Complete Guide to Honda HS520 Repair Manual

When it comes to maintaining and troubleshooting outdoor machinery, having a thorough reference is essential for every user. This document serves as a vital resource, providing insights into common issues and offering step-by-step instructions to ensure optimal performance. Understanding your device’s functionality can significantly enhance your experience and extend its lifespan.

Throughout this guide, you will discover various techniques and tips designed to facilitate effective maintenance and address potential challenges. Whether you’re a novice or an experienced user, the information presented here aims to empower you with the knowledge needed to handle your equipment confidently. From routine checks to more intricate repairs, you will find clear explanations to help navigate through each process.

Equipped with this knowledge, you can ensure that your machinery operates efficiently and reliably. By following the suggestions laid out in this resource, you can approach any task with the assurance that you are making informed decisions to enhance the functionality of your equipment.

When working with snow removal machines, users often encounter a variety of challenges that can hinder performance. Understanding these typical problems can help in maintaining optimal functionality and ensuring a smooth operation during harsh winter conditions.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | The engine may fail to ignite due to fuel issues or spark plug problems. | Check the fuel level and quality; replace the spark plug if necessary. |

| Loss of Power | Users may experience a reduction in power during operation, often due to blockages. | Inspect and clear any snow or ice buildup in the auger and discharge chute. |

| Unusual Noises | Strange sounds can indicate loose components or wear in the drive system. | Tighten any loose parts and examine belts for wear or damage. |

| Difficulty Steering | Steering issues can arise from cable misalignment or mechanical failure. | Inspect steering cables for proper alignment and adjust as needed. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your outdoor equipment. Regular upkeep is essential for preventing breakdowns and enhancing efficiency. Follow these outlined steps to keep your machine running smoothly.

Begin by gathering the necessary tools and materials for routine checks and adjustments. A well-prepared workspace will facilitate the maintenance process and help you stay organized.

| Task | Frequency | Details |

|---|---|---|

| Inspect the Engine | Every 25 hours | Check for leaks, unusual noises, and ensure proper oil levels. |

| Clean the Air Filter | Every 50 hours | Remove and clean or replace the air filter to ensure proper airflow. |

| Sharpen the Blades | Every 25 hours | Ensure blades are sharp for effective cutting and to prevent damage. |

| Check Spark Plug | Every 100 hours | Inspect for wear and replace if necessary to maintain engine performance. |

| Inspect Belts and Cables | Every 50 hours | Check for signs of wear and ensure proper tension and alignment. |

By adhering to this maintenance guide, you can significantly enhance the durability and efficiency of your equipment, ensuring that it operates at peak performance for years to come.

Tools Needed for Repairs

Undertaking maintenance on your equipment requires a well-thought-out selection of instruments to ensure efficiency and precision. Proper tools not only facilitate the process but also enhance the quality of the work performed. Below is a list of essential devices that will aid in various tasks.

Essential Instruments

Having the right instruments at your disposal is crucial for successful upkeep. Here’s a detailed overview of the primary tools you’ll need:

| Tool | Description |

|---|---|

| Socket Set | A collection of various sized sockets for loosening or tightening bolts and nuts. |

| Screwdriver Set | Includes different types of screwdrivers for various screw heads, aiding in disassembly and assembly. |

| Pliers | Useful for gripping, twisting, or cutting wires and other materials. |

| Wrench | Allows for easy manipulation of fasteners, particularly in tight spaces. |

| Multimeter | Essential for measuring voltage, current, and resistance, ensuring electrical components function properly. |

Additional Supplies

In addition to the primary instruments, consider these supplementary items to enhance your maintenance efforts:

| Supply | Purpose |

|---|---|

| Lubricant | Reduces friction and wear on moving parts, prolonging lifespan. |

| Cleaning Supplies | Helps maintain cleanliness, preventing dirt build-up and potential damage. |

| Safety Gear | Includes gloves and goggles to protect against injuries during maintenance tasks. |

