Ultimate Guide to Repairing the Honda ES6500 Generator

Maintaining and troubleshooting machinery can be a daunting task for many. Understanding the intricacies of your equipment is essential for ensuring optimal performance and longevity. A well-structured resource can serve as a valuable companion for both novice and experienced users alike, simplifying the complexities involved in upkeep.

Within this guide, you will discover a wealth of information aimed at enhancing your familiarity with your power source. From identifying common issues to exploring effective solutions, this document is designed to empower you with the knowledge needed to tackle challenges head-on. The clarity of explanations and step-by-step instructions will help you navigate repairs and maintenance with confidence.

Equipped with detailed insights, you will learn how to perform essential checks and adjustments, ensuring your equipment runs smoothly. This resource not only addresses common pitfalls but also offers tips for preventive care, allowing you to minimize potential disruptions. Embracing this knowledge will transform your approach, making machinery management a more accessible and less intimidating endeavor.

Understanding the Honda ES6500 Generator

This section aims to provide a comprehensive overview of a specific portable power source, highlighting its key features, functionality, and maintenance considerations. It serves as a guide for users to familiarize themselves with the essential aspects of this generator, ensuring optimal performance and longevity.

Key Features

One of the standout characteristics of this power generator is its robust output capacity, designed to meet the demands of various applications, from home backup to outdoor activities. The unit typically incorporates advanced technology for fuel efficiency, resulting in prolonged operation without frequent refueling. Additionally, it often includes user-friendly controls and indicators that simplify the monitoring of performance metrics.

Maintenance Tips

To ensure the generator operates efficiently, regular upkeep is crucial. Inspecting the oil level and changing it as needed is fundamental for engine health. Cleaning the air filter regularly prevents debris accumulation that could hinder performance. Moreover, checking the spark plug and fuel system contributes significantly to reliable starting and overall functionality.

Common Issues and Troubleshooting Tips

When dealing with portable generators, understanding frequent challenges and how to address them is essential for maintaining optimal performance. This section highlights typical problems users may encounter and offers practical solutions to ensure efficient operation.

Common Problems

| Issue | Description | Possible Solution |

|---|---|---|

| Starting Difficulties | Generator fails to start or starts inconsistently. | Check fuel level, inspect the battery, and ensure the choke is in the correct position. |

| Low Power Output | Unit is not delivering expected wattage. | Inspect for overloaded circuits and verify proper load connections. |

| Unusual Noises | Generator produces strange sounds during operation. | Examine for loose components or damaged parts that may require tightening or replacement. |

| Overheating | Unit becomes excessively hot during use. | Ensure proper ventilation and check for any blocked air intakes. |

Troubleshooting Steps

In the event of encountering any issues, follow these troubleshooting steps:

- Review the user documentation for specific guidance on error codes.

- Perform regular maintenance checks, including oil levels and air filters.

- Keep the unit clean and free from debris to prevent operational hindrances.

- If problems persist, consider consulting a professional technician for further diagnosis.

Essential Tools for Repairing ES6500

When tackling maintenance and troubleshooting tasks, having the right set of instruments is crucial for efficiency and effectiveness. This section outlines the necessary equipment that will facilitate the process, ensuring that you can address any issues with precision and confidence.

Basic Toolkit

A well-rounded toolkit forms the foundation of any service endeavor. Below is a list of fundamental items that are indispensable for various tasks:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Screwdrivers | Essential for removing and securing screws in different sizes. |

| Pliers | Helpful for gripping, twisting, and cutting wires or other materials. |

| Socket Set | Facilitates work on fasteners in tight spaces. |

Specialized Equipment

In addition to the basic toolkit, certain specialized instruments enhance your capability to perform detailed assessments and repairs:

| Tool | Purpose |

|---|---|

| Multimeter | Used for measuring voltage, current, and resistance. |

| Compression Tester | Helps evaluate engine performance by measuring cylinder pressure. |

| Fuel Pressure Gauge | Allows for the assessment of fuel system performance. |

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

Step-by-Step Guide to Maintenance

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular attention not only enhances efficiency but also minimizes the risk of unexpected failures. This guide provides a structured approach to maintaining your device effectively.

Essential Maintenance Tasks

To keep your equipment in top shape, consider the following key tasks:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh to ensure smooth operation and reduce wear. |

| Filter Replacement | Every 100 hours | Change air and fuel filters to maintain clean airflow and optimal fuel efficiency. |

| Battery Check | Monthly | Inspect battery condition and terminals for corrosion; clean as necessary. |

| Inspection of Hoses | Every 200 hours | Check hoses for signs of wear or damage; replace if necessary. |

Tips for Effective Maintenance

In addition to routine tasks, following these tips can further enhance the upkeep of your equipment:

- Keep the workspace clean and organized to prevent unnecessary hazards.

