Comprehensive Repair Guide for Honda HRR2163TDA Lawnmower

Maintaining your outdoor equipment is crucial for ensuring optimal performance and longevity. This guide focuses on a specific model of lawn care machinery, providing detailed insights into its upkeep and troubleshooting. By following comprehensive instructions and expert tips, users can enhance the reliability of their machines.

Understanding the mechanics behind your equipment can significantly aid in identifying common issues and implementing effective solutions. With a systematic approach to maintenance, you can prevent minor problems from escalating into costly repairs. Regular check-ups and timely interventions are key to achieving a well-functioning unit.

In this resource, you will find step-by-step instructions tailored to the unique features of the specific model in question. From routine cleaning procedures to addressing more complex malfunctions, every aspect is covered to ensure that users feel confident in their ability to care for their machinery effectively.

Understanding the Honda HRR2163TDA

This section aims to provide a comprehensive overview of a popular lawn care machine, focusing on its features, functionality, and user experience. By delving into its design and capabilities, one can appreciate how it meets the needs of homeowners and professionals alike in maintaining a well-kept lawn.

Equipped with advanced technology, this equipment ensures efficient grass cutting and effortless maneuverability. Its robust engine delivers consistent power, allowing for swift navigation across various terrains. Additionally, the thoughtful engineering behind its cutting deck facilitates precise trimming, making lawn maintenance a more manageable task.

Users often highlight the convenience of adjustable settings, which cater to different grass heights and types. The easy-start mechanism further enhances usability, enabling individuals to get to work quickly without unnecessary delays. This device is designed not only for performance but also for user comfort, with ergonomic handles and manageable weight.

Regular upkeep and understanding of this machine’s components are essential for optimal operation. Familiarity with its structure helps users troubleshoot common issues and maintain efficiency over time. Thus, knowledge of this equipment is invaluable for anyone looking to achieve a pristine outdoor space.

Common Issues with Honda Mowers

Maintaining lawn equipment is essential for ensuring longevity and optimal performance. Users often encounter specific challenges that can affect the functionality of their machines. Recognizing these problems early can save time and resources in the long run.

Frequent Problems

- Starting Difficulties: Many users report issues with ignition, which may stem from a faulty spark plug or a drained battery.

- Uneven Cutting: A common complaint is an uneven cut, often caused by dull blades or an improper mowing height setting.

- Fuel System Issues: Clogged fuel filters or stale gasoline can lead to poor engine performance and starting problems.

- Overheating: Machines may overheat due to insufficient oil levels or blocked air vents, resulting in potential engine damage.

Preventive Measures

- Regularly check and replace the spark plug as needed.

- Sharpen or replace blades at the start of the mowing season.

- Use fresh fuel and inspect the fuel system periodically.

- Keep the engine well-lubricated and ensure proper ventilation.

Addressing these common challenges proactively can enhance the performance and lifespan of your lawn maintenance equipment.

Essential Tools for Repairs

When it comes to maintaining and restoring machinery, having the right set of instruments is crucial. Whether you’re addressing minor issues or conducting thorough overhauls, the proper equipment not only enhances efficiency but also ensures safety throughout the process. Below, we outline the indispensable tools that every technician should have at their disposal.

Basic Hand Tools

Fundamental hand tools form the backbone of any maintenance project. A reliable set of wrenches and screwdrivers is essential for loosening and tightening various components. Pliers can aid in gripping and bending materials, while a hammer is indispensable for driving fasteners or fitting parts together. Investing in a quality toolbox to organize these items can significantly streamline your workflow.

Specialized Equipment

In addition to basic tools, certain specialized equipment can greatly enhance your ability to tackle complex tasks. A multimeter is invaluable for diagnosing electrical issues, while a mechanical gauge can help in assessing the performance of engine components. For those dealing with engine maintenance, a compression tester can provide insights into engine health. These tools not only improve accuracy but also extend the lifespan of the equipment you’re working on.

