Comprehensive Repair Guide for Honda CBR250R

This section offers a detailed overview of essential procedures and guidelines for keeping your two-wheeled companion in optimal condition. Understanding the intricacies of routine servicing and troubleshooting can significantly enhance the longevity and performance of your vehicle.

In this guide, you will discover practical insights on various aspects, from basic upkeep tasks to more complex interventions. Mastering these techniques not only ensures a smoother ride but also empowers you to tackle challenges effectively, fostering a deeper connection with your machine.

Whether you are a novice or a seasoned enthusiast, having access to well-structured information is crucial. This compilation aims to provide you with the knowledge needed to confidently address maintenance tasks, ultimately leading to a more rewarding riding experience.

Understanding the Honda CBR250R

This section provides an overview of a popular sportbike known for its agility and efficiency. With a blend of performance and user-friendly features, it has become a favorite among both new and experienced riders. The design emphasizes lightweight construction and responsive handling, making it suitable for various riding conditions.

Key Features

- Compact and lightweight frame

- Powerful single-cylinder engine

- Sporty aesthetics and comfortable seating

- Advanced braking systems for enhanced safety

Performance and Handling

The model excels in urban environments, offering nimble handling and quick acceleration. Its suspension system is designed to absorb bumps effectively, contributing to a smooth ride even on uneven surfaces. Riders often appreciate its fuel efficiency, which makes it a practical choice for daily commuting.

Essential Tools for Repairs

Having the right equipment is crucial for performing maintenance and addressing issues effectively. Proper tools not only facilitate the process but also ensure safety and accuracy, making tasks more manageable. This section highlights the must-have instruments that can help tackle various mechanical challenges.

Basic Hand Tools

Starting with the fundamentals, a good set of hand tools is essential for any mechanical work. Items such as wrenches, pliers, and screwdrivers form the backbone of any toolkit. Socket sets are particularly valuable, as they provide flexibility for different fasteners and allow for easier access to tight spaces. Additionally, a reliable torque wrench is necessary to apply the correct amount of force when securing components, preventing damage or loosening over time.

Specialized Equipment

In addition to basic tools, certain specialized instruments can significantly enhance efficiency. A service stand is indispensable for stability while working, especially when handling heavier components. Furthermore, diagnostic tools like multimeters and scan tools are invaluable for troubleshooting electrical systems and ensuring everything operates smoothly. Investing in quality equipment pays off in both performance and longevity.

Common Issues and Solutions

Maintaining a motorcycle can sometimes lead to unexpected challenges, even for the most diligent owners. Understanding typical problems and their respective remedies can greatly enhance the riding experience and prolong the lifespan of the vehicle. Below, we explore some frequently encountered difficulties and practical solutions to address them effectively.

Engine Starting Problems

One of the most prevalent issues faced by riders is difficulty in starting the engine. This can stem from various factors, including a drained battery, faulty spark plugs, or issues with the fuel delivery system. To resolve this, check the battery voltage and connections, replace worn spark plugs, and ensure that the fuel lines are clear and free from blockages. Regular maintenance of these components can help prevent starting issues.

Brake Performance Issues

Another common concern relates to the braking system, which may exhibit reduced responsiveness or unusual noises. This can result from worn brake pads, air in the brake lines, or insufficient brake fluid. To address this, inspect the brake pads for wear and replace them if necessary. Additionally, bleed the brake lines to remove any trapped air and check the fluid levels, topping up as needed. Ensuring the braking system is in optimal condition is crucial for rider safety.

Maintenance Schedule Overview

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Adhering to a systematic maintenance schedule helps in identifying potential issues before they escalate into significant problems. This section outlines the key intervals and tasks that should be performed to maintain peak efficiency and safety.

Daily Checks: Before each ride, it is advisable to inspect critical components such as tire pressure, fluid levels, and lights. These simple checks can prevent accidents and enhance safety on the road.

Weekly Maintenance: Every week, ensure that the chain is properly lubricated and adjusted, and check the brakes for responsiveness. These actions contribute to the overall functionality and safety of the machine.

Monthly Servicing: Once a month, conduct a thorough inspection of the air filter, battery condition, and brake fluid. Replacing the air filter when necessary helps maintain engine performance, while battery checks prevent unexpected failures.

Seasonal Care: As seasons change, it is crucial to perform a more extensive maintenance routine. Tasks include checking spark plugs, coolant levels, and replacing worn parts as needed. This proactive approach ensures the vehicle remains reliable regardless of weather conditions.

Following this structured maintenance schedule will not only enhance the vehicle’s performance but also extend its lifespan, providing a smoother and safer riding experience.

