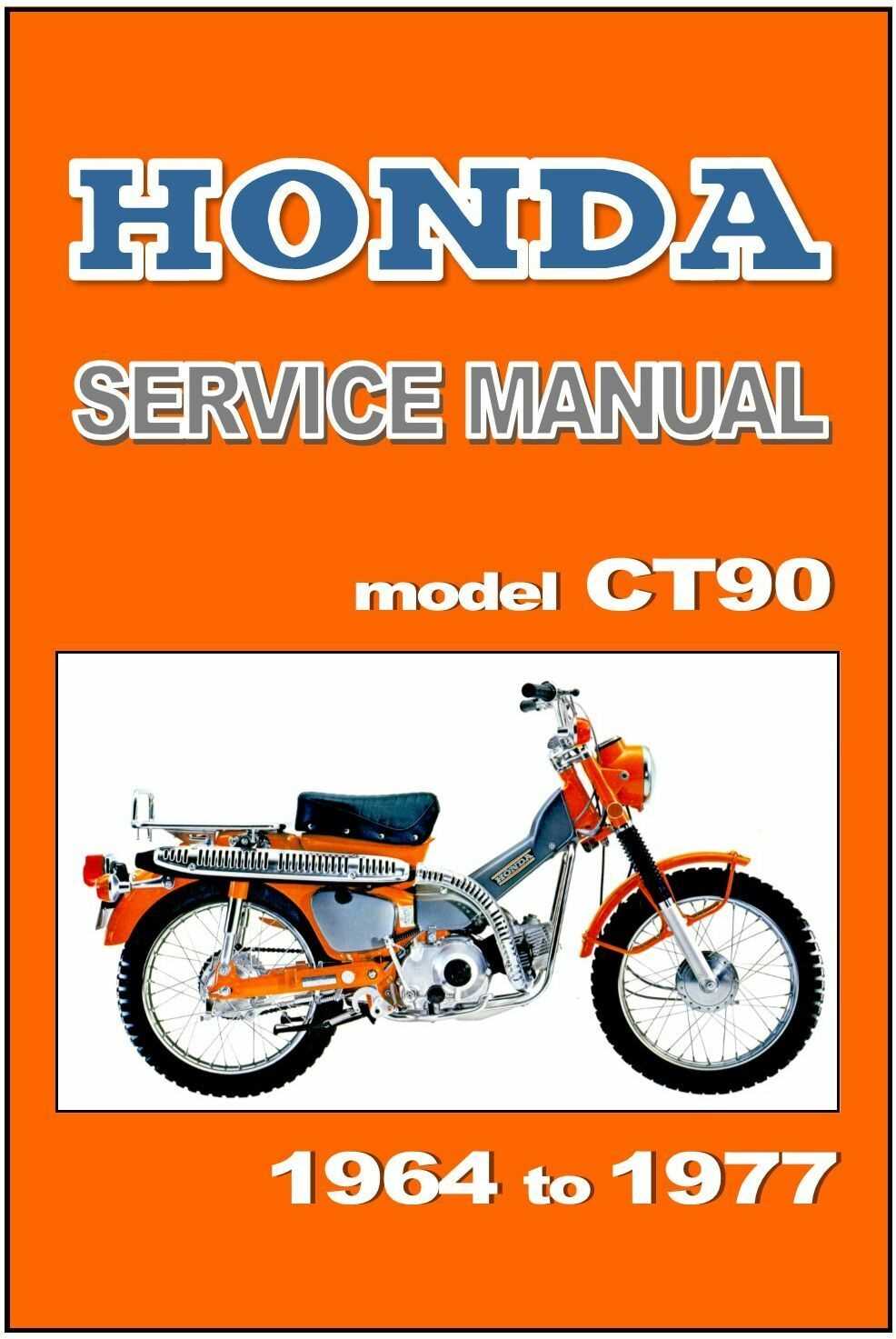

Honda Trail 90 Repair Guide

Maintaining a classic motorcycle is essential for ensuring its longevity and optimal performance. This section provides insights into common practices that enthusiasts and owners can adopt to keep their machines in top shape. From basic upkeep to more detailed interventions, understanding the nuances of motorcycle care is vital.

