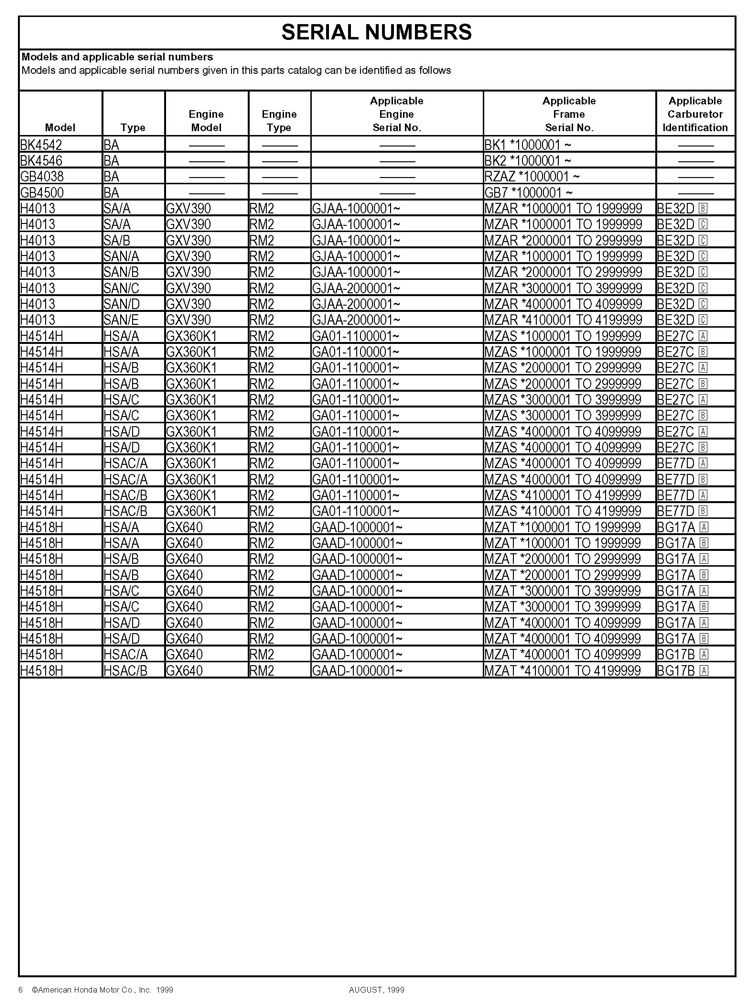

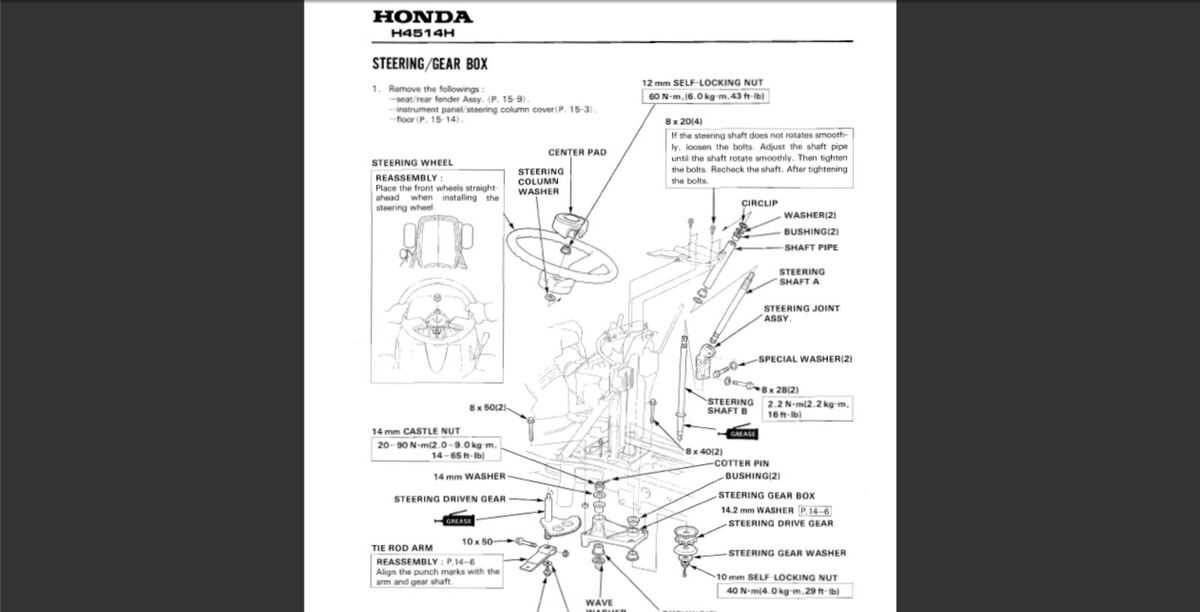

Comprehensive Guide to Honda H4514H Repair

Ensuring the longevity and optimal performance of your machinery requires a comprehensive understanding of its components and functionalities. Proper upkeep not only enhances efficiency but also minimizes the risk of unexpected failures. This section is dedicated to providing essential insights for effectively managing your equipment.

