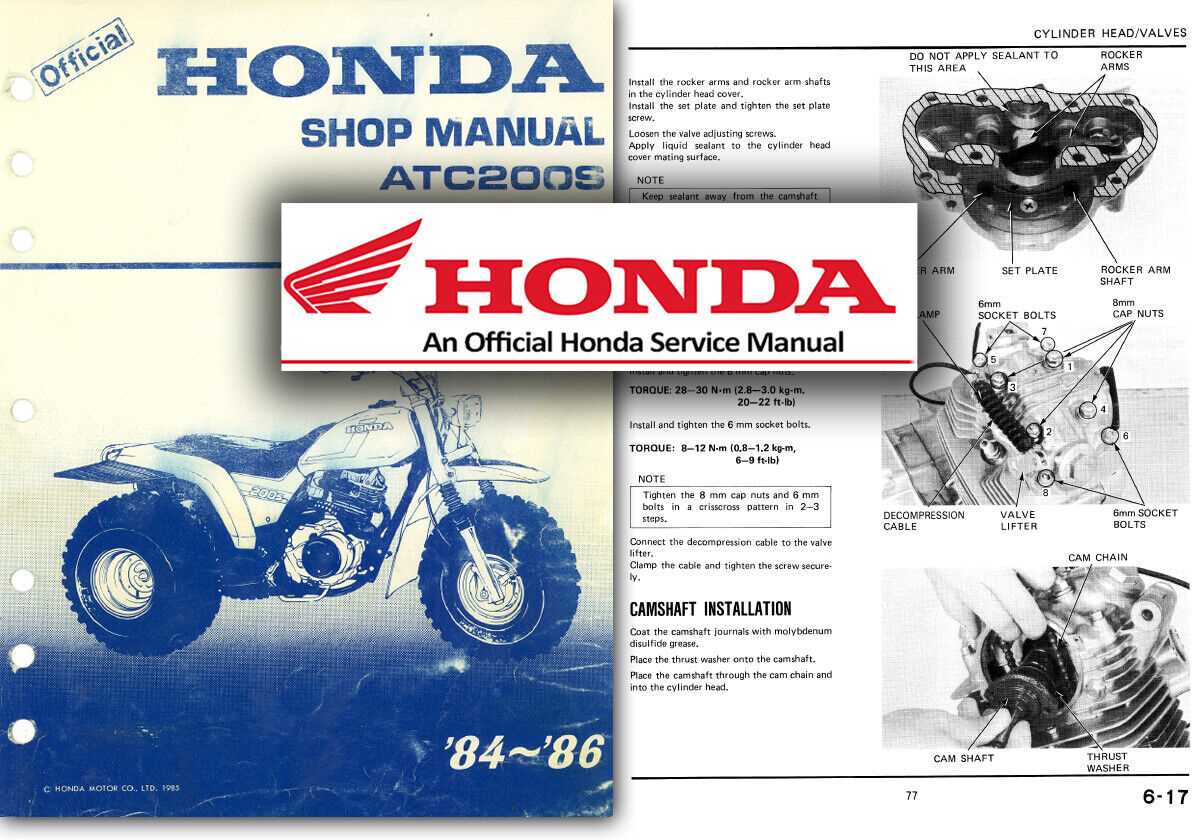

Comprehensive Repair Guide for the 1984 Honda Big Red 200ES

Maintaining an all-terrain vehicle is crucial for ensuring its longevity and optimal performance. This guide offers insights into the essential aspects of upkeep, focusing on troubleshooting, parts replacement, and general care. Whether you’re a seasoned enthusiast or a novice, understanding the intricacies of your vehicle can enhance your riding experience and prevent potential issues.

From routine checks to advanced repairs, this resource equips you with the knowledge needed to tackle common challenges. With step-by-step instructions and clear explanations, you can confidently navigate the complexities of maintaining your machine. By prioritizing care and attention, you’ll keep your vehicle in peak condition, ready for any adventure.

Furthermore, exploring the inner workings of your vehicle not only fosters a deeper appreciation for its design but also empowers you to take control of its maintenance. Dive into this essential guide and unlock the full potential of your all-terrain vehicle.

Overview of the 1984 Honda Big Red 200ES

This section provides a comprehensive look at a versatile all-terrain vehicle known for its durability and reliability. Designed for both recreational and practical use, this machine has made a significant impact in the world of off-road vehicles. Its robust features and user-friendly design have attracted a diverse range of enthusiasts and operators alike.

