Comprehensive Guide to Honda Outboard Repair Manual

Maintaining the optimal performance of your aquatic propulsion system is essential for ensuring smooth navigation and enjoyment on the water. Understanding the intricacies of these powerful machines allows enthusiasts to extend their lifespan and enhance reliability, making every voyage memorable.

Regular upkeep is not just about addressing issues as they arise; it’s about proactively preventing potential problems. This involves familiarizing oneself with essential components and the necessary steps to service them effectively. With the right knowledge, you can tackle various challenges and keep your engine in prime condition.

This informative resource serves as a detailed reference for those looking to deepen their understanding of their marine engines. From routine inspections to troubleshooting complex issues, the information provided here will empower you to take control of your aquatic adventures.

Understanding Honda Outboard Engines

This section provides an overview of the key aspects related to marine propulsion systems, focusing on the internal workings, maintenance, and common issues faced by users. A solid grasp of these elements is essential for effective management and optimal performance of your vessel.

Core Components

Marine engines comprise several crucial parts that work in harmony to ensure smooth operation. Understanding these components can enhance troubleshooting and maintenance efforts:

- Powerhead: The main assembly housing the engine’s vital parts.

- Lower Unit: Contains gears and propeller, facilitating movement through water.

- Fuel System: Responsible for delivering the necessary energy for combustion.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Common Maintenance Practices

Routine upkeep is vital for longevity and reliability. Here are some essential practices to consider:

- Regular Oil Changes: Ensures engine lubrication and reduces wear.

- Fuel Filter Replacement: Keeps the fuel system clean and efficient.

- Inspection of Anodes: Protects against corrosion and prolongs component life.

- Gear Lubrication: Maintains smooth operation of the lower unit.

By familiarizing yourself with these foundational aspects, you can better understand how to enhance performance and ensure the durability of your marine propulsion system.

Common Issues with Outboard Motors

When it comes to marine engines, various complications can arise, affecting performance and reliability. Understanding these frequent challenges can help boat owners maintain their vessels more effectively. From power loss to starting difficulties, recognizing symptoms early is key to ensuring a smooth experience on the water.

1. Starting Difficulties: One of the most common problems faced by users is trouble starting the engine. This can stem from issues such as a drained battery, faulty spark plugs, or fuel delivery problems. Regular checks and maintenance of the ignition system can prevent these headaches.

2. Overheating: An overheating engine is a critical issue that can lead to severe damage. Common causes include blocked cooling passages, a malfunctioning water pump, or low coolant levels. Monitoring the temperature gauge and conducting routine inspections can help identify and rectify this issue early.

3. Fuel Problems: Fuel-related issues, including contamination or evaporation, can severely impact engine performance. Regularly inspecting fuel lines and filters can help ensure a clean supply. Using fresh, high-quality fuel is also essential for optimal operation.

4. Steering and Control Malfunctions: Difficulty steering or controlling the vessel can be both frustrating and dangerous. This may be caused by damaged cables, misaligned components, or lack of lubrication. Regular maintenance and proper adjustments can mitigate these risks.

5. Excessive Vibration: Unusual vibrations during operation can indicate mechanical issues such as misalignment or damaged components. Addressing these concerns promptly is vital to prevent further damage and ensure a safe boating experience.

By being aware of these common challenges, boat enthusiasts can take proactive steps to maintain their marine engines, ensuring a more enjoyable and trouble-free journey on the water.

Essential Tools for Repairing Honda Engines

Having the right equipment is crucial for anyone looking to maintain and troubleshoot marine propulsion systems effectively. A well-equipped workspace not only enhances efficiency but also ensures that tasks are performed safely and accurately. This section outlines the fundamental instruments needed for optimal service and upkeep of engine components.

Socket Set: A comprehensive socket set is indispensable. It allows for quick access to various fasteners, facilitating the disassembly and assembly of parts. Look for a set that includes both metric and imperial sizes to cover a range of applications.

Torque Wrench: Precision is vital in mechanical work. A torque wrench helps ensure that bolts and nuts are tightened to the manufacturer’s specifications, preventing damage from over-tightening and ensuring reliability.