In the following passages, you will find detailed guidance on troubleshooting common issues, performing routine checks, and undertaking essential servicing tasks. By adhering to these practices, you can safeguard your investment and maintain the operational integrity of your device.

Knowledge is key in maintaining any machine. Familiarizing yourself with the necessary procedures will empower you to tackle maintenance tasks confidently, ensuring your equipment remains in peak condition.

To ensure the extended lifespan of your machinery, regular upkeep and proper care are essential. Adhering to specific maintenance protocols can significantly enhance performance and prevent potential issues. This section outlines key practices that contribute to the durability and efficiency of your equipment.

Regular Inspections

Routine examinations help identify wear and tear early. Consider the following:

- Check fluid levels frequently, including oil and coolant.

- Inspect belts and hoses for any signs of damage or wear.

- Look for leaks under the machine, which may indicate maintenance needs.

Cleaning and Lubrication

Keeping components clean and well-lubricated is vital for smooth operation. Implement these practices:

- Clean air filters regularly to maintain airflow.

- Apply lubricant to moving parts to reduce friction.

- Remove debris from the exterior and ensure vents are clear.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and fixing tasks. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. Whether you are tackling minor adjustments or significant overhauls, specific tools will facilitate the job and help achieve optimal results.

Basic Hand Tools

Fundamental hand tools are indispensable for any maintenance work. They assist in disassembling components and securing parts effectively. Below is a table highlighting some essential hand tools:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening or tightening screws |

| Wrenches | Ideal for gripping and turning nuts and bolts |

| Pliers | Useful for gripping, twisting, and cutting wires |

| Socket Set | Provides a range of sizes for different fasteners |

Specialized Equipment

In addition to basic tools, certain specialized equipment can greatly enhance your capability to perform specific tasks. These items are tailored for particular functions, making them valuable assets in any toolkit.

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures accurate tightening of fasteners |

| Multimeter | Measures voltage, current, and resistance |

| Compression Tester | Assesses engine compression levels |

| Oil Filter Wrench | Simplifies the removal of oil filters |

Step-by-Step Repair Procedures

This section provides a structured approach to addressing common issues encountered in machinery maintenance. By following clear and concise instructions, users can effectively troubleshoot and resolve problems, ensuring optimal performance and longevity of the equipment.

Initial Assessment

Begin with a thorough evaluation of the unit to identify visible signs of wear or malfunction. Check for leaks, unusual noises, or any irregularities in operation. Document any findings to guide subsequent steps.

Disassembly and Inspection

Carefully disassemble the necessary components, taking care to organize parts for reassembly. Inspect each piece for damage or excessive wear. Replace any faulty parts and clean components to facilitate better functionality.

Safety Precautions During Maintenance

Ensuring safety during maintenance activities is paramount to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly reduce risks associated with equipment servicing.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Keep the work area clean and well-lit to avoid tripping hazards and improve visibility.

- Ensure that all tools are in good condition and suitable for the tasks at hand.

- Disconnect power sources before beginning any maintenance work to prevent accidental starts.

It is also essential to follow proper procedures and guidelines during servicing. Familiarizing oneself with the equipment and its components helps in identifying potential risks.

- Read all relevant documentation and instructions prior to starting work.

- Utilize locking mechanisms to secure any movable parts during maintenance.

- Do not work alone; having a partner can provide assistance in case of an emergency.

- Handle hazardous materials according to safety guidelines and dispose of them properly.

By adhering to these precautions, individuals can significantly enhance their safety while maintaining equipment, ensuring a more secure working environment.

Replacing Key Components Effectively

Maintaining optimal performance of any machinery involves the timely replacement of essential parts. This process not only ensures longevity but also enhances overall functionality. Understanding how to efficiently swap out these critical elements can significantly reduce downtime and improve operational efficiency.

Identification of Components

The first step in effective replacement is accurately identifying the components that require attention. Regular inspections can help in spotting wear and tear before they lead to larger issues. Below is a table summarizing common components that often need replacement and their typical symptoms of failure:

| Component | Symptoms of Failure |

|---|---|

| Air Filter | Reduced airflow, engine misfiring |

| Spark Plug | Difficulty starting, poor acceleration |

| Belt | Squeaking noise, visible cracks |

| Battery | Dim lights, slow cranking |

Replacement Procedure

Once the necessary components are identified, follow a systematic approach for replacement. Ensure all tools are ready and safety precautions are taken before proceeding. Following the manufacturer’s guidelines will aid in achieving a successful and safe component change. Keeping a checklist can streamline the process and minimize the chances of overlooking any crucial steps.

