Ultimate Guide to Repairing the Honda GX240

Ensuring the longevity and efficiency of small power units is essential for both professionals and enthusiasts. Proper care and troubleshooting can prevent costly repairs and extend the life of your machinery. This guide serves as a comprehensive resource for addressing common issues and performing routine tasks, enabling users to maintain optimal performance.

Understanding the intricacies of your engine is crucial for effective upkeep. From identifying symptoms of malfunction to implementing corrective measures, this section equips you with the knowledge needed to tackle various challenges. Whether it’s a minor adjustment or a more involved fix, familiarity with your equipment enhances your ability to respond swiftly and efficiently.

With a focus on practical advice and step-by-step instructions, this resource empowers you to take charge of your equipment’s health. By following best practices and employing the right techniques, you can achieve reliable operation and enjoy a seamless experience in your projects. Embrace the opportunity to learn and enhance your skills in engine maintenance.

Understanding the Honda GX240 Engine

The engine in question is a reliable and efficient power unit widely utilized in various applications. Its design incorporates advanced technology that ensures both performance and durability, making it a popular choice for many users. Understanding the key components and features of this engine is essential for effective operation and maintenance.

Key Features

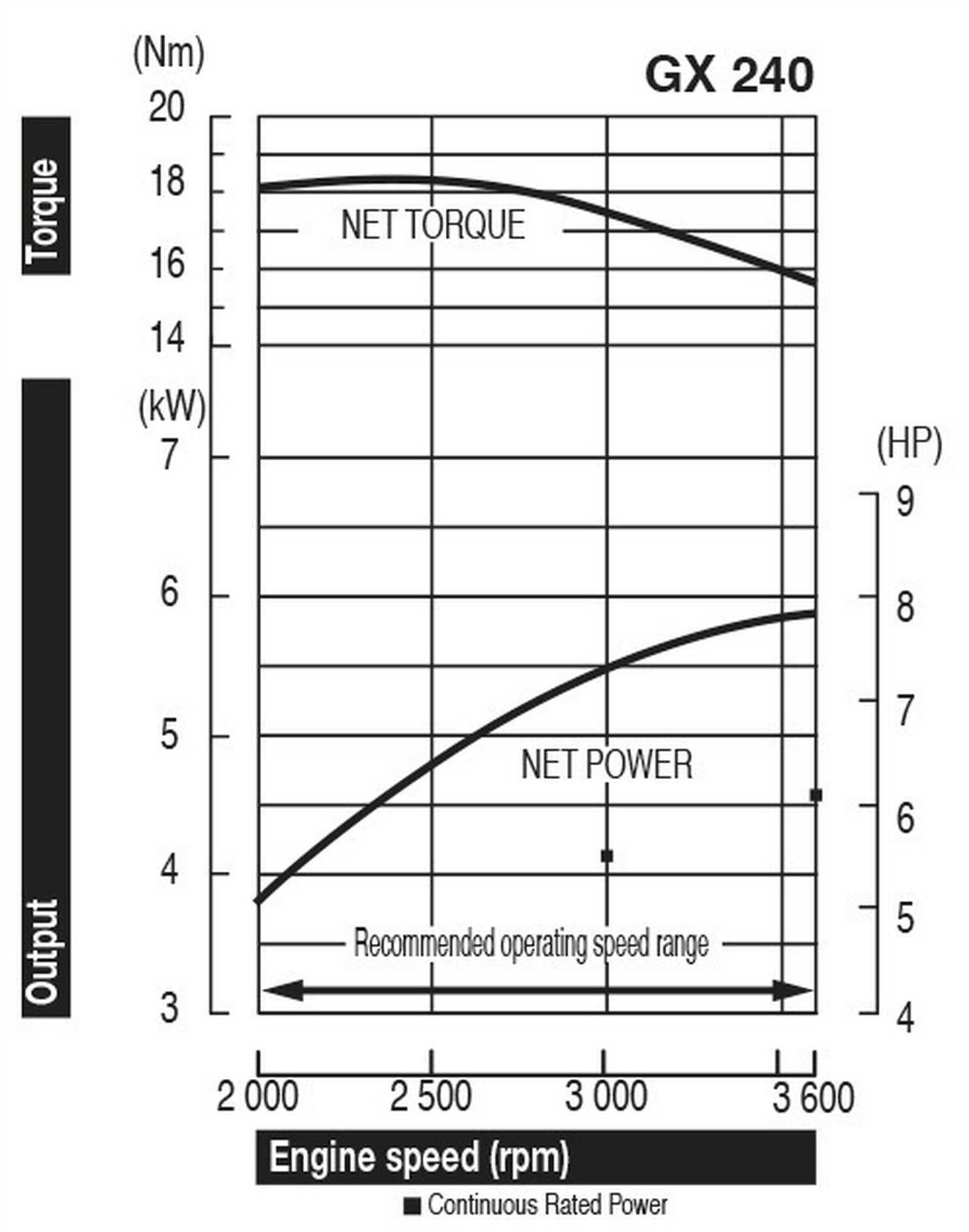

This power unit boasts a robust build, featuring a four-stroke cycle that provides a steady power output. Its air-cooled design allows for optimal temperature management, reducing the risk of overheating during prolonged use. Additionally, the engine is equipped with a reliable ignition system, which contributes to smooth startups and consistent operation.

Components Overview

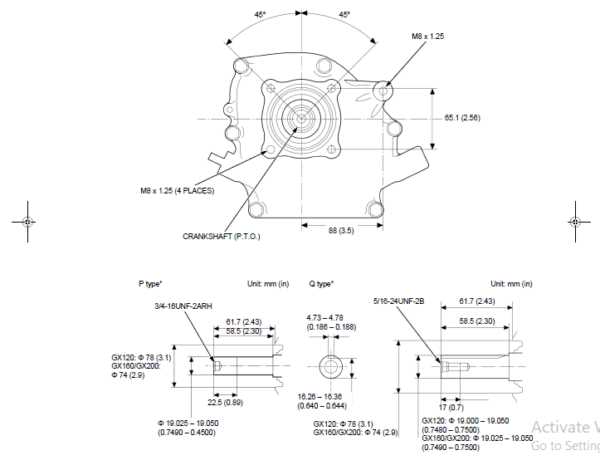

Among its significant components are the cylinder head, crankshaft, and fuel system. The cylinder head plays a crucial role in the combustion process, while the crankshaft converts linear motion into rotational power. The fuel system, including the carburetor, ensures the right mixture for efficient combustion, further enhancing the engine’s performance.

Maintenance Tips

Regular maintenance is vital to prolong the life of this power unit. It is advisable to check the oil levels frequently, replace the air filter, and ensure that the spark plug is functioning correctly. Keeping the fuel system clean and free from debris will also help maintain optimal performance.

