Comprehensive Guide to Honda Recon Repair Manual

In the world of outdoor vehicles, ensuring peak performance is crucial for an enjoyable experience. This guide offers insights into the intricacies of upkeep and problem-solving techniques, catering to enthusiasts and casual users alike.

Whether you’re facing common challenges or seeking to enhance functionality, understanding the essential components is key. This resource aims to empower users with knowledge, enabling them to tackle issues confidently.

With a focus on practical solutions and detailed instructions, you will delve into the ultimate strategies for maintaining your vehicle. Prepare to enhance your skills and extend the life of your outdoor companion.

Understanding Honda Recon Specifications

Grasping the essential details of your all-terrain vehicle is crucial for optimal performance and longevity. This section explores key attributes and metrics that define the model, allowing users to make informed decisions and understand their machine better. From engine capacity to handling characteristics, each specification plays a vital role in how the vehicle operates in various environments.

Focusing on power output, torque ratings, and overall weight can greatly influence your experience. Familiarity with these aspects not only enhances riding confidence but also aids in maintenance and upgrades. By delving into these specifications, enthusiasts can tailor their vehicle to meet personal preferences and specific riding conditions.

Common Issues with Honda Recon

Many owners of these all-terrain vehicles encounter specific challenges that can affect performance and reliability. Understanding these frequent problems can help in maintaining optimal functionality and enhancing the riding experience. Below are some of the typical concerns faced by users, along with potential solutions and maintenance tips.

| Issue | Description | Solution |

|---|---|---|

| Starting Problems | Difficulty in starting the engine can arise from battery issues or fuel delivery problems. | Check the battery charge and connections; inspect fuel lines for clogs. |

| Overheating | Excessive heat may occur due to low coolant levels or a malfunctioning radiator. | Regularly check coolant levels and inspect the cooling system for leaks. |

| Transmission Issues | Shifting difficulties can be caused by worn components or low fluid levels. | Examine transmission fluid levels and replace any worn parts as necessary. |

| Brake Failure | Inadequate braking response often results from worn pads or low fluid. | Inspect and replace brake pads, and ensure the brake fluid is at the correct level. |

| Electrical Failures | Malfunctions in the electrical system may be due to damaged wiring or faulty connections. | Conduct a thorough inspection of wiring and connections; replace any damaged parts. |

Being aware of these common problems and addressing them promptly can significantly extend the lifespan of the vehicle and ensure a smoother riding experience.

Tools Needed for Repair Tasks

When tackling maintenance and troubleshooting tasks on your vehicle, having the right equipment is essential for achieving efficient and effective results. Proper tools not only facilitate the process but also ensure that you can address various issues with confidence and precision. Below is a comprehensive overview of the essential instruments required for such endeavors.

Essential Tool Categories

Understanding the categories of tools can help in organizing your toolkit. The primary types typically include hand tools, power tools, and diagnostic instruments. Each category serves a specific purpose and is crucial for various tasks.

| Tool Type | Common Tools | Purpose |

|---|---|---|

| Hand Tools | Wrenches, Screwdrivers, Pliers | For tightening, loosening, and manipulating various components. |

| Power Tools | Drills, Impact Wrenches | For heavy-duty tasks requiring more force and speed. |

| Diagnostic Tools | Multimeter, OBD-II Scanner | For troubleshooting electrical systems and reading error codes. |

Additional Supplies

In addition to the primary tools, certain supplies enhance the overall effectiveness of maintenance tasks. Fasteners, lubricants, and cleaning agents play vital roles in ensuring that all components function smoothly and are well-maintained. Having these items readily available can save time and improve the quality of your work.

Step-by-Step Repair Process Overview

This section provides a detailed outline of the procedure for restoring functionality to your vehicle. Following a systematic approach ensures that each aspect is addressed methodically, resulting in effective solutions and optimal performance.

Initial Assessment

Begin by evaluating the current state of the machine. Identify visible issues and listen for unusual sounds during operation. This initial inspection is crucial for determining the areas that require attention and prioritizing the tasks ahead.

Disassembly and Inspection

Once the assessment is complete, proceed with the careful disassembly of components. Take note of any damaged parts and clean the area to ensure a clear view of the underlying mechanisms. Thorough inspection at this stage will aid in making informed decisions about necessary replacements or repairs.

Maintenance Tips for Longevity

Ensuring the long-term performance of your all-terrain vehicle requires consistent care and attention. By following some essential maintenance practices, you can enhance its lifespan and reliability. Below are several tips to keep your vehicle in top shape.

- Regular Cleaning: Remove dirt, mud, and debris after every use to prevent corrosion and wear.

