Comprehensive Guide to Repairing the Honda GX100 Engine

Understanding the intricacies of small engine upkeep is crucial for optimal performance and longevity. This section will explore fundamental techniques and insights that empower users to effectively address common issues and ensure seamless operation.

Throughout the discussion, readers will uncover practical advice, troubleshooting steps, and preventative measures that can be applied to various models. By gaining a comprehensive understanding of engine components and functionality, one can significantly enhance efficiency and reliability.

Whether you’re a novice or seasoned enthusiast, this guide serves as an ultimate resource, delving into the details that matter most for successful maintenance practices. Embrace the knowledge that will keep your machinery running smoothly for years to come.

Understanding the Honda GX100 Engine

This section provides an insightful overview of a widely used small engine known for its reliability and efficiency. Designed for a range of applications, this power unit is appreciated for its durability and ease of use, making it a popular choice among enthusiasts and professionals alike.

Key Features

The engine is characterized by its lightweight construction and compact design, enabling seamless integration into various equipment. With a simple start mechanism and low vibration levels, it offers a user-friendly experience. Its robust performance is complemented by fuel efficiency, allowing for extended operation without frequent refueling.

Maintenance Tips

Regular upkeep is crucial for optimal performance. Inspecting oil levels, air filters, and spark plugs can prevent potential issues and prolong the engine’s lifespan. Additionally, cleaning the exterior helps avoid debris buildup, ensuring smooth operation during use. Following a consistent maintenance schedule will significantly enhance reliability and efficiency.

Common Issues with Honda GX100

When dealing with small engines, several recurring problems can arise that affect performance and reliability. Understanding these challenges can aid in timely troubleshooting and maintenance, ensuring efficient operation.

- Fuel System Problems:

- Clogged fuel lines

- Old or contaminated fuel

- Malfunctioning carburetor

- Starting Difficulties:

- Weak or dead battery

- Faulty ignition system

- Incorrect choke settings

- Overheating:

- Insufficient cooling airflow

- Low oil levels

- Dirty air filters

- Noisy Operation:

- Worn bearings

- Loose components

- Exhaust leaks

Identifying these issues early can lead to simple fixes and prolong the life of the engine. Regular maintenance and monitoring can mitigate many of these common concerns.

Essential Tools for Repairs

When it comes to maintaining small engines, having the right instruments at your disposal can significantly enhance the efficiency and effectiveness of your work. Whether you are performing routine maintenance or troubleshooting issues, a well-equipped toolkit is essential for achieving optimal performance.

Basic Instruments

- Wrenches: A variety of sizes, including adjustable and socket types, for tightening and loosening bolts.

- Screwdrivers: Both flathead and Phillips head options are necessary for various screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage.

Specialized Equipment

- Multimeter: For checking electrical connections and diagnosing issues.

- Fuel System Cleaner: Helps in maintaining the fuel system by removing deposits.

- Compression Tester: Measures the engine’s compression to assess its condition.

- Oil Filter Wrench: Simplifies the process of changing the oil filter.

Having these tools at hand will not only streamline your tasks but also contribute to the longevity and reliability of your engine. Investing in quality instruments pays off in the long run, ensuring that you can tackle any challenge that arises with confidence.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your small engine. By following systematic procedures, you can prevent common issues and enhance efficiency through regular care and attention.

Routine Inspections

Scheduled Servicing

Diagnosing Engine Performance Problems

Identifying issues related to engine functionality requires a systematic approach. By understanding the symptoms and underlying causes, one can effectively troubleshoot and restore optimal performance. This section will guide you through the key steps in diagnosing common engine performance issues.

Start by observing the engine’s behavior and noting any irregularities. Look for specific symptoms that may indicate a problem:

- Difficulty starting the engine

- Unusual noises during operation

- Reduced power or acceleration

- Increased fuel consumption

- Excessive smoke or emissions

Next, conduct a visual inspection of critical components. Check for:

- Fuel leaks or blockages

- Damaged or worn belts and hoses

- Corroded electrical connections

- Dirty air and fuel filters

- Signs of oil leakage

If visual checks do not reveal the issue, proceed with more detailed diagnostics. Utilize tools such as:

- Multimeter for electrical testing

- Compression gauge for assessing cylinder pressure

- Vacuum gauge for analyzing manifold pressure

Document all findings and observations. This information will be invaluable in pinpointing the root cause of performance issues and determining the necessary repairs. By following this structured approach, you can enhance your ability to diagnose and address engine performance concerns effectively.