Key Features

Equipped with a powerful engine, this model boasts impressive torque and performance on various terrains. The vehicle’s suspension system ensures a smooth ride, even on rough surfaces. Additionally, its cargo capacity allows for efficient transport of gear, making it ideal for outdoor adventures and work-related tasks.

Usage and Popularity

Favored by farmers, outdoor enthusiasts, and hobbyists, this model has earned a reputation for its reliability in challenging environments. Its ease of operation appeals to both seasoned riders and newcomers, contributing to its lasting popularity in the market. Whether used for work or leisure, this all-terrain vehicle remains a top choice for many.

Common Issues with the Big Red 200ES

When it comes to maintaining an all-terrain vehicle, understanding potential problems can greatly enhance the ownership experience. Many enthusiasts encounter a variety of challenges that may arise due to age, wear and tear, or environmental factors. Addressing these common issues can help prolong the life and performance of the machine.

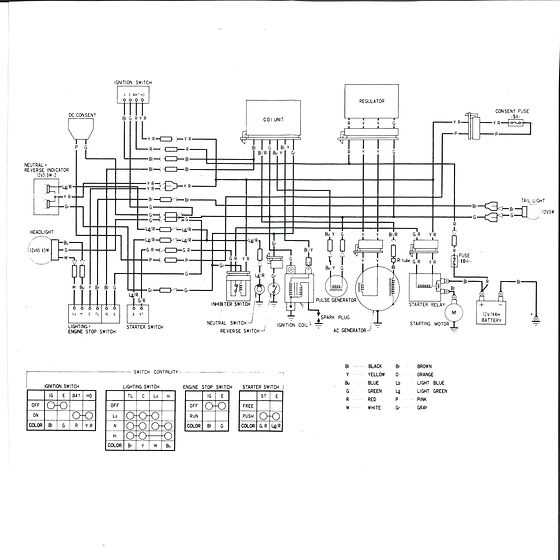

Electrical System Failures: One frequent concern involves the electrical components. Issues such as faulty wiring, corroded connectors, and malfunctioning ignition systems can lead to starting difficulties or intermittent power loss. Regular inspections can prevent these problems from escalating.

Fuel System Problems: Another common issue pertains to the fuel delivery system. Clogs in the fuel lines or a dirty carburetor can hinder performance, resulting in poor acceleration and engine stalling. Maintaining cleanliness and ensuring proper fuel flow is essential for optimal operation.

Suspension Wear: The suspension system is crucial for a smooth ride, yet it often experiences significant wear. Signs of degradation include a bumpy ride and difficulty navigating rough terrain. Routine checks and timely replacements of worn-out components can mitigate these issues.

Brake Malfunctions: Effective braking is vital for safety, and problems in this area should not be overlooked. Worn brake pads, fluid leaks, or air in the brake lines can compromise stopping power. Regular maintenance of the braking system ensures reliability and performance.