- Fluid Checks: Frequently inspect and change engine oil, coolant, and other essential fluids as recommended by the manufacturer.

- Tire Maintenance: Keep tires properly inflated and check for any signs of damage or uneven wear.

In addition to these foundational practices, consider the following:

- Battery Care: Inspect battery terminals for corrosion and ensure connections are secure.

- Brake Inspection: Regularly check brake pads and fluid levels to ensure optimal stopping power.

- Storage Precautions: When not in use, store the vehicle in a dry, covered area to protect it from the elements.

By incorporating these strategies into your maintenance routine, you will help ensure that your vehicle remains functional and efficient for years to come.

Electrical System Troubleshooting Guide

This section aims to assist users in diagnosing and resolving common issues related to the electrical components of their vehicle. Understanding the various elements of the electrical system is crucial for effective troubleshooting and maintenance. With a systematic approach, you can identify problems and restore functionality efficiently.

Common Symptoms and Their Causes

Several symptoms may indicate electrical malfunctions. For instance, if the vehicle fails to start, it could be due to a drained battery or faulty starter motor. Flickering lights may suggest a poor connection or a failing alternator. Each symptom often has multiple potential causes, requiring careful examination of the system.

Basic Troubleshooting Steps

Begin by checking the battery connections for corrosion and ensuring they are tight. Utilize a multimeter to measure voltage and assess the battery’s health. Next, inspect fuses and relays for damage. If everything appears intact, move on to the wiring harnesses for any signs of wear or fraying. Document your findings throughout the process to track the steps taken and any parts replaced.

Should you encounter persistent issues, consider consulting a professional technician. Timely attention to electrical problems can prevent more extensive damage and ensure the longevity of your vehicle.

Engine Overhaul Instructions

This section provides a comprehensive guide for disassembling, inspecting, and reassembling the power unit. Proper procedures ensure optimal performance and longevity of the engine. Following these instructions will help in identifying worn components and making necessary adjustments or replacements.

Preparation Steps

Before starting the overhaul process, gather all necessary tools and materials. Create a clean workspace to avoid contamination of engine parts. It’s also advisable to have a detailed schematic of the engine layout for reference.

