Comprehensive Guide to Repairing the Honda GX270 Engine

Understanding the intricacies of small engine upkeep is vital for enthusiasts and professionals alike. Proper maintenance not only prolongs the lifespan of machinery but also ensures optimal performance during operation. This section delves into the fundamental practices that every user should know, enhancing reliability and efficiency.

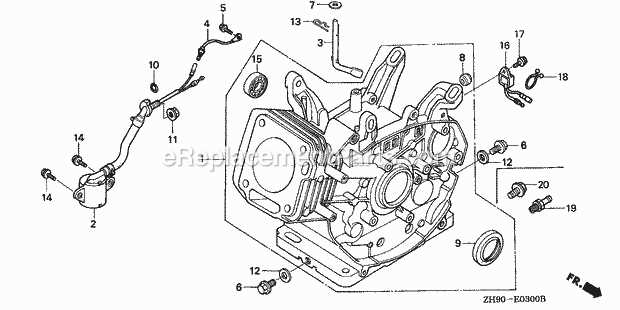

Comprehensive knowledge of engine components and their functions is crucial for effective troubleshooting. Familiarity with various parts empowers individuals to diagnose issues accurately and implement suitable solutions. Whether you’re facing minor glitches or significant malfunctions, a systematic approach can save time and resources.

In addition to practical skills, having access to detailed guidelines can be invaluable. These resources provide step-by-step instructions and insights, making the maintenance process straightforward. By following best practices and adhering to recommended procedures, users can ensure their equipment operates smoothly and remains in peak condition.

Understanding the Honda GX270 Engine

This section provides an overview of a popular small engine model that is widely used in various applications. Known for its reliability and performance, this engine is favored by both professionals and hobbyists alike. By exploring its key features and components, users can better appreciate its design and functionality.

Key Features

This engine is characterized by its robust construction and efficient operation. With a focus on longevity and ease of maintenance, it has become a go-to choice for many equipment types.

| Feature | Description |

|---|---|

| Engine Type | 4-stroke, air-cooled engine |

| Displacement | 270 cc |

| Power Output | Approximately 9 HP |

| Starting System | Recoil starter |

| Fuel Type | Unleaded gasoline |

Applications

This versatile engine is commonly used in a range of machinery, from generators to pressure washers. Its adaptability and efficient power delivery make it suitable for both commercial and residential use.

Common Issues with the GX270

Understanding typical problems that may arise with small engines can help users maintain optimal performance and extend their lifespan. This section highlights frequent challenges encountered during operation, along with potential solutions to address these issues effectively.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hard Starting | Difficulty in starting the engine, often due to fuel or ignition problems. | Check the fuel system for clogs, ensure the battery is charged, and inspect spark plugs for wear. |

| Overheating | Engine running hotter than normal, potentially leading to damage. | Ensure adequate cooling by checking the coolant levels and cleaning the air filter. |

| Unusual Noises | Strange sounds during operation may indicate mechanical issues. | Inspect for loose components, and check oil levels and quality. |

| Vibration | Excessive shaking can be a sign of imbalance or misalignment. | Check for uneven wear on parts and ensure all mounts are secure. |

| Reduced Power | Engine not delivering expected performance, possibly due to blockages or wear. | Examine the air intake, fuel filter, and exhaust for restrictions. |

Essential Tools for Repairing GX270

Having the right instruments is crucial for effective maintenance and troubleshooting of small engines. This section highlights the key equipment necessary for ensuring optimal performance and longevity of these power units. With the proper tools at your disposal, you can tackle a variety of tasks with confidence and precision.

Basic Hand Tools

Every mechanic should start with a solid set of hand tools. A combination wrench set and a socket set are essential for loosening and tightening various fasteners. Additionally, a flathead and Phillips screwdriver will aid in disassembling components with ease. A torque wrench is also vital for applying the correct amount of force when reassembling, ensuring that parts are secure without being over-tightened.

Specialized Equipment

In addition to standard hand tools, some specialized instruments can significantly enhance your maintenance capabilities. A compression tester is invaluable for assessing engine health, while a multimeter helps diagnose electrical issues. Furthermore, having a fuel pressure gauge can assist in determining fuel delivery problems, allowing for more efficient troubleshooting and repairs.

Step-by-Step Maintenance Guide

Proper upkeep of your engine is essential for ensuring optimal performance and longevity. Regular maintenance tasks can prevent potential issues, enhance efficiency, and extend the life of your machinery. This guide outlines key procedures to follow for effective servicing, ensuring that your equipment runs smoothly for years to come.

Below is a detailed breakdown of maintenance tasks that should be performed periodically:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh oil to maintain lubrication and prevent engine wear. |

| Air Filter Cleaning | Every 25 hours | Remove and clean the air filter to ensure proper airflow and prevent dirt buildup. |

| Spark Plug Inspection | Every 100 hours | Check and replace the spark plug if necessary to ensure reliable ignition and performance. |

| Fuel System Check | Every season | Inspect the fuel lines and filter for leaks or clogs, and replace stale fuel to prevent starting issues. |

| General Cleaning | As needed | Keep the exterior clean to prevent corrosion and allow for easier inspections. |

By adhering to these maintenance guidelines, you can ensure that your engine operates efficiently and reliably. Regular attention to these tasks will help you identify any potential problems early, saving you time and resources in the long run.