Screwdrivers: A collection of screwdrivers, including flathead and Phillips types, is essential for working with different screws found in engine assemblies. Magnetic tips can be particularly helpful for retrieving dropped fasteners in tight spaces.

Pliers and Wrenches: Adjustable wrenches and various types of pliers provide versatility when gripping, twisting, or cutting components. They are necessary for tasks that require a strong grip or manipulation of stubborn parts.

Diagnostic Tools: Investing in diagnostic equipment, such as a multimeter, can significantly aid in identifying electrical issues. This tool allows you to measure voltage, current, and resistance, helping to pinpoint faults in the electrical system.

Cleaning Supplies: Proper maintenance involves keeping components free from debris and contaminants. Brushes, rags, and specialized cleaners will ensure that all parts remain in good condition, which is essential for longevity and performance.

Equipping yourself with these vital tools will greatly enhance your ability to service marine engines effectively, ensuring their optimal performance on the water.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficiency of your marine engine. Following a structured approach to maintenance helps identify potential issues early and keeps performance at its peak. This section outlines essential steps that every owner should follow to maintain their watercraft propulsion system effectively.

Initial Inspection

Begin by examining the exterior components for signs of wear or damage. Look for any cracks, corrosion, or loose fittings. Ensure that the cooling system is free of debris and that the intake is unobstructed. Checking the fuel system for leaks or contamination is crucial for preventing operational issues.

Fluid Changes and Replacements

Regularly changing the lubricants and coolants is vital. Drain the old oil and replace it with fresh, high-quality lubricant, ensuring it meets the required specifications. Don’t forget to inspect and replace the fuel filter as needed, and top off the coolant to maintain optimal operating temperatures. Following these steps will significantly enhance the reliability and efficiency of your engine.