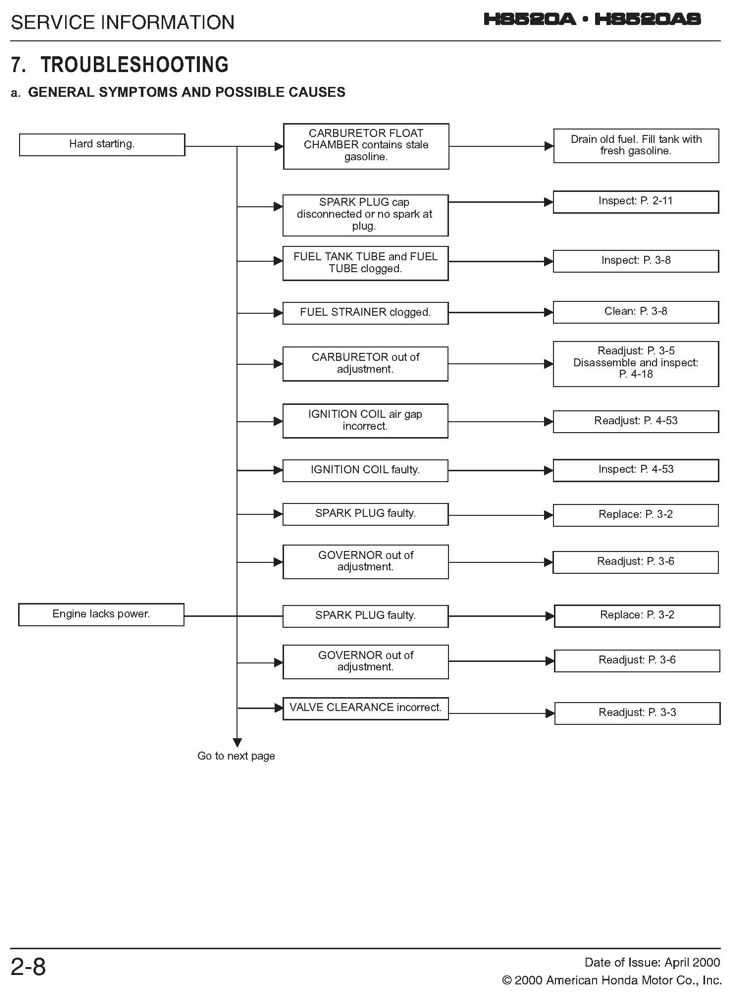

How to Troubleshoot Engine Problems

Identifying issues with your engine can often feel overwhelming, but a systematic approach can simplify the process. By following a few logical steps, you can effectively diagnose the problem and take necessary actions to rectify it. Understanding the potential signs and symptoms of malfunction can save time and effort in repairs.

Common Symptoms to Look For

Engines can exhibit a range of warning signs when something is amiss. Familiarizing yourself with these indicators can help pinpoint the issue more efficiently. Here are some frequent symptoms to monitor:

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Battery issues, faulty ignition system |

| Unusual noises | Loose components, worn parts |

| Excessive smoke | Oil leaks, coolant issues |

| Poor performance | Clogged filters, fuel delivery problems |

Steps for Diagnosis

Once you’ve identified the symptoms, follow these steps to further investigate the underlying causes:

1. Check the fuel supply and ensure it is reaching the engine properly. This includes inspecting the fuel lines and filters for blockages.

2. Inspect the electrical components, including spark plugs and wiring, to ensure they are functioning correctly.

3. Examine the air intake system for clogs or obstructions that could hinder performance.

4. Consult user resources or seek assistance if the problem persists, as expert guidance may be necessary for complex issues.

Replacing the Spark Plug

Maintaining optimal performance in your outdoor power equipment often involves periodic replacement of critical components. One such element that plays a vital role in engine efficiency is the spark plug. This guide outlines the process of substituting this essential part, ensuring your machinery runs smoothly and effectively.

Tools and Materials Needed

Before you begin, gather the necessary tools and supplies. You will require a socket wrench, a new spark plug suitable for your engine, and possibly a gap gauge to ensure proper spacing. Having these items on hand will streamline the process and prevent interruptions.

Steps for Replacement

Start by disconnecting the spark plug wire to avoid any accidental ignition. Use the socket wrench to remove the old spark plug by turning it counterclockwise. Once removed, inspect the condition of the old plug for any signs of wear or damage, which can indicate engine issues. Next, take the new spark plug and ensure the gap is set according to the manufacturer’s specifications. Install the new plug by carefully threading it into the socket and tightening it securely, but avoid over-tightening to prevent damage. Finally, reconnect the spark plug wire, ensuring it is seated firmly.