How to Diagnose Engine Problems

Identifying issues in a power unit requires a systematic approach to pinpoint the source of the malfunction. By observing symptoms and conducting thorough checks, one can effectively determine what needs attention. This process not only saves time but also prevents further damage by addressing problems early.

Common Symptoms to Look For

Pay close attention to irregular sounds, reduced performance, or unusual vibrations during operation. These signs often indicate underlying issues that warrant investigation. Additionally, monitor fluid levels and check for leaks, as changes in oil or coolant levels can also signal potential problems.

Step-by-Step Diagnosis

Begin with a visual inspection of the engine components, looking for any obvious signs of wear or damage. Next, utilize diagnostic tools to assess electrical systems and fuel delivery mechanisms. Following this, test compression and ignition to evaluate engine performance. Documenting each finding will aid in tracking the issue and planning necessary repairs.

Replacing Spark Plugs Effectively

Ensuring optimal performance of your engine often involves routine maintenance tasks, one of which is changing the ignition components. This process not only enhances efficiency but also contributes to the longevity of the machinery. Properly replacing these components can lead to smoother operation and reduced fuel consumption.

Before starting the replacement, gather the necessary tools and materials to streamline the process. A clean workspace will also help in keeping track of small parts. Follow the guidelines below for a successful replacement:

| Step | Description |

|---|---|

| 1 | Ensure the engine is cool to avoid burns. |

| 2 | Disconnect the spark plug wire carefully. |

| 3 | Use a spark plug socket to remove the old component. |

| 4 | Inspect the old plug for wear and damage. |

| 5 | Prepare the new plug by checking the gap and applying anti-seize compound if necessary. |

| 6 | Install the new component and tighten it to the manufacturer’s specifications. |

| 7 | Reconnect the spark plug wire securely. |

| 8 | Start the engine to ensure proper functioning. |

By adhering to these steps, you can efficiently replace ignition components and maintain the performance of your engine. Regular checks and timely replacements can prevent potential issues, ensuring your equipment runs smoothly.

Fuel System Troubleshooting Tips

Ensuring optimal performance of small engines often involves diagnosing issues within the fuel system. By addressing common problems, you can enhance efficiency and longevity. Here are some practical suggestions to help identify and resolve fuel-related concerns.

- Check Fuel Quality: Always start by examining the fuel itself. Stale or contaminated fuel can lead to numerous issues. Replace old fuel with fresh, high-quality gasoline.

- Inspect Fuel Lines: Look for cracks or leaks in the fuel lines. Any damage can lead to loss of pressure, causing the engine to run poorly.

- Examine the Fuel Filter: A clogged fuel filter restricts flow. Replace the filter if it appears dirty or hasn’t been changed recently.

- Verify Fuel Pump Operation: Ensure the fuel pump is functioning correctly. Listen for unusual noises or test its pressure output.

- Clean the Carburetor: A dirty carburetor can disrupt the air-fuel mixture. Disassemble and clean all components to restore proper function.

- Check for Air Leaks: Inspect gaskets and seals for wear. Air leaks can cause an imbalanced mixture, leading to performance issues.

- Test for Proper Ventilation: Ensure the fuel tank vent is not blocked. Proper airflow is essential for fuel flow and pressure.

By systematically checking these components, you can effectively troubleshoot and resolve fuel system issues, ensuring reliable operation of your engine.

Checking and Changing Oil

Maintaining the proper oil level and quality is crucial for the longevity and efficiency of any engine. Regularly checking and replacing the lubricant ensures smooth operation and prevents damage from wear and tear. This process involves assessing the oil’s condition and topping it off or replacing it as needed.

Inspecting Oil Level

Begin by positioning the equipment on a level surface to obtain an accurate reading. Remove the dipstick, wipe it clean, and reinsert it to check the oil level. If the oil appears low, it is important to add the appropriate type of lubricant until it reaches the recommended mark. Regular checks can help identify any leaks or excessive consumption.

Changing Oil

To perform an oil change, first ensure the engine is cool. Drain the old lubricant by removing the drain plug, allowing the fluid to flow into a suitable container. After draining, replace the drain plug securely. Next, refill with fresh oil through the designated opening, following the manufacturer’s specifications for type and quantity. Finally, run the engine briefly and check for any leaks around the drain plug and seals.

Remember: Regular oil maintenance not only enhances performance but also extends the lifespan of your engine.

Electrical Components and Repairs

The functionality of any engine relies heavily on its electrical system. Understanding the various components involved is crucial for ensuring optimal performance. This section will explore essential parts such as ignition systems, wiring, and connectors, along with common issues that may arise.

