Honda HS80 Repair Guide

In colder climates, efficient snow clearing equipment is essential for navigating the winter season smoothly. To ensure a snow blower operates reliably, understanding its components and maintenance needs can be invaluable. Regular care and precise attention to mechanical details allow for prolonged performance and improved durability, keeping essential equipment ready for any snowfall.

Each machine has unique requirements, from fuel systems to ignition components. For those eager to maintain these devices in prime condition, an in-depth look into core systems and their upkeep can provide both clarity and confidence. By familiarizing yourself with component functions, troubleshooting steps, and routine care practices, you can handle adjustments and minor fixes effectively.

Following detailed guidelines on essential systems can make upkeep straightforward, giving you the knowledge to identify potential issues early. This approach helps prevent larger problems, ensuring the equipment remains dependable during harsh weather conditions. An informed approach to mechanical care is both practical and cost-effective, especially when snow is piling up outside.

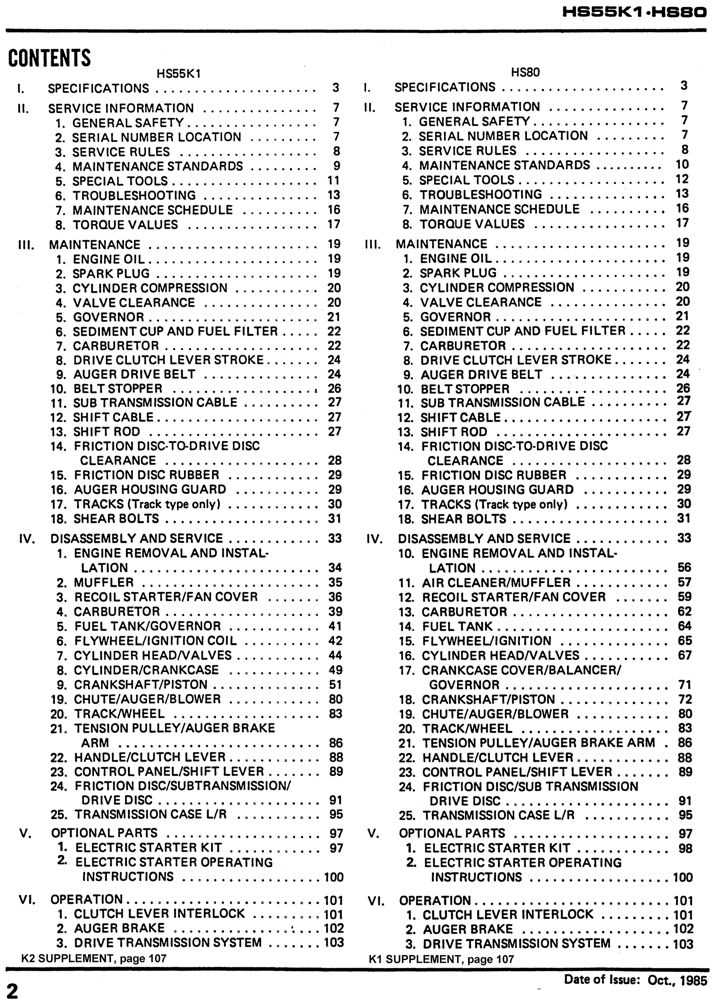

Honda HS80 Maintenance Guide

Regular upkeep of this snow-clearing equipment ensures both reliable performance and a prolonged lifespan. By attending to essential components and following a systematic approach, owners can optimize functionality and efficiency throughout the winter months.

- Engine Inspection: Periodic checks of the engine’s oil level and quality are crucial. Replace the oil as recommended to keep the internal parts lubricated and functioning smoothly.

- Fuel System Care: Use fresh fuel to prevent clogs and ensure smooth operation. Avoid leaving unused fuel in the tank during off-seasons to prevent residue build-up.

- Auger Maintenance: Clear the auger after each use to prevent ice buildup and inspect for any debris or wear. Ensure blades are sharp and replace if needed.