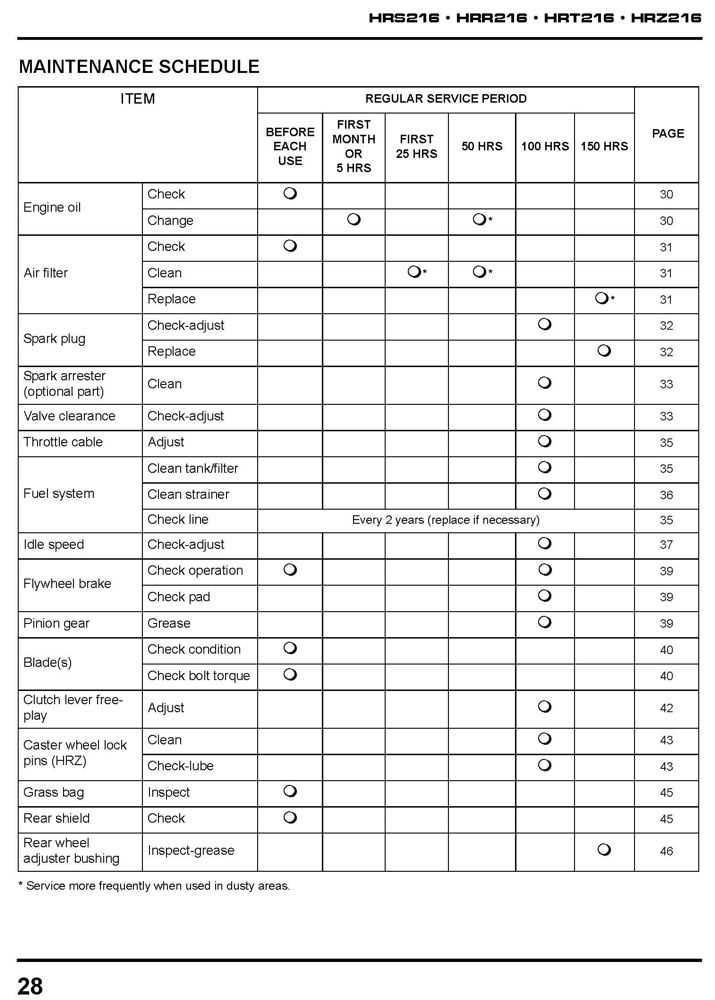

Step-by-Step Maintenance Guide

Proper upkeep of your equipment ensures optimal performance and longevity. By following a systematic approach, you can enhance efficiency and prevent common issues. This guide outlines essential tasks that should be regularly performed to keep your machinery in peak condition.

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Before each use | Ensure the oil level is sufficient to maintain smooth operation. |

| Inspect Blades | Every month | Look for wear and damage; sharpen or replace as needed. |

| Clean Air Filter | Every 25 hours | Remove and clean to prevent dirt buildup and ensure proper airflow. |

| Check Spark Plug | Every season | Inspect for wear; replace if it appears worn or damaged. |

| Examine Fuel System | Every season | Check for leaks and ensure fuel is fresh to avoid starting issues. |

Troubleshooting Engine Problems

When faced with engine issues, it is essential to systematically diagnose the problem to restore optimal performance. Understanding common symptoms and their potential causes can significantly streamline the troubleshooting process, enabling effective solutions.

Below is a table outlining common engine issues, possible symptoms, and recommended actions to take for each scenario:

| Engine Issue | Symptoms | Recommended Actions |

|---|---|---|

| Engine Won’t Start | Clicking sound, no power | Check battery connections and charge the battery. |

| Rough Idle | Inconsistent RPMs, vibrations | Inspect spark plugs and fuel filters for clogs. |

| Overheating | Steam from engine, high temperature gauge | Examine coolant levels and inspect for leaks. |

| Loss of Power | Unresponsive throttle, slow acceleration | Check air filter and fuel supply for restrictions. |

| Excessive Smoke | Visible exhaust smoke, strong odor | Investigate oil levels and assess for oil leaks. |

By utilizing this guide, users can identify and address engine-related issues effectively, ensuring longevity and reliable performance.

Blade Replacement Procedures

Replacing the cutting blade is essential for maintaining optimal performance in lawn care equipment. Regularly updating the blade ensures that grass is cut cleanly and efficiently, preventing damage to the lawn and improving overall aesthetics.

Tools Needed

- Socket wrench set

- Safety gloves

- Protective eyewear

- Blade sharpening tool (if applicable)

- Grease or lubricant

Step-by-Step Instructions

- Ensure the machine is powered off and disconnected from any power source.

- Wear safety gloves and eyewear for protection.

- Using the socket wrench, remove the bolt securing the current blade. Turn counterclockwise to loosen.

- Carefully detach the blade from the spindle, noting the orientation for installation of the new blade.

- Inspect the spindle and clean any debris or grass clippings.

- If sharpening the old blade, use the sharpening tool to achieve a clean edge. Otherwise, proceed with the new blade.

- Align the new blade with the spindle, ensuring it matches the original orientation.

- Secure the blade by tightening the bolt clockwise until firmly in place.

- Apply a small amount of grease to the spindle to ensure smooth operation.

- Reconnect the power source and perform a test run to ensure proper functionality.

Regularly checking and replacing the blade will enhance performance and prolong the life of the equipment.

Cleaning and Caring for Filters

Maintaining optimal performance in your equipment involves regular attention to various components, including filters. These essential parts help ensure that air and fluids circulate efficiently, preventing dirt and debris from causing damage. Proper cleaning and care of filters can significantly extend their lifespan and enhance overall functionality.

Steps for Cleaning Air Filters

Begin by removing the air filter from its housing. Gently tap it to dislodge any loose dirt. For more thorough cleaning, use a soft brush or compressed air to remove stubborn particles. If the filter is washable, rinse it under lukewarm water and allow it to dry completely before reinserting it. Ensure that it fits snugly to prevent contaminants from entering the engine.

