Comprehensive Honda CRF250R Repair Manual for Every Rider

The performance and longevity of your off-road motorcycle significantly depend on proper upkeep and timely interventions. Understanding the intricate details of its functioning can enhance your riding experience and prevent costly breakdowns. This guide serves as a comprehensive resource for enthusiasts seeking to optimize their machine’s efficiency.

Whether you’re an experienced rider or a newcomer to the world of dirt biking, familiarizing yourself with essential procedures and troubleshooting techniques is crucial. By grasping the ultimate components of your vehicle, you can ensure it remains in peak condition, ready to conquer challenging terrains.

Delve into the various aspects of maintenance, from routine checks to more complex repairs. This knowledge empowers you to tackle issues proactively, keeping your adventure spirit alive and your motorcycle performing at its best.

Overview of Honda CRF250R Repair Manual

This section provides a comprehensive guide focused on the maintenance and troubleshooting aspects of a popular off-road motorcycle model. It encompasses essential information for ensuring optimal performance and longevity of the vehicle. Understanding the contents of this guide is crucial for enthusiasts and mechanics alike.

Key Features

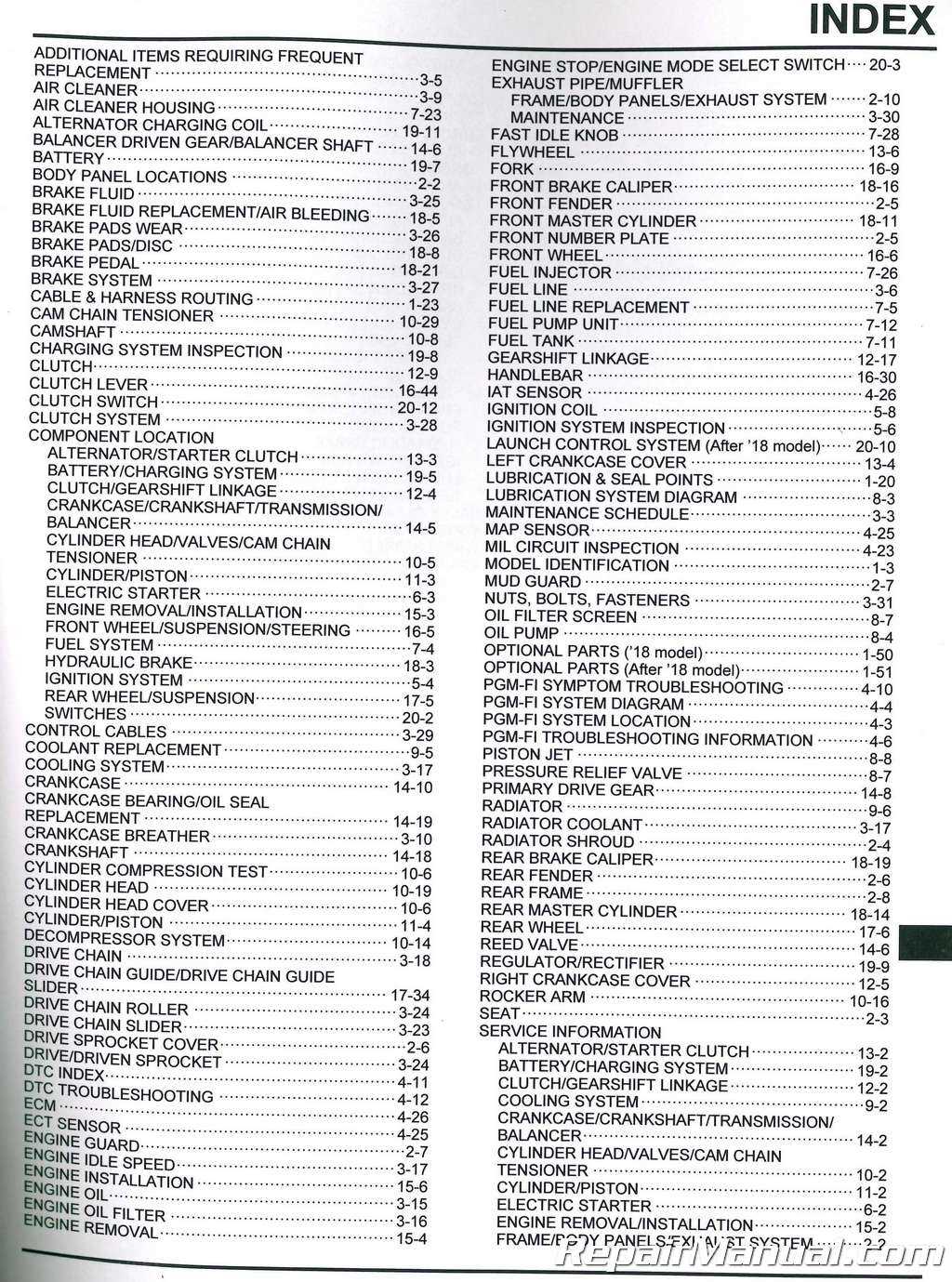

Among the highlights are detailed instructions on routine servicing, including oil changes, air filter cleaning, and chain maintenance. Additionally, the documentation includes specifications for parts and tools, making it easier for users to identify necessary resources for repairs.

Troubleshooting Guidance

This resource also offers systematic approaches to diagnosing common issues. Step-by-step procedures are provided to aid users in resolving mechanical problems effectively. By following the outlined processes, individuals can enhance their troubleshooting skills and improve their machine’s reliability.

