Honda 4514 Lawn Tractor Repair Guide

Maintaining outdoor equipment is essential for ensuring optimal performance and longevity. This section delves into various aspects of upkeep, focusing on common issues and solutions that users may encounter with their machines. Understanding the intricacies of these devices not only enhances their functionality but also empowers owners to tackle challenges effectively.

The insights presented here are tailored to assist individuals in navigating the complexities of maintenance. From troubleshooting minor faults to performing routine checks, this guide offers valuable information aimed at both novice and seasoned users. Proper attention to detail can significantly reduce downtime and extend the operational lifespan of your equipment.

By familiarizing yourself with the underlying principles of functionality, you will gain confidence in addressing potential setbacks. Engaging with this material will equip you with the knowledge necessary to maintain your machinery, ensuring that it operates smoothly throughout the seasons.

Honda 4514 Lawn Tractor Repair Manual

This section provides essential guidance for maintaining and troubleshooting a specific model of garden machinery. It focuses on common issues that users may encounter, along with effective solutions to enhance performance and longevity. By following the outlined steps, owners can ensure their equipment remains in optimal condition.

Understanding Maintenance Practices

Regular upkeep is crucial for the functionality of any outdoor equipment. Performing scheduled inspections and addressing minor concerns promptly can prevent larger problems from developing. Users should familiarize themselves with the basic components and operational principles to facilitate this process.

Troubleshooting Common Issues

Identifying typical malfunctions is the first step toward effective resolution. Problems such as poor performance, unusual noises, or starting difficulties often stem from a lack of maintenance or worn parts. Knowing how to diagnose these issues can save time and resources.

Service Procedures and Guidelines

When it comes to servicing the machinery, adhering to established protocols is essential. This includes following systematic procedures for part replacement, fluid changes, and safety checks. By sticking to these guidelines, users can confidently manage their equipment’s health and ensure safe operation.

Overview of Honda 4514 Tractor Features

This section provides a comprehensive look at the essential characteristics and functionalities of a well-engineered gardening vehicle designed for efficiency and user-friendliness. By understanding these features, operators can maximize performance and maintain optimal operation for various tasks.

Key Specifications

The following table outlines the primary specifications of this gardening machine, highlighting its capabilities and design elements:

| Feature | Description |

|---|---|

| Engine Type | Powerful four-stroke engine for reliable performance. |

| Cutting Width | Generous cutting width for efficient mowing. |

| Transmission | Seamless gear shifting for smooth operation. |

| Fuel Capacity | Large tank size for extended usage without frequent refueling. |

| Turning Radius | Tight turning radius for maneuverability in tight spaces. |

Additional Features

In addition to its core specifications, this gardening vehicle includes several innovative features aimed at enhancing user experience and comfort. Ergonomic seating and easy-access controls ensure that operators can work for extended periods without discomfort. Moreover, the inclusion of durable materials contributes to longevity, making it a reliable choice for various outdoor tasks.

Understanding Common Tractor Issues

Identifying frequent challenges in outdoor equipment can significantly enhance the maintenance process. Many individuals encounter similar problems, which can stem from various components failing to operate as intended. Recognizing these issues is the first step toward effective troubleshooting and ensuring optimal performance.

Engine Performance Problems: A common concern involves irregular engine behavior, which may manifest as difficulty starting or unexpected stalling. Such issues often result from fuel delivery problems or air filter blockages. Regular checks of these components can prevent larger malfunctions.

Transmission Difficulties: Issues with the transmission system can lead to challenges in movement and speed adjustments. Users may notice slipping gears or an inability to shift properly. Ensuring the transmission fluid is at the appropriate level and free from contaminants is essential for smooth operation.

Electrical System Failures: The electrical components may also present obstacles, such as malfunctioning lights or battery problems. Inspecting wiring and connections regularly can help detect wear and tear, thus avoiding sudden failures.

By understanding these common challenges, operators can perform timely maintenance and reduce the likelihood of extensive repairs, keeping their equipment in peak condition.

Essential Tools for Tractor Repair

Having the right equipment is crucial for maintaining and fixing outdoor machinery effectively. Proper tools not only facilitate smoother operations but also ensure safety and efficiency during maintenance tasks. This section outlines the fundamental instruments necessary for handling various challenges that may arise during upkeep.

Basic Hand Tools

- Wrenches: A variety of sizes to accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips for versatile applications.