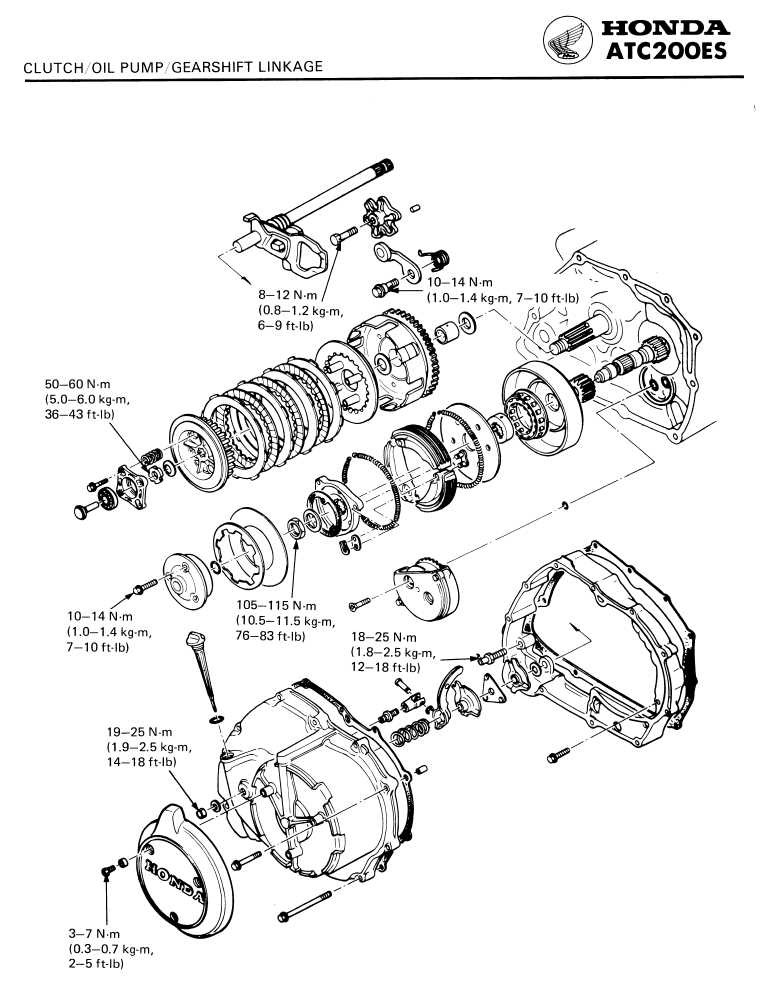

Transmission Issues: Finally, transmission problems can affect the vehicle’s overall functionality. Difficulty in shifting gears or unusual noises may indicate underlying issues that require attention. Prompt diagnosis and repair are necessary to avoid more severe complications.

Essential Tools for Repairs

When embarking on any maintenance or restoration task, having the right equipment at your disposal is crucial. A well-organized toolkit can significantly streamline the process, ensuring that each task is executed efficiently and effectively. This section will outline the fundamental instruments needed to tackle various challenges associated with your vehicle.

Basic Hand Tools

At the core of any toolkit are essential hand tools. Items such as wrenches, screwdrivers, and pliers form the foundation for most tasks. A set of metric and standard wrenches is particularly beneficial for accommodating different fasteners. Moreover, a magnetic screwdriver can simplify the process of dealing with screws in tight spaces.

Specialized Equipment

In addition to basic tools, specialized equipment is often necessary for more complex procedures. For instance, a torque wrench ensures that bolts are tightened to the correct specifications, while a multimeter allows for thorough electrical diagnostics. Investing in these specialized items can make a significant difference in both the quality and safety of your work.