Engine Specifications and Performance

This section provides an overview of the key specifications and performance metrics associated with the motorcycle’s power unit. Understanding these elements is crucial for enthusiasts and technicians who seek to optimize the vehicle’s performance and maintain its efficiency.

Key Engine Specifications

- Engine Type: Single-cylinder, four-stroke

- Displacement: Approximately 249 cc

- Compression Ratio: 10.7:1

- Maximum Power: Around 26.5 horsepower at 8,500 RPM

- Maximum Torque: Approximately 23 Nm at 7,500 RPM

- Fuel System: Electronic fuel injection (EFI)

Performance Overview

The performance characteristics of this model reflect its design as a balance of agility and efficiency. Here are some notable aspects:

- Quick acceleration from a standstill due to its lightweight structure.

- Smooth power delivery across the RPM range enhances rideability in various conditions.

- Excellent fuel efficiency, making it ideal for daily commuting.

- Responsive braking system complements the engine’s power for improved handling.

Overall, the specifications and performance of the power unit contribute to a dynamic riding experience, appealing to both novice and experienced riders.

Electrical System Troubleshooting

The electrical system of a motorcycle is crucial for its overall performance and functionality. Diagnosing issues in this system can be challenging due to the complexity and interconnectivity of various components. Understanding the basic principles and common problems associated with electrical systems can help in identifying faults and implementing effective solutions.

