Comprehensive Guide to Repairing the 2004 Honda 400EX

Owning a recreational vehicle involves understanding its intricacies and ensuring it remains in optimal condition. This section aims to provide essential insights and guidance for maintaining your ATV, covering various aspects crucial for its longevity and performance.

Whether you’re addressing minor issues or preparing for comprehensive servicing, having a clear and structured approach can make all the difference. From troubleshooting common concerns to following systematic procedures, the knowledge shared here will empower you to enhance your riding experience.

Explore detailed information regarding parts, tools, and techniques that are fundamental in keeping your vehicle operating smoothly. With the right resources at your fingertips, you can confidently tackle maintenance tasks and enjoy your adventures to the fullest.

Essential Maintenance for 2004 Honda 400EX

Proper upkeep is crucial for maximizing the performance and longevity of your all-terrain vehicle. Regular attention to various components not only enhances functionality but also ensures safety during operation. This section highlights key practices that every owner should follow to keep their vehicle in optimal condition.

Regular Fluid Checks

Monitoring and changing fluids is vital for the smooth operation of your machine. Regularly inspect the engine oil, coolant, and brake fluid levels. Replace old fluids with recommended types to prevent engine wear and maintain optimal performance. This simple task can significantly prolong the lifespan of your vehicle.

Air Filter Maintenance

The air filter plays a critical role in maintaining engine efficiency. A clean air filter ensures that the engine receives adequate airflow, improving performance and fuel efficiency. Inspect the filter regularly and replace or clean it as necessary, especially after riding in dusty or muddy conditions. Keeping the air intake system clear enhances overall engine health.

Common Issues and Troubleshooting Tips

In the realm of all-terrain vehicles, understanding prevalent problems and effective solutions is crucial for maintaining optimal performance. This section highlights frequent challenges owners may encounter, along with practical advice for addressing them.

Engine Performance Issues: One of the most common concerns is related to engine efficiency. If the vehicle experiences difficulty starting or exhibits rough idling, it may indicate a clogged air filter or fuel line. Regularly inspecting and cleaning these components can significantly enhance performance.

Transmission Problems: Transmission issues can manifest as slipping gears or unusual noises. These symptoms may arise from low fluid levels or worn components. Checking the fluid levels and replacing any damaged parts promptly can help restore smooth operation.

Electrical Failures: Electrical systems are vital for functionality. If lights flicker or fail to operate, this may point to a faulty battery or loose connections. Ensuring all connections are secure and the battery is charged can resolve many electrical dilemmas.

Suspension Concerns: A well-functioning suspension system is essential for a comfortable ride. If the vehicle feels bumpy or unstable, it may be due to worn-out shock absorbers. Regularly inspecting and replacing these parts will improve stability and control.

By identifying these common issues and following the outlined troubleshooting tips, owners can maintain their vehicles effectively, ensuring a reliable and enjoyable riding experience.

Understanding the Engine Components

The engine serves as the heart of any vehicle, playing a crucial role in its performance and efficiency. A thorough understanding of its various components is essential for effective maintenance and troubleshooting. Each part contributes to the overall functionality, and recognizing their roles can greatly enhance your ability to keep the engine running smoothly.

Main Components

Several key elements work together to ensure the engine operates efficiently. Below is a brief overview of these components:

| Component | Function |

|---|---|

| Cylinder Head | Encloses the combustion chamber and houses the intake and exhaust valves. |

| Piston | Moves up and down within the cylinder, compressing the air-fuel mixture. |

| Crankshaft | Converts the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of the intake and exhaust valves. |

| Oil Pan | Holds engine oil for lubrication of moving parts. |

Importance of Each Component

Understanding the significance of each part helps in diagnosing issues and performing maintenance. Regular checks and services can prolong the life of these components and ensure optimal performance.

Guidelines for Safe Operation

Ensuring a safe riding experience is essential for both the operator and the surrounding environment. Proper practices can significantly reduce the risk of accidents and enhance the enjoyment of your vehicle. Following established safety measures is crucial for maintaining control and awareness while navigating various terrains.

Always wear appropriate protective gear. This includes a helmet, gloves, long sleeves, and sturdy footwear. Such equipment minimizes injury risk in the event of a fall or collision. Additionally, it is advisable to use eyewear to shield your eyes from debris and harsh weather conditions.

Familiarize yourself with the vehicle before operating it. Understanding the controls, features, and limitations will improve handling and response in different situations. Take the time to read the guidelines thoroughly and practice in a safe area to build confidence.