- Belt Check: The drive belt should be checked for wear or slack. Replace it if it shows signs of fraying or cracking to maintain power transmission to the auger.

- Tire or Track Care: Inspect tires or tracks regularly for proper inflation or tension. Well-maintained mobility components prevent slipping and improve handling.

- Battery and Electrical: Regularly test the battery and other electrical components. Charge or replace the battery if it shows signs of weakness to ensure reliable starts in cold conditions.

By following these steps, owners can ensure that their snow-clearing equipment remains effective, safe, and ready to tackle heavy snowfall each season.

Common Issues and Troubleshooting

Maintenance and regular troubleshooting are essential to keep snow-clearing equipment running efficiently. Understanding recurring challenges and their solutions helps prevent costly downtime and ensures smoother performance. This guide highlights frequent issues and practical methods to address them.

| Problem | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel line blockage or stale fuel | Check fuel line, replace old fuel, and clean carburetor |

| Low power output | Dirty air filter or spark plug | Replace air filter and inspect spark plug for wear |

| Unusual vibrations | Loose bolts or worn parts | Tighten all fasteners and inspect for worn components |

| Poor snow ejection | Clogged chute or auger issues | Clear the chute and inspect auger for obstructions |

Following these tips will help keep your equipment in optimal condition, improving performance and prolonging its service life. Regular inspections and timely repairs can prevent minor issues from becoming major setbacks during winter operations.

Essential Tools for Repair Work

To successfully complete a maintenance project on small machinery, having the right set of instruments is crucial. This section highlights the most essential items needed for efficient and safe adjustments.

- Screwdrivers: Various sizes and types of screwdrivers are necessary to handle diverse fasteners and allow secure removal and reassembly of parts.

- Wrenches: A set of adjustable and combination wrenches will help tackle bolts and nuts of different dimensions, ensuring precise tightening and loosening.

- Socket Set: A well-equipped socket set is essential for accessing hard-to-reach areas, especially where bolts are tightly fastened.

- Pliers: Different types, including needle-nose and locking pliers, provide grip for handling small components and wires.

- Torque Wrench: Using a torque wrench guarantees that bolts are secured to the recommended tension, reducing the risk of over-tightening.

- Multimeter: A digital or analog multimeter is invaluable for testing electrical connections and diagnosing potential faults within the system.

- Work Light: Adequate lighting enhances visibility, especially when working in low-light conditions, allowing for precise adjustments.

- Safety Gear: Protective gloves and eyewear are essential to safeguard against any unexpected hazards during the process.

Equipped with these fundamental tools, one can approach tasks with confidence, ensuring efficient and reliable outcomes in maintenance efforts.

Engine Inspection and Cleaning Tips

Regular examination and maintenance of a machine’s power unit are essential to ensure optimal performance and longevity. Proper cleaning and inspection routines help identify any potential issues early, reduce wear, and enhance the efficiency of the system. This section outlines practical guidelines for safely assessing and cleaning critical components to keep the unit in top condition.

Inspection for Wear and Damage

Begin by checking visible parts of the engine for signs of wear, corrosion, or damage. Carefully examine seals, gaskets, and connectors for any leaks or deterioration. Inspect the cylinder head and exhaust areas for buildup that could affect functionality. It is also essential to review the condition of the fuel and air filters, replacing them if necessary to maintain optimal airflow and fuel quality.

Cleaning Process and Safety Measures

When cleaning, ensure the unit is turned off and completely cool to avoid accidents. Use a soft brush or cloth to remove dirt and debris from sensitive areas, taking care around small or intricate parts. For more stubborn buildup, a mild cleaning solution applied with a soft brush can help clear away grime. Avoid excessive moisture, especially near electrical components, as it may lead to malfunctions. Regular cleaning and safe handling practices will help maintain the engine’s efficiency and prevent issues from arising over time.