Essential Tools for Maintenance

Proper upkeep of your two-wheeled companion requires a selection of fundamental instruments. Having the right gear not only simplifies the process but also ensures that every task is executed with precision. Whether you are tackling routine inspections or more extensive repairs, equipping yourself with essential tools is crucial for optimal performance.

Basic Tool Kit

A comprehensive toolkit is the cornerstone of any maintenance endeavor. At a minimum, you should include the following:

- Wrenches: A variety of sizes, both metric and imperial, will allow you to tighten and loosen bolts effectively.

- Screwdrivers: Flathead and Phillips screwdrivers are essential for various fasteners.

- Socket Set: A set with different socket sizes provides versatility for different applications.

- Pliers: Useful for gripping and bending components.

Specialized Equipment

In addition to the basic toolkit, consider investing in specialized equipment to enhance your maintenance capabilities:

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Chain Tool: Essential for maintaining and adjusting the drive chain.

- Oil Filter Wrench: Facilitates easy removal and installation of oil filters during oil changes.

- Stand: Provides stability and ease of access for performing maintenance tasks.

With these tools in hand, you will be well-prepared to keep your machine in peak condition, ensuring longevity and reliability on every ride.

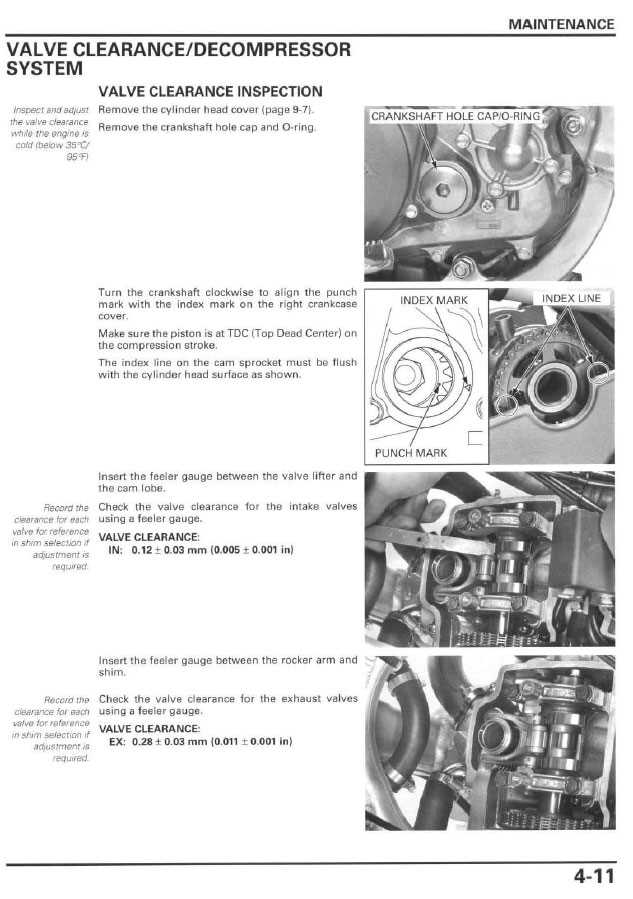

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to addressing issues within the power unit of your vehicle. Whether you are experiencing performance problems or unusual noises, following a structured method can lead to successful troubleshooting and restoration of functionality. Careful attention to detail and adherence to guidelines will help ensure a thorough and effective process.