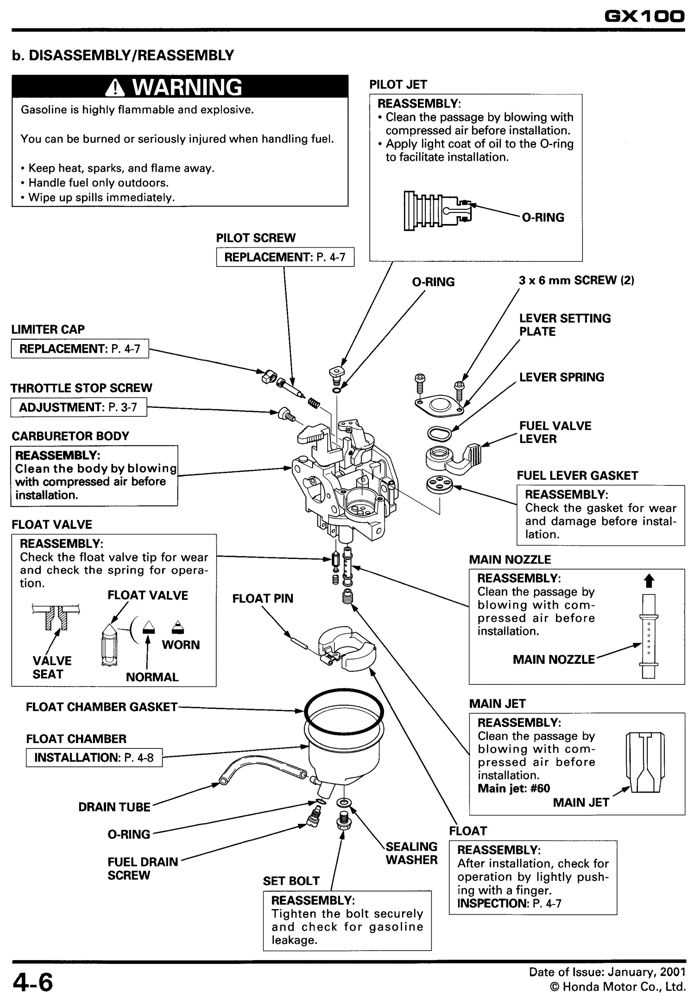

Replacing Key Components Safely

Ensuring the safe replacement of essential parts in your machinery is crucial for optimal performance and longevity. Proper procedures not only prevent damage but also enhance user safety during the process. Familiarizing yourself with each component’s function and the steps involved in their removal and installation is fundamental.

Before beginning the replacement, it’s essential to gather all necessary tools and protective equipment. Always consult the specific guidelines related to the parts in question, as this will provide insights into the correct techniques and potential hazards. Taking the time to prepare will lead to a smoother and more secure operation.

When removing components, carefully note their arrangement and connections. This attention to detail will assist in accurate reassembly, minimizing the risk of errors. Additionally, consider labeling parts and fasteners to avoid confusion. When installing new components, ensure they are compatible and securely fastened to prevent future issues.

Finally, after completing the replacement, conduct thorough checks to ensure everything functions correctly. Testing the machinery in a controlled environment will help identify any potential problems before regular use. Prioritizing safety and accuracy during this process will contribute to the reliability and efficiency of your equipment.

Fuel System Troubleshooting Techniques

Understanding and diagnosing issues within the fuel delivery system is essential for optimal engine performance. By employing systematic techniques, one can identify and resolve common problems that may arise, ensuring smooth operation and longevity of the equipment. This section outlines effective strategies for addressing fuel system complications.

Common Symptoms and Initial Checks

Before delving into complex diagnostics, it is crucial to recognize the primary indicators of fuel system malfunctions. Symptoms such as difficulty starting, poor acceleration, or irregular idling often point to underlying issues. Begin with basic inspections to check fuel levels, leaks, and the condition of filters. Make sure to verify that the fuel supply is clean and free from contaminants.