Effective maintenance encompasses a range of procedures aimed at addressing wear and tear over time. Regular inspections, fluid changes, and part replacements play a crucial role in preventing breakdowns and enhancing the overall riding experience. By following structured guidelines, owners can safeguard their vehicles against potential issues.

For those eager to delve deeper into specific tasks, a comprehensive overview of troubleshooting techniques and solutions is invaluable. Whether you are a seasoned mechanic or a novice, equipping yourself with the right knowledge will empower you to tackle challenges confidently and efficiently.

tags: Understanding the Honda Trail 90

tags: Understanding the Honda Trail 90″>

tags: Understanding the Honda Trail 90″>

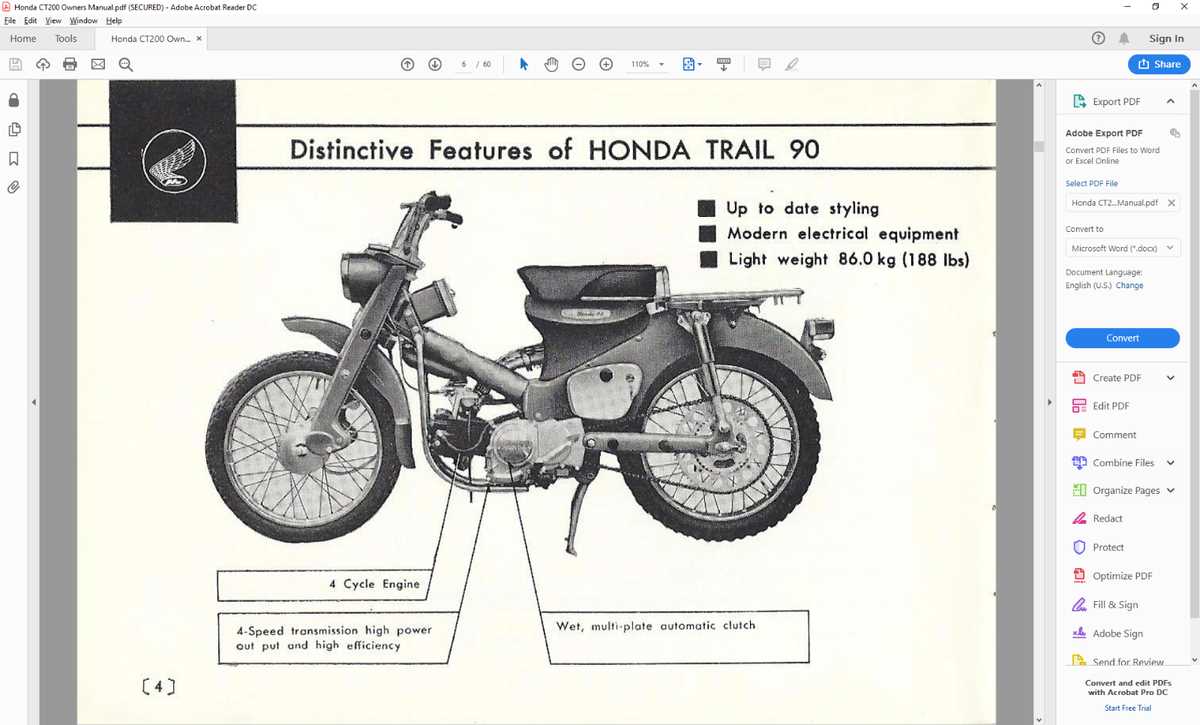

The vehicle in question is a classic two-wheeled machine, known for its reliability and versatility. This section aims to provide a comprehensive overview, focusing on essential aspects that enthusiasts and owners should consider when maintaining and enhancing performance.

Historical Context: Understanding the background of this model can greatly enhance appreciation for its design and functionality. This vehicle has a rich legacy, appealing to a wide range of riders over the decades.

Technical Specifications: Familiarity with key specifications is vital for effective maintenance. Insights into engine capacity, weight, and features can guide owners in making informed decisions regarding upgrades and repairs.

Common Issues: Identifying typical challenges faced by users allows for proactive measures. By addressing these issues early, riders can ensure their machine remains in optimal condition.

Maintenance Tips: Regular upkeep is crucial for longevity. Simple yet effective maintenance strategies can prevent larger problems and enhance the overall riding experience.