Gathering Tools and Preparing the Workspace

Before commencing any work, it is essential to assemble the necessary tools and create a suitable environment. A clean and organized workspace minimizes the risk of losing components and enhances efficiency. Common tools include wrenches, screwdrivers, and a torque wrench. Ensure you have all safety gear on hand, such as gloves and goggles, to protect yourself during the process.

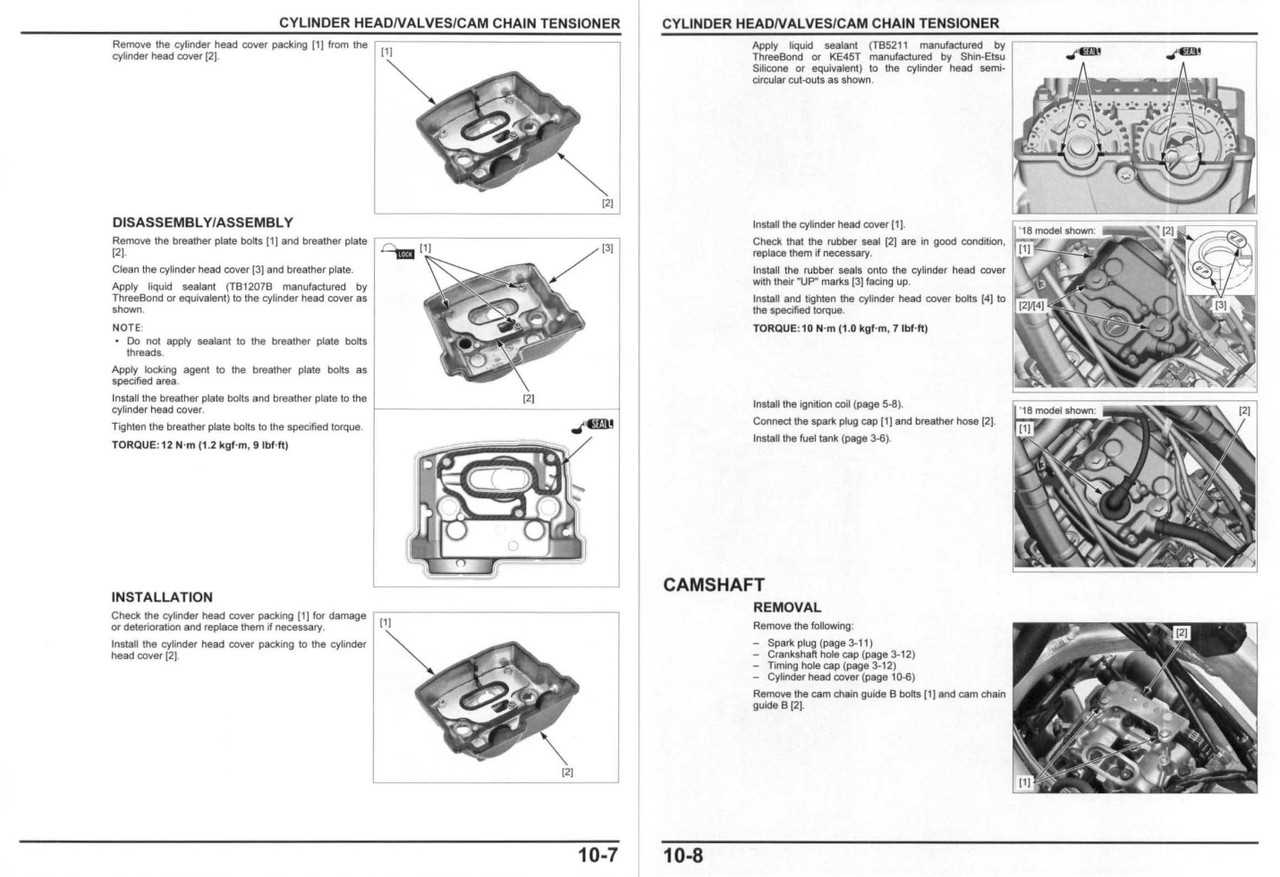