Conduct regular inspections of your machine to ensure everything is functioning properly. Check the brakes, tires, and fluid levels before each ride. Identifying potential issues beforehand can prevent unexpected failures and enhance safety during operation.

Be mindful of the terrain and weather conditions. Adapt your riding style to the environment, whether it’s muddy, rocky, or steep. Avoid hazardous areas and be cautious of other individuals and vehicles to maintain a safe distance at all times.

Follow local regulations and guidelines to ensure compliance with legal requirements. Respect speed limits and designated trails, as this helps to preserve natural landscapes and ensures the safety of all users.

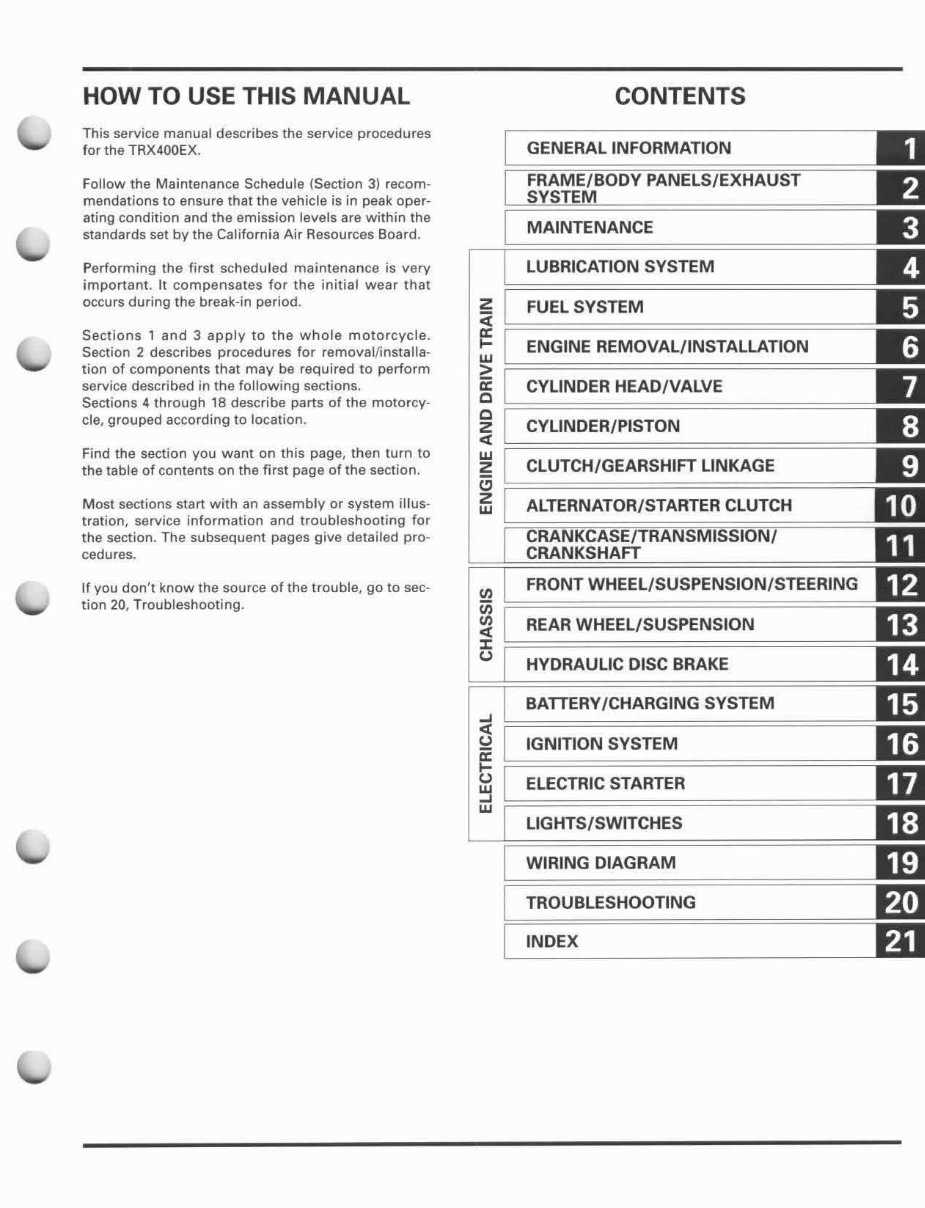

Step-by-Step Repair Procedures

This section provides a detailed approach to maintenance tasks, ensuring optimal performance and longevity of your vehicle. Following systematic guidelines helps in identifying issues and applying solutions effectively.