Common Issues and Solutions

This section addresses frequent problems encountered by users of small motorcycles and offers practical solutions to ensure optimal performance. By understanding typical challenges, owners can effectively troubleshoot and maintain their vehicles.

Electrical System Troubles

One of the most common issues involves the electrical system, which can lead to starting difficulties or dim lighting. It is essential to check battery connections and wiring integrity regularly.

| Issue | Solution |

|---|---|

| Dead Battery | Charge or replace the battery |

| Flickering Lights | Inspect wiring and connections |

| Starter Problems | Test starter motor and switch |

Fuel and Performance Concerns

Another area that often requires attention is the fuel system. Issues such as poor acceleration or engine stalling can usually be traced back to fuel delivery problems.

| Issue | Solution |

|---|---|

| Clogged Fuel Filter | Replace the fuel filter |

| Stale Fuel | Drain and refill with fresh fuel |

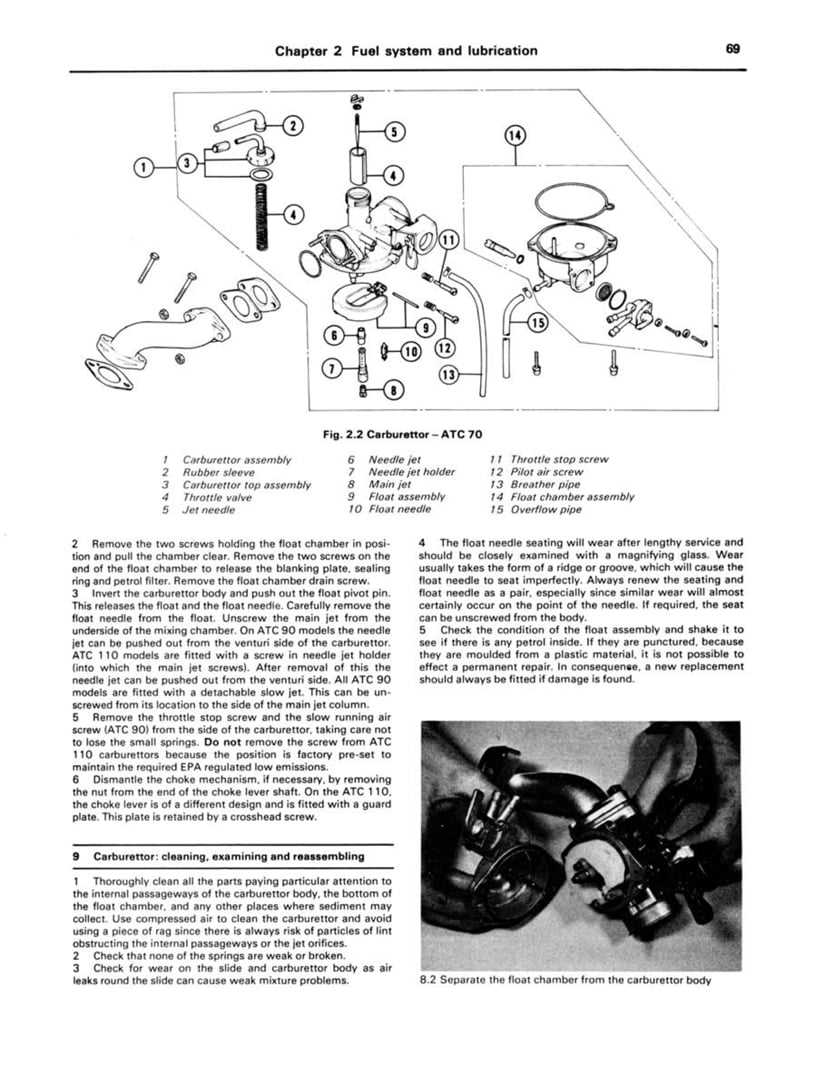

| Carburetor Malfunction | Clean or rebuild the carburetor |

Maintenance Tips for Longevity

Ensuring the prolonged performance of your vehicle requires regular care and attention. Implementing a few essential practices can significantly enhance its lifespan and reliability, allowing for a smoother riding experience over time.