Replacing Worn Out Components

Over time, frequent use can lead to the natural degradation of certain parts, which may impact the overall functionality of the equipment. Addressing these issues by identifying and substituting outdated components can enhance performance and prolong the lifespan of the machine.

Key Parts to Inspect

When considering component replacement, some parts require more attention due to their frequent wear. Below is a list of the essential areas to inspect and potentially replace:

- Drive belts

- Bearings

- Control cables

- Seals and gaskets

Replacement Part Specifications

For effective replacement, having the correct specifications is crucial. Reference the table below to understand common replacement options and compatibility details.

| Component | Recommended Material | Expected Lifespan |

|---|---|---|

| Drive Belt | Reinforced Rubber | 5-7 years |

| Bearings | Stainless Steel | 3-5 years |

| Control Cable | High-Grade Steel | 5 years |

| Seals and Gaskets | Neoprene or Rubber | 3-4 years |

Regularly assessing and renewing these components can ensure smoother operation and prevent unexpected malfunctions, ultimately extending the operational life of the equipment.

Understanding the Fuel System

The fuel system is a vital component in ensuring the efficient operation of any engine. It is responsible for delivering the appropriate mixture of fuel and air to the combustion chamber, allowing for optimal performance. Understanding how this system functions is essential for troubleshooting issues that may arise during operation.

At its core, the fuel system typically consists of several key elements: the fuel tank, pump, filters, and injectors. Each part plays a crucial role in maintaining the flow of fuel and preventing contaminants from entering the engine. The fuel tank stores the liquid, while the pump is responsible for transporting it to the engine. Filters are essential for removing impurities, and injectors ensure that the fuel is delivered in the correct amount and at the right time.

Maintaining the integrity of the fuel system is crucial for enhancing engine efficiency and longevity. Regular inspections can help identify potential issues, such as clogs or leaks, before they lead to more significant problems. By understanding the function and maintenance of the fuel system, operators can ensure their equipment operates smoothly and reliably.

Adjusting Carburetor Settings

Proper calibration of the fuel delivery system is essential for optimal engine performance. This process involves fine-tuning various components to ensure a balanced air-fuel mixture, which directly influences efficiency and power output. Understanding how to adjust these settings can lead to improved functionality and longevity of the equipment.

Begin by locating the adjustment screws on the carburetor. Typically, there are two main screws: one for idle speed and another for mixture. Carefully turning these screws can significantly impact engine behavior. Use a screwdriver to make slight adjustments while monitoring the engine’s response.

Start with the idle speed adjustment: Turn the screw clockwise to increase RPM and counterclockwise to decrease it. Aim for a stable idle that does not stall. Once the idle is set, move on to the mixture adjustment.

For the mixture adjustment: Turn the screw clockwise to enrich the mixture (more fuel) or counterclockwise to lean it out (less fuel). Listen for changes in engine sound, which can indicate whether the mixture is too rich or too lean. Finding the optimal setting may require several iterations.

Always remember to perform these adjustments gradually and make note of each change to track progress. Regularly maintaining these settings will help sustain the overall efficiency of your equipment.