By following these steps, you can enhance the performance of your equipment, ensuring it operates at its best for years to come.

Adjusting the Carburetor Settings

Fine-tuning the fuel delivery system is essential for optimal engine performance. Proper adjustments can lead to improved efficiency, smoother operation, and reduced emissions. This section outlines the necessary steps to achieve the right balance in your device’s settings.

Before beginning, gather the following tools:

- Screwdriver

- Wrench set

- Tachometer

- Clean cloth

Follow these steps to adjust the fuel system:

- Start the engine and allow it to reach normal operating temperature.

- Locate the adjustment screws, usually found on the side of the carburetor.

- Using the screwdriver, gently turn the idle screw clockwise to increase RPM or counterclockwise to decrease it.

- Next, adjust the mixture screw to ensure the correct air-fuel ratio. Turn it in small increments and monitor engine response.

- Repeat the process, fine-tuning both screws until you achieve a steady idle and smooth acceleration.

Regular maintenance of these settings will help prolong the lifespan of your machine and enhance its performance. Always refer to manufacturer specifications for optimal values.

Blade Maintenance and Replacement

Proper upkeep of cutting components is essential for optimal performance and longevity. Regular inspections and timely replacements not only enhance efficiency but also ensure safety during operation. This section delves into the best practices for maintaining and replacing these crucial parts.

Regular checks should be performed to identify signs of wear or damage. Dull blades can lead to inefficient cutting and potential harm to the machine. To maintain sharpness, consider the following recommendations:

| Action | Frequency | Description |

|---|---|---|

| Inspection | After every use | Look for cracks, bends, or dull edges. |

| Sharpening | As needed | Use a sharpening tool to restore blade edges. |

| Replacement | When damaged | Install new blades if repairs are not feasible. |

By adhering to these practices, users can ensure their cutting components function efficiently, reducing the risk of accidents and prolonging the life of the equipment. Regular maintenance not only enhances performance but also contributes to a safer working environment.

Cleaning the Fuel System

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity. Over time, debris and contaminants can accumulate, potentially hindering functionality. This section provides guidelines for ensuring that the fuel delivery components remain clear and efficient.

Regular cleaning can prevent issues such as starting difficulties, rough idling, and reduced power output. Below are the steps to effectively clean the fuel system:

- Gather necessary tools and materials, including:

- Fuel system cleaner

- Protective gloves

- Clean rags

- Safety goggles

- Ensure the machine is off and cool before starting the cleaning process.

- Remove any fuel caps or covers to access the fuel lines.

- Apply the fuel system cleaner according to the manufacturer’s instructions:

- Introduce the cleaner into the fuel tank or directly into the fuel line, as directed.

- Allow the cleaner to sit for the recommended duration.

- Flush the system with fresh fuel to remove any residues:

- Reconnect any fuel lines that were detached.

- Fill the tank with high-quality fuel.

After completing these steps, monitor the machine’s performance. Regular checks and maintenance can lead to better efficiency and a more reliable operation.

Electrical System Diagnostics

Understanding the functionality of the electrical framework in outdoor equipment is essential for ensuring optimal performance. This segment delves into the methodologies employed to identify and address issues within the power supply and control systems, facilitating effective troubleshooting.

To commence diagnostics, it is crucial to utilize appropriate tools such as multimeters to measure voltage and resistance. Establishing a baseline for normal readings allows for accurate comparisons when anomalies arise. Regularly checking connections for wear and corrosion can prevent failures and maintain efficiency.

Furthermore, visual inspections play a significant role in the process. Examining wiring for fraying or damage helps in preemptively addressing potential problems. Should discrepancies be identified, referring to specific schematics ensures a comprehensive approach to resolving issues within the electrical setup.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential. Adhering to safety guidelines not only protects the individual working but also safeguards the equipment. By following a set of precautions, one can minimize risks and enhance the overall efficiency of the process.

Essential Guidelines

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace tidy to prevent accidents caused by clutter.

- Ensure all tools are in good condition and suitable for the tasks at hand.

Emergency Preparedness

- Familiarize yourself with the location of first aid kits and fire extinguishers.

- Have a plan in place for emergencies, including a contact list for assistance.

- Ensure that all electrical equipment is properly grounded and free from damage.