Ignition Systems: The ignition system is vital for starting the engine and maintaining its operation. It typically includes components like spark plugs, coils, and control modules. Regular checks are essential to ensure that these parts are functioning correctly, as a malfunction can lead to starting issues or erratic performance.

Wiring: The wiring harness connects all electrical components, facilitating communication between them. Over time, wires may become frayed or damaged due to wear and tear. Inspecting the wiring for signs of corrosion or breaks is crucial. Replacing faulty sections can prevent larger electrical failures.

Connectors: Electrical connectors play a significant role in maintaining secure and efficient connections. Loose or corroded connectors can lead to intermittent electrical problems. Cleaning or replacing these connectors ensures that the system operates smoothly, reducing the risk of unexpected shutdowns.

In summary, a thorough understanding of the electrical components is essential for diagnosing and resolving issues. Regular maintenance and timely intervention can enhance the longevity and reliability of the engine’s performance.

Understanding the Cooling System

The cooling mechanism of an engine plays a crucial role in maintaining optimal operating temperatures. It ensures that the engine components function efficiently and prevents overheating, which can lead to severe damage. Understanding how this system operates is essential for anyone involved in engine maintenance or troubleshooting.

Components of the Cooling System

The primary elements of a cooling system include the radiator, water pump, thermostat, and cooling passages. The radiator dissipates heat, allowing coolant to flow through it while the engine is running. The water pump circulates the coolant, ensuring it moves efficiently between the engine and the radiator. The thermostat regulates the temperature by controlling the flow of coolant based on the engine’s needs.

Importance of Regular Maintenance

How to Replace Air Filters

Regular maintenance of air intake components is essential for optimal engine performance. Replacing air filters ensures that clean air flows into the combustion chamber, which enhances efficiency and prolongs the lifespan of the equipment. This guide outlines the steps needed to perform this task effectively.

First, gather the necessary tools, including a screwdriver, a clean cloth, and a new air filter compatible with your engine model. Before beginning, ensure the engine is turned off and has cooled down to prevent any accidents.

Next, locate the air filter housing, usually secured with clips or screws. Carefully detach the housing cover, taking care not to damage any components. Once open, remove the old filter and inspect the housing for any debris or dust buildup, cleaning it with a cloth if needed.

Install the new air filter by ensuring it fits snugly into the housing, aligning it properly to avoid any gaps. Replace the cover, securing it with the clips or screws you removed earlier. Finally, run the engine briefly to check for any unusual noises, ensuring everything is functioning smoothly.

Best Practices for Engine Storage

Proper storage of engines is crucial for maintaining their performance and longevity. Taking the right steps during the storage period can prevent deterioration and ensure that the unit is ready for use when needed. Following a few essential guidelines will help keep the engine in optimal condition.

1. Clean Thoroughly: Before storage, clean the exterior and interior components. Remove any dirt, debris, or fuel residues that could lead to corrosion or other damage. A clean engine is less prone to wear and will function more efficiently when restarted.

2. Fuel Stabilization: If the engine uses fuel, consider adding a fuel stabilizer. This additive helps prevent the fuel from breaking down and forming varnish or gum, which can clog fuel lines and filters. Be sure to run the engine for a few minutes after adding the stabilizer to circulate it throughout the system.

3. Oil Change: Change the engine oil before storing it. Fresh oil contains additives that can protect the internal components from corrosion. Old oil may contain contaminants that can harm the engine during long-term storage.

4. Disconnect Battery: If the unit has a battery, disconnect it to prevent drainage. Store the battery in a cool, dry place, and consider using a trickle charger to keep it in good condition during the storage period.

5. Cover Properly: Use a breathable cover to protect the engine from dust and moisture. Avoid plastic covers that can trap moisture, leading to mold and corrosion. A good cover will keep the engine safe from the elements while allowing airflow.

6. Store in a Controlled Environment: Ideally, store the engine in a dry, temperature-controlled space. Extreme temperatures and humidity can accelerate wear and tear. A well-ventilated area away from direct sunlight is best.

By following these practices, you can ensure that your engine remains in excellent condition during periods of inactivity. Regular maintenance and attention to storage conditions will extend its life and enhance its reliability when you need it most.

Safety Tips During Repairs

When undertaking maintenance tasks, prioritizing safety is crucial. Proper precautions can prevent accidents and ensure a smooth process, allowing you to focus on the job at hand without unnecessary interruptions. Below are some essential guidelines to enhance your safety while working on machinery.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and sturdy footwear to shield yourself from potential hazards. |

| Work in a Well-Ventilated Area | Ensure your workspace is properly ventilated to avoid inhaling harmful fumes and dust. |

| Disconnect Power Sources | Before starting any work, make sure to unplug or turn off all power sources to prevent accidental activation. |

| Organize Your Workspace | Keep tools and materials neatly arranged to reduce the risk of tripping or misplacing essential items. |

| Follow Manufacturer Guidelines | Refer to the provided documentation to understand specific safety instructions and procedures for your equipment. |

By adhering to these recommendations, you can create a safer environment and significantly reduce the likelihood of mishaps during your maintenance activities.