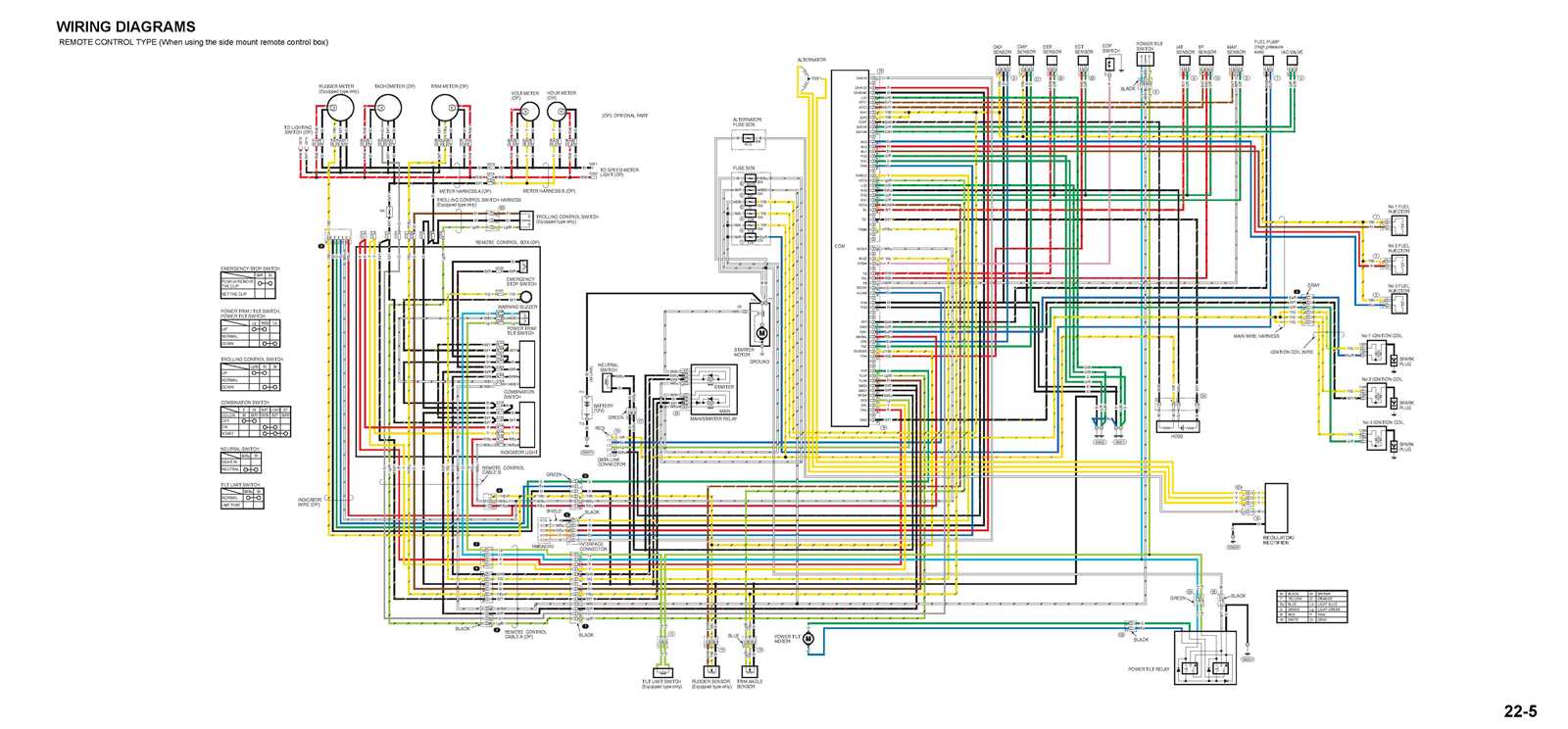

Identifying Electrical Problems in Outboards

Understanding the signs of electrical issues in marine engines is crucial for maintaining optimal performance. Detecting these problems early can prevent significant damage and costly repairs. This section focuses on common indicators of electrical malfunctions and offers guidance on troubleshooting techniques.

Common Symptoms of Electrical Issues

Various symptoms can indicate electrical troubles in marine engines. Recognizing these signs promptly is essential for effective intervention. Below are some typical manifestations:

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Dead battery, faulty ignition switch |

| Intermittent power loss | Loose connections, damaged wiring |

| Overheating | Faulty sensors, electrical short |

| Unresponsive control panel | Corroded terminals, blown fuses |

Troubleshooting Techniques

Effective troubleshooting involves a systematic approach to pinpointing issues. Start by inspecting all visible wiring for damage or corrosion. Use a multimeter to test voltage and continuity across key components. Additionally, verifying ground connections is crucial, as poor grounding can lead to erratic performance. Following these steps will help identify and resolve electrical faults efficiently.

Fuel System Troubleshooting Techniques

When facing issues with the fuel delivery system, a systematic approach can help identify and resolve problems effectively. Understanding how various components interact and function together is crucial for diagnosing faults. A methodical examination allows for pinpointing malfunctions that can affect performance and efficiency.

1. Visual Inspection: Start with a thorough visual check of the entire fuel system. Look for signs of leaks, cracks, or corrosion on hoses and fittings. Ensure all connections are tight and secure.

2. Fuel Quality Assessment: Evaluate the fuel itself. Old or contaminated fuel can cause starting issues and erratic performance. Check for water separation and debris in the fuel tank.

3. Filter and Line Examination: Inspect fuel filters for clogs. A dirty filter can restrict flow, leading to insufficient fuel delivery. Clear any blockages in the fuel lines and replace any damaged components.

4. Pump Functionality: Test the fuel pump’s operation. Ensure it is delivering the correct pressure and volume. Listen for unusual sounds that might indicate wear or malfunction.

5. Systematic Component Testing: Utilize diagnostic tools to check sensors and electronic components involved in fuel management. Ensure they are functioning within specified parameters.

6. Pressure Tests: Conduct pressure tests at various points in the system. This will help identify leaks or areas of reduced pressure that can hinder performance.

By following these techniques, one can effectively troubleshoot fuel-related issues, ensuring optimal performance and reliability of the engine.

