Essential Repair Guide for the 1994 Jeep Wrangler

When it comes to maintaining your adventurous vehicle, having access to comprehensive resources is crucial. Whether you’re a seasoned enthusiast or a casual driver, understanding the intricacies of your four-wheeled companion can enhance both its performance and longevity. This guide aims to provide you with valuable insights and practical tips to keep your ride in optimal condition.

Familiarizing yourself with the specific components and systems of your vehicle is key to effective upkeep. From the engine and transmission to the suspension and electrical systems, each element plays a vital role in ensuring a smooth driving experience. With the right knowledge, you can tackle common issues and perform necessary adjustments, saving both time and money.

Furthermore, a well-informed owner is equipped to make decisions about upgrades and modifications, which can significantly enhance the overall driving experience. By understanding the fundamental aspects of vehicle care, you’ll be better prepared to address challenges that may arise on your journeys, allowing you to explore new terrains with confidence.

Understanding the 1994 Jeep Wrangler

This section explores the fundamental aspects of an iconic off-road vehicle, emphasizing its rugged design and versatile capabilities. Built for adventure, this model captures the spirit of exploration and outdoor enjoyment.

Performance is one of the standout features, with robust engine options that provide both power and reliability. Driving experience is enhanced by the responsive handling, making it suitable for various terrains.

The interior offers a blend of comfort and practicality, with a layout designed to accommodate the needs of adventurous users. Durable materials and user-friendly controls ensure a functional environment.

Maintenance is essential for longevity, with key components that require regular attention to keep the vehicle in optimal condition. Understanding these elements is crucial for anyone looking to maximize their experience.

Common Issues with Jeep Wrangler

Many enthusiasts encounter recurring problems with their off-road vehicles, which can affect performance and reliability. Understanding these challenges is essential for maintaining optimal functionality and ensuring a smooth driving experience.

- Electrical System Failures: Issues with wiring and connections often lead to malfunctioning lights and gauges.

- Transmission Problems: Shifting difficulties can arise, resulting in jerky movements or slipping gears.

- Suspension Wear: Components such as shocks and struts may wear out, leading to a bumpy ride.

- Cooling System Leaks: Overheating can occur due to radiator or hose leaks, requiring prompt attention.

- Fuel System Issues: Fuel pumps and injectors may become clogged, affecting engine performance.

Regular inspections and timely maintenance can mitigate many of these concerns, ensuring that your vehicle remains in peak condition for any adventure.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of vehicles. A well-equipped workspace not only enhances efficiency but also ensures safety and precision during the process. Below is a list of indispensable tools that every automotive enthusiast should consider having on hand.

- Socket Set: A comprehensive socket set is essential for loosening and tightening various fasteners. Look for both standard and metric sizes.

- Wrenches: An assortment of wrenches, including open-end and box-end types, allows for flexibility in accessing different areas of the vehicle.

- Screwdrivers: Flathead and Phillips screwdrivers in various sizes will help tackle a wide range of screws.

- Jack and Jack Stands: A reliable hydraulic jack and sturdy jack stands are necessary for lifting the vehicle safely during maintenance tasks.

- Pliers: Needle-nose, slip-joint, and cutting pliers are versatile tools for gripping, twisting, and cutting wire or other materials.

- Torque Wrench: This tool is essential for applying the correct amount of torque to bolts and nuts, especially during assembly.

- Multimeter: A multimeter is invaluable for diagnosing electrical issues, measuring voltage, current, and resistance.

- Oil Filter Wrench: This specialized tool makes it easier to remove and replace oil filters without damage.

- Shop Manual: While not a tool in the traditional sense, having a detailed guide can provide essential insights and procedures for various tasks.

Investing in these tools not only prepares you for a range of projects but also enhances your confidence and skill in performing maintenance tasks. Proper care and organization of your tools will further contribute to a successful experience.

Step-by-Step Maintenance Guide

This guide provides essential procedures for ensuring the longevity and performance of your vehicle. Regular upkeep not only enhances functionality but also prevents potential issues that may arise from neglect. Following a systematic approach will help you maintain optimal operation and safety on the road.