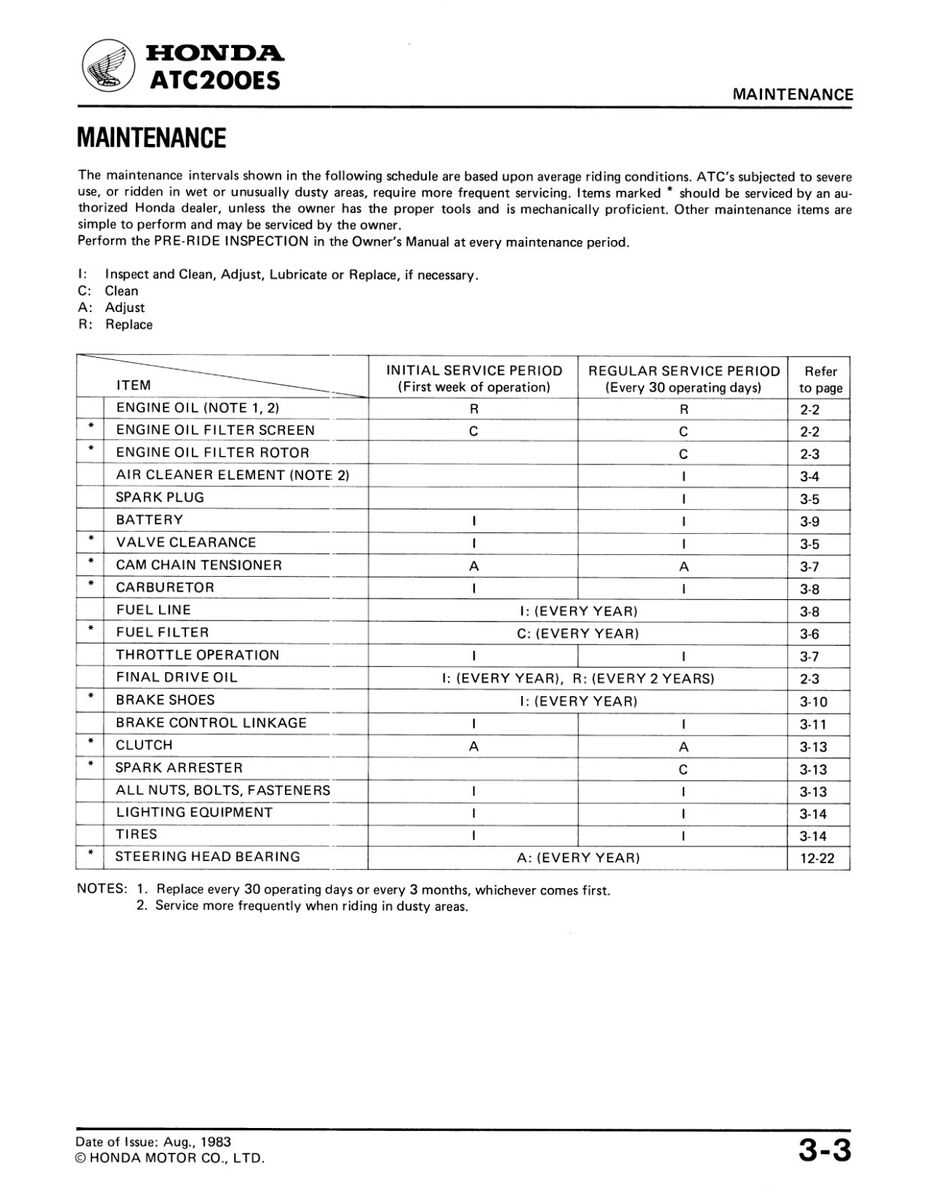

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. This guide provides clear, sequential instructions to help you maintain your machine effectively, covering key aspects that are often overlooked. By following these steps, you can enhance reliability and reduce the risk of unexpected issues.

1. Check and Change the Oil: Begin by inspecting the oil level using the dipstick. If necessary, drain the old oil and replace it with fresh lubricant suitable for your engine type. This should be done at regular intervals to prevent wear.

2. Inspect the Air Filter: A clean air filter ensures proper airflow to the engine. Remove the filter and clean or replace it as needed. This simple task can significantly improve performance.