- Preparation:

- Gather necessary tools and equipment.

- Ensure the workspace is clean and well-lit.

- Review safety precautions before starting any work.

- Assessment:

- Inspect the vehicle for visible damage or wear.

- Check fluid levels and conditions.

- Listen for unusual sounds during operation.

- Disassembly:

- Carefully remove components as needed for access.

- Label parts to ensure correct reassembly.

- Keep track of any fasteners and small pieces.

- Repair or Replacement:

- Identify faulty components that require attention.

- Follow manufacturer guidelines for replacements.

- Make adjustments to ensure proper function.

- Reassembly:

- Reinstall parts in the reverse order of disassembly.

- Ensure all connections are secure and tight.

- Double-check alignment and fit of components.

- Testing:

- Start the vehicle to verify successful repairs.

- Monitor for any issues during initial operation.

- Take a test drive to ensure everything functions smoothly.

By adhering to these structured procedures, you can maintain and enhance the performance of your machine, addressing problems efficiently and effectively.

Tools Required for Effective Repairs

To achieve successful maintenance and enhancements on your vehicle, having the right set of instruments is crucial. Proper tools not only facilitate the work process but also ensure safety and efficiency during tasks. Below is a list of essential equipment that will aid in a smooth and effective service experience.

Basic Hand Tools: A reliable collection of hand tools is fundamental. This includes wrenches, screwdrivers, pliers, and sockets, which are vital for loosening and tightening various components. High-quality hand tools can significantly reduce the risk of damage during disassembly and reassembly.

Torque Wrench: This instrument is indispensable for ensuring that bolts and nuts are tightened to the manufacturer’s specified torque. Utilizing a torque wrench prevents over-tightening, which could lead to stripped threads or component failure.

Specialized Instruments: Depending on the specific tasks at hand, specialized tools such as a feeler gauge, compression tester, or spark plug wrench may be necessary. These tools are designed to address particular aspects of vehicle maintenance, enhancing accuracy and reliability.

Cleaning Supplies: Keeping your work area tidy is essential. Cleaning agents, rags, and brushes are important for maintaining the condition of components and preventing contaminants from causing issues during the service process.

Safety Gear: Never overlook the importance of personal protective equipment. Gloves, goggles, and ear protection should always be worn to safeguard against potential hazards encountered during maintenance activities.

By equipping yourself with these essential tools and gear, you can ensure a more effective and enjoyable experience when tending to your vehicle’s needs.

Oil Change and Fluid Maintenance

Regular maintenance of lubricants and fluids is crucial for the longevity and performance of your vehicle. Ensuring that these components are kept in optimal condition helps prevent wear and tear, reduces the risk of mechanical failure, and enhances overall efficiency. This section outlines the essential steps for changing oil and maintaining fluids effectively.

1. Oil Change Procedure

To begin the oil change, ensure that the engine is warm but not too hot. This allows the oil to flow more easily. First, locate the drain plug under the engine and place a container underneath to catch the old oil. Remove the drain plug and let the oil completely drain out. Afterward, replace the drain plug securely.

Next, remove the old oil filter using an oil filter wrench. Before installing a new filter, apply a small amount of new oil to the rubber gasket of the new filter. This ensures a proper seal. Screw on the new filter until it is snug, but avoid over-tightening.

Finally, fill the engine with the appropriate type and amount of fresh oil using a funnel. Check the dipstick to ensure the oil level is within the recommended range. Start the engine and let it run for a few minutes, then recheck the oil level and add more if necessary.

2. Fluid Maintenance

In addition to oil changes, it is important to routinely check and maintain other fluids. This includes coolant, brake fluid, and transmission fluid. Regular inspections can help identify leaks or low levels before they become serious issues.

For coolant, check the reservoir and top it off with the correct mixture of antifreeze and water as needed. Brake fluid should be clear and at the appropriate level; if it appears dark or contaminated, it may need to be replaced. Similarly, check the transmission fluid for color and level, ensuring it is within the manufacturer’s specifications.

By adhering to these maintenance practices, you can significantly improve the reliability and performance of your vehicle, ensuring it operates smoothly for years to come.

Adjusting the Suspension System

The suspension system plays a crucial role in ensuring a smooth ride and maintaining control over rough terrains. Proper adjustment of this system is essential for optimizing performance, enhancing comfort, and ensuring safety during operation. Regular maintenance and fine-tuning can significantly improve the handling characteristics of the vehicle.