In summary, understanding the various aspects of this engine will not only aid in its effective use but also ensure longevity and reliability in performance across different applications.

Common Issues with Honda GX240

Engines designed for various applications often experience a range of recurring problems. Understanding these common challenges can help users maintain performance and longevity. Below are some frequent issues encountered, along with potential solutions to ensure optimal functionality.

Fuel System Problems

One prevalent issue relates to the fuel delivery system. Users may notice difficulties in starting or inconsistent operation, which can stem from clogged filters or stale fuel. Regularly replacing filters and using fresh fuel can mitigate these concerns, ensuring a smooth running engine.

Starting Difficulties

Another common challenge involves ignition failures. Symptoms might include a failure to start or irregular running. This can often be traced back to spark plug issues or battery malfunctions. Ensuring that spark plugs are clean and replacing them as needed can significantly enhance reliability and ease of starting.

Essential Tools for Repairing GX240

To effectively maintain and service small engines, having the right set of tools is crucial. The correct equipment not only facilitates the process but also ensures safety and precision during work. Below is a comprehensive list of must-have instruments for anyone looking to undertake such tasks.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types, are essential for loosening and tightening bolts.

- Screwdrivers: Both flat-head and Phillips screwdrivers will be necessary for different types of screws.

- Pliers: Needle-nose and slip-joint pliers can assist in gripping and manipulating small parts.

- Hex keys: Also known as Allen wrenches, these are vital for handling hexagonal screws and bolts.

Specialized Equipment

- Torque wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Compression tester: Used to check the engine’s compression, helping diagnose potential issues.

- Fuel pressure gauge: Monitors fuel pressure to ensure proper operation of the fuel system.

- Multimeter: Essential for electrical troubleshooting, allowing measurement of voltage, current, and resistance.

Having these essential tools on hand will significantly improve the efficiency and effectiveness of any maintenance or service work on small engines. Proper preparation with the right instruments leads to better outcomes and prolongs the life of the equipment.