Understanding the Engine Specifications

When it comes to the heart of any machinery, comprehending the technical details is crucial for optimal performance and longevity. The engine serves as the powerhouse, generating the necessary energy to operate various functions. By familiarizing oneself with the specifications, one can ensure efficient maintenance and troubleshoot potential issues effectively.

Key Features and Metrics

Several critical characteristics define the efficiency and capabilities of the engine. These include displacement, power output, and torque ratings, which play significant roles in overall functionality. Each aspect contributes to how well the engine performs under various conditions.

Performance Table

| Specification | Value |

|---|---|

| Displacement | 500 cc |

| Power Output | 14 HP |

| Torque | 25 Nm |

| Fuel Type | Gasoline |

Understanding these specifications not only aids in recognizing the potential of the engine but also enhances the overall experience of using the equipment effectively. Regular monitoring and attention to these metrics can lead to improved reliability and performance.

Tips for Seasonal Storage

Preparing equipment for seasonal storage is essential to ensure its longevity and optimal performance. Proper care and maintenance during this process can prevent issues that may arise when it’s time to use the machinery again.

- Clean Thoroughly: Remove any dirt, debris, and residue. Use a soft brush and appropriate cleaning solutions to ensure all surfaces are spotless.

- Check Fluids: Drain or replace fluids as necessary, including fuel, oil, and coolant. This helps prevent corrosion and other damage.

- Inspect Parts: Look for any signs of wear and tear. Replace or repair any damaged components to avoid complications later.

- Store in a Dry Place: Choose a sheltered location that is free from moisture to avoid rust and mold growth.

- Use Covers: Protect the equipment with breathable covers to shield it from dust and environmental elements.

By following these guidelines, you can ensure your machinery remains in excellent condition and is ready for use when the season changes.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting. Whether you’re a novice or an experienced user, understanding typical concerns can streamline the process and enhance your experience.

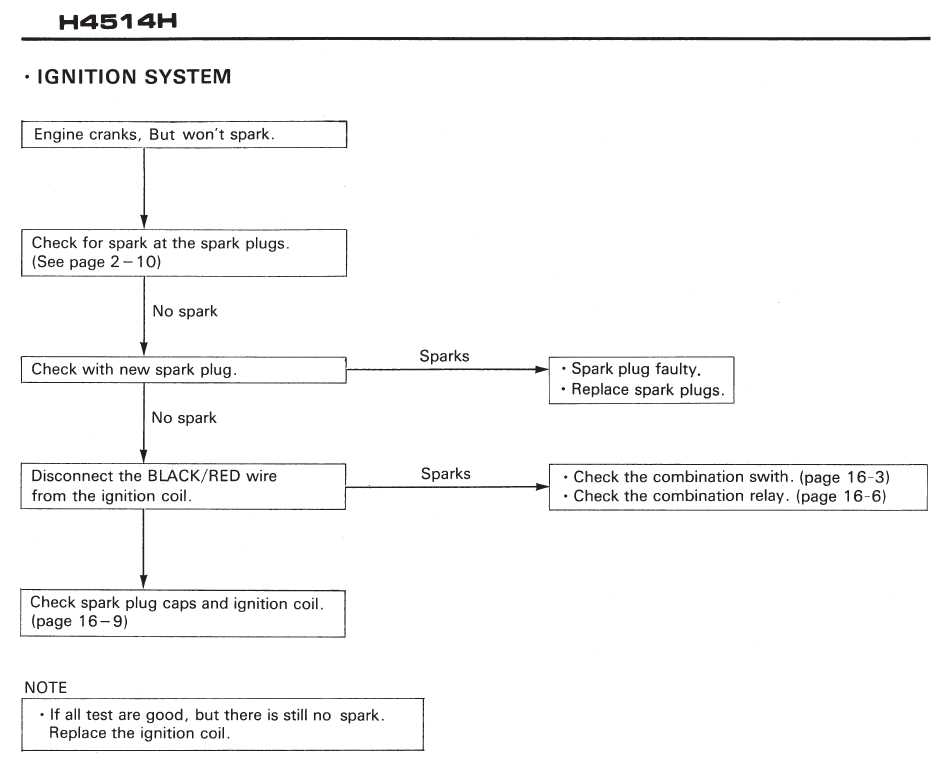

What are the common issues faced?

Users often encounter a range of challenges, from minor adjustments to significant performance problems. Common concerns may include unusual noises, difficulties in operation, or issues with starting. Identifying these problems early can prevent further complications.

How can I troubleshoot effectively?

To troubleshoot efficiently, begin with a systematic approach. Inspect the essential components, check for any visible signs of wear, and consult basic guidelines. Documenting symptoms can also help pinpoint the root cause and simplify discussions with professionals if needed.