Regular Inspections

Conduct frequent checks on key components, including tires, brakes, and fluid levels. Early detection of wear or damage can prevent more significant issues down the line, ensuring your vehicle remains in optimal condition.

Proper Cleaning and Lubrication

Maintaining cleanliness is crucial for preventing rust and corrosion. Regularly clean the frame and other exposed parts. Additionally, lubricating moving components will reduce friction and wear, promoting better functionality.

Essential Tools for Repair

Having the right equipment is crucial for maintaining and fixing vehicles effectively. A well-stocked toolkit not only simplifies the process but also ensures that tasks are completed safely and efficiently. Understanding which tools are fundamental can make a significant difference in performance and ease during any service task.

Basic hand tools such as wrenches, screwdrivers, and pliers are essential for any maintenance work. They provide the versatility needed for various tasks, from tightening bolts to adjusting components. Additionally, specialized tools designed for specific functions can enhance the quality of work and prevent potential damage to delicate parts.

For effective diagnostics, incorporating measuring instruments like multimeters and pressure gauges is vital. These tools assist in accurately assessing the condition of different systems and identifying any underlying issues. Furthermore, a sturdy workbench and quality lighting can create an ideal workspace, promoting both safety and productivity.

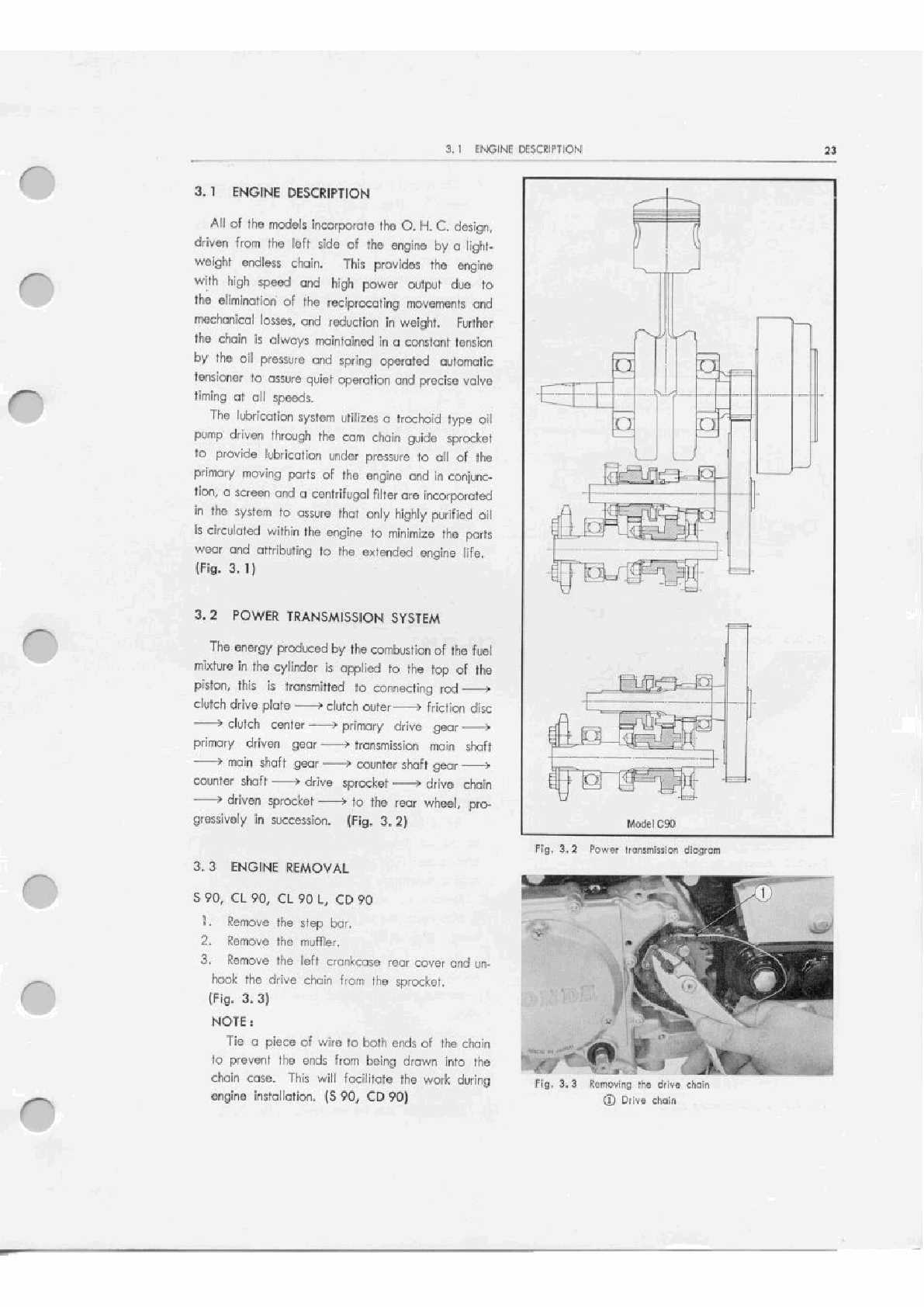

Engine Overhaul Procedures

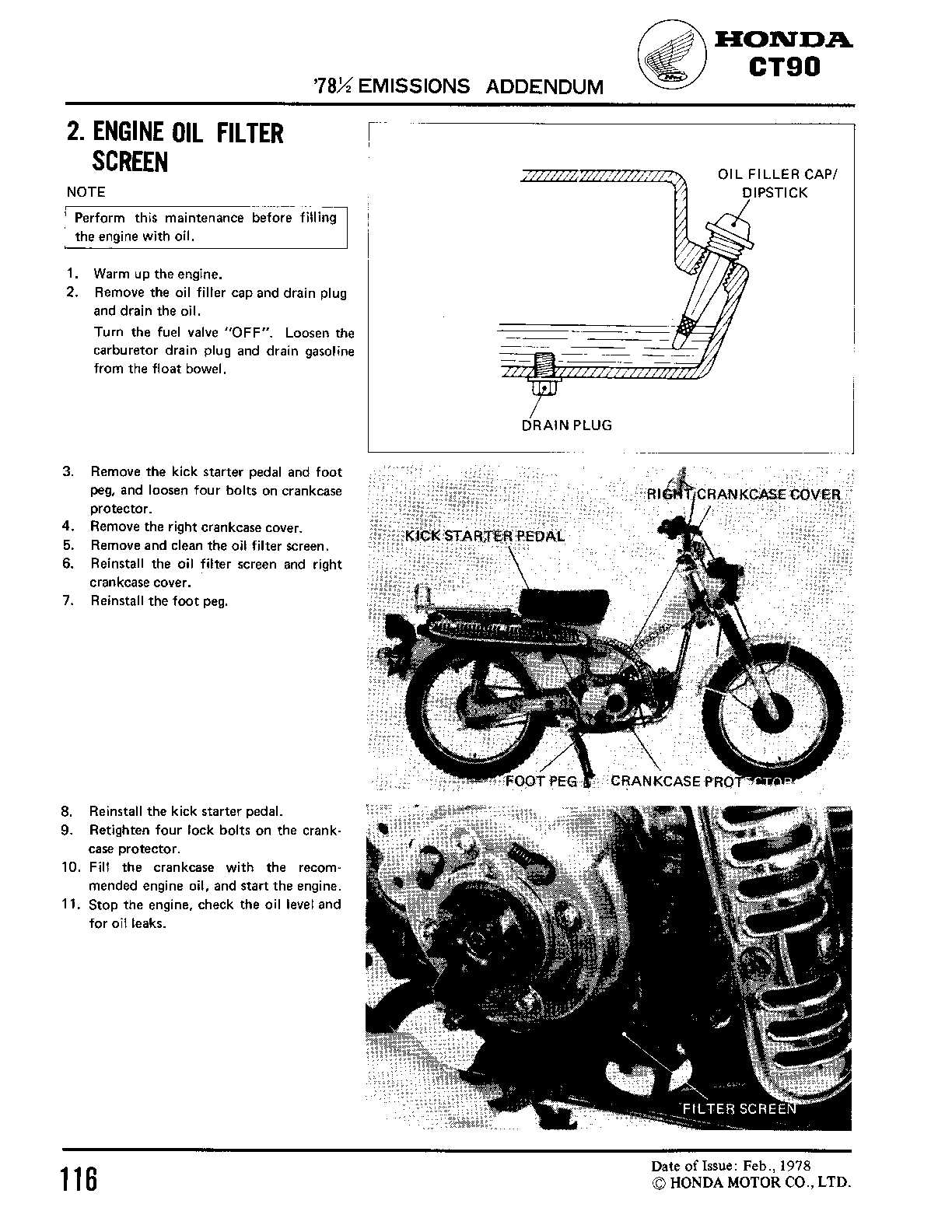

Overhauling the engine is a crucial process that ensures optimal performance and longevity of your vehicle. This procedure involves a thorough inspection and refurbishment of various engine components, which may include the cylinder head, pistons, and crankshaft. Proper execution of these tasks can restore functionality and efficiency, enhancing the overall driving experience.

Disassembly and Inspection

The first step in the overhaul process is disassembling the engine. Carefully remove all components while documenting their condition. Inspect each part for wear, damage, or any signs of failure. This stage is essential for determining which components need replacement and which can be reused after cleaning and servicing.

Reassembly and Testing