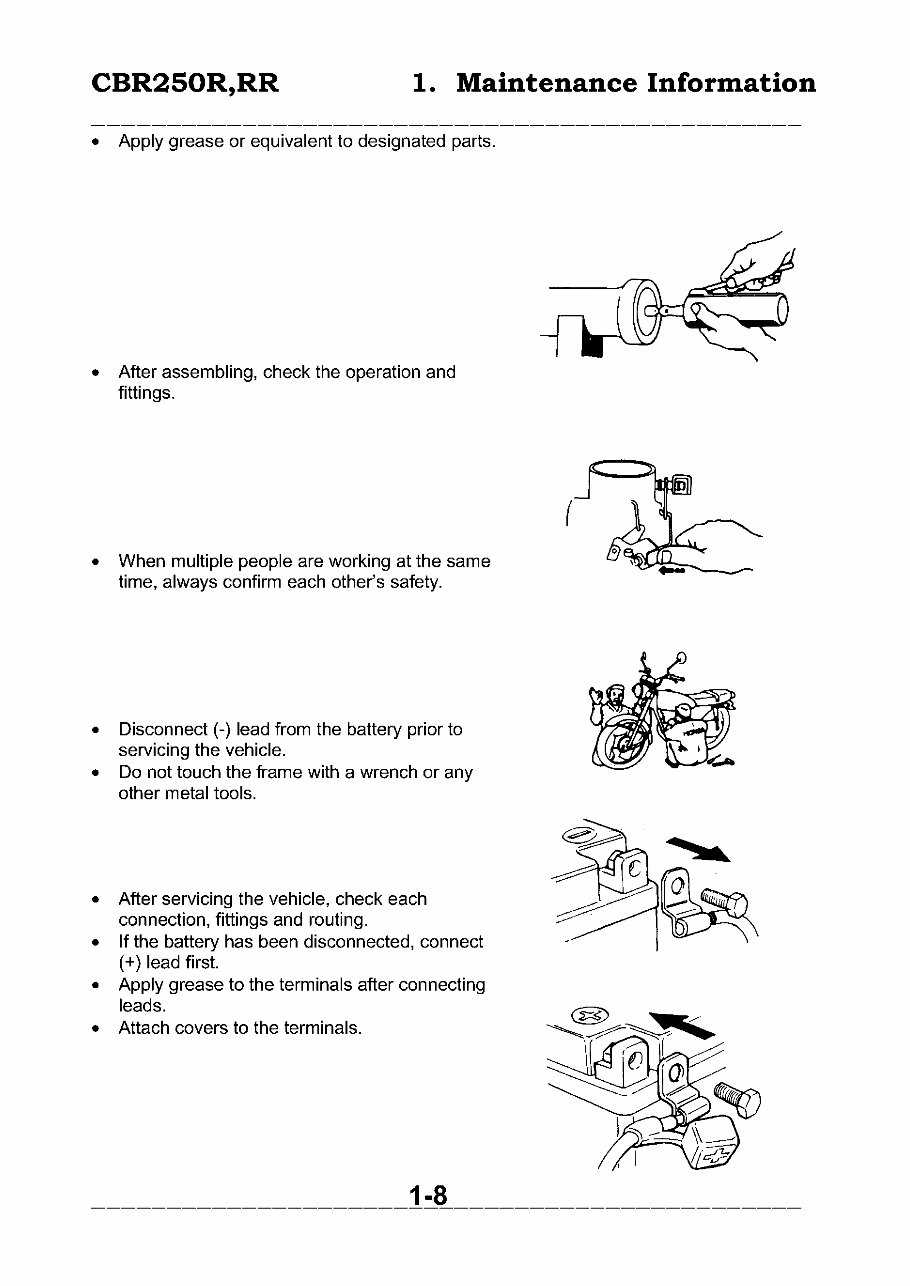

Step 1: Inspect the Battery

Start by examining the battery, as it is the heart of the electrical system. Check for signs of corrosion on terminals and ensure that connections are tight. A multimeter can be used to measure the voltage; a reading below 12.4 volts may indicate a weak battery that requires charging or replacement.

Step 2: Check Fuses and Wiring

Next, review the fuses and wiring for any signs of damage or blown fuses. Replace any faulty fuses and look for frayed or broken wires that may be causing shorts or open circuits. Pay special attention to connections that may have been exposed to moisture or wear.

Step 3: Test the Charging System

Testing the charging system is essential to ensure that the battery receives adequate power while the engine is running. Use a multimeter to check the voltage output from the alternator. The reading should typically range between 13.5 to 14.5 volts when the engine is at a moderate RPM. If the output is outside this range, further investigation into the rectifier or stator may be necessary.

Step 4: Diagnose Electrical Components

Lastly, inspect individual electrical components such as lights, indicators, and the ignition system. Ensure all connections are secure and free from corrosion. If certain components are not functioning, testing them separately may help isolate the problem. For example, using a continuity tester can verify whether switches or relays are operational.

By following these steps, one can effectively troubleshoot electrical issues and restore functionality to the system, ensuring a smooth riding experience.

Braking System Inspection Tips

Regular evaluation of the braking mechanism is essential for ensuring safety and optimal performance. A well-maintained system not only enhances the rider’s control but also prevents potential failures that could lead to hazardous situations. Here are some valuable tips to help you effectively inspect the braking system.

Visual Checks

Begin with a thorough visual examination of the braking components. Look for any signs of wear, such as cracks in the brake pads or discoloration on the rotors. Ensure that there are no leaks in the brake lines, as this can significantly impact braking efficiency. Pay attention to the brake fluid level; it should be within the recommended range as indicated in the specifications.

Functionality Tests

After the visual inspection, conduct functionality tests. Squeeze the brake lever and listen for any unusual noises, which could indicate problems with the calipers or pads. Ensure that the lever feels firm and responsive; a spongy feel may suggest air in the hydraulic lines. Additionally, test the brakes at low speeds in a safe environment to assess their effectiveness and response.

Suspension Setup and Adjustments

Proper tuning of the suspension system is crucial for achieving optimal handling and ride comfort on two-wheeled vehicles. This section delves into the key elements of suspension setup, emphasizing the importance of adjustments to enhance performance based on individual riding preferences and conditions.

The suspension system comprises various components, including forks, shock absorbers, and linkage systems. Each element plays a vital role in absorbing impacts and maintaining stability. Adjusting preload, compression, and rebound settings can significantly influence how the bike responds to different terrains and riding styles.

To begin adjustments, it’s essential to understand the rider’s weight and intended use. For sport-oriented riding, a stiffer setup may be preferred to minimize body roll during aggressive cornering. Conversely, a softer configuration can enhance comfort and traction for leisurely rides or uneven surfaces.

Start by measuring the sag, which refers to how much the suspension compresses under the rider’s weight. The ideal sag measurement varies depending on the type of riding but typically falls within a specific range. Adjusting the preload allows for achieving the correct sag, ensuring the suspension performs efficiently.

Next, focus on the compression and rebound settings. Compression controls the rate at which the suspension compresses during impacts, while rebound manages how quickly it returns to its original position. A balanced approach to these adjustments ensures a smooth ride and optimal traction during acceleration and braking.

Finally, consider testing the settings in real-world conditions. Take the vehicle for a ride and evaluate its performance. Make further adjustments as necessary to fine-tune the setup according to personal preferences and riding experiences. With the right suspension setup, riders can enjoy enhanced control, comfort, and overall riding enjoyment.

Bodywork Repair Techniques

Effective techniques for addressing damage to the outer shell of a vehicle are essential for maintaining its aesthetic and structural integrity. Whether dealing with minor dents or significant scratches, understanding the appropriate methods can greatly enhance the outcome of the restoration process.