- Pliers: Essential for gripping, twisting, and cutting wires or small components.

- Socket Set: Useful for accessing hard-to-reach bolts and nuts.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Jack and Stands: Necessary for lifting heavy machinery safely.

- Multimeter: A vital tool for diagnosing electrical issues.

- Oil Filter Wrench: Specifically designed for removing oil filters with ease.

Engine Troubleshooting Tips

When encountering issues with a power unit, a systematic approach to diagnostics can help identify and resolve common problems effectively. Understanding the potential causes of malfunction allows for efficient troubleshooting and ensures optimal performance.

Check Fuel Supply: Begin by verifying that the fuel system is functioning properly. Ensure that there is sufficient fuel in the tank and that the fuel lines are free from obstructions. Contaminated fuel can lead to poor engine performance, so consider replacing old fuel.

Inspect Spark Plug: The spark plug plays a crucial role in ignition. Remove it and examine for wear or carbon buildup. Cleaning or replacing the spark plug may restore proper ignition and enhance overall performance.

Evaluate Air Filter: A clean air filter is essential for efficient combustion. Inspect the filter for dirt and debris. If it appears clogged, cleaning or replacing it can improve airflow, leading to better engine function.

Monitor Oil Levels: Regularly checking oil levels is vital for engine health. Low or dirty oil can cause excessive wear or overheating. If necessary, change the oil and replace the oil filter to maintain optimal lubrication.

Test Electrical Connections: Loose or corroded connections can disrupt the electrical system. Inspect wiring and connectors for signs of damage. Tightening or cleaning these connections can often resolve starting or running issues.

Maintaining Optimal Battery Performance

Ensuring the longevity and efficiency of a power source is crucial for optimal operation. Proper upkeep not only extends the life of the battery but also enhances overall functionality. Following best practices can help in achieving peak performance and reliability.

Here are some essential tips for maintaining battery health:

- Regular Inspections: Check the terminals and connections for corrosion or damage.

- Keep Clean: Ensure that the battery and its surroundings are free from dirt and debris.

- Charge Properly: Use the recommended charging equipment and avoid overcharging.

- Temperature Awareness: Store the battery in a moderate environment to prevent overheating or freezing.

- Fluid Levels: If applicable, maintain proper electrolyte levels to ensure efficient operation.

Implementing these practices can significantly enhance the reliability and lifespan of your power source, ensuring that it remains in optimal condition for all your needs.

Steps to Replace the Air Filter

Maintaining optimal performance of your machine involves regular replacement of the air filtration component. A clean filter ensures efficient airflow and enhances engine longevity. Follow the steps outlined below to effectively replace this essential part.

- Gather the necessary tools and materials, including a new air filter, a screwdriver, and a clean cloth.

- Ensure the engine is turned off and cool to the touch before beginning the process.

- Locate the air filter housing, typically situated near the engine.

- Use the screwdriver to remove any screws or fasteners securing the housing cover.

- Carefully lift off the cover to access the air filter.

- Remove the old air filter, taking note of its orientation for proper installation of the new one.

- Clean any debris from the filter housing using the cloth.

- Insert the new air filter in the same orientation as the old one.

- Reattach the housing cover, securing it with screws or fasteners.

- Dispose of the old filter responsibly, ensuring environmental safety.

Regularly replacing the air filtration component will significantly improve the efficiency of your equipment and prolong its operational lifespan.