- Utilize the correct tools and parts to ensure compatibility and reliability.

- Document all maintenance activities for future reference and to track performance over time.

Replacing Parts: A Quick Overview

Maintaining equipment in optimal condition often requires the timely substitution of components that may wear out over time. This section provides a concise guide on how to approach the replacement of various parts, ensuring functionality and longevity.

Understanding Component Wear

Every machine comprises numerous elements that can degrade due to use and environmental factors. Recognizing the signs of wear is essential. Common indicators include unusual noises, decreased performance, or visible damage. Regular inspections can help identify these issues early.

Gathering Necessary Tools

Before initiating the replacement process, it is vital to have the right tools on hand. A well-equipped toolkit typically includes wrenches, screwdrivers, pliers, and any specialized tools required for specific parts. Having everything ready can streamline the procedure and minimize downtime.

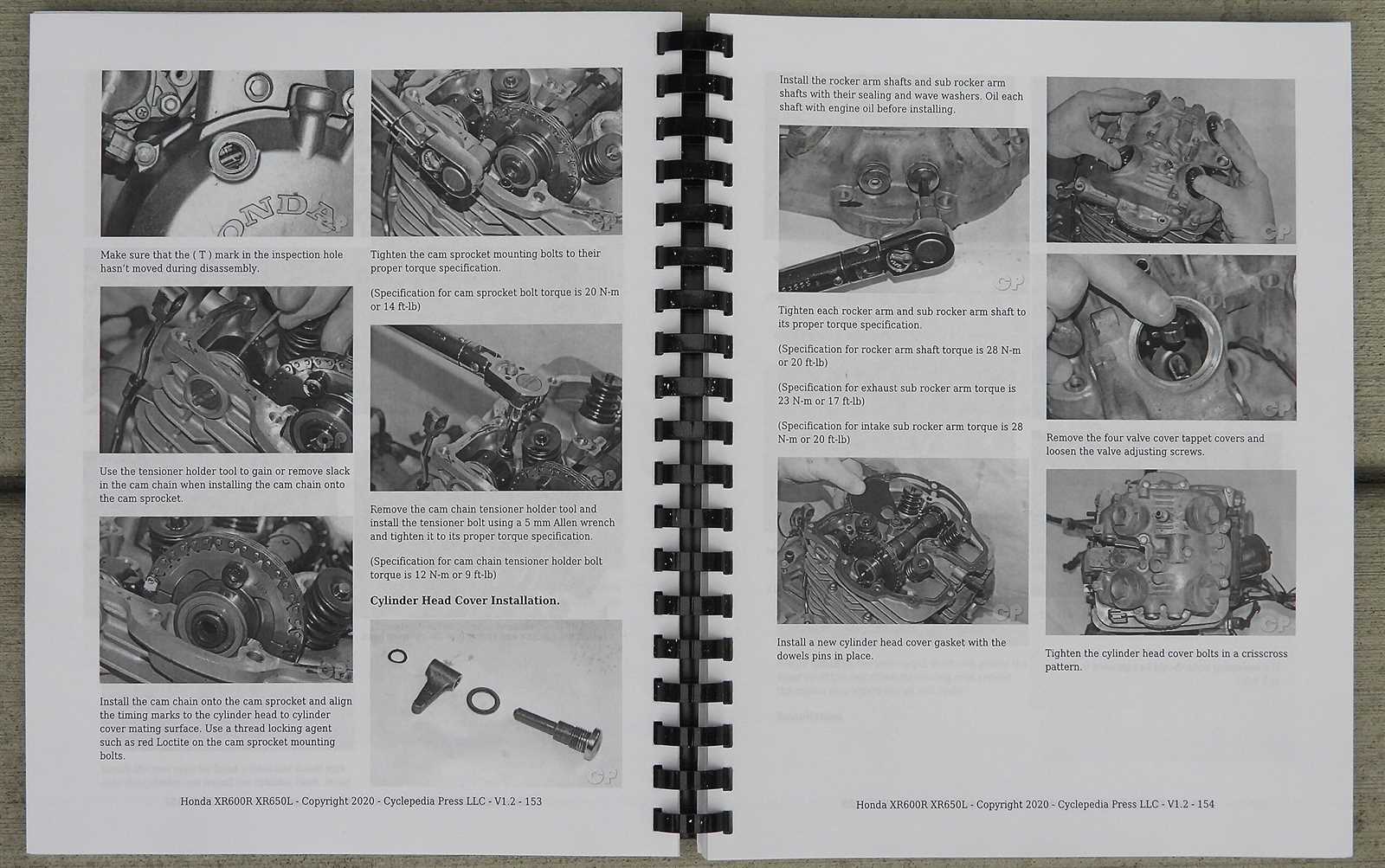

Following Instructions

Referencing detailed guidelines specific to the equipment is crucial when replacing parts. These instructions typically outline the steps necessary to safely remove the old component and install the new one. Adhering to these recommendations can prevent mistakes and ensure proper installation.