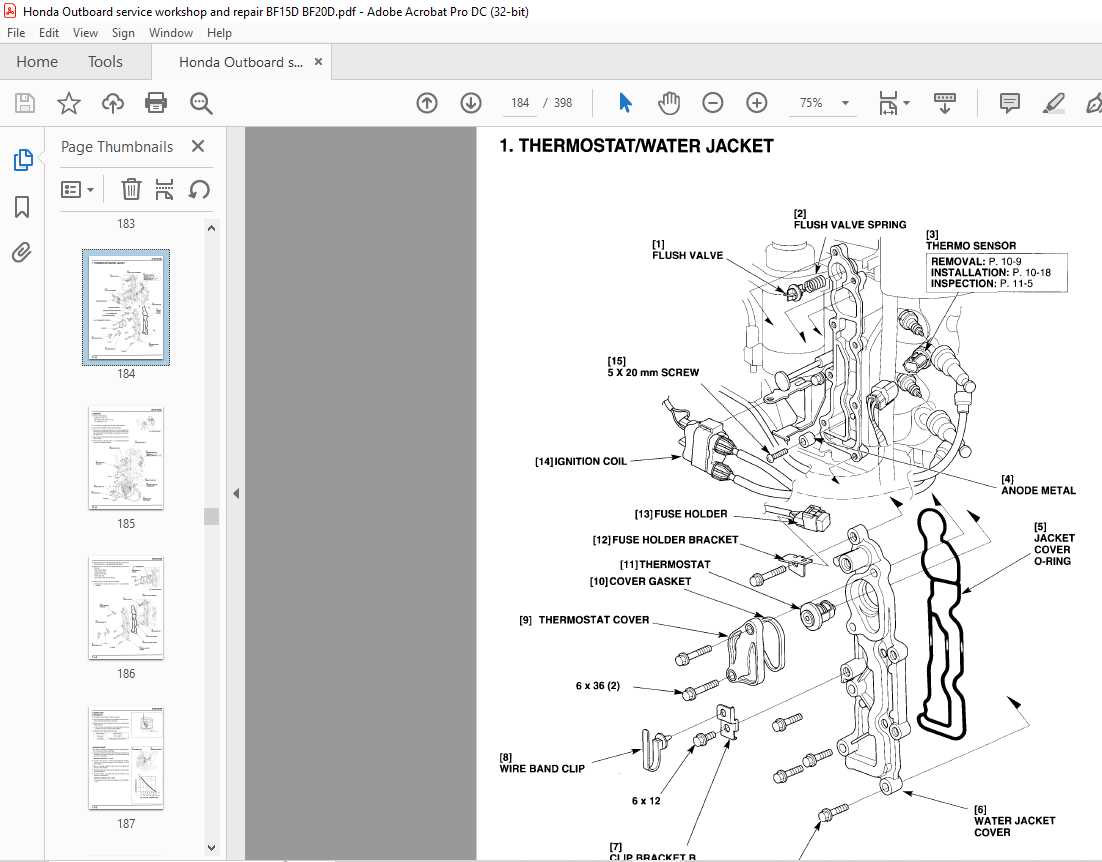

Cooling System Inspection and Repair

Maintaining an efficient thermal management system is crucial for optimal engine performance. This section focuses on evaluating the cooling components to ensure they function correctly and prevent overheating issues. Regular assessment and necessary adjustments will extend the lifespan of the engine and enhance its reliability.

Inspection Steps

To effectively inspect the cooling system, follow these steps:

- Check the water intake for obstructions.

- Inspect hoses and connections for wear and leaks.

- Examine the thermostat for proper operation.

- Assess the condition of the water pump impeller.

- Monitor temperature gauges during operation.

Common Issues and Solutions

Identifying and addressing typical problems can prevent more significant failures:

- Clogged Intake: Clear any debris blocking the water intake.

- Leaking Hoses: Replace any damaged or worn hoses immediately.

- Thermostat Malfunction: Test and replace the thermostat if it does not open or close correctly.

- Worn Impeller: Regularly replace the impeller to ensure effective water circulation.

- Overheating: Investigate the root cause and rectify any identified issues promptly.

Gearbox and Propeller Maintenance Tips

Proper upkeep of the transmission and propeller system is crucial for ensuring smooth performance and longevity of your vessel. Regular attention to these components not only enhances efficiency but also prevents costly repairs down the line.

1. Routine Inspections: Regularly check for any signs of wear or damage. Look for cracks, corrosion, or loose connections in the gearbox and propeller. Early detection can save time and resources.