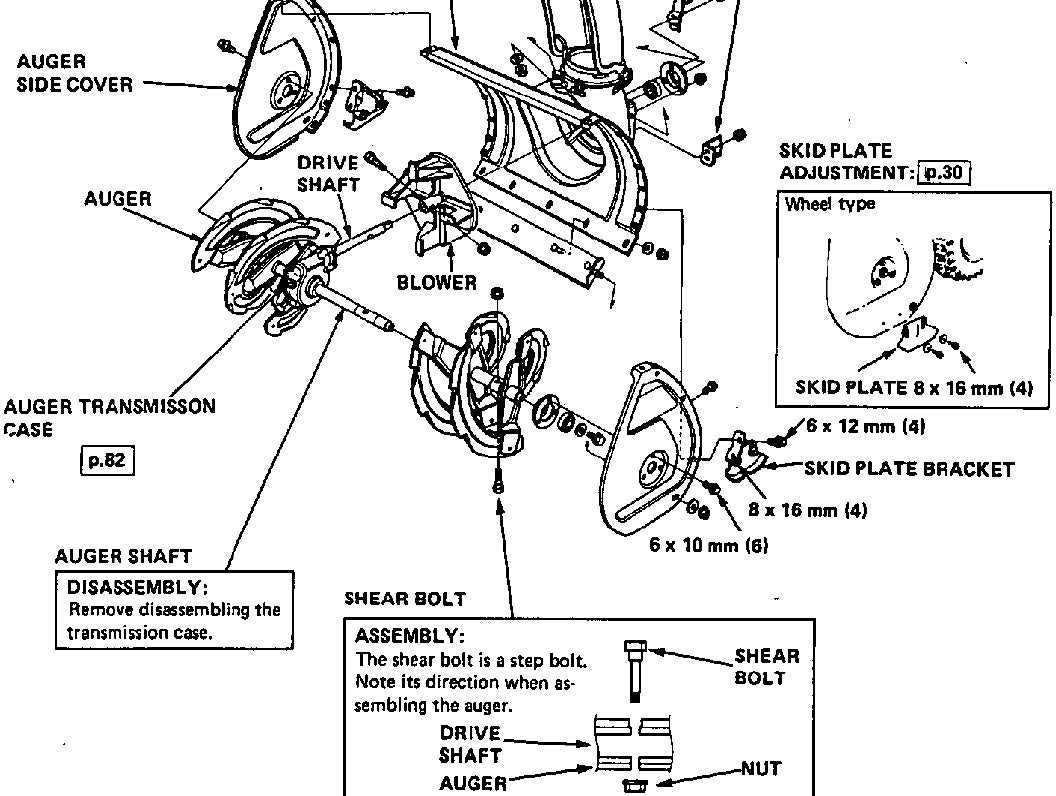

Inspecting and Repairing the Auger

Regular examination and maintenance of the snow removal mechanism are crucial for ensuring optimal performance during winter operations. This section will guide you through the essential steps to assess and fix any issues that may arise with the component responsible for moving snow efficiently.

Visual Inspection: Begin by closely examining the auger for any signs of wear, damage, or obstruction. Check for bent or cracked blades, as these can hinder functionality. Ensure there are no foreign objects lodged within the mechanism, which could lead to further complications.

Blade Replacement: If the blades show significant wear or damage, they should be replaced. Remove the old blades by loosening the fasteners and carefully detaching them from the housing. Install the new blades securely, ensuring they are aligned correctly to maintain balance during operation.

Lubrication: Proper lubrication is vital for the smooth operation of the auger. Apply a suitable lubricant to the moving parts, including bearings and gear assemblies. This will reduce friction and prevent premature wear, prolonging the lifespan of the component.

Testing: After completing the inspection and any necessary repairs, conduct a test run to ensure the auger operates smoothly. Pay attention to any unusual noises or vibrations, which may indicate underlying issues that require further attention.

Transmission and Drive Mechanism Care

Proper maintenance of the transmission and drive components is essential for ensuring optimal performance and longevity of any machine. Regular attention to these elements can prevent significant issues and enhance the overall efficiency of operation. This section highlights crucial practices to keep these systems in top condition.

Regular Inspection: Frequent assessments of the drive mechanism are vital. Look for signs of wear, unusual noises, or any fluid leaks that could indicate potential problems. Early detection is key to preventing further damage.

Lubrication: Adequate lubrication is crucial for the smooth operation of the transmission. Use high-quality lubricants recommended for the specific system, and ensure that all moving parts are well-greased to minimize friction and wear.

Cleaning: Accumulation of dirt and debris can hinder the performance of the drive system. Regular cleaning of all components, including belts and gears, will help maintain their functionality and prevent premature wear.

