Comprehensive Guide to Honda Helix Repair Manual

For enthusiasts and everyday users alike, understanding the intricacies of their two-wheeled companions is essential. This guide offers valuable insights into the upkeep and problem-solving processes necessary to ensure optimal performance. With the right knowledge, riders can enhance the longevity and reliability of their vehicles.

Maintenance is not merely a routine task; it is an art that involves a deep understanding of the mechanics involved. From engine diagnostics to electrical systems, each component plays a crucial role in the overall function. This resource will equip you with the essential techniques and tips to navigate common challenges and keep your machine in top condition.

Whether you are a seasoned mechanic or a novice, this compilation aims to demystify complex procedures. By following detailed instructions and embracing a proactive approach, you can tackle repairs with confidence. Let’s embark on this journey towards mastery and ensure that your ride remains smooth and enjoyable for years to come.

Understanding Honda Helix Specifications

Grasping the technical details of any two-wheeled vehicle is essential for optimal performance and longevity. Specifications serve as a foundation, offering insights into engine dynamics, dimensions, and operational capacities. This knowledge aids owners in making informed decisions regarding maintenance, upgrades, and modifications.

Key Features

Several characteristics define the functionality and appeal of this model. From power output to weight distribution, each aspect contributes to the overall riding experience. Here’s a closer look at some crucial features:

| Feature | Specification |

|---|---|

| Engine Type | Single-cylinder, four-stroke |

| Displacement | 250 cc |

| Transmission | Automatic CVT |

| Fuel Capacity | 11 liters |

| Seat Height | 780 mm |

Performance Metrics

Understanding performance metrics allows enthusiasts to assess capabilities effectively. Acceleration, top speed, and fuel efficiency are just a few indicators of how well a vehicle performs under various conditions. Familiarity with these metrics ensures riders can maximize their experience on the road.

Common Issues with Honda Helix

This section outlines frequently encountered problems that owners of this particular scooter model may face. Understanding these common challenges can help in identifying and addressing issues promptly, ensuring a smoother riding experience.

-

Electrical Problems:

- Faulty ignition system

- Battery drainage issues

- Malfunctioning lights or indicators

-

Engine Performance:

- Difficulty starting the engine

- Unusual noises during operation

- Decreased acceleration and power loss

-

Transmission Issues:

- Slipping gears

- Delayed shifting

- Unresponsive throttle

-

Braking Concerns:

- Worn brake pads

- Spongy or unresponsive brakes

- Brake fluid leaks

-

Tire Wear:

- Uneven tread wear

- Low tire pressure

- Vibration during rides

Addressing these issues through regular maintenance and timely interventions can prolong the lifespan of the vehicle and enhance overall performance.

Tools Needed for Repair

Having the right equipment is essential for maintaining and restoring any type of vehicle. Proper tools not only streamline the process but also ensure that tasks are performed safely and effectively. This section outlines the necessary implements to tackle common maintenance challenges.

Basic Hand Tools are fundamental for any project. A reliable set of wrenches, sockets, and screwdrivers will cover most assembly and disassembly tasks. Pay attention to the sizes and types, as having a complete range will save time and frustration.

Diagnostic Equipment is crucial for identifying issues. An OBD-II scanner can provide valuable insights into the electronic systems, helping pinpoint problems that are not immediately visible. Additionally, multimeters are handy for testing electrical components.

Specialized Tools may be necessary for specific tasks. For instance, a torque wrench ensures that bolts are tightened to the manufacturer’s specifications. Similarly, a compression tester can assess the health of the engine, providing essential information about its performance.

Safety Gear should never be overlooked. Protective eyewear, gloves, and a sturdy apron can prevent injuries while working on various components. Ensuring personal safety is just as important as maintaining the vehicle itself.

In conclusion, assembling a comprehensive toolkit tailored to your needs will enhance your ability to perform effective maintenance and address issues efficiently. Investing in quality tools pays off in both time and durability, leading to better outcomes in your automotive endeavors.