Step-by-Step Maintenance Procedures

Regular upkeep of your small engine is crucial for ensuring optimal performance and longevity. By following a systematic approach to maintenance, you can prevent potential issues and keep your equipment running smoothly. This section outlines essential procedures that should be carried out periodically to maintain efficiency and reliability.

1. Change the Oil: Start by draining the old oil and replacing it with fresh oil suitable for your engine type. This step helps to reduce wear and tear on internal components and ensures proper lubrication.

2. Clean the Air Filter: Remove the air filter and inspect it for dirt and debris. A clean filter allows for better airflow, enhancing combustion and performance. Replace it if it appears excessively dirty or damaged.

3. Inspect the Spark Plug: Check the spark plug for carbon buildup or wear. Clean it or replace it if necessary to ensure efficient ignition. Proper functioning of the spark plug is vital for smooth operation.

4. Examine Fuel Lines: Inspect all fuel lines for cracks or leaks. Damaged lines can lead to fuel loss and performance issues. Replace any compromised sections to maintain fuel integrity.

5. Check the Cooling System: Ensure that the cooling fins and air passages are free of debris. Proper cooling is essential to prevent overheating, which can cause significant damage over time.

6. Tighten Fasteners: Periodically check and tighten all bolts and screws to ensure that everything is securely fastened. Vibrations during operation can loosen components, leading to potential failures.

7. Store Properly: When not in use, store the equipment in a dry, sheltered area. Consider using a cover to protect it from dust and moisture, which can lead to corrosion and deterioration.

By adhering to these straightforward maintenance tasks, you can significantly extend the lifespan of your equipment and enhance its operational efficiency.

Troubleshooting Engine Performance Problems

Addressing issues related to engine performance can significantly enhance the efficiency and longevity of your machinery. When you notice a decline in power, unusual noises, or irregular operation, it’s essential to systematically diagnose the underlying causes. This process involves inspecting various components and understanding how they interact within the system.

Step 1: Check Fuel Quality

Fuel quality plays a critical role in engine operation. Stale or contaminated fuel can lead to performance issues. Ensure that the fuel is fresh and free from impurities. If necessary, drain the old fuel and refill the tank with high-quality gasoline.

Step 2: Inspect the Air Filter

An obstructed air filter can restrict airflow, causing the engine to run rich or lean. Regularly inspect and clean or replace the air filter to ensure optimal air intake. This simple step can often resolve performance issues.

Step 3: Examine Spark Plug Condition

The spark plug is vital for ignition. A worn or fouled spark plug can lead to misfires and reduced power. Remove the spark plug and check for signs of wear or carbon buildup. Replace it if necessary to restore proper ignition performance.

Step 4: Look for Fuel Line Blockages

Fuel line blockages can severely affect engine performance. Inspect the fuel lines for any kinks, leaks, or clogs. Clear any obstructions to ensure a steady flow of fuel to the engine.

Step 5: Monitor Engine Temperature

Overheating can cause significant damage and performance loss. Ensure that the cooling system is functioning properly and that there are no leaks or blockages in the cooling passages. Regularly check coolant levels and replace old coolant as needed.

Step 6: Conduct a Compression Test

A compression test can reveal underlying mechanical issues such as worn piston rings or valves. Low compression can indicate serious problems that require attention. If the compression readings are below manufacturer specifications, further investigation may be necessary.

By methodically addressing these areas, you can identify and rectify performance problems, leading to a more reliable and efficient engine. Regular maintenance and timely troubleshooting will ensure optimal operation and prolong the life of your equipment.

Replacing Key Components of GX240

Maintaining optimal performance of your engine often requires attention to various critical parts. Understanding how to replace these essential elements can significantly extend the lifespan and efficiency of your machine. This section will guide you through the process of substituting vital components, ensuring that your unit runs smoothly and reliably.

Common Components to Replace

Several parts are frequently subject to wear and tear. Identifying these components and knowing when to replace them can prevent larger issues down the line. Here are the key elements to consider:

| Component | Symptoms of Wear | Replacement Frequency |

|---|---|---|

| Air Filter | Reduced power output, excessive fuel consumption | Every 50 hours of operation |

| Spark Plug | Difficulty starting, irregular engine performance | Every 100 hours of operation |

| Oil Filter | Increased engine noise, oil leaks | Every 100 hours of operation |

Replacement Process

Replacing these components involves a straightforward procedure. First, ensure that the engine is turned off and cooled down. Gather the necessary tools and replacement parts. Carefully remove the old component and install the new one, following manufacturer specifications to ensure proper fitting. Regular maintenance will not only improve performance but also enhance safety during operation.