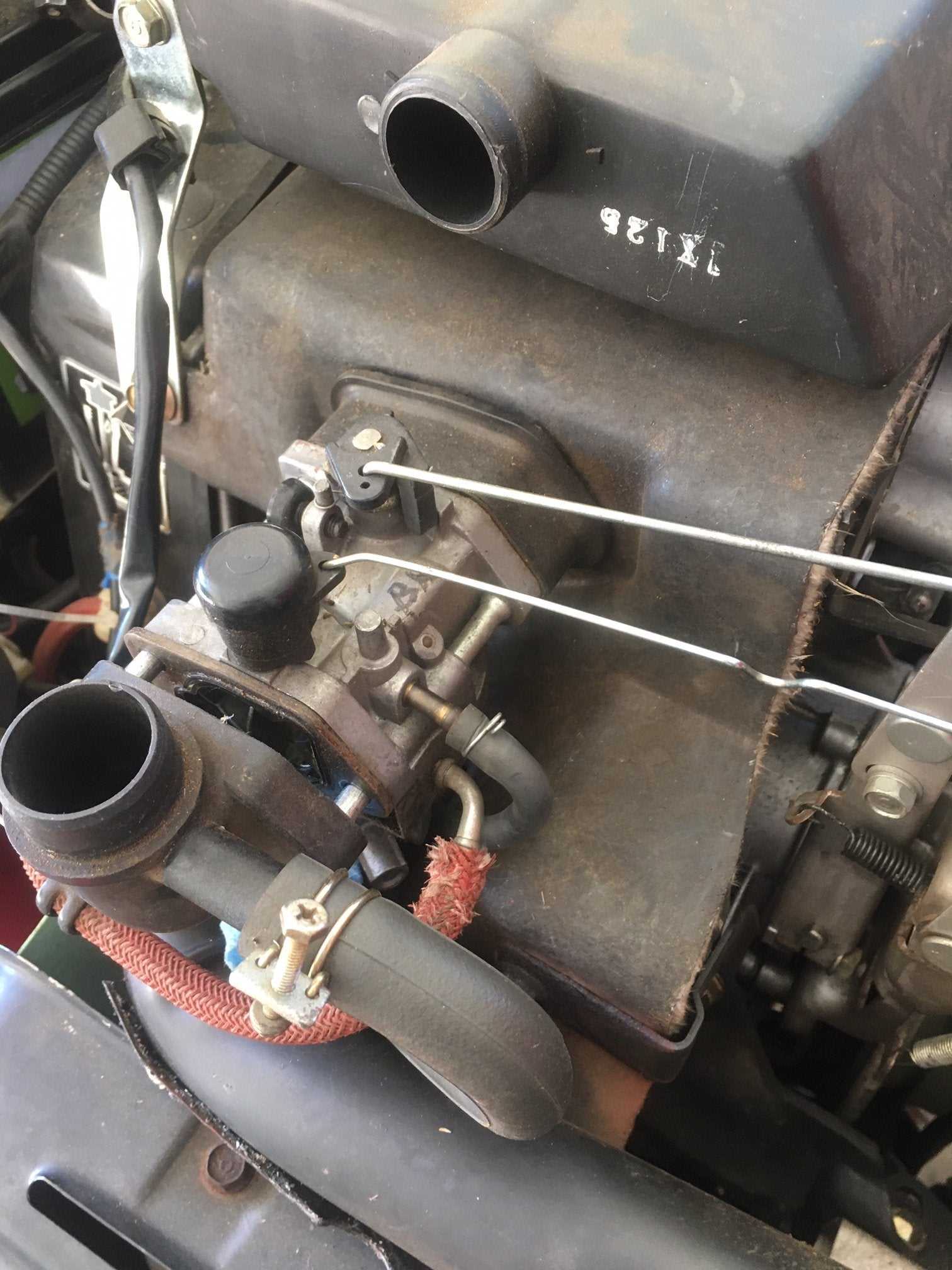

Guide to Adjusting the Carburetor

Ensuring optimal performance of your engine often requires precise adjustments to its fuel delivery system. This guide will walk you through the essential steps needed to fine-tune the carburetor, enhancing efficiency and responsiveness.

Understanding the Basics

The carburetor plays a crucial role in mixing air and fuel for combustion. Proper calibration is essential for smooth operation. Familiarize yourself with the main components: the idle screw, mixture screw, and throttle plate. Each element must work harmoniously to achieve the desired outcome.

Step-by-Step Adjustment Process

Begin by starting the engine and letting it warm up to operating temperature. Locate the idle adjustment screw; turning it clockwise typically increases the idle speed, while counterclockwise decreases it. Next, focus on the mixture screw. Adjust this by making small turns, observing engine response. Aim for a smooth idle, listening for any irregularities in sound. After adjustments, recheck the idle speed and make final tweaks as necessary.

Regular maintenance and tuning of the carburetor can significantly extend the life of your engine and improve overall performance.

Inspecting and Replacing Spark Plugs

Regular examination and substitution of ignition components are vital for ensuring optimal engine performance. Properly functioning spark plugs are crucial for efficient combustion, which directly impacts power output and fuel efficiency. This section outlines the essential steps for checking and replacing these components to maintain smooth operation.