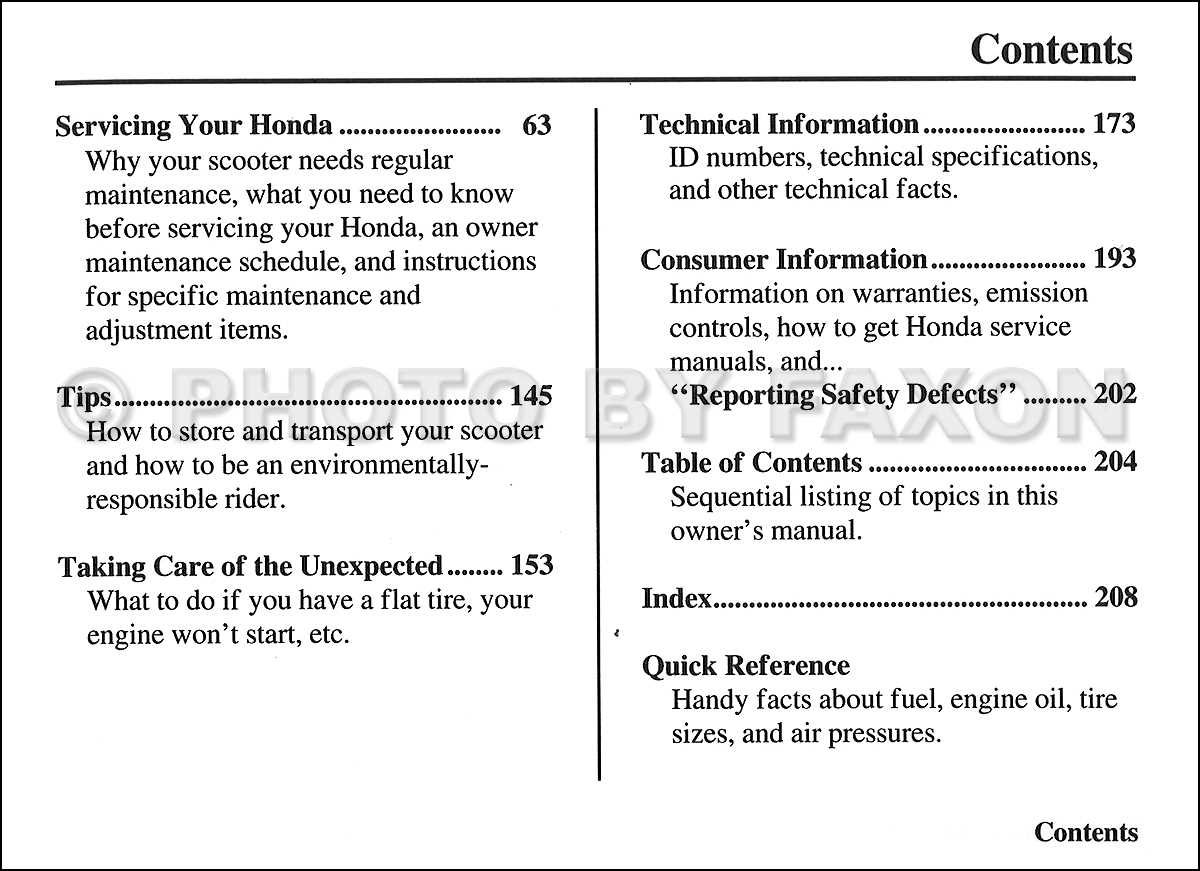

Step-by-Step Maintenance Guide

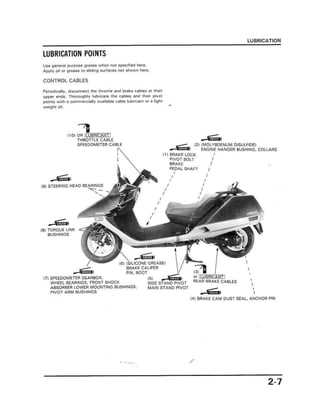

This section provides a comprehensive approach to keeping your vehicle in optimal condition through regular upkeep. Following a systematic procedure will ensure longevity and performance, allowing you to enjoy a smooth ride for years to come.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000 miles | Replace engine oil and filter to maintain lubrication and efficiency. |

| Tire Inspection | Monthly | Check tire pressure and tread depth for safety and performance. |

| Brake Check | Every 6,000 miles | Examine brake pads and fluid levels to ensure effective stopping power. |

| Battery Maintenance | Every 3 months | Inspect terminals for corrosion and ensure secure connections. |

| Air Filter Replacement | Every 12,000 miles | Swap out the air filter to maintain optimal engine performance. |

Replacing Honda Helix Parts

When it comes to maintaining a scooter, understanding the process of part replacement is essential for optimal performance and longevity. Each component plays a crucial role in the overall functionality, and timely replacements can prevent more significant issues down the line. This section outlines the necessary steps and considerations for efficiently substituting various elements of your vehicle.