2. Lubrication: Keep all moving parts well-lubricated. Use the recommended grease for your specific setup. This reduces friction and helps maintain optimal functionality.

3. Seal Checks: Inspect seals for integrity. Worn or damaged seals can lead to fluid leaks, compromising performance. Replace any seals that show signs of deterioration.

4. Propeller Cleaning: Remove any debris, barnacles, or marine growth from the propeller. This not only improves performance but also prevents imbalance that could damage the gearbox.

5. Alignment and Tightening: Ensure that the propeller is properly aligned and securely fastened. Loose propellers can cause vibrations that may lead to severe damage over time.

6. Gear Oil Change: Change the gear oil as per the manufacturer’s recommendations. Contaminated oil can cause wear and overheating, affecting overall performance.

7. Storage Precautions: When not in use, take care to store your equipment properly. Use covers and ensure that the components are protected from the elements to prolong their life.

Following these tips will help maintain the efficiency and reliability of your propulsion system, allowing you to enjoy smooth sailing for years to come.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance tasks is crucial for both the individual performing the work and the equipment itself. Proper precautions minimize risks and enhance efficiency, making the process smoother and more effective.

Personal Protective Equipment

Wearing appropriate protective gear is essential. Items such as gloves, goggles, and masks can shield against potential hazards like chemicals, debris, and sharp objects. Always assess the situation to determine the necessary equipment to safeguard your well-being.

Workspace Organization

A tidy and well-organized workspace significantly reduces the likelihood of accidents. Ensure tools and materials are stored properly, and remove any unnecessary items from the vicinity. A clear environment allows for better focus and reduces distractions, ultimately promoting safer handling of all components.

When to Seek Professional Help

Understanding when to call in an expert can save time and prevent further complications. While many issues can be addressed with basic knowledge and tools, certain situations demand the expertise of a trained technician. Recognizing the signs that indicate a need for professional intervention is crucial for the longevity and performance of your marine engine.

Signs Indicating Professional Assistance is Needed

Several indicators may suggest that it’s time to seek expert help:

| Indicator | Description |

|---|---|

| Persistent Problems | If issues recur despite attempts at fixing them, it may signal a deeper underlying problem. |

| Unusual Noises | Strange sounds during operation can indicate mechanical failure that needs expert evaluation. |

| Fluid Leaks | Visible leaks may suggest serious internal damage that requires specialized repair. |

| Electrical Issues | Complex electrical problems often require advanced diagnostics that professionals can provide. |

Benefits of Professional Assistance

Engaging a skilled technician can lead to more efficient resolutions and can also help in preventing future issues. Experts not only possess the necessary tools but also have experience that can identify problems quickly and accurately, ultimately saving time and money in the long run.