After completing the necessary repairs and replacements, reassemble the engine with precision. Follow the manufacturer’s specifications for torque settings and assembly sequences to ensure everything fits correctly. Once reassembled, conduct tests to verify the engine’s performance and make any necessary adjustments before putting the vehicle back into operation.

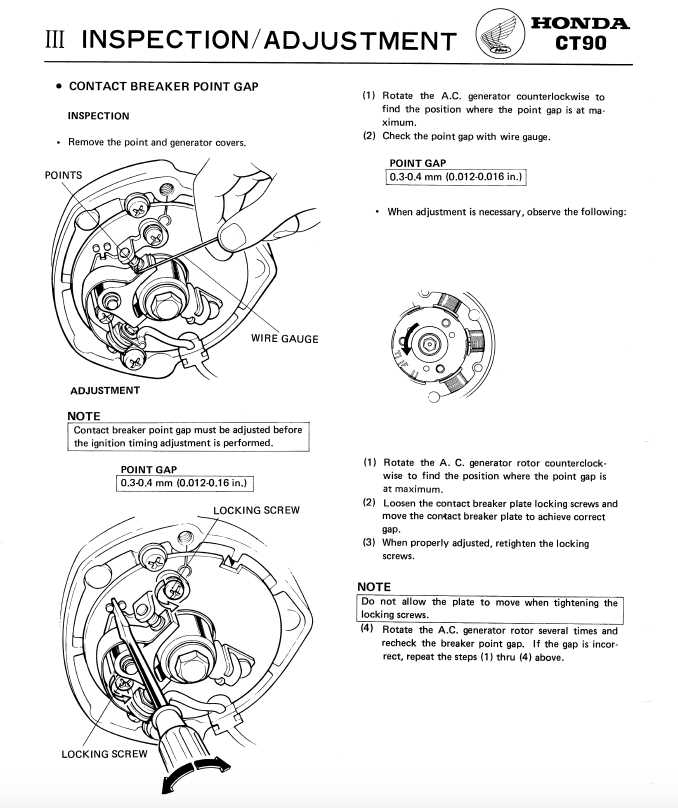

Electrical System Troubleshooting

Diagnosing issues within the electrical system is essential for ensuring optimal performance. Understanding the components involved and the common symptoms of failure can greatly assist in identifying and resolving problems efficiently.

Common Symptoms of Electrical Issues

- Inconsistent lighting or dimming lights

- Unresponsive starting mechanism

- Flickering indicators or gauges

- Unexpected electrical failures in accessories

Steps for Troubleshooting

- Check the battery voltage and connections to ensure proper contact.

- Inspect fuses for any signs of damage or blown components.

- Examine wiring for frays, corrosion, or loose connections.

- Test the charging system to confirm it is functioning correctly.

By following these steps, you can systematically address electrical system challenges and restore functionality.