Before diving into the replacement process, it is vital to gather the appropriate tools and components. Familiarizing yourself with the parts and their specific functions will ensure a smoother experience. Below is a table highlighting common components and their replacement procedures:

| Component | Replacement Steps |

|---|---|

| Battery | 1. Disconnect the terminals 2. Remove the old battery 3. Install the new battery 4. Reconnect terminals |

| Brake Pads | 1. Remove the wheel 2. Take out old pads 3. Install new pads 4. Reassemble the wheel |

| Air Filter | 1. Open the air filter cover 2. Remove the old filter 3. Insert the new filter 4. Close the cover |

| Oil Filter | 1. Drain the oil 2. Unscrew the old filter 3. Screw in the new filter 4. Refill with oil |

After replacing any part, it is advisable to test the vehicle to ensure everything is functioning correctly. Regular checks and timely replacements will contribute to a safer and more enjoyable riding experience.

Electrical System Troubleshooting

This section provides guidance for diagnosing issues within the electrical framework of your vehicle. Understanding the components and their functions is crucial for effective problem-solving.

Common symptoms of electrical problems include:

- Inconsistent engine performance

- Failure to start

- Flickering lights

- Malfunctioning accessories

To systematically address these issues, follow these steps:

- Check the Battery:

- Inspect for corrosion on terminals.

- Ensure it holds a proper charge.

- Examine Fuses:

- Locate the fuse box and check for blown fuses.

- Replace any damaged fuses with ones of the correct amperage.

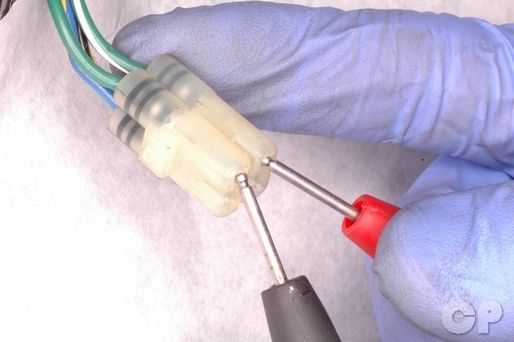

- Test the Wiring:

- Look for frayed or damaged wires.

- Ensure connections are secure and free of rust.

- Inspect the Alternator:

- Verify that it is functioning properly by checking voltage output.

- Listen for unusual noises indicating wear or damage.

By following these steps, you can identify and resolve common electrical issues effectively, ensuring a reliable and smooth operation of your vehicle.

Engine Overhaul Procedures

Rebuilding an engine is a meticulous process that aims to restore performance and extend the lifespan of the unit. This section outlines the essential steps to effectively disassemble, inspect, and reassemble the engine components, ensuring that each part functions optimally.