Maintaining Fuel Filters

Fuel filters are crucial for preventing impurities from damaging the fuel system. Regularly check for signs of clogging, such as reduced performance. If necessary, replace the filter according to the manufacturer’s guidelines. When replacing, ensure that the new filter is properly sealed to avoid leaks. Keeping fuel filters clean is essential for efficient operation and can save you from costly repairs down the line.

Adjusting the Mower’s Height

Setting the cutting height of your lawn equipment is essential for achieving the perfect lawn. Proper adjustments ensure that grass is trimmed to an optimal level, promoting health and appearance while preventing damage to the blades and the turf. Understanding how to modify the height can enhance your mowing experience and maintain the aesthetics of your yard.

Why Height Adjustment Matters

Maintaining the right cutting height offers several benefits:

- Encourages healthy grass growth.

- Reduces weed proliferation.

- Improves the overall look of your lawn.

- Prevents scalping or damaging the turf.

Steps to Adjust the Cutting Height

Follow these steps to ensure accurate height modification:

- Ensure the mower is on a flat surface for precise measurements.

- Locate the height adjustment lever or knob, typically found on the wheels or the mower body.

- Decide on the desired height based on grass type and season:

- For cool-season grasses, aim for 2.5 to 4 inches.

- For warm-season grasses, set it between 1.5 to 3 inches.

Regularly checking and adjusting the cutting height will contribute significantly to the maintenance and beauty of your lawn.

Electrical System Diagnostics

Understanding the electrical framework of outdoor power equipment is crucial for ensuring optimal performance and longevity. A systematic approach to troubleshooting can help identify issues that may arise within the circuitry and components.

Common Issues and Indicators

Frequent problems include faulty connections, damaged wires, and malfunctioning switches. Symptoms such as inconsistent operation or complete failure can serve as red flags. Regular inspections can help pinpoint potential failures before they escalate.

Diagnostic Procedures

Begin by visually inspecting all electrical connections and components. Utilize a multimeter to measure voltage and continuity, ensuring that power is flowing correctly. Isolate the problematic sections and delve into each component for further analysis. Document findings for reference in future maintenance.

Fuel System Maintenance Tips

Ensuring optimal performance of your machine’s fuel system is essential for longevity and efficiency. Regular upkeep can prevent issues and enhance the overall functionality, allowing for smooth operation and reliable performance.

Routine Checks

- Inspect fuel lines for leaks or wear, replacing any damaged sections promptly.

- Examine the fuel filter regularly; replace it according to the manufacturer’s schedule to prevent clogs.

- Check for any signs of corrosion in the tank or components, which can lead to serious malfunctions.

Storage Considerations

- When storing your equipment for an extended period, ensure the fuel tank is either emptied or treated with a fuel stabilizer to prevent degradation.

- Store the machine in a cool, dry place to minimize the risk of moisture accumulation, which can affect fuel quality.

- Regularly run the engine for a few minutes to keep the fuel circulating and to identify any potential issues early on.

Storing Your Mower Correctly

Proper storage of your lawn maintenance equipment is essential to ensure its longevity and optimal performance. Taking the right steps to protect your machine from the elements and potential damage can prevent costly repairs and enhance its efficiency during use.

Preparing for Storage

Before placing your mower in storage, there are several important tasks to complete. This preparation will help maintain the equipment’s condition over time.

| Task | Description |

|---|---|

| Clean the Deck | Remove grass clippings and debris from the cutting deck to prevent rust and corrosion. |

| Drain Fuel | Empty the fuel tank or add a stabilizer to prevent fuel degradation. |

| Check Blades | Inspect and sharpen the blades to ensure optimal cutting performance for the next season. |

| Change Oil | Replace the oil to remove contaminants and prolong engine life. |

| Battery Maintenance | If applicable, remove the battery and store it in a cool, dry place. |

Ideal Storage Conditions

Storing your equipment in the right environment is crucial. Choose a location that is dry and well-ventilated to prevent moisture buildup, which can lead to rust and mold. Avoid placing the mower in direct sunlight, as excessive heat can damage plastic components and lead to fading. Keeping your equipment covered with a breathable tarp can also protect it from dust and potential scratches.

When to Seek Professional Help

Understanding when to consult an expert can save time, money, and frustration. While many minor issues can be resolved with basic knowledge and tools, certain situations may require the expertise of a trained technician. Recognizing the signs that indicate the need for professional assistance is crucial for maintaining efficiency and safety.

Consider seeking expert advice in the following scenarios:

- Persistent Issues: If problems continue despite your efforts to fix them, it may be time to get help.

- Complex Repairs: Tasks that involve intricate components or systems often require specialized skills.

- Safety Concerns: Any situation that poses a risk to your safety or others should be addressed by a professional.

- Unfamiliar Sounds: Unusual noises can indicate serious issues that might not be obvious.

- Lack of Knowledge: If you feel uncertain about your ability to tackle a problem, it’s better to consult an expert.

In summary, knowing when to reach out for professional assistance is essential for effective problem-solving. By recognizing specific indicators, you can ensure that your equipment remains in optimal condition while avoiding potential hazards.