Comprehensive Guide to 1989 Jeep Wrangler Repair Manual

Owning a classic off-road vehicle is not just about the thrill of adventure; it’s also about understanding its mechanics and ensuring optimal performance. For enthusiasts and hobbyists alike, having access to comprehensive resources is crucial for tackling various maintenance tasks and troubleshooting potential issues. This guide aims to provide insights into effectively caring for your beloved machine.

Whether you’re a seasoned mechanic or a novice looking to enhance your skills, knowing the intricacies of your vehicle is paramount. From routine checks to more complex repairs, understanding the essential components and systems will empower you to address problems confidently. With a systematic approach, you can keep your vehicle in top shape, ready for any terrain.

In the following sections, we will delve into practical tips, detailed procedures, and expert advice tailored for vintage off-road models. This knowledge will not only save you time and money but will also deepen your appreciation for the engineering marvel that is your vehicle. Prepare to embark on a journey of discovery and empowerment in the world of automotive care.

Essential Tools for Jeep Wrangler Repairs

Maintaining and fixing your vehicle requires a set of indispensable instruments. These tools not only simplify the tasks at hand but also ensure that the work is performed efficiently and safely. A well-equipped toolkit can significantly enhance the experience of handling various challenges that arise during maintenance.

Here are some vital tools that every enthusiast should consider for effective vehicle upkeep:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening nuts and bolts. |

| Wrench Set | Essential for working in tight spaces and achieving leverage. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Jack and Jack Stands | For safely lifting the vehicle during repairs. |

| Multimeter | Helps diagnose electrical issues effectively. |

| Screwdriver Set | Necessary for various fasteners, both standard and Phillips. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Oil Filter Wrench | Facilitates easy removal of oil filters. |

Investing in quality tools not only saves time but also minimizes the risk of damage during maintenance tasks. Properly selected instruments will enhance your ability to tackle any challenges that may arise with your vehicle.

Common Issues in the 1989 Model

This section highlights frequent challenges encountered in this particular model year, offering insights into potential maintenance and troubleshooting. Understanding these common problems can assist owners in ensuring optimal performance and longevity of their vehicle.

Electrical Problems

One of the prevalent issues is related to the electrical system. Owners may experience difficulties with the battery and alternator, leading to starting problems or inconsistent power supply. Additionally, wiring harnesses can become brittle over time, resulting in shorts or other electrical failures.

Transmission Concerns

Another notable concern is the transmission. Many users report rough shifting or slipping, which can stem from low fluid levels or worn components. Regular checks and timely maintenance can mitigate these issues and enhance driving experience.

| Issue | Description | Solution |

|---|---|---|

| Electrical Failures | Battery and alternator issues, brittle wiring. | Regular checks, replace worn components. |

| Transmission Problems | Rough shifting, fluid leaks, slipping. | Check fluid levels, perform maintenance. |

Step-by-Step Guide to Engine Maintenance

Proper upkeep of your vehicle’s power unit is essential for ensuring optimal performance and longevity. Regular checks and routine servicing can prevent larger issues and enhance fuel efficiency. This guide provides a structured approach to maintaining the core of your automobile, ensuring it runs smoothly and reliably.

1. Regular Oil Changes: Change the engine oil at recommended intervals. Fresh oil lubricates components effectively, reducing wear and tear. Always use the type of oil specified in your owner’s documentation.

2. Air Filter Inspection: Check the air intake filter periodically. A clean filter allows for better airflow, improving combustion efficiency. Replace it if it appears dirty or clogged.

3. Coolant Level Check: Maintain the appropriate coolant level to prevent overheating. Inspect hoses for wear or leaks and replace any damaged components.

4. Spark Plug Replacement: Inspect spark plugs for signs of wear or deposits. Replace them as needed to ensure smooth ignition and efficient fuel consumption.

5. Fuel System Cleaning: Regularly clean the fuel injectors and the fuel system. This practice helps to maintain engine performance and efficiency.

6. Battery Maintenance: Check battery terminals for corrosion and ensure a secure connection. Clean the terminals if necessary and check the fluid level if applicable.

7. Belts and Hoses Inspection: Regularly inspect all belts and hoses for signs of cracking, fraying, or leaks. Replace any components that show signs of wear to avoid breakdowns.

8. Engine Diagnostics: Use diagnostic tools to monitor the performance and health of your power unit. Address any trouble codes promptly to avoid more serious issues.

By following these steps diligently, you can ensure that your vehicle’s engine remains in top condition, ready to deliver performance and reliability when you need it most.