Understanding Suspension Components

Familiarizing yourself with the various components of the suspension system is vital. Key elements include shock absorbers, springs, and linkage systems. Each part contributes to the overall functionality, affecting how the vehicle reacts to bumps and obstacles. Regular inspections can help identify wear and ensure that all components are functioning correctly.

Adjustment Procedures

To achieve the desired ride quality, adjustments may involve altering the preload on the springs, modifying the compression and rebound settings of the shock absorbers, and fine-tuning the overall alignment of the suspension components. Taking precise measurements before and after adjustments ensures consistency and allows for a better understanding of how changes affect handling. Always refer to the specific guidelines for optimal settings tailored to your riding style and conditions.

Electrical System Diagnostics

This section focuses on the essential procedures for evaluating and troubleshooting the electrical components of your vehicle. Proper diagnostics ensure optimal performance and longevity of the electrical system, helping to identify any issues before they lead to significant problems.

Begin by verifying the condition of the battery, as it serves as the primary power source. A fully charged and functioning battery is crucial for the reliable operation of electrical components.

Next, inspect the wiring harness and connections for any signs of wear, corrosion, or loose connections that may hinder electrical flow. It is vital to maintain a clear path for current to ensure the system operates efficiently.

| Component | Diagnostic Steps |

|---|---|

| Battery | Check voltage and terminals for corrosion. |

| Fuses | Inspect for blown fuses and replace if necessary. |

| Wiring | Examine for fraying, disconnections, or shorts. |

| Switches | Test functionality and ensure proper operation. |

| Relays | Check for proper engagement and continuity. |

Following these diagnostic procedures will assist in pinpointing issues within the electrical system, facilitating effective repairs and maintenance.

Cleaning and Replacing Air Filters

Proper maintenance of air filtration systems is essential for ensuring optimal performance and longevity of the engine. Regular cleaning and timely replacement of these components help maintain airflow, enhance efficiency, and prevent potential damage. This section outlines the procedures for effectively managing air filters, contributing to the overall functionality of the vehicle.

To begin the process, gather the necessary tools and materials. Ensure that the work area is clean and free from debris to avoid contamination of the filter. Follow the steps below for thorough cleaning and replacement.

| Step | Action |

|---|---|

| 1 | Remove the air filter cover carefully to access the filter. |

| 2 | Inspect the filter for dirt and damage. If it’s reusable, proceed to clean it. |

| 3 | Use compressed air to blow out dirt from the filter, working from the inside out. |

| 4 | If necessary, wash the filter with mild soap and water, then let it dry completely. |

| 5 | For damaged filters, replace them with a new component that meets specifications. |

| 6 | Reinstall the air filter and cover securely to complete the process. |

By adhering to these steps, you can ensure that the air filtration system operates efficiently, promoting better engine performance and durability.

Brake System Inspection Techniques

Ensuring the effectiveness of the braking mechanism is crucial for safety and performance. Regular evaluation of the components can help identify potential issues before they escalate. This section outlines various methods for thoroughly examining the braking system.

Visual Examination

A visual check is the first step in assessing the braking system. Look for signs of wear or damage on critical parts.

- Inspect brake pads for thickness and even wear.

- Examine brake discs for grooves or scoring.

- Check for leaks in brake lines and cylinders.

Functional Testing

Conducting functional tests helps ensure the system operates as intended. Follow these steps for effective evaluation:

- Engage the brakes gradually while in motion to assess responsiveness.

- Test the brake lever or pedal for firmness and travel distance.

- Listen for unusual noises during braking, which could indicate problems.

Consistent inspections using these techniques can enhance the longevity of the braking system and improve overall safety. Regular maintenance is key to optimal performance.

Performance Upgrades and Modifications

Enhancing the capabilities of an all-terrain vehicle can lead to improved power, handling, and overall enjoyment. There are numerous options available for enthusiasts looking to elevate their ride, ranging from engine modifications to suspension upgrades. Each alteration not only boosts performance but also tailors the vehicle to better suit individual riding styles and terrains.

Engine Modifications

Boosting engine performance can significantly enhance acceleration and top speed. Consider installing a high-performance air filter and exhaust system to improve airflow and reduce back pressure. Additionally, upgrading the carburetor or fuel injection system can optimize fuel delivery, resulting in more power output. These enhancements create a more responsive and thrilling ride.

Suspension Improvements

To complement engine upgrades, modifying the suspension is crucial for handling and stability. Upgrading to aftermarket shocks and springs can provide better control over rough terrain. Adjustability options allow riders to customize the setup according to their preferences and riding conditions. Stronger components enhance durability and ensure a smoother experience during adventurous outings.