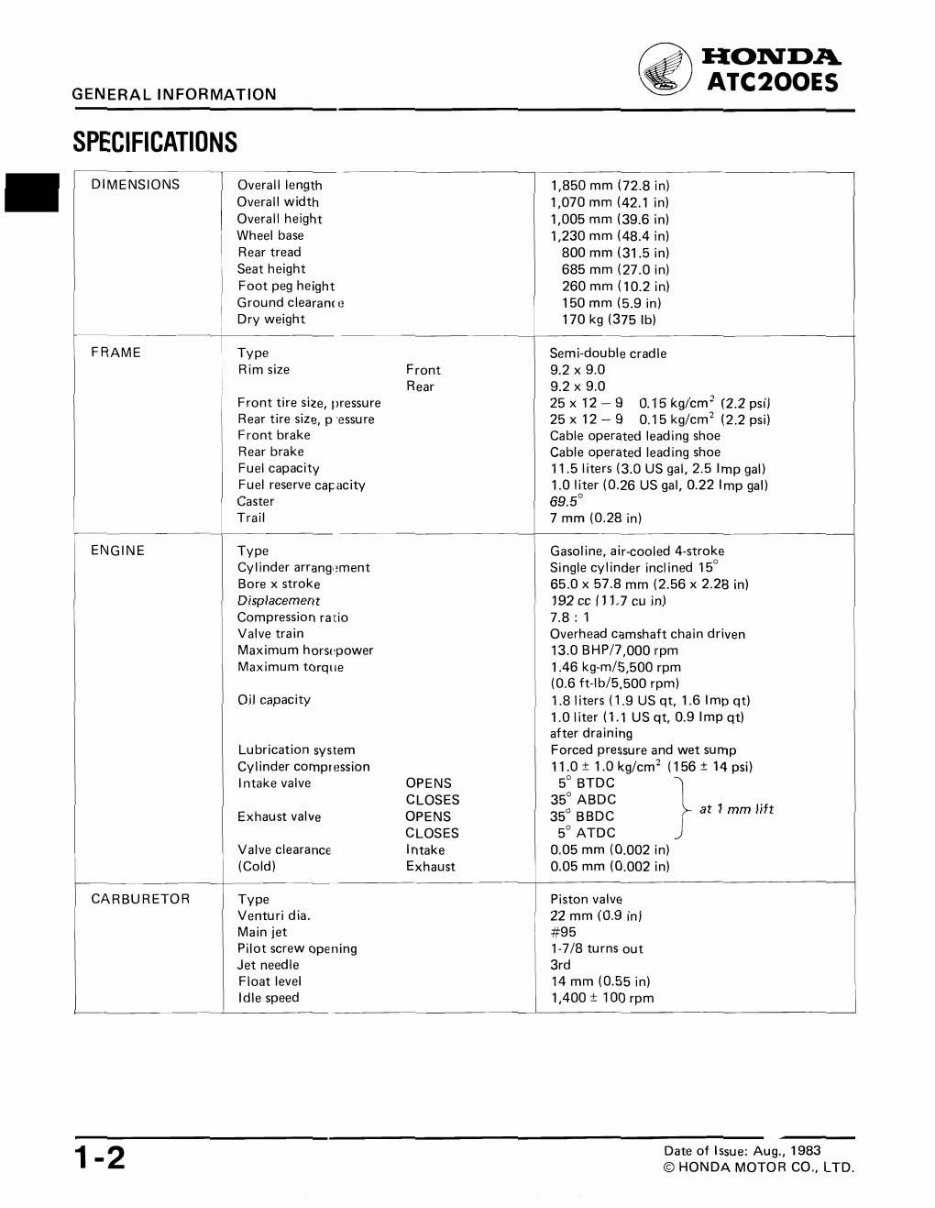

3. Examine the Tires: Proper tire pressure is crucial for safety and efficiency. Check for wear, damage, and ensure they are inflated to the manufacturer’s recommended levels.

4. Brake System Maintenance: Regularly inspect brake pads and fluid levels. Replace worn pads and top off the fluid to ensure responsive braking performance.

5. Battery Care: Check the battery terminals for corrosion and ensure a secure connection. Clean any buildup and test the battery’s charge regularly to avoid starting issues.

6. Lubricate Moving Parts: Apply lubricant to all pivot points and joints to reduce friction and prevent wear. This includes throttle cables and suspension components.

7. Clean the Exterior: Regular washing and waxing not only keep your vehicle looking good but also protect the surface from rust and corrosion. Pay attention to undercarriage cleaning as well.

8. Perform Regular Inspections: Conduct periodic checks on all systems including electrical, fuel, and cooling. Address any anomalies promptly to avoid more significant repairs down the line.

By adhering to this structured maintenance approach, you can ensure that your machine operates smoothly and remains in excellent condition for years to come.

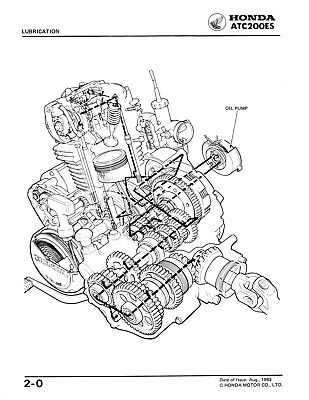

Engine Troubleshooting Techniques

Diagnosing engine issues requires a systematic approach to identify and resolve problems effectively. By understanding the various symptoms and potential causes, one can methodically assess the situation, leading to efficient repairs and optimal performance.

1. Visual Inspection: Start with a thorough visual examination of the engine compartment. Look for obvious signs of wear, damage, or loose connections. Check fluid levels and inspect hoses for cracks or leaks.

2. Listen for Unusual Noises: Strange sounds can be indicative of specific problems. Pay attention to knocking, grinding, or hissing noises, as these may signal issues like improper lubrication or failing components.

3. Check Engine Codes: Utilizing a diagnostic tool to read error codes can provide invaluable information. These codes pinpoint specific malfunctions, streamlining the troubleshooting process and guiding the technician toward the root cause.

4. Test Electrical Systems: Many engine problems stem from electrical issues. Ensure that the battery, wiring, and sensors are functioning properly. Use a multimeter to check voltage and continuity.

5. Assess Performance Metrics: Monitoring performance indicators, such as fuel consumption and power output, can help identify inefficiencies. A noticeable decrease in performance often points to underlying issues needing attention.

6. Conduct Compression Tests: Evaluating the compression levels in each cylinder can reveal significant information about the engine’s internal health. Low compression may suggest problems with the piston rings or valves.