Transmission Troubleshooting Techniques

Addressing issues within the shifting mechanism of your vehicle can be a complex task, requiring a systematic approach to identify and resolve problems. Whether it’s a slipping sensation, unusual noises, or difficulty in gear engagement, understanding the fundamentals of transmission diagnostics is crucial for effective resolution.

Identifying Symptoms

Begin by paying close attention to the signs indicating potential complications. Slipping gears can manifest as a sudden loss of power during acceleration or an unexpected jump in RPMs. Additionally, listen for grinding sounds during shifts, which may indicate wear or misalignment. Finally, note any fluid leaks under the vehicle, as low fluid levels can lead to overheating and damage.

Basic Diagnostic Steps

Once symptoms are identified, proceed with a series of diagnostic steps. Start with checking the transmission fluid level and condition; dark, burnt-smelling fluid is a clear indicator of trouble. Next, inspect the linkage and cables for any signs of wear or misalignment, which could affect performance. Utilizing a code scanner can also reveal any electronic issues if the vehicle is equipped with modern diagnostics, providing insight into potential faults.

Electrical System Diagnostics for Wranglers

The electrical framework of any vehicle is crucial for its overall performance and reliability. Understanding how to effectively diagnose issues within this system is essential for maintaining optimal functionality. This section provides a comprehensive overview of diagnostic approaches that can aid in identifying electrical anomalies and ensuring proper operation.

Common Electrical Issues

Electrical problems can manifest in various ways, from minor inconveniences to significant operational failures. Recognizing common symptoms is the first step in troubleshooting. Here are several typical issues that may arise:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Dim or Flickering Lights | Weak battery, poor connections, or faulty alternator | Check battery voltage, clean terminals, or test alternator output |

| Inoperable Accessories | Blown fuses or malfunctioning switches | Inspect and replace fuses, test switches for continuity |

| Starting Issues | Defective starter or battery issues | Examine starter connections and test battery health |

Diagnostic Tools and Techniques

Utilizing the right diagnostic tools is vital for accurately assessing electrical problems. A multimeter can help measure voltage, current, and resistance, providing insights into potential faults. Additionally, a scan tool can retrieve diagnostic trouble codes (DTCs) from the vehicle’s onboard computer, aiding in pinpointing issues. Regular inspections and testing can prevent small problems from escalating into major repairs.

Suspension Upgrades and Repairs

Enhancing and maintaining the suspension system of a vehicle is crucial for improving ride quality, handling, and off-road capability. Upgrades can lead to better shock absorption and stability, while regular maintenance ensures optimal performance and longevity. Understanding the various components involved is essential for effective modifications and repairs.

| Component | Upgrade Options | Repair Tips |

|---|---|---|

| Shocks and Struts | High-performance or adjustable units | Check for leaks and listen for noise; replace if necessary |

| Coil Springs | Progressive or heavy-duty springs | Inspect for sagging or damage; consider replacement for improved height |

| Sway Bars | Upgraded sway bars for reduced body roll | Ensure mounting points are secure; replace bushings as needed |

| Control Arms | Adjustable arms for better alignment | Check bushings for wear; inspect for bending or damage |

| Lift Kits | Install a kit for increased ground clearance | Follow installation instructions closely; check alignment after installation |

Regular inspections and upgrades not only enhance performance but also ensure safety during driving. Keeping the suspension system in peak condition is vital for both on-road comfort and off-road adventure.

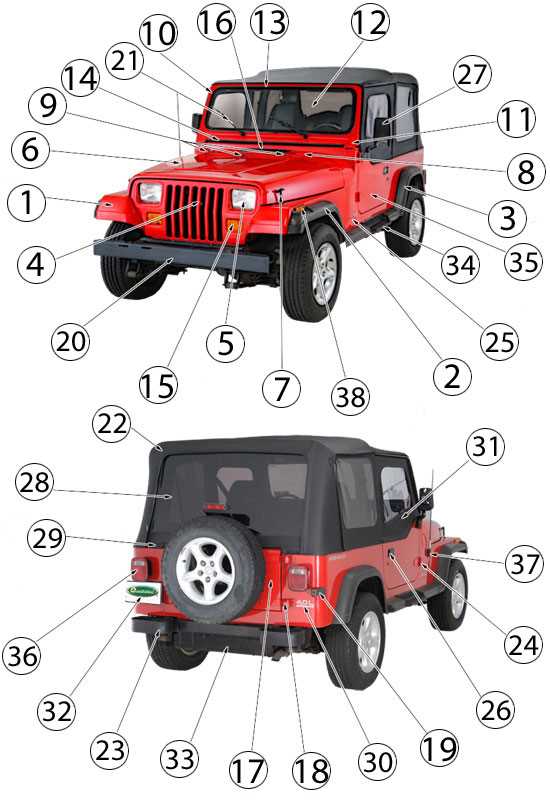

Bodywork Techniques for Jeep Owners

Maintaining the exterior of your off-road vehicle is essential for both aesthetics and performance. Proper techniques can help you tackle common issues, ensuring your ride remains in top condition while also enhancing its longevity. Whether you’re dealing with scratches, dents, or rust, understanding the fundamentals of bodywork can make a significant difference in the overall look and functionality of your vehicle.