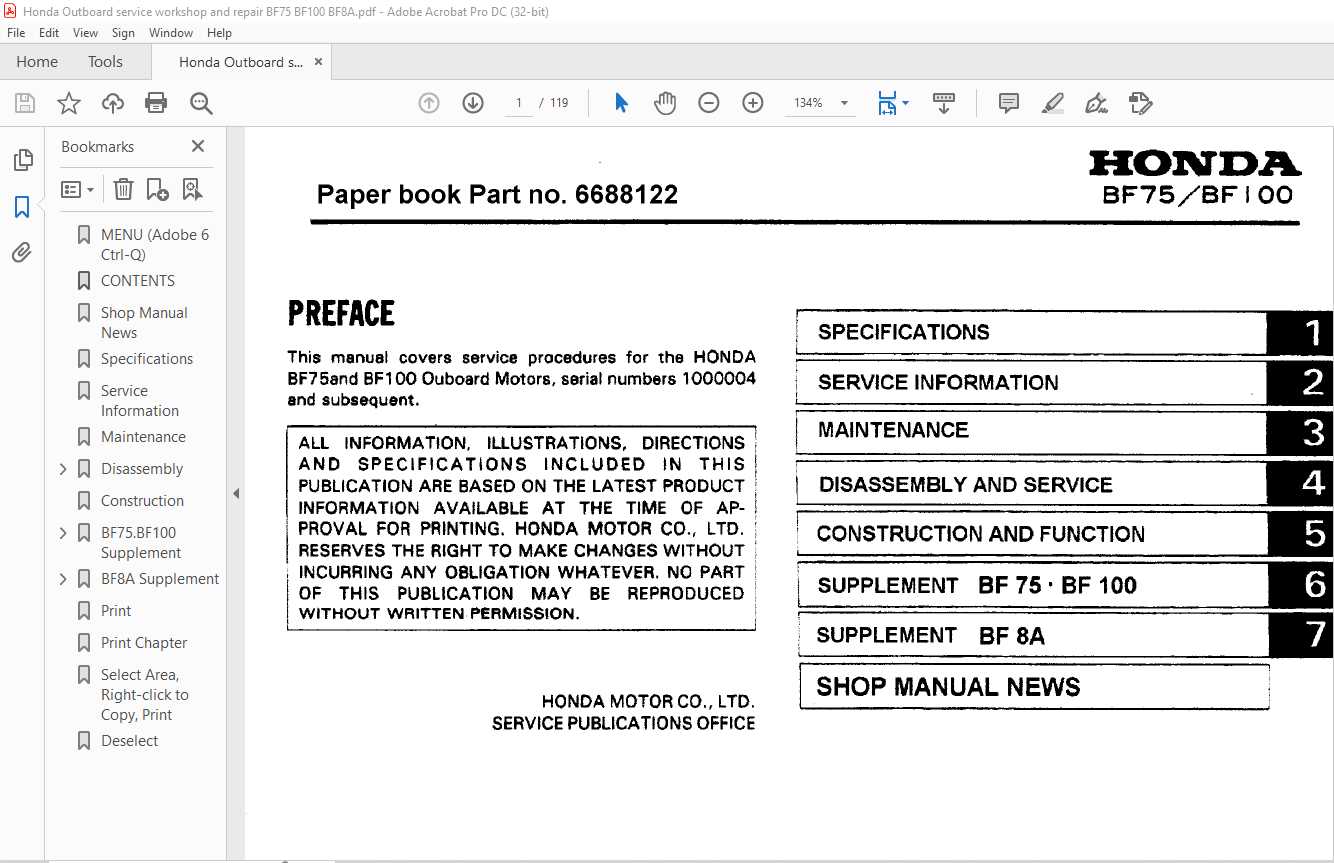

Resources for Honda Outboard Owners

For enthusiasts of aquatic adventures, having reliable information and tools is essential for maintaining optimal performance and longevity of their marine equipment. This section highlights valuable resources that provide support, guidance, and essential insights for those dedicated to keeping their vessels in top condition.

Online Communities and Forums

Engaging with fellow boat owners can be incredibly beneficial. Online forums and community groups offer a platform for exchanging tips, troubleshooting advice, and shared experiences. Websites dedicated to marine enthusiasts often have sections specifically for discussions about maintenance techniques, common issues, and upgrades. Joining these communities fosters a sense of camaraderie and allows for a wealth of knowledge to be accessed.

Official Documentation and Guides

Accessing official documentation is crucial for understanding the intricacies of your marine equipment. Manufacturer websites typically provide downloadable resources that cover specifications, maintenance schedules, and troubleshooting techniques. These guides are designed to enhance the owner’s understanding and facilitate proper care. Utilizing these official resources ensures that you are following recommended practices for safety and efficiency.

Storing Your Outboard for Longevity

Properly preserving your marine engine during the off-season is crucial for maintaining its performance and extending its lifespan. Following a few essential steps ensures that your equipment remains in optimal condition, ready for use when the time comes.

Here are key practices to consider:

- Clean Thoroughly: Remove any dirt, salt, or debris from the exterior and internal components.

- Drain Fluids: Empty the fuel tank and replace with fresh fuel to prevent varnishing. Also, drain the oil and replace it with new oil to safeguard the internal parts.

- Check for Damage: Inspect for any signs of wear or damage that may require attention before storage.

- Protect with Lubrication: Apply a corrosion inhibitor to prevent rust and other forms of degradation.

- Store in a Dry Location: Choose a cool, dry area to keep your equipment safe from moisture and temperature fluctuations.

By following these guidelines, you can significantly enhance the durability of your marine engine, ensuring it performs reliably for many seasons to come.