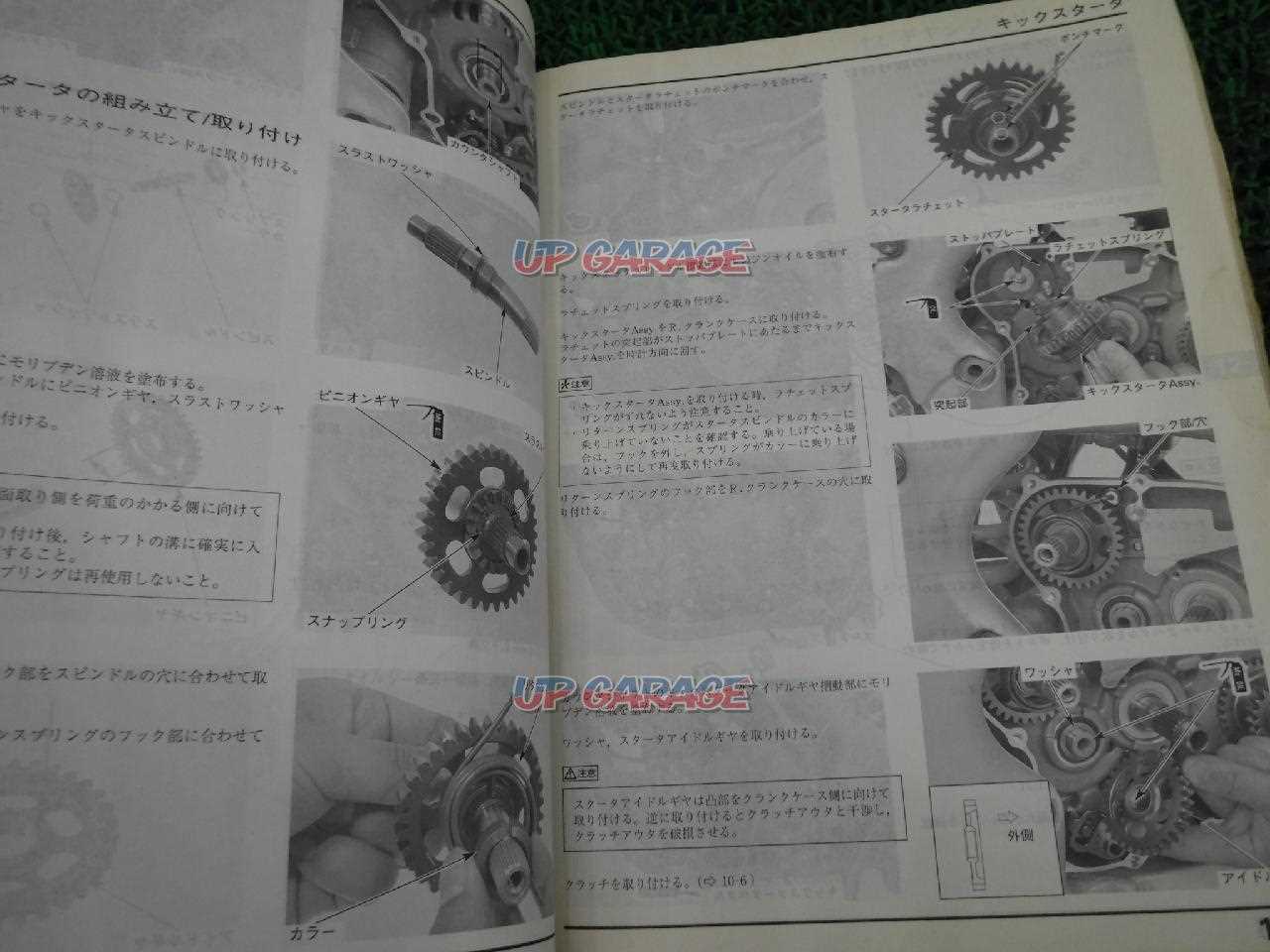

Disassembly and Inspection

Begin by carefully disassembling the engine components. Take note of the order in which parts are removed to facilitate reassembly. Inspect each component for signs of wear, damage, or contamination. Pay particular attention to gaskets, seals, and bearings, as these areas often lead to performance issues. Document any findings, as this information will guide your repair strategy.

