examining the brake components for signs of wear, damage, or leakage.

- Fluid Check: Ensure the brake fluid is at the correct level and inspect for contamination.

- Brake Pad Assessment: Check the thickness of the brake pads; replace them if they are worn down.

- Test Functionality: Engage the brakes to assess responsiveness and listen for unusual noises.

Following these steps can help you delve into the root causes of braking issues and lead you towards the ultimate resolution.

Upgrading Components for Better Performance

Enhancing the efficiency of your motorcycle involves a strategic approach to component upgrades. By selecting high-quality parts, riders can experience improved speed, handling, and overall ride quality. This section explores various modifications that can lead to noticeable performance gains.

Here are some key areas to focus on when considering enhancements:

- Exhaust System: Replacing the stock exhaust with a high-performance option can reduce weight and improve airflow, resulting in better acceleration.

- Carburetors: Upgrading to more efficient carburetors can enhance fuel delivery, which optimizes combustion and boosts power output.

- Ignition System: An upgraded ignition system can provide a stronger spark, leading to improved throttle response and engine efficiency.

- Suspension: Investing in quality suspension components can greatly enhance handling and stability, particularly during aggressive riding.

- Brakes: High-performance brake kits offer superior stopping power and responsiveness, essential for safety and control.

When planning upgrades, it is vital to consider compatibility and ensure that modifications work harmoniously with existing components. Research and consultation with experts can help in making informed choices.

Ultimately, thoughtful upgrades can transform the riding experience, making it not only more exhilarating but also safer and more reliable.

Finding Replacement Parts for CB360

Locating suitable components for vintage motorcycles can be a challenging yet rewarding endeavor. Whether restoring or maintaining your bike, understanding where to search for quality parts is essential to ensure optimal performance and reliability.

There are several avenues to explore when seeking out replacements:

- Online Marketplaces: Websites such as eBay, Craigslist, and specialized motorcycle forums often have listings for both new and used items.

- Specialty Shops: Local motorcycle shops or those dedicated to classic models may carry parts or be able to order them for you.

- Manufacturer Distributors: Some companies specialize in reproducing or selling OEM components, ensuring authenticity and compatibility.

- Salvage Yards: Visiting a motorcycle salvage yard can yield unexpected finds, providing access to parts from bikes that are no longer in service.

When searching, it’s beneficial to:

- Join online forums and communities where enthusiasts share resources and tips.

- Attend local motorcycle events or swap meets to network and discover vendors.

- Utilize social media groups focused on classic bikes to stay updated on part availability.

By exploring these options, you’ll increase your chances of finding the right parts to keep your motorcycle running smoothly and looking great.