Safety Precautions During Repairs

When working on machinery, prioritizing safety is essential to prevent accidents and injuries. Implementing proper precautions not only safeguards the individual performing the task but also protects the equipment being serviced. A proactive approach to safety ensures a smooth and efficient process, allowing for successful maintenance without unnecessary risks.

Personal Protective Equipment (PPE)

Always equip yourself with appropriate personal protective gear. This includes gloves, safety goggles, and steel-toed boots. Wearing PPE significantly reduces the risk of injuries from sharp objects, chemicals, or heavy components. Ensure that your protective equipment fits well and is in good condition to maximize its effectiveness.

Workspace Organization

A well-organized workspace contributes greatly to a safe working environment. Keep tools and materials neatly arranged and within reach to avoid hazards associated with clutter. Proper organization minimizes the chances of accidents and enhances focus during the task at hand. Make sure to secure loose items and provide adequate lighting to illuminate the area clearly.

Upgrading Parts for Better Performance

Enhancing the efficiency and capability of your engine can lead to significant improvements in overall functionality. By upgrading specific components, you can achieve increased power output, better fuel efficiency, and an extended lifespan of your machine. This section explores various modifications that can help you attain optimal performance.

Choosing the Right Components

When considering enhancements, it is essential to select parts that are compatible with your existing system. Upgrading elements such as the air filter, exhaust system, and ignition components can drastically improve airflow and combustion efficiency. For instance, a high-performance air filter can enhance airflow, while a well-designed exhaust system can reduce back pressure, allowing for a smoother exit of exhaust gases.

Importance of Quality Materials

Investing in high-quality materials for your upgrades is crucial. Using durable and reliable parts not only ensures longevity but also contributes to better performance. Components made from advanced materials can withstand higher temperatures and pressures, leading to improved reliability during operation. This investment in quality will pay off with a noticeable enhancement in performance and efficiency.

Recommended Oil and Fuel Types

Choosing the right lubricants and fuels is crucial for optimal engine performance and longevity. Using suitable products can significantly enhance efficiency and reduce wear and tear over time.

For best results, consider the following recommendations:

- Engine Oil: Select a high-quality, detergent oil that meets the specifications for small engines. Common viscosities include:

- 10W-30

- 10W-40

- SAE 30 (for warmer conditions)

Regularly checking and changing oil and fuel will help maintain the engine’s performance and extend its lifespan.

When to Seek Professional Help

Understanding the limits of your expertise is essential for maintaining equipment effectively. While many issues can be resolved through basic troubleshooting and repairs, certain situations may require the intervention of a qualified technician. Recognizing these scenarios can save time, prevent further damage, and ensure safety.

| Signs You Need Expert Assistance | Description |

|---|---|

| Persistent Issues | If problems continue after multiple attempts to fix them, it may be a sign of a deeper underlying issue. |

| Strange Noises | Unusual sounds during operation can indicate mechanical failure or other serious problems that need professional attention. |

| Smoke or Burning Smell | These are critical warning signs that should never be ignored and necessitate immediate professional evaluation. |

| Complex Repairs | For intricate components or systems, it’s advisable to consult an expert who has the proper tools and knowledge. |

| Safety Concerns | If you feel unsure about handling certain repairs, prioritizing your safety by seeking help is wise. |

Ultimately, knowing when to call in a professional can lead to better maintenance practices and enhance the longevity of your equipment.

Resources for Further Reading

This section provides a collection of valuable materials for those seeking to deepen their understanding of small engine maintenance and troubleshooting. Whether you are a beginner or an experienced user, these resources can enhance your knowledge and skills, helping you tackle various challenges effectively.

| Resource Type | Title | Author/Publisher | Link |

|---|---|---|---|

| Book | Small Engine Repair | Robert S. O’Brien | Link |

| Online Course | Basic Engine Maintenance | Skillshare | Link |

| Video Series | Engine Troubleshooting Techniques | YouTube Channel | Link |

| Website | Small Engine Repair Guides | EngineCare.com | Link |

Exploring these references can provide insights into best practices, common issues, and advanced techniques that will aid in successful engine upkeep and repair efforts.