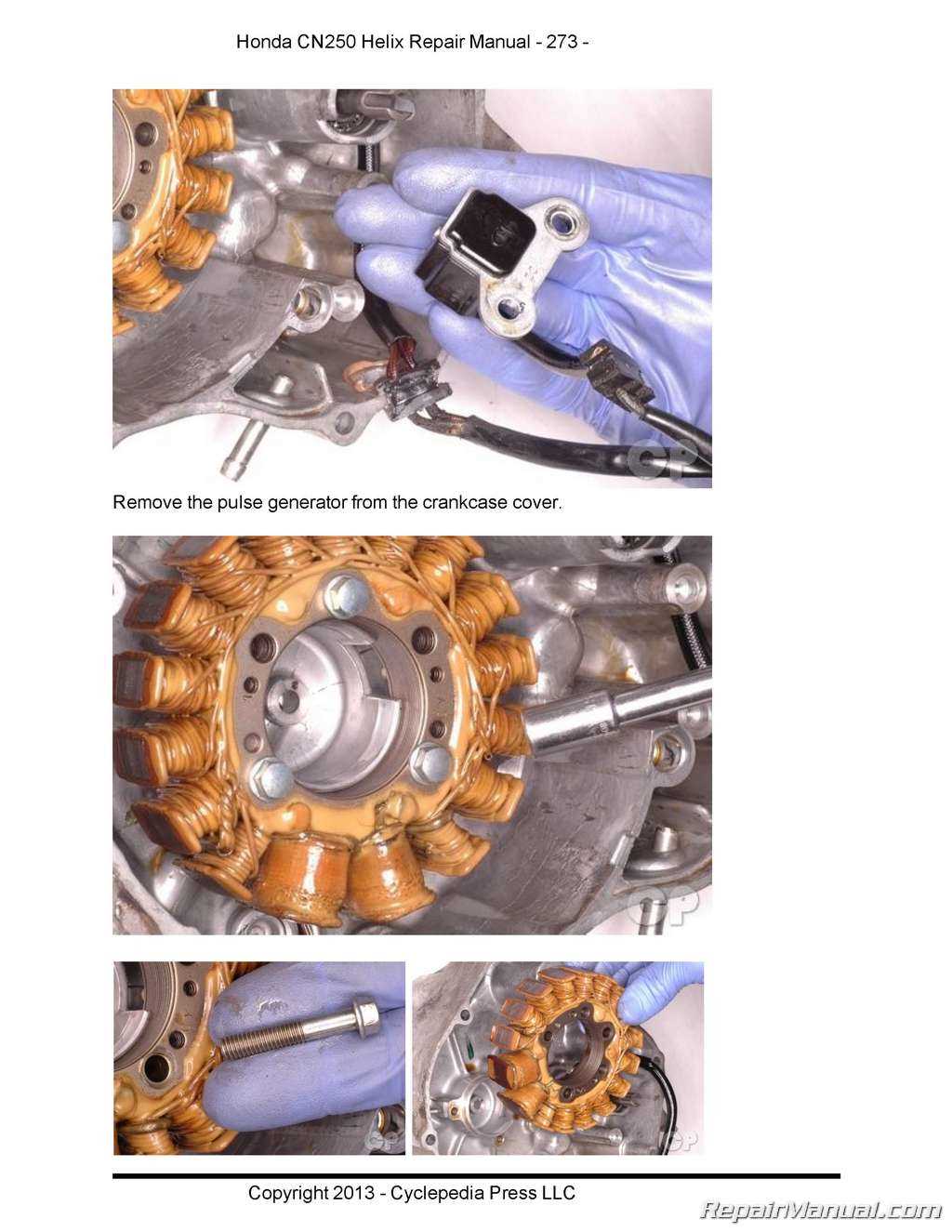

Disassembly is the first crucial phase. Begin by removing the engine from the chassis, followed by detaching all ancillary systems, such as the fuel and cooling systems. Carefully document the order of disassembly and label components to avoid confusion during reassembly.

Once disassembled, proceed to inspection. Each part should be thoroughly examined for wear, cracks, or damage. Utilize precision measuring tools to check tolerances, ensuring that all components meet the manufacturer’s specifications. Components that are worn beyond acceptable limits should be replaced or refurbished.

After inspection, the next step is cleaning. Remove all debris, oil, and carbon buildup from the parts. Ultrasonic cleaners can be particularly effective in restoring cleanliness to intricate components. This step is vital for ensuring proper sealing and function when the engine is reassembled.

When ready for reassembly, follow the documented order and use new gaskets and seals where necessary. Proper torque specifications are essential to avoid future leaks or failures. Pay attention to the sequence of tightening bolts, as this can impact the integrity of the assembly.

Finally, conduct testing after reassembly. Start the engine and allow it to reach operating temperature while monitoring for leaks, unusual noises, or performance issues. A thorough road test will help verify that the engine operates smoothly and efficiently, ensuring the success of the overhaul process.

Transmission Repair Techniques

Effective maintenance of a vehicle’s transmission system is crucial for ensuring optimal performance and longevity. Understanding various methods for addressing issues within this complex assembly can significantly enhance both functionality and reliability. This section delves into essential practices and approaches to troubleshoot and resolve common transmission challenges.

Diagnostic Approaches

Before initiating any corrective measures, thorough diagnostics must be performed to identify the root cause of transmission problems. Utilizing specialized tools to analyze fluid condition, sensor data, and electronic control units can provide valuable insights. Conducting a comprehensive visual inspection can also reveal signs of wear, leaks, or other anomalies that may affect operation.