Here are the key steps to follow for routine maintenance:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000-5,000 miles | Replace old oil with new to ensure engine efficiency. |

| Tire Rotation | Every 5,000-7,000 miles | Rotate tires to promote even wear and extend lifespan. |

| Fluid Check | Monthly | Inspect and top off essential fluids, including coolant and brake fluid. |

| Brake Inspection | Every 10,000 miles | Examine brake pads and rotors for wear and replace as needed. |

| Battery Maintenance | Every 6 months | Check battery terminals for corrosion and ensure a secure connection. |

| Air Filter Replacement | Every 12,000-15,000 miles | Change air filter to maintain optimal airflow and engine performance. |

By adhering to these steps, you can significantly enhance your vehicle’s reliability and efficiency, ensuring a smoother driving experience for years to come.

Engine Troubleshooting Techniques

When facing issues with an engine, a systematic approach is essential for effective diagnosis and resolution. Understanding the fundamental aspects of engine operation can aid in pinpointing the source of malfunctions, allowing for targeted interventions. This section outlines several essential methods for troubleshooting engine-related problems.

Visual Inspection: Begin with a thorough visual examination of the engine compartment. Look for obvious signs of wear or damage, such as frayed wires, cracked hoses, or oil leaks. This preliminary step can often reveal issues that may not require extensive diagnostics.

Listening for Abnormal Sounds: Engine noise can provide critical clues about underlying problems. Pay attention to any unusual sounds, such as knocking, hissing, or grinding, which may indicate specific issues like internal damage or exhaust leaks.

Checking Fluid Levels: Regularly monitoring engine fluids, including oil, coolant, and transmission fluid, is crucial. Low levels or contamination can lead to overheating and poor performance, so ensure all fluids are at the recommended levels and in good condition.

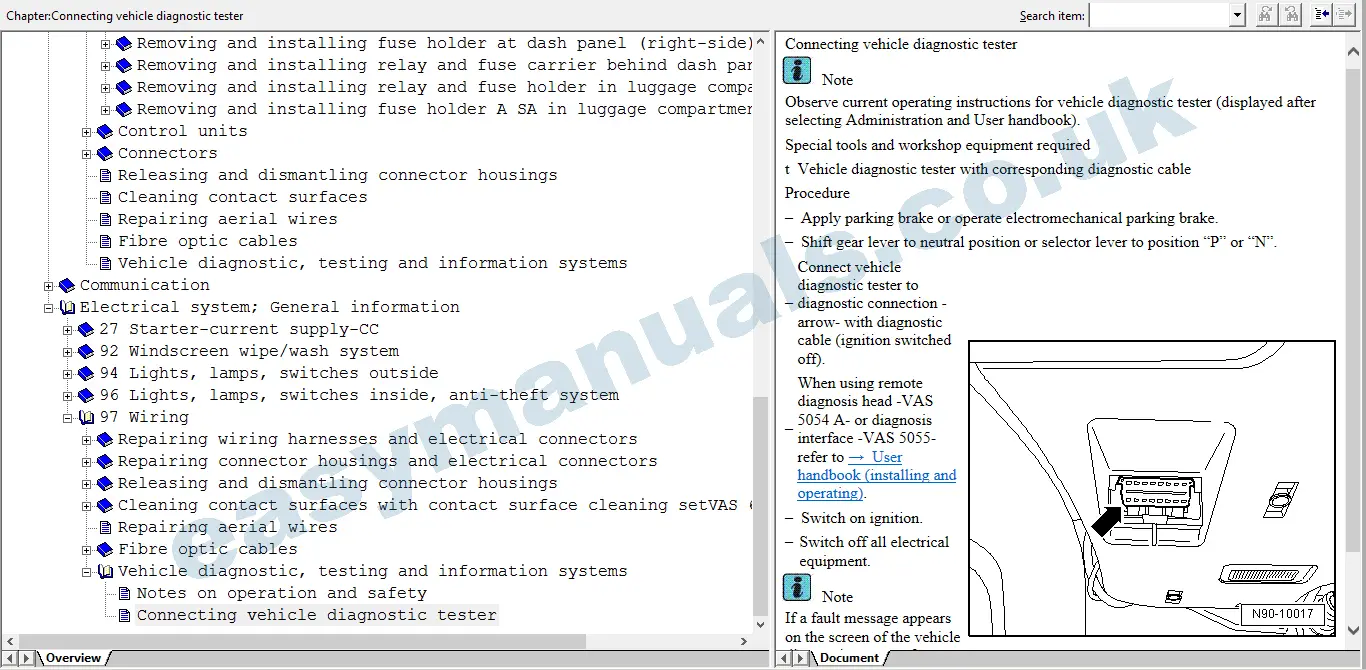

Using Diagnostic Tools: Employing electronic diagnostic equipment can greatly enhance troubleshooting efforts. Scan tools can read error codes from the engine control unit, providing insights into potential faults that require further investigation.