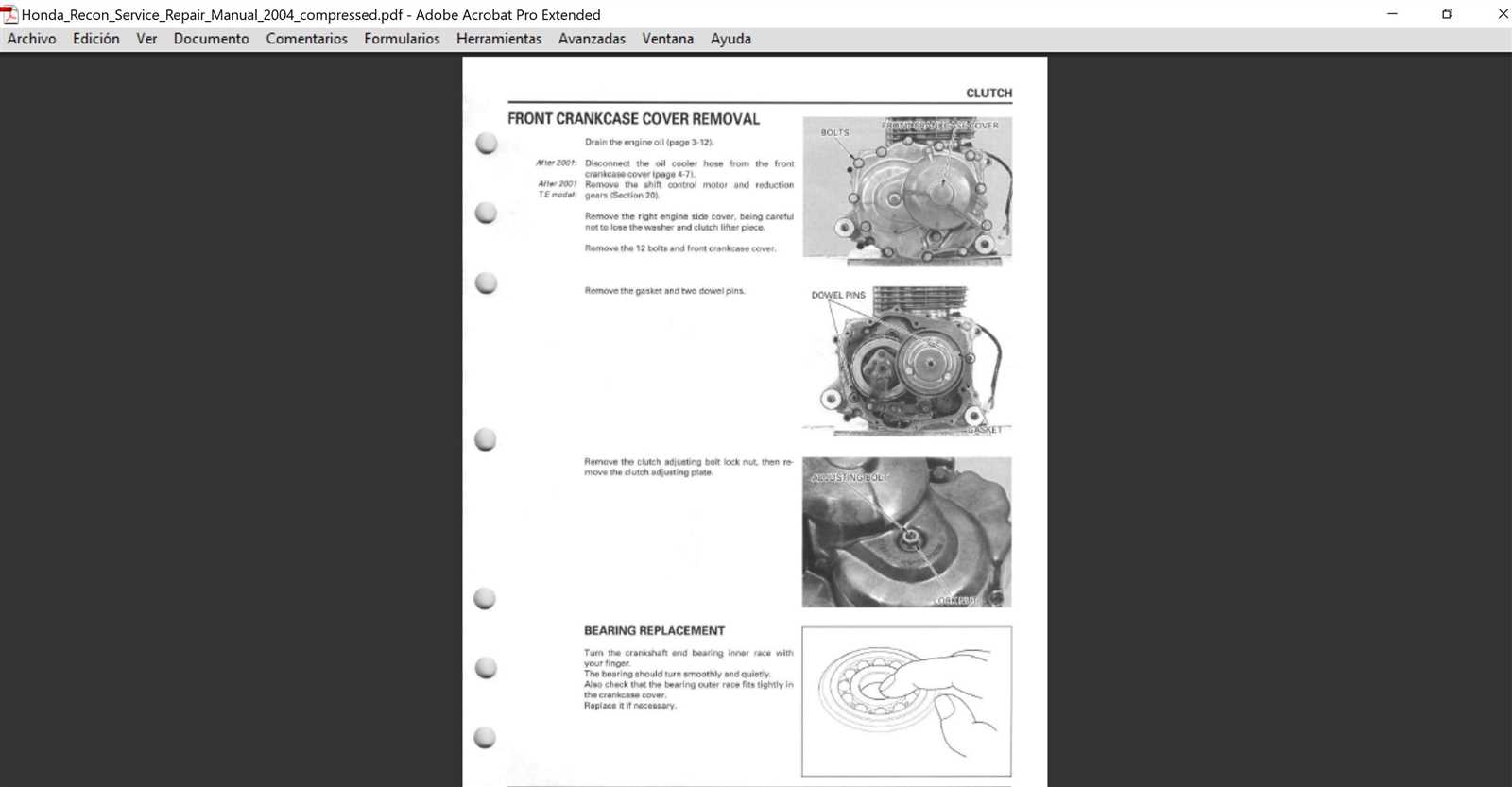

Disassembly Process

Begin by removing all external components connected to the engine. Follow these steps:

| Step | Description |

|---|---|

| 1 | Drain all fluids, including oil and coolant, to prevent spills. |

| 2 | Remove the air intake system and exhaust components. |

| 3 | Detach the electrical connections and sensors. |

| 4 | Unscrew the engine mounts and lift the unit out of the frame. |

| 5 | Take apart the engine by removing the cylinder head and oil pan. |

Once disassembled, carefully inspect each part for wear and damage. This will help determine which components need to be replaced or refurbished before reassembly.

Replacing the Transmission Components

Maintaining the functionality of the power transfer system is crucial for optimal performance. This section provides an overview of the process involved in substituting the essential parts that facilitate gear shifting and torque distribution.

Tools and Materials Needed

- Socket set

- Torque wrench

- Replacement components

- Gasket maker

- Cleaning solvent

Step-by-Step Procedure

- Begin by ensuring the vehicle is on a flat surface and securely supported.

- Remove the necessary panels to access the transmission assembly.

- Disconnect the battery to prevent electrical shorts during the process.

- Carefully detach the existing components, noting their arrangement for reinstallation.

- Clean all surfaces thoroughly to ensure a proper seal with new parts.

- Install the new components in the reverse order of removal, applying gasket maker where necessary.

- Reattach the battery and panels, ensuring everything is secured properly.

- Test the system by running the vehicle and checking for any abnormalities.

Braking System Maintenance Essentials

The braking system is a critical component of any vehicle, ensuring safety and control during operation. Regular upkeep is vital to maintain optimal performance and prevent potential failures. By following a systematic approach to maintenance, vehicle owners can ensure their braking systems operate effectively and reliably.

Inspection of Brake Components

Routine inspection of brake components is essential for identifying wear and tear before they lead to serious issues. Check the condition of brake pads, rotors, and calipers regularly. Look for signs of uneven wear, cracks, or corrosion. Replacing worn components promptly can prevent further damage and enhance overall braking efficiency.

Fluid Quality and Levels

Brake fluid is crucial for transferring force from the pedal to the brakes themselves. It’s important to monitor the quality and levels of the fluid. If the fluid appears dirty or if the level is low, it may indicate a leak or contamination. Regularly replacing the fluid, as recommended by the manufacturer, will help maintain hydraulic pressure and responsiveness.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on your vehicle is paramount. Proper precautions help prevent accidents and injuries, creating a secure environment for both the individual performing the task and those nearby. Awareness of potential hazards and adopting appropriate measures can significantly reduce risks associated with mechanical work.

Personal Protective Equipment

Wearing suitable personal protective equipment (PPE) is essential. Always use gloves to protect your hands from sharp objects and chemicals. Safety goggles or glasses should be worn to shield your eyes from debris and harmful substances. Additionally, sturdy footwear can help prevent injuries from falling tools or equipment.

Workspace Organization

Maintaining a tidy workspace contributes to safety. Ensure that all tools are stored properly and that the area is free from clutter. Adequate lighting is also critical, as it allows for better visibility of small components and reduces the likelihood of accidents. Make sure to have a fire extinguisher nearby in case of emergencies.