7. Review Maintenance History: Understanding past maintenance can offer insights into recurring problems. Regular service records may indicate trends or specific components that frequently fail.

By employing these techniques, one can enhance diagnostic accuracy, leading to timely and effective solutions for engine-related challenges.

Electrical System Diagnostics

Effective troubleshooting of electrical components is essential for maintaining optimal performance. This section focuses on identifying issues within the circuitry and understanding how each part interacts within the system. A methodical approach will help ensure that electrical malfunctions are resolved efficiently.

Initial Assessment: Start by visually inspecting the wiring and connectors for any signs of wear or damage. Look for frayed wires, corrosion, or loose connections, as these can significantly impact functionality. A clean and organized workspace will facilitate the diagnostic process.

Testing Components: Use a multimeter to measure voltage, continuity, and resistance in various parts of the system. This tool will provide valuable data to pinpoint any anomalies. Checking the battery’s voltage is crucial, as it serves as the power source for all electrical functions.

Troubleshooting Techniques: If an issue is detected, consult the specific specifications for the components involved. Follow a logical sequence in your testing to isolate the problem. For example, if a light is not functioning, verify the bulb, switch, and wiring in succession.

Documentation: Keep detailed records of your findings and any repairs made. This documentation can be invaluable for future diagnostics and helps establish a pattern of issues that may arise over time.

By following these steps and employing careful analysis, one can effectively diagnose and address electrical system concerns, ensuring reliable operation and longevity of the equipment.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal engine performance. Regular cleaning helps prevent buildup that can lead to inefficiencies and operational issues. This section outlines effective methods to ensure your fuel system remains in peak condition, enhancing overall vehicle reliability and longevity.

Steps for Cleaning the Fuel System

Follow these systematic steps to thoroughly clean the fuel system:

- Gather necessary tools and cleaning agents.

- Disconnect the fuel line and drain any remaining fuel.

- Remove the fuel filter and inspect for contaminants.

- Clean the fuel tank using a suitable solvent.

- Use a fuel system cleaner as per manufacturer recommendations.

- Reassemble components, ensuring all connections are secure.

Recommended Cleaning Agents

Choosing the right cleaning agents is crucial for effective results. Below is a table of recommended products:

| Product Name | Type | Usage Instructions |

|---|---|---|

| Fuel Injector Cleaner | Liquid | Mix with fuel tank; follow label instructions. |

| Tank Cleaning Solvent | Solvent | Apply directly to tank; allow to sit before rinsing. |

| Fuel System Flush | Aerosol | Spray into intake while engine is running. |

By adhering to these procedures and using the right cleaning agents, you can ensure that your fuel system operates efficiently, ultimately extending the life of your engine and enhancing performance.

Transmission Service Instructions

This section provides essential guidelines for maintaining and servicing the transmission system of your vehicle. Proper care ensures smooth operation and extends the lifespan of critical components, allowing for optimal performance during use.

Fluid Inspection and Replacement

Regularly checking the transmission fluid is crucial for maintaining performance. Start by locating the dipstick, then withdraw it to assess fluid levels. If the fluid appears dark or has a burnt smell, it’s time for a change. To replace the fluid, follow these steps:

- Drain the old fluid by removing the drain plug.

- Replace the transmission filter if applicable.

- Refill with the manufacturer-recommended fluid type.

Adjusting the Transmission Cables

Proper adjustment of the transmission cables is vital for ensuring accurate shifting. To adjust:

- Locate the adjustment points on the cable assembly.

- Loosen the locking nuts, and adjust the cable tension as needed.

- Tighten the nuts securely and test the shifting to ensure smooth operation.

Following these instructions will help maintain the efficiency and reliability of the transmission system, allowing for a more enjoyable driving experience.

Suspension and Steering Adjustments

Ensuring optimal performance of your vehicle involves meticulous attention to the suspension and steering systems. Proper adjustments in these areas contribute to a smoother ride, improved handling, and enhanced safety. This section outlines essential steps to achieve ideal settings for both suspension and steering mechanisms.

Suspension System Setup

The suspension system plays a critical role in maintaining vehicle stability and comfort. Adjustments may be necessary to accommodate varying loads and driving conditions. Consider the following points:

- Check the shock absorbers for wear; replacing them can drastically improve ride quality.

- Adjust the preload on the springs to cater to the weight distribution of the vehicle.

- Ensure that the alignment of the suspension components is precise to prevent uneven tire wear.