Once you have assessed the condition of the engine, you can proceed with necessary replacements or repairs, ensuring that each step is executed with precision and care.

Suspension Adjustments and Tips

Fine-tuning the suspension system of your off-road motorcycle is essential for achieving optimal performance and comfort during rides. Proper adjustments can significantly enhance handling, stability, and overall riding experience, allowing the bike to respond effectively to varied terrains.

Start by assessing the current setup based on your weight, riding style, and the conditions you typically encounter. Adjusting preload is crucial; it determines the initial tension in the springs and affects ride height. For a balanced feel, ensure that the sag–measured with the rider on the bike–is within recommended limits.

Next, focus on compression and rebound damping settings. Compression controls how quickly the suspension absorbs bumps, while rebound affects how fast it returns to its original position. Gradually tweak these settings, testing your changes on different surfaces to find the perfect balance between comfort and control.

Regular maintenance is vital for the longevity of your suspension components. Check for leaks, inspect seals, and clean the forks and shock regularly. A well-maintained system not only performs better but also ensures safety and reliability on the trails.

Lastly, don’t hesitate to experiment with various settings. Every rider has unique preferences, and fine adjustments can lead to a more personalized and enjoyable riding experience. Take notes on what works best for you, and don’t be afraid to seek advice from fellow riders or professionals.

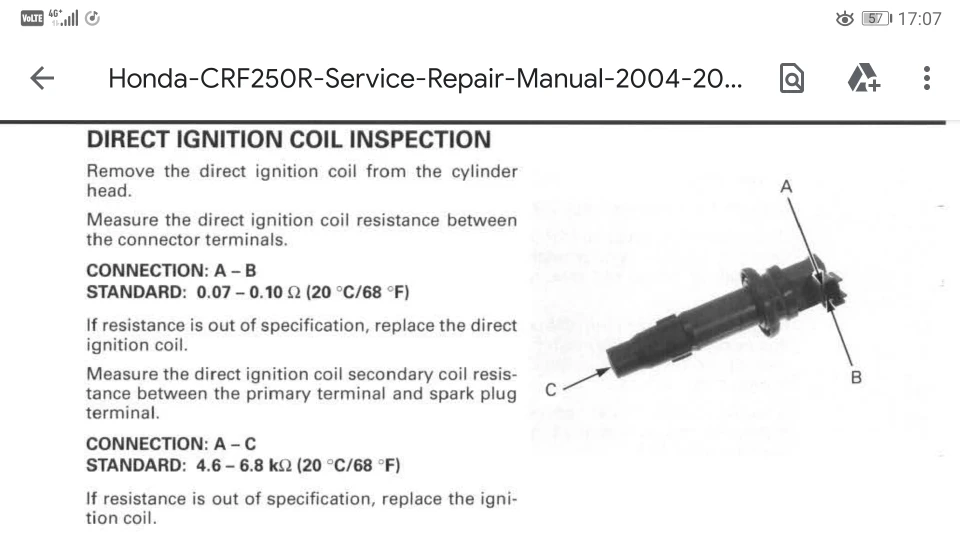

Electrical System Troubleshooting Techniques

Diagnosing issues within an electrical system requires a systematic approach to identify and resolve malfunctions effectively. By employing a series of structured techniques, one can isolate problems and restore functionality, ensuring optimal performance. This section outlines essential methods to help navigate common electrical challenges.

Visual Inspection: Begin with a thorough examination of all visible components. Look for signs of wear, corrosion, or damage to wires and connectors. Ensure that all connections are secure, as loose terminals can lead to intermittent issues.

Multimeter Usage: Utilizing a multimeter is crucial for measuring voltage, resistance, and continuity. Start by checking the battery voltage to ensure it is within acceptable limits. Next, test various circuit points to trace any potential failures in the system.