Adjustment: Keeping the drive mechanism properly adjusted is necessary for optimal performance. Regularly check belt tension and alignment, and make necessary adjustments to ensure everything operates smoothly.

Replacement of Worn Parts: Components that show signs of significant wear should be replaced promptly. Neglecting to do so can lead to more extensive damage and costly repairs in the long run. Always consult the specifications to select appropriate replacement parts.

Safety Precautions for DIY Repairs

Engaging in self-servicing tasks can be rewarding, but it is essential to prioritize safety to prevent accidents and injuries. Understanding the necessary precautions will enhance the repair experience and ensure a secure environment.

Before commencing any maintenance work, it is advisable to equip oneself with the appropriate safety gear. This includes protective eyewear, gloves, and sturdy footwear. Additionally, ensuring a well-lit workspace free from clutter will help minimize risks associated with hazards.

| Safety Gear | Purpose |

|---|---|

| Protective Eyewear | To shield eyes from debris and harmful substances |

| Gloves | To protect hands from sharp edges and chemicals |

| Sturdy Footwear | To provide support and prevent foot injuries |

| Ear Protection | To guard against loud noises during operation |

Moreover, being aware of the equipment and tools being utilized is crucial. Familiarize yourself with their functions and limitations to avoid misuse. Always follow the manufacturer’s guidelines and keep an emergency kit nearby in case of unforeseen incidents.

Electrical System Maintenance

Maintaining the electrical framework of your equipment is essential for optimal performance and longevity. This section outlines the key practices and considerations necessary to ensure that the electrical components function smoothly, reducing the likelihood of malfunctions and enhancing overall efficiency.

Routine Inspection

Regular examination of electrical connections and components is crucial. Look for signs of wear, corrosion, or loose connections that could lead to operational issues. Implementing a schedule for inspections can help identify potential problems before they escalate, ensuring reliable functionality.

Battery Care

The power source requires special attention to maintain its effectiveness. Keep the battery terminals clean and free from corrosion, as this can hinder performance. Additionally, ensure that the battery is securely mounted and regularly charged to avoid unexpected failures.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect electrical connections | Monthly | Look for corrosion and loose wires. |

| Clean battery terminals | Every three months | Use a mixture of baking soda and water. |

| Test battery charge | Monthly | Ensure battery is fully charged before use. |

Preparing for Seasonal Storage

Proper preparation for seasonal storage is essential to ensure the longevity and optimal performance of your outdoor equipment. Taking a few steps before placing your machinery in storage can prevent damage and ensure it’s ready for use when needed again. This process involves cleaning, maintenance, and careful packing.

Cleaning and Maintenance

Before storage, thoroughly clean all components to remove dirt, debris, and any residues. Pay special attention to the engine, fuel system, and blades, as these areas can accumulate grime. Inspect for any signs of wear or damage that may need addressing before the next season.

Fuel and Fluids Management

Emptying the fuel tank is crucial to avoid contamination and degradation during storage. Alternatively, consider adding a fuel stabilizer to the remaining fuel to maintain its quality. Additionally, check and replace engine oil and other fluids to ensure everything is in top condition for the upcoming operational period.

Choosing Quality Replacement Parts

Selecting high-grade components for your equipment is crucial for maintaining optimal performance and longevity. Whether you are facing a malfunction or upgrading certain elements, the choice of parts significantly impacts overall functionality. Quality replacements ensure that your machinery operates smoothly and efficiently, ultimately saving time and costs associated with frequent repairs.

Importance of Compatibility

When sourcing new components, it is vital to ensure compatibility with your specific model. Mismatched parts can lead to operational issues and further damage. Always consult specifications and cross-reference parts to guarantee a proper fit, thus enhancing the overall effectiveness of your machinery.

Evaluating Quality Standards

Prioritize components that meet established quality standards. Look for parts from reputable manufacturers known for durability and reliability. Research customer reviews and product ratings to make informed decisions. Investing in high-quality replacements can prevent premature wear and enhance the lifespan of your equipment.