Testing After Replacement

Once the new part is installed, it’s important to test the equipment to confirm that everything functions correctly. Monitor for any irregularities during operation and ensure that the new component integrates seamlessly with the existing system.

By understanding the basics of part replacement and following these steps, users can effectively maintain their machinery, enhancing its performance and lifespan.

How to Handle Fuel System Problems

Addressing issues within the fuel delivery mechanism is crucial for ensuring optimal performance and longevity of the equipment. This section outlines common symptoms, diagnostic steps, and effective solutions to tackle complications that may arise in this system.

Recognizing the signs of fuel system failures can prevent further damage and improve efficiency. Below are some typical symptoms and their potential causes:

| Symptom | Possible Causes |

|---|---|

| Engine won’t start | Empty fuel tank, clogged filter, faulty pump |

| Engine misfires | Poor fuel quality, air leaks, injector issues |

| Reduced power output | Fuel line blockages, filter obstructions, improper pressure |

| Excessive fuel consumption | Leaking injectors, malfunctioning regulator, incorrect settings |

Once symptoms are identified, the next step involves conducting a thorough inspection. Start by checking the fuel level and quality, then move on to examining filters and lines for blockages. Use appropriate tools to test the pressure generated by the pump.

If a specific issue is detected, consider the following solutions:

- Replace the fuel filter if it appears clogged.

- Clean or replace fuel injectors to ensure proper flow.

- Inspect and repair any leaks in the fuel lines.

- Ensure the fuel pump is functioning within specified pressure ranges.

By systematically diagnosing and addressing these concerns, you can restore functionality and enhance the performance of your equipment, ensuring it operates smoothly and efficiently.

Electrical System Diagnostics Explained

Understanding the functionality and performance of an electrical system is crucial for ensuring optimal operation. Diagnosing issues within this system involves a systematic approach that identifies faults and determines necessary actions for repair or maintenance. Proper diagnostics can save time and resources while enhancing the reliability of the equipment.

Common Electrical Issues

Various problems can arise within an electrical system. Some of the most frequent issues include:

- Battery failures

- Faulty wiring connections

- Malfunctioning circuit breakers

- Defective components, such as fuses and relays

Diagnostic Steps

To effectively diagnose electrical issues, follow these essential steps:

- Visual Inspection: Check for obvious signs of damage, corrosion, or loose connections.

- Testing Voltage: Use a multimeter to measure voltage at various points in the system.

- Continuity Testing: Ensure that current flows through circuits as intended by checking for breaks.

- Component Testing: Isolate and test individual components to verify their functionality.

By employing these methods, technicians can accurately identify and address electrical issues, leading to improved performance and longevity of the system.

Improving Generator Longevity and Performance

Ensuring the extended lifespan and optimal functionality of your power source requires a combination of regular maintenance practices and mindful usage habits. By implementing these strategies, you can enhance efficiency and reduce the likelihood of breakdowns, leading to more reliable operation over time.

Regular Maintenance Checks

Routine inspections play a crucial role in maintaining the health of your unit. Check oil levels and quality, as well as air filters and spark plugs, to ensure everything is functioning smoothly. Changing the oil at recommended intervals prevents engine wear, while clean filters enhance airflow, optimizing performance.

Optimal Usage Practices

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Implementing protective measures not only safeguards the individual but also ensures the longevity of the equipment being serviced.

First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to shield against potential hazards. Additionally, make sure to work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Furthermore, it is crucial to disconnect power sources before beginning any work. This simple step can prevent electrical shocks and equipment damage. Lastly, keep your workspace organized to minimize the risk of tripping or misplacing tools, which can lead to accidents.

Frequently Asked Questions About ES6500

This section aims to address common inquiries related to the generator model in question. Whether you’re facing operational challenges or seeking maintenance tips, the following FAQs provide valuable insights to enhance your experience and ensure optimal performance.

| Question | Answer |

|---|---|

| What are the key features of this generator? | This model offers a robust power output, fuel efficiency, and a compact design, making it suitable for various applications. |

| How often should I perform maintenance? | Regular maintenance is recommended every 100 hours of operation or at least once a year to ensure longevity. |

| What type of oil should I use? | It is advisable to use high-quality oil that meets the manufacturer’s specifications for optimal performance. |

| Can I use this generator for my home? | Yes, it is capable of powering essential appliances during outages, but be sure to calculate your power needs beforehand. |

| How do I troubleshoot starting issues? | Check the fuel level, ensure the choke is set correctly, and inspect the battery connections for any corrosion. |