- Inspect bushings and mounts for any signs of deterioration, as they can affect handling.

Steering Alignment and Calibration

Proper steering alignment is crucial for precise handling and tire longevity. Follow these guidelines for effective adjustments:

- Begin by checking the toe settings; slight misalignments can lead to rapid tire degradation.

- Evaluate the camber angle to ensure even tire contact with the road surface.

- Adjust the steering wheel position to ensure it is centered when driving straight.

- Regularly inspect the steering components, including tie rods and steering rack, for any damage.

By regularly maintaining and adjusting the suspension and steering systems, you can enhance the overall driving experience and ensure your vehicle remains safe and reliable on the road.

Braking System Repair Methods

The braking system is crucial for safety and control in any vehicle. Proper maintenance and timely intervention can prevent major issues and ensure optimal performance. This section explores various techniques for addressing common braking system problems, providing insights into effective solutions that enhance safety and functionality.

Identifying Common Issues

Before embarking on repairs, it’s essential to recognize the signs of malfunction. Common symptoms include squeaking noises, reduced responsiveness, or pulling to one side. Conducting a thorough inspection of the brake components, including pads, rotors, and fluid levels, will help identify the root causes of these issues.

Step-by-Step Repair Techniques

Once problems are identified, specific repair methods can be applied. For instance, replacing worn brake pads requires removing the wheel, detaching the caliper, and installing new pads. If rotor damage is evident, resurfacing or replacement may be necessary. Additionally, ensuring that brake fluid is clean and at the proper level is vital for maintaining hydraulic pressure. Regularly bleeding the system can also eliminate air bubbles that compromise performance.

Bodywork and Aesthetic Improvements

This section explores enhancements to the exterior and visual appeal of your vehicle, focusing on both practical modifications and stylistic upgrades. Improving the outer shell not only boosts the overall look but can also enhance functionality and protection against environmental factors.

Consider repainting or applying a vinyl wrap to refresh the appearance. This not only allows for personalization but can also shield the underlying material from wear and tear. Adding decals or custom graphics can provide a unique touch that reflects your personality.

Additionally, inspecting and replacing damaged panels or fenders is crucial for maintaining structural integrity and aesthetic coherence. Upgrading to more durable or lightweight materials can yield significant benefits in both appearance and performance.

Incorporating LED lighting or upgraded mirrors can modernize the look while improving visibility. Furthermore, accessorizing with bumpers or skid plates can provide a rugged aesthetic and enhanced protection, making your vehicle stand out both on and off the road.

Upgrades and Performance Enhancements

Enhancing the capabilities and efficiency of your off-road vehicle can significantly improve both its functionality and enjoyment. Various modifications can lead to increased power output, improved handling, and overall better performance. In this section, we will explore several popular upgrades that can elevate your riding experience.

Engine Modifications

One of the most effective ways to boost performance is through engine upgrades. Replacing the stock air filter with a high-flow variant can enhance airflow, allowing the engine to breathe better. Additionally, installing a performance exhaust system can reduce back pressure and increase horsepower. Consider tuning the engine’s ECU to optimize fuel delivery and ignition timing for even greater gains.

Suspension Improvements

Upgrading the suspension system is crucial for better handling and ride comfort. Investing in high-quality shocks and struts can provide improved stability and responsiveness on rough terrain. Furthermore, adjusting the suspension settings for your specific riding style can help achieve optimal performance. Don’t forget to check and upgrade the tires; choosing models designed for off-road conditions will greatly enhance traction and control.

Where to Find Replacement Parts

Locating suitable components for vintage machines can be a rewarding yet challenging task. Enthusiasts often seek reliable sources that provide quality pieces to ensure optimal performance and longevity.

Online Marketplaces: Numerous websites specialize in vintage equipment parts. Platforms such as eBay or Craigslist often feature listings from private sellers and shops, providing a variety of options.

Local Dealerships: Some dealerships may still stock or have access to older models’ components. Visiting or calling them can yield unexpected finds.

Salvage Yards: Visiting salvage yards can be a treasure hunt. Many of these facilities have a range of machines from which you can source usable parts.

Specialty Retailers: Certain retailers focus specifically on vintage machinery. They often have knowledgeable staff who can guide you in your search for the right components.

Engaging with online forums and communities can also be invaluable. Members frequently share insights on where to find rare parts and may even have extras available for sale.