Begin by gathering the necessary tools, including a socket wrench, gap gauge, and replacement plugs. Follow these steps to conduct a thorough inspection:

| Step | Description |

|---|---|

| 1 | Disconnect the ignition system to ensure safety while working. |

| 2 | Locate the spark plugs and remove them using a socket wrench. |

| 3 | Examine the plugs for signs of wear, such as corrosion or carbon buildup. |

| 4 | Check the gap using a gap gauge, adjusting if necessary to meet specifications. |

| 5 | If the plugs are damaged or excessively worn, replace them with new ones. |

| 6 | Reinstall the plugs securely and reconnect the ignition system. |

Following these steps ensures the ignition components are functioning correctly, contributing to the overall efficiency and reliability of the engine. Regular maintenance of these parts helps prevent potential issues and prolongs the life of the machinery.

Hydraulic System Maintenance Guide

Proper upkeep of the hydraulic mechanism is essential for optimal performance and longevity of your equipment. Regular inspections and maintenance can prevent costly repairs and ensure smooth operation. This guide outlines key practices to help you maintain the hydraulic system effectively.

Regular Inspections

Conducting frequent checks on hydraulic components is crucial. Look for signs of leaks, wear, or damage in hoses and connections. Ensure that the fluid levels are adequate and that the fluid itself is clean and free from contaminants. Replacing worn seals and filters promptly can help avoid more serious issues down the line.

Fluid Replacement and Quality

Using the correct hydraulic fluid is vital for maintaining system integrity. Follow the manufacturer’s specifications for fluid type and viscosity. Regularly replace the hydraulic fluid based on usage or at intervals recommended in the maintenance guidelines. This practice will help maintain optimal performance and extend the lifespan of hydraulic components.

How to Adjust Brake Settings

Properly setting the braking mechanism is essential for optimal safety and functionality of your equipment. This process ensures that the device operates smoothly and responds effectively during use. Adjustments may vary based on specific models, but the principles remain largely the same.

Tools and Materials Needed

- Wrench set

- Screwdriver

- Tape measure

- Lubricant

Steps for Adjustment

- Start by parking the equipment on a flat, stable surface and ensuring the engine is off.

- Locate the brake adjustment mechanism, typically found near the rear of the device.

- Using the appropriate wrench, loosen the locking nut to allow for adjustments.

- Turn the adjustment screw clockwise to tighten the brakes or counterclockwise to loosen them, aiming for a snug fit without excessive resistance.

- Test the braking response by pushing the equipment slightly; make further adjustments as necessary.

- Once satisfied, retighten the locking nut to secure the setting.

- Lubricate the moving parts to enhance performance and reduce wear.

Regular maintenance of the braking system contributes to the longevity and safety of your machinery. Always consult your specific guidelines for more detailed instructions.

Tire and Wheel Maintenance Tips

Proper upkeep of tires and wheels is crucial for optimal performance and safety. Regular maintenance not only extends the lifespan of these components but also ensures smooth operation and enhances the overall efficiency of your equipment.

Regular Inspection

- Check for any signs of wear or damage, including cracks, bulges, or foreign objects embedded in the rubber.

- Monitor the tread depth to ensure adequate traction on various surfaces.

- Examine wheel rims for dents or bends that could affect stability.

Inflation and Pressure Management

- Maintain the recommended air pressure for your tires to improve handling and reduce the risk of blowouts.

- Regularly check tire pressure, especially before use, to account for temperature changes and air loss.

- Adjust pressure as needed based on load and terrain to optimize performance.

Preparing for Seasonal Storage

Properly preparing equipment for seasonal storage is essential to ensure its longevity and optimal performance. This process involves a series of systematic steps aimed at safeguarding the machinery from potential damage during extended periods of inactivity.

Start by thoroughly cleaning the exterior and any accessible components to remove dirt, debris, and grass clippings. This helps prevent rust and corrosion. After cleaning, inspect all parts for wear and tear, addressing any necessary repairs before storage.

Next, drain fuel from the tank and carburetor to minimize the risk of gumming and deterioration. If applicable, apply a protective oil to critical parts, including the engine, to further enhance protection. Additionally, ensure that all fluids are topped off and changed if necessary, as clean fluids can help prevent internal corrosion.

Finally, store the equipment in a dry, sheltered location to protect it from the elements. Covering it with a breathable tarp or dedicated cover can provide extra protection against dust and moisture, ensuring it remains in peak condition for future use.