Grounding Checks: A poor ground connection can lead to numerous electrical problems. Inspect grounding points for tightness and cleanliness, as any oxidation or looseness can disrupt the flow of electricity.

Component Testing: Isolate and test individual components, such as switches, relays, and fuses. By removing them from the circuit and testing their functionality, you can determine if a specific part is at fault.

Wiring Diagrams: Refer to wiring diagrams to understand the system layout. This can provide clarity on how components are interconnected and assist in pinpointing the source of issues more efficiently.

Systematic Approach: Adopt a methodical approach to troubleshooting. Start from the power source and work your way through the system, checking each segment before moving on. This reduces the chances of overlooking critical elements.

By implementing these techniques, one can enhance the efficiency of diagnosing electrical issues, leading to quicker resolutions and improved performance of the machine.

Common Problems and Their Solutions

When it comes to maintaining high-performance two-wheeled vehicles, certain issues can frequently arise, impacting both performance and safety. Understanding these common challenges and their effective solutions is crucial for every rider looking to keep their machine in top shape.

Engine Performance Issues

One prevalent concern involves engine performance, often manifested as difficulty starting or inconsistent power delivery. This can be attributed to factors such as fuel quality, air filter condition, or spark plug wear. To address this, ensure the fuel used is of high quality, replace the air filter regularly, and check the spark plug for signs of damage. Regular maintenance of these components can significantly enhance engine reliability.

Suspension Troubles

Another frequent problem pertains to the suspension system, which may lead to poor handling or an uncomfortable ride. This issue can arise from inadequate lubrication, worn seals, or incorrect settings. To resolve these problems, inspect the suspension components for wear, replace seals as necessary, and adjust the settings according to the manufacturer’s recommendations. Keeping the suspension properly maintained ensures a smoother and more controlled ride.

Importance of Regular Oil Changes

Maintaining optimal performance and longevity of your engine relies heavily on the quality and condition of its lubricating fluid. Regularly replacing this vital fluid ensures that the internal components function smoothly, reducing wear and tear while enhancing overall efficiency.

Fresh oil plays a crucial role in keeping the engine clean by trapping contaminants and preventing sludge buildup. As the fluid ages, its ability to lubricate diminishes, leading to increased friction and potential damage. Regular changes not only replenish the oil’s protective qualities but also help to avoid costly repairs down the line.

Moreover, routine oil changes contribute to better fuel efficiency. When the engine is properly lubricated, it operates more smoothly, allowing for optimal power output without excessive strain. This results in improved mileage, saving you money in the long run.

In conclusion, prioritizing regular oil changes is essential for maintaining the health of your engine. It ensures efficient operation, minimizes wear, and ultimately extends the lifespan of your vehicle.

Brake System Maintenance Essentials

Ensuring optimal performance of the braking system is crucial for safety and reliability. Regular upkeep not only enhances the longevity of components but also guarantees responsive stopping power, which is vital in various riding conditions.

Inspection of Brake Pads: Periodically checking the condition of the brake pads is essential. Look for wear indicators, and replace them if they appear thin or uneven. Maintaining adequate pad thickness is key to preventing damage to the rotors.

Fluid Quality and Levels: The brake fluid should be clean and at the appropriate level. Contaminated or low fluid can lead to brake failure. Regularly bleed the system to remove air bubbles and ensure effective hydraulic function.

Rotor Condition: Inspect the brake rotors for any signs of warping, scoring, or excessive wear. Smooth and even rotors provide the necessary friction for effective braking. Resurfacing or replacing damaged rotors can significantly improve performance.

Caliper Functionality: Ensure that the calipers are functioning properly. Check for leaks and make sure they are free from dirt and debris. A well-maintained caliper will apply even pressure, contributing to consistent braking performance.

Regular Maintenance Schedule: Establishing a routine maintenance schedule will help in early detection of potential issues. Following manufacturer recommendations and keeping a log of inspections and repairs can enhance overall system reliability.

Adhering to these maintenance essentials will not only improve performance but also enhance safety, providing peace of mind during every ride.