Common Repairs and Their Solutions

Addressing minor scratches and blemishes can often be accomplished with touch-up paint and polishing compounds. For more significant damage, such as dents, utilizing a heat source or specialized tools can help restore the original shape of the metal. It’s crucial to assess the severity of the damage before deciding on the best approach, as some issues may require professional intervention.

Protective Measures

Prevention is key when it comes to maintaining the exterior finish. Applying a high-quality wax or sealant regularly not only provides a protective barrier against environmental elements but also enhances the shine of your vehicle. Additionally, using mud flaps and fender liners can minimize the risk of rocks and debris causing damage during your off-road adventures.

Braking System Maintenance Tips

Maintaining an efficient stopping mechanism is crucial for safe driving. Regular care and timely interventions can prevent potential issues and extend the lifespan of components. Here are some essential tips to keep your braking system in optimal condition.

Regular Inspections

- Check brake pads for wear. Replace them when they reach the manufacturer’s recommended thickness.

- Inspect brake discs for any signs of scoring or warping.

- Examine the brake fluid level regularly; ensure it is at the appropriate mark.

- Look for leaks in brake lines or around calipers.

Cleaning and Lubrication

- Keep brake components clean to prevent dust and debris from affecting performance.

- Apply appropriate lubricant to caliper slides and other moving parts to ensure smooth operation.

- Flush brake fluid periodically to remove contaminants and moisture buildup.

By following these guidelines, you can ensure that your stopping system remains reliable, enhancing both performance and safety on the road.

Cooling System Troubles and Solutions

The efficiency of the cooling system is vital for maintaining optimal engine performance and preventing overheating. Various issues can arise, leading to reduced effectiveness or complete failure of the system. Understanding common problems and their remedies is essential for any vehicle owner seeking to ensure reliability and longevity.

Common Issues

A frequent challenge is coolant leakage, which can occur due to worn hoses, faulty clamps, or a damaged radiator. Symptoms include visible puddles beneath the vehicle or a drop in coolant levels. Another common problem is overheating, often caused by a malfunctioning thermostat, blocked radiator, or insufficient coolant flow. Additionally, air pockets within the system can disrupt circulation, leading to erratic temperature readings and potential engine damage.

Solutions and Maintenance Tips

Understanding Jeep Wrangler Wiring Diagrams

Wiring diagrams are essential tools for anyone looking to troubleshoot electrical issues in vehicles. They provide a visual representation of the electrical systems, helping users identify connections, components, and the flow of electricity throughout the setup. A clear understanding of these diagrams can significantly simplify the process of diagnosing and fixing electrical problems.

Key Components of Wiring Diagrams

- Symbols: Various shapes represent different components like batteries, switches, and sensors.

- Lines: Solid lines typically indicate connections, while dashed lines may denote alternate pathways.

- Colors: Wiring colors provide additional information about the purpose and type of the wire.

How to Read a Wiring Diagram

- Start by familiarizing yourself with the symbols used.

- Trace the lines to follow the circuit’s path.

- Identify the components and their functions within the system.

- Pay attention to any notes or legends that may clarify connections.

With practice, understanding these diagrams can lead to more effective repairs and maintenance of electrical systems in vehicles.

Finding Quality Replacement Parts

Ensuring the longevity and performance of your vehicle often hinges on sourcing reliable components. The market is filled with options, but discerning high-quality parts from inferior alternatives is crucial for optimal functionality. A well-informed approach can save time and money while enhancing your driving experience.

Start by identifying reputable suppliers who specialize in the specific make and model of your vehicle. Look for vendors with positive reviews and a track record of customer satisfaction. Many online platforms provide user feedback, which can be invaluable in making an informed decision.

When evaluating parts, consider factors such as warranty coverage and manufacturer reputation. Genuine components typically offer better reliability, but certified aftermarket options can also provide excellent performance. Always cross-reference part numbers and specifications to ensure compatibility.

Finally, don’t overlook the importance of price. While it may be tempting to opt for the cheapest option available, remember that investing in quality often pays off in the long run. A well-made part can reduce the frequency of replacements and maintain your vehicle’s performance over time.