Advanced Diagnostic Techniques

If initial checks do not reveal the source of the problem, more advanced diagnostic methods may be required. Utilizing tools like a fuel pressure gauge can provide insights into the system’s efficiency. Inspect fuel lines for blockages and ensure that the pump is functioning correctly. Additionally, evaluating the carburetor or injector performance can help pinpoint specific failures within the fuel system.

Electrical System Inspection Procedures

The effective functioning of an electrical system is vital for the overall performance and reliability of small engines. Proper inspection procedures ensure that all components work harmoniously, preventing unexpected failures and enhancing longevity. This section outlines key steps for evaluating the electrical components and connections, enabling users to maintain optimal operation.

Visual Inspection

Testing Electrical Components

Utilize a multimeter to test the voltage and continuity of key components, such as the ignition coil, spark plug, and battery. Check the resistance of the coil to ensure it falls within the manufacturer’s specifications. Perform continuity tests on wires and connections to confirm that electrical pathways are intact and functioning properly.

Preventive Measures for Longevity

Ensuring the long-term performance and durability of any engine requires a proactive approach. By implementing specific strategies and maintenance routines, users can significantly extend the life of their equipment. These practices not only enhance reliability but also optimize efficiency, reducing the likelihood of unexpected breakdowns and costly repairs.

Regular Maintenance Checks

Conducting routine inspections is essential for identifying potential issues before they escalate. Checking fluid levels, examining filters, and inspecting belts and hoses should be part of a regular schedule. This helps in maintaining peak performance and prevents premature wear.

Proper Storage and Usage

Storing machinery in a clean, dry environment protects it from environmental factors that could cause damage. Additionally, using the equipment within its specified limits ensures that it operates smoothly without undue stress. Following the manufacturer’s guidelines for operation and maintenance will further enhance longevity.

Finding Genuine Replacement Parts

When it comes to maintaining and restoring machinery, sourcing authentic components is crucial for optimal performance and longevity. Ensuring the use of original parts not only enhances efficiency but also preserves the integrity of the entire system.

Here are several strategies to find trustworthy replacement components:

- Authorized Dealers: Always check with official distributors who specialize in genuine parts. They often provide a warranty and ensure the quality of their products.

- Manufacturer’s Website: Many manufacturers have sections dedicated to parts, allowing you to search for specific items and confirm their authenticity.

- Part Numbers: When looking for replacements, having the correct part number can streamline your search and prevent the acquisition of incorrect components.

- Local Repair Shops: Establish a relationship with trusted repair professionals who can guide you toward authentic options based on their experience.

By prioritizing genuine parts, you contribute to the longevity and efficiency of your equipment, ensuring it operates at its best for years to come.

Expert Tips for Efficient Repairs

When tackling maintenance tasks on small engines, having a strategic approach can make a significant difference. Understanding the intricacies of the machinery not only enhances the repair process but also ensures longevity and optimal performance. Here are some valuable insights to streamline your efforts and achieve effective outcomes.

1. Thorough Preparation: Before beginning any task, ensure that you have all necessary tools and parts at hand. Organizing your workspace can save time and reduce frustration. Create a checklist of items needed to avoid interruptions during the process.

2. Understand the Components: Familiarize yourself with the engine’s parts and their functions. This knowledge allows you to diagnose issues more accurately and efficiently. Consider referring to diagrams or guides that outline the assembly and operation of the engine.

3. Follow a Systematic Approach: Tackle repairs methodically. Start from one area and work your way through systematically, checking each component as you go. This organized method helps in identifying the root cause of problems more easily.

4. Utilize Quality Parts: Always opt for high-quality replacements when necessary. Using subpar components can lead to repeated issues and ultimately cost more in the long run. Investing in reliable parts ensures better performance and durability.

5. Document Your Work: Keep a detailed record of the repairs performed, including dates and issues addressed. This documentation can be invaluable for future maintenance and can help track the history of the engine’s performance.

6. Seek Advice and Share Experiences: Engage with a community of enthusiasts or professionals. Sharing tips and experiences can provide new insights and solutions to common challenges encountered during maintenance tasks.

Implementing these strategies will not only enhance your efficiency but also improve the overall reliability of the equipment. Consistent attention to detail and a proactive approach will yield the best results in maintaining engine performance.