Reconditioning Techniques

Once the issues are pinpointed, various reconditioning techniques can be applied to restore the transmission to optimal working order. This may include cleaning and replacing components such as filters, seals, and gaskets. In cases of wear, refurbishing parts through machining or replacement ensures that the transmission operates smoothly. Additionally, recalibrating the system’s electronic components can enhance performance and prevent future complications.

Bodywork and Cosmetic Repairs

Maintaining the exterior appearance of your vehicle is essential not only for aesthetic appeal but also for preserving its value. This section focuses on the essential techniques and methods to address surface imperfections, ensuring a polished and appealing finish. From minor scratches to more significant dents, understanding the necessary procedures can greatly enhance the look and longevity of your ride.

Assessing Damage: Before initiating any restoration, it’s crucial to evaluate the extent of the damage. Look for scratches, dents, and rust spots, as these can affect both appearance and structural integrity. Documenting the issues with photographs can help plan your repair approach effectively.

Surface Preparation: Proper preparation is key to achieving a flawless finish. Clean the affected areas thoroughly to remove dirt, grease, and debris. Depending on the type of damage, sanding may be necessary to create a smooth surface for further treatment. Use appropriate grits to ensure the area is ready for repair materials.

Filling Imperfections: For deeper scratches and dents, applying a filler is often required. Select a suitable compound that can easily adhere to the surface and sand down to a smooth finish once cured. Follow the manufacturer’s instructions for application and drying times to ensure optimal results.

Painting Techniques: Once the surface is prepared and imperfections are filled, it’s time to apply paint. Choose a high-quality automotive paint that matches your vehicle’s color. Utilize techniques such as spraying or brush application, depending on the area size. Multiple thin coats generally yield better results than one thick coat.

Finishing Touches: After the paint has dried, consider applying a clear coat to protect the new finish from environmental factors. Polishing the area can enhance shine and blend repairs seamlessly with the surrounding surface. Regular maintenance, such as waxing, will also help preserve the vehicle’s appearance over time.

Upgrades for Enhanced Performance

Improving the capabilities of your two-wheeled machine can significantly elevate your riding experience. Whether you seek better acceleration, increased stability, or enhanced handling, a range of modifications can help you achieve your goals. Focusing on key areas such as the engine, suspension, and exhaust can lead to substantial performance gains.

Engine Enhancements

Upgrading the powertrain is one of the most effective ways to boost performance. Consider installing a high-performance air filter to improve airflow and fuel efficiency. Additionally, a tuning module can optimize fuel mapping, allowing the engine to deliver more power when needed. Re-calibrating the ECU ensures that your machine runs smoothly and efficiently with any modifications made.

Suspension and Handling

Improving the suspension system can greatly enhance stability and cornering capabilities. Investing in adjustable shock absorbers allows for fine-tuning based on riding style and terrain. Upgrading to high-quality tires also plays a critical role in traction and handling, providing better grip and confidence on the road. By addressing these aspects, you’ll notice a remarkable difference in how your vehicle performs during rides.

Finding Reliable Replacement Parts

When maintaining a vehicle, sourcing trustworthy components is crucial for ensuring optimal performance and longevity. The market offers a variety of options, making it essential to discern which sources provide high-quality items that can withstand the demands of regular use.

Researching Suppliers is the first step in your quest for dependable parts. Look for vendors with a solid reputation and positive reviews from previous customers. Online platforms and forums can provide insights into the reliability of various suppliers. Engaging with communities dedicated to similar vehicles can also yield valuable recommendations.

Evaluating Quality is paramount. Always check for certifications and warranties that indicate a manufacturer’s commitment to quality. Parts that meet industry standards are often more reliable and may save you money in the long run by reducing the need for frequent replacements.

Consider Aftermarket Options as well. Many aftermarket components offer competitive quality and performance compared to original parts. However, it’s essential to thoroughly investigate the brand and ensure that they have a good track record in the industry.

Local vs. Online Shopping presents another decision. While local stores may provide immediate access to parts, online retailers often have a wider selection and better pricing. Weigh the pros and cons of each option to determine what best suits your needs.

By taking these steps and being diligent in your search, you can find reliable components that enhance the performance and safety of your vehicle.