Performing Compression Tests: A compression test measures the pressure in each cylinder, helping to identify issues related to valves, pistons, or head gaskets. Discrepancies in readings can highlight specific areas needing attention.

Evaluating Fuel Delivery: Ensuring the engine receives the proper fuel mixture is vital for optimal performance. Check the fuel pump, filters, and injectors for blockages or malfunctions that could affect fuel flow and combustion efficiency.

By applying these techniques methodically, you can effectively diagnose and address engine problems, leading to improved functionality and reliability.

Electrical System Diagnostics

Effective evaluation of the electrical system is crucial for maintaining optimal vehicle performance. This section focuses on identifying issues and ensuring the integrity of various components through systematic testing.

Key areas to investigate include:

- Battery condition and connections

- Fuses and relays functionality

- Wiring integrity and insulation

- Ground points and their effectiveness

Follow these steps for thorough diagnostics:

- Inspect the battery for corrosion and secure connections.

- Test fuses using a multimeter to confirm continuity.

- Examine wiring for signs of wear or damage.

- Verify all ground points are clean and properly attached.

By diligently addressing these components, one can ultimately enhance reliability and performance.

Suspension and Steering Adjustments

Proper calibration of the suspension and steering systems is essential for maintaining optimal handling and ride quality. Adjustments ensure that all components function harmoniously, providing both safety and comfort during operation.

| Adjustment Type | Description | Tools Required |

|---|---|---|

| Alignment | Ensures wheels are parallel and angles are set correctly for even tire wear. | Alignment rack, wrenches |

| Ride Height | Adjusts the distance between the chassis and ground for stability. | Measuring tape, adjusting tools |

| Steering Play | Reduces excessive movement in the steering wheel for precise control. | Wrenches, screwdriver |

| Shock Absorber Settings | Modifies damping levels to enhance comfort and handling characteristics. | Adjustable wrench, torque wrench |

Brake System Overhaul Process

Revising the braking apparatus is essential for ensuring the vehicle operates safely and efficiently. This procedure involves a comprehensive examination and replacement of worn components, ultimately enhancing the overall performance of the stopping mechanism.

Preparation is key to a successful overhaul. Begin by gathering all necessary tools and replacement parts, such as pads, rotors, and fluid. Ensuring a clean workspace will facilitate a smoother workflow.

Next, removal of the existing brake elements is crucial. Carefully detach the wheel assembly to access the braking components. Pay attention to any signs of damage or excessive wear, as these can indicate underlying issues that may need addressing.

Once disassembled, inspection of each part is vital. Examine rotors for grooves or warping, and check pads for thickness. Replace any components that do not meet safety standards to guarantee optimal performance.

After completing the inspection, installation of new parts should follow. Ensure all components are fitted securely, and follow manufacturer specifications to maintain integrity. Once everything is in place, bleed the brake lines to remove any air pockets, ensuring consistent pressure.

Finally, testing the system is imperative. Conduct a thorough evaluation by driving the vehicle at low speeds and testing the responsiveness of the brakes. Any unusual noises or vibrations should be addressed immediately to prevent future complications.

By adhering to this process, vehicle owners can restore their braking system to peak condition, promoting safety and reliability on the road.

Transmission Repair Insights

Understanding the intricacies of transmission maintenance is essential for ensuring optimal performance and longevity of any vehicle. This component plays a critical role in power transfer and requires attention to detail during troubleshooting and overhauling processes. Addressing issues promptly can prevent further complications and enhance the driving experience.

Common Issues and Symptoms

Vehicles may exhibit a range of problems related to the transmission system. Slipping gears, unusual noises, or leaking fluids can indicate underlying issues that require immediate examination. These symptoms often serve as warning signs, suggesting the need for careful diagnostics and potential intervention to restore functionality.