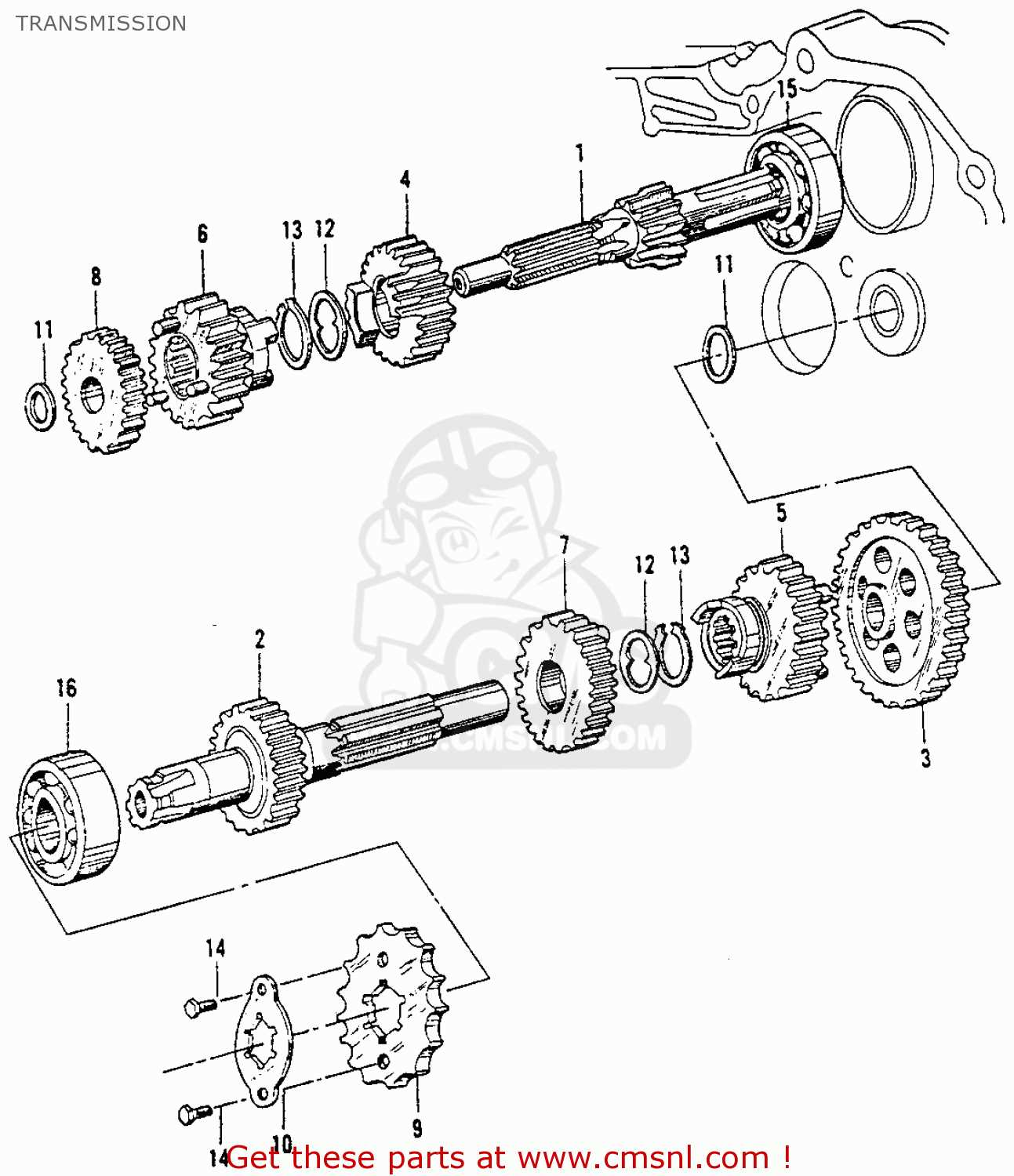

Transmission and Gear Adjustments

The functionality of a vehicle’s transmission system is crucial for optimal performance and efficiency. Proper adjustments ensure that the gear shifting is smooth, providing a seamless driving experience. Regular checks and calibrations can prevent potential issues, enhancing both reliability and longevity of the mechanism.

Understanding the Components

The transmission consists of various components that work in harmony. Familiarizing yourself with these parts, including gears, linkages, and the clutch mechanism, is essential for effective adjustments. Each element plays a significant role in how power is transferred from the engine to the wheels.