Assessment and Preparation

The first step in the repair process is to evaluate the extent of the damage. This includes:

- Inspecting the surface for dents, scratches, and cracks.

- Identifying the materials used in the bodywork to choose suitable repair methods.

- Cleaning the affected area to ensure optimal adhesion of repair materials.

Repair Techniques

Once the damage has been assessed, various methods can be employed to restore the bodywork:

- Filling: For deeper scratches or small dents, a filler material can be applied. After curing, it should be sanded smooth.

- Painting: Matching the original color and applying a clear coat can restore the visual appeal. Multiple thin layers are recommended for even coverage.

- Polishing: Light scratches can often be buffed out using a polishing compound, restoring the surface’s shine.

- Heat Treatment: For minor dents, applying heat followed by cooling can sometimes reshape the material back to its original form.

By employing these methods thoughtfully, one can achieve a seamless and professional finish, preserving the vehicle’s aesthetic and value.

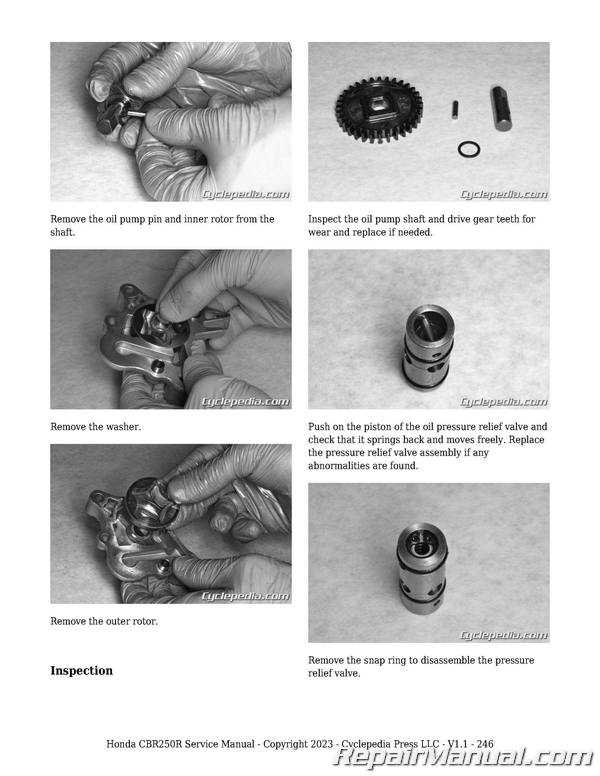

Fuel System Cleaning Guidelines

Maintaining optimal performance of the fuel delivery system is essential for the longevity and efficiency of any two-wheeled vehicle. Regular cleaning helps to prevent clogs and ensures that the engine receives the appropriate mixture of air and fuel. This section provides practical steps for effectively cleaning the fuel system, enhancing overall engine functionality.

Preparation Steps

Before commencing the cleaning process, it is crucial to gather the necessary tools and materials. Ensure you have a clean workspace, appropriate safety gear, and a fuel system cleaning solution. Disconnect the battery and relieve fuel pressure to avoid any accidents during the procedure. Proper preparation is key to achieving satisfactory results.

Cleaning Process

Begin by removing the fuel filter and any components that may obstruct access to the injectors and fuel lines. Use the cleaning solution as per the manufacturer’s instructions, ensuring that it penetrates the entire system. After cleaning, flush the system with fresh fuel to remove any residues. Reassemble all parts carefully, ensuring tight seals to prevent leaks. Finally, reconnect the battery and conduct a thorough check for any irregularities in the system.

Note: Always consult specific guidelines for your model to ensure compatibility with cleaning products and methods.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when conducting maintenance on any vehicle. Adhering to certain guidelines not only protects the individual working but also safeguards the machine itself from potential damage. Awareness of the risks involved and taking appropriate measures can greatly enhance safety during the process.

Before commencing any task, it is essential to gather the necessary tools and protective equipment. This preparation helps minimize hazards associated with unexpected incidents. Below is a table outlining key safety measures to consider:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and a helmet to protect against injuries. |

| Proper Ventilation | Ensure the workspace is well-ventilated to avoid inhaling harmful fumes. |

| Clear Workspace | Keep the area tidy to prevent tripping hazards and improve accessibility. |

| Use of Jack Stands | When lifting the vehicle, utilize jack stands to provide stable support. |

| Disconnecting Battery | Before starting any electrical work, disconnect the battery to prevent shocks. |

Implementing these safety precautions can significantly reduce the risk of accidents and ensure a more efficient maintenance experience. Prioritizing safety should always be the foremost concern when engaging in any hands-on tasks.