Maintenance Tips

Regular upkeep is crucial for transmission health. Routine checks of fluid levels, timely replacements, and adherence to service schedules can significantly reduce the likelihood of severe malfunctions. Using the correct fluid type and monitoring for contaminants are also vital practices that contribute to a well-functioning system.

Bodywork and Rust Prevention Tips

Maintaining the exterior of your vehicle is crucial for its longevity and aesthetics. Proper care can prevent deterioration and preserve the structural integrity of the bodywork. Here are some essential strategies to keep your vehicle looking great and protected from corrosion.

| Tip | Description |

|---|---|

| Regular Washing | Frequent cleaning removes dirt, salt, and contaminants that can lead to rust. |

| Waxing | Applying wax creates a protective layer that shields the paint from moisture and UV rays. |

| Inspect for Damage | Regularly check for scratches, chips, and dents to address them before they lead to corrosion. |

| Rust Inhibitors | Use sprays or treatments specifically designed to prevent rust formation on exposed metal surfaces. |

| Undercoating | Consider applying a protective coating to the undercarriage to guard against road salt and moisture. |

| Dry Storage | Whenever possible, store your vehicle in a dry place to minimize exposure to the elements. |

Implementing these practices will help ensure your vehicle remains in excellent condition, reducing the likelihood of rust and maintaining its appeal for years to come.

Upgrading Components for Better Performance

Enhancing the functionality of your vehicle can significantly improve its overall performance and driving experience. By focusing on key elements, you can achieve better power, handling, and efficiency. This section explores essential upgrades that can elevate your ride, ensuring it meets your expectations on and off the road.

Engine Modifications: Upgrading the engine components is one of the most effective ways to boost power output. Consider installing a high-performance air intake system and a more efficient exhaust system. These enhancements can improve airflow, allowing the engine to breathe better and perform more efficiently.

Suspension Upgrades: The suspension system plays a crucial role in handling and stability. Upgrading to high-quality shocks and springs can enhance ride comfort and off-road capability. Additionally, adjustable control arms can provide better articulation and adjustability for varying terrain conditions.

Tire and Wheel Improvements: Choosing the right tires can significantly affect traction and handling. Opt for all-terrain or mud-terrain tires depending on your driving style. Pairing these with lightweight alloy wheels can reduce unsprung weight, improving acceleration and handling response.

Braking System Enhancements: Upgrading the braking components is essential for safety and performance, especially if you increase power. High-performance brake pads and rotors can provide better stopping power, while stainless steel brake lines can enhance pedal feel and responsiveness.

Electronic Enhancements: Modern vehicles often benefit from electronic upgrades. Consider installing a performance chip or tuner that optimizes engine performance parameters. Additionally, upgrading the vehicle’s lighting system can improve visibility, enhancing safety during night drives.

By thoughtfully selecting and upgrading these components, you can create a more powerful, responsive, and enjoyable driving experience. Each enhancement contributes to an overall improvement, allowing you to fully enjoy the capabilities of your vehicle.

Finding Reliable Replacement Parts

When it comes to maintaining your vehicle, sourcing dependable components is crucial for ensuring longevity and performance. With a multitude of options available, it’s essential to navigate the market wisely to avoid subpar items that could jeopardize the integrity of your automobile.

Evaluating Suppliers

Choosing the right vendor is key to obtaining high-quality parts. Look for suppliers with a strong reputation and positive customer feedback. Consider factors such as their return policy, warranty offerings, and customer service responsiveness. This diligence can save you time and money in the long run.

Understanding Quality Standards

Not all components are created equal. Familiarize yourself with industry standards and certifications that indicate quality. OEM (Original Equipment Manufacturer) parts typically offer better reliability compared to aftermarket alternatives, though some aftermarket options can also meet or exceed these standards.

| Part Type | Source | Quality Level |

|---|---|---|

| Engine Components | OEM | High |

| Braking System | Aftermarket | Variable |

| Suspension Parts | OEM & Aftermarket | Medium to High |

| Electrical Components | Aftermarket | Variable |

In conclusion, thorough research and consideration of your options are vital when sourcing replacement components. Prioritizing quality over price can lead to a more dependable vehicle and a smoother driving experience.