Adjustment Process

Begin the adjustment process by inspecting the current alignment of the gear selector. Misalignment can lead to difficulties in shifting. Adjust the linkage as necessary, ensuring that it operates smoothly across all gears. It’s also vital to check the clutch cable tension, as improper tension can affect engagement and disengagement, impacting overall performance.

Regular Maintenance

Routine maintenance of the transmission system is essential for preventing wear and tear. Regularly changing the transmission fluid and inspecting for leaks can help maintain optimal function. Additionally, periodic adjustments based on usage patterns will contribute to the longevity of the components.

Brake System Inspection

Regular examination of the braking mechanism is essential for ensuring optimal performance and safety. A well-maintained braking system not only enhances control but also minimizes the risk of accidents. This section outlines the key steps for effectively assessing the braking components.

To conduct a thorough inspection, follow these steps:

- Visual Check:

- Examine brake pads for wear and damage.

- Inspect brake discs for grooves or cracks.

- Check brake lines for leaks or wear.

- Functional Test:

- Engage the brakes to evaluate responsiveness.

- Listen for unusual sounds during operation.

- Ensure that the brake lever feels firm and operates smoothly.

- Fluid Level Assessment:

- Check the brake fluid reservoir for adequate levels.

- Inspect for any signs of contamination.

- Replace fluid if it appears dirty or discolored.

Following these steps can help maintain the efficiency of the braking system and extend its lifespan. Regular inspections are vital for safety and performance.

Wheel and Tire Care

Maintaining the wheels and tires of your vehicle is crucial for ensuring optimal performance and safety. Proper care not only enhances the longevity of these components but also improves handling and fuel efficiency. Regular inspections and timely maintenance can prevent costly repairs and enhance your riding experience.

Regular Inspections

Frequent checks of tire pressure and tread depth are essential. Under-inflated tires can lead to uneven wear and decreased fuel efficiency, while over-inflated tires may cause blowouts. Always refer to the manufacturer’s recommendations for the ideal pressure.

Cleaning and Protection

Keeping your tires clean from dirt and debris is vital for maintaining their condition. Use a mild detergent and water to wash them, avoiding harsh chemicals that could cause damage. Additionally, applying a protective dressing can help prevent cracking and fading from UV exposure.

Fuel System Cleaning Techniques

Maintaining the cleanliness of the fuel system is crucial for optimal engine performance. Various methods can be employed to ensure that fuel lines, injectors, and carburetors remain free from deposits and contaminants that can hinder functionality.

Regular Maintenance Practices

Implementing routine checks and cleanings can significantly extend the life of the fuel system components. Simple tasks, such as replacing the fuel filter and using fuel additives, can prevent buildup over time.

Deep Cleaning Methods

For more thorough cleaning, professionals often recommend techniques such as ultrasonic cleaning or using specialized cleaning solutions. These methods effectively dissolve stubborn deposits and restore optimal flow rates.

| Cleaning Method | Description | Frequency |

|---|---|---|

| Fuel Filter Replacement | Replaces clogged filters to ensure proper flow. | Every 10,000 miles |

| Fuel Additives | Enhances fuel quality and cleans injectors. | Every oil change |

| Ultrasonic Cleaning | Uses high-frequency sound waves to clean components. | As needed |

Safety Precautions During Repairs

Ensuring safety is crucial when performing maintenance on any vehicle. Adopting the right precautions helps prevent accidents and injuries, ensuring a smooth process. It is important to create a safe working environment and follow guidelines to protect both the technician and the equipment.

- Wear Protective Gear: Always use appropriate safety equipment such as gloves, goggles, and sturdy footwear to minimize the risk of injury.

- Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated to avoid inhaling harmful fumes or gases.

- Disconnect the Battery: Before beginning any work, disconnect the battery to prevent electrical shocks or shorts.

- Keep Tools Organized: Use a clean and organized workspace to reduce the chance of accidents caused by misplaced tools.

- Follow Manufacturer Guidelines: Adhere to the safety instructions provided by the manufacturer to ensure proper handling of components.

- Have a First Aid Kit Handy: Always keep a well-stocked first aid kit nearby in case of minor injuries.

By following these essential safety measures, individuals can greatly enhance their protection while maintaining or servicing their vehicles. Always prioritize safety to ensure a successful and injury-free experience.