Understanding the Fuel System

The fuel system is a crucial component of any motorized vehicle, responsible for delivering the right amount of fuel to the engine for optimal performance. A thorough comprehension of its parts and functionality is essential for ensuring efficiency and reliability.

At the heart of the fuel system is the fuel tank, where the fuel is stored before being sent to the engine. From there, the fuel pump plays a vital role in transporting the fuel through the lines under pressure. This ensures that the engine receives a consistent supply, which is essential for smooth operation.

Next, the fuel filter serves to remove impurities from the fuel, protecting the engine from potential damage caused by contaminants. Regular inspection and replacement of the filter can prevent significant issues down the line.

Once the fuel reaches the engine, the injectors or carburetor (depending on the system design) atomize the fuel, mixing it with air for combustion. The precision of this mixture is critical; too much or too little fuel can lead to performance problems.

Finally, understanding the fuel lines and their connections is important for maintaining the integrity of the system. Any leaks or blockages can hinder performance and should be addressed immediately. Overall, knowledge of the fuel system allows for better maintenance and troubleshooting, enhancing the longevity and efficiency of the vehicle.

Clutch Adjustments and Replacements

The proper functioning of the clutch system is crucial for optimal performance and smooth operation of the motorcycle. Adjustments and replacements of clutch components ensure that the rider maintains control and efficiency while navigating different terrains. Regular maintenance can prevent excessive wear and enhance the longevity of the assembly.

Adjustment Procedures

To achieve the correct clutch engagement and disengagement, adjustments are necessary. Follow these steps to ensure proper setup:

| Step | Description |

|---|---|

| 1 | Locate the clutch adjustment mechanism, typically found near the lever. |

| 2 | Loosen the lock nut and turn the adjustment screw to achieve desired free play. |

| 3 | Tighten the lock nut to secure the setting. |

| 4 | Test the clutch lever for proper engagement before taking the vehicle for a ride. |

Replacement Guidelines

When wear and tear render components ineffective, replacement is necessary. Follow these guidelines for a successful swap:

| Step | Description |

|---|---|

| 1 | Remove the clutch cover and carefully detach the old components. |

| 2 | Inspect the pressure plate, clutch plates, and springs for any damage. |

| 3 | Install new components, ensuring they are properly aligned and secured. |

| 4 | Reassemble the clutch cover and test the system for proper functionality. |

Frame and Chassis Inspection Guide

Regular evaluation of the frame and chassis is essential for ensuring optimal performance and safety. This section outlines critical steps and considerations for a thorough inspection, helping to identify any potential issues that may affect the vehicle’s handling and stability.

Visual Inspection

Begin with a detailed visual examination of the frame and chassis components. Look for signs of wear, damage, or corrosion. Pay close attention to the following areas:

- Weld joints and seams

- Suspension mounts

- Footpeg brackets

- Swingarm connections

- Any visible cracks or bends

Structural Integrity Check

After completing the visual inspection, proceed with assessing the structural integrity. This can involve the following steps:

- Perform a flex test on the frame by applying pressure in various directions.

- Check for any unusual noises or creaking sounds during movement.

- Inspect the chassis alignment using a level or straight edge.

- Examine all fasteners for tightness and integrity.

Following these guidelines will help maintain the durability and reliability of your vehicle, ensuring a safe and enjoyable riding experience.

Safety Precautions During Repairs

Ensuring personal safety while performing maintenance tasks is crucial. Adopting the right measures can prevent accidents and promote a secure working environment. Proper preparation and awareness of potential hazards are key components of any successful mechanical undertaking.

Essential Safety Gear

Wearing appropriate protective equipment is vital. This gear can significantly reduce the risk of injury from tools, chemicals, or moving parts. Here is a list of recommended items:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals |

| Gloves | Prevents cuts and chemical exposure |

| Steel-toed Boots | Offers protection from heavy objects |

| Dust Mask | Prevents inhalation of harmful particles |

| Ear Protection | Reduces noise exposure from equipment |

Work Area Organization

A tidy workspace is essential for safety. Keeping tools and materials organized helps prevent accidents and ensures efficiency. Here are some tips for maintaining an orderly environment:

- Clear clutter from the workspace to allow for safe movement.

- Store tools in designated areas after use.

- Ensure good lighting to enhance visibility.