Comprehensive Guide to Repairing the 2012 Jeep Compass

In the realm of automotive care, having access to detailed information about a specific model can significantly enhance the ownership experience. This resource provides essential insights into various aspects of upkeep and troubleshooting for a popular compact utility vehicle. With a focus on both routine tasks and complex issues, it aims to empower owners with the knowledge they need to ensure optimal performance.

Understanding the intricacies of your vehicle is crucial for maintaining its longevity. From basic inspections to more elaborate repairs, this guide covers vital procedures and specifications that will aid in keeping the vehicle in peak condition. By familiarizing oneself with these guidelines, one can approach any challenge with confidence and expertise.

Whether you are a seasoned enthusiast or a first-time owner, having a reliable reference is invaluable. This compilation not only emphasizes the importance of regular maintenance but also offers tips for addressing common problems efficiently. Embracing these practices can lead to a more enjoyable driving experience and prolong the life of the vehicle.

Understanding Vehicle Maintenance Basics

Proper upkeep of an automobile is essential for ensuring its longevity and optimal performance. Routine attention to various components helps prevent major issues and enhances safety. Understanding fundamental maintenance practices equips vehicle owners with the knowledge needed to keep their machines running smoothly.

Essential Maintenance Tasks

Regular checks on oil levels, tire pressure, and brake functionality are crucial. Oil changes should occur at recommended intervals to ensure the engine operates efficiently. Additionally, monitoring tire conditions and rotating them as needed can prolong their lifespan and improve fuel economy.

The Importance of Scheduled Services

Adhering to a service schedule is vital for maintaining vehicle health. These sessions often include thorough inspections of critical systems such as cooling, electrical, and transmission components. Ignoring scheduled maintenance can lead to unexpected breakdowns and costly repairs in the future.

Common Issues with the 2012 Model

This section addresses frequent challenges encountered by owners of this vehicle variant. While the design and performance generally receive favorable reviews, specific concerns have emerged that warrant attention. Understanding these issues can assist in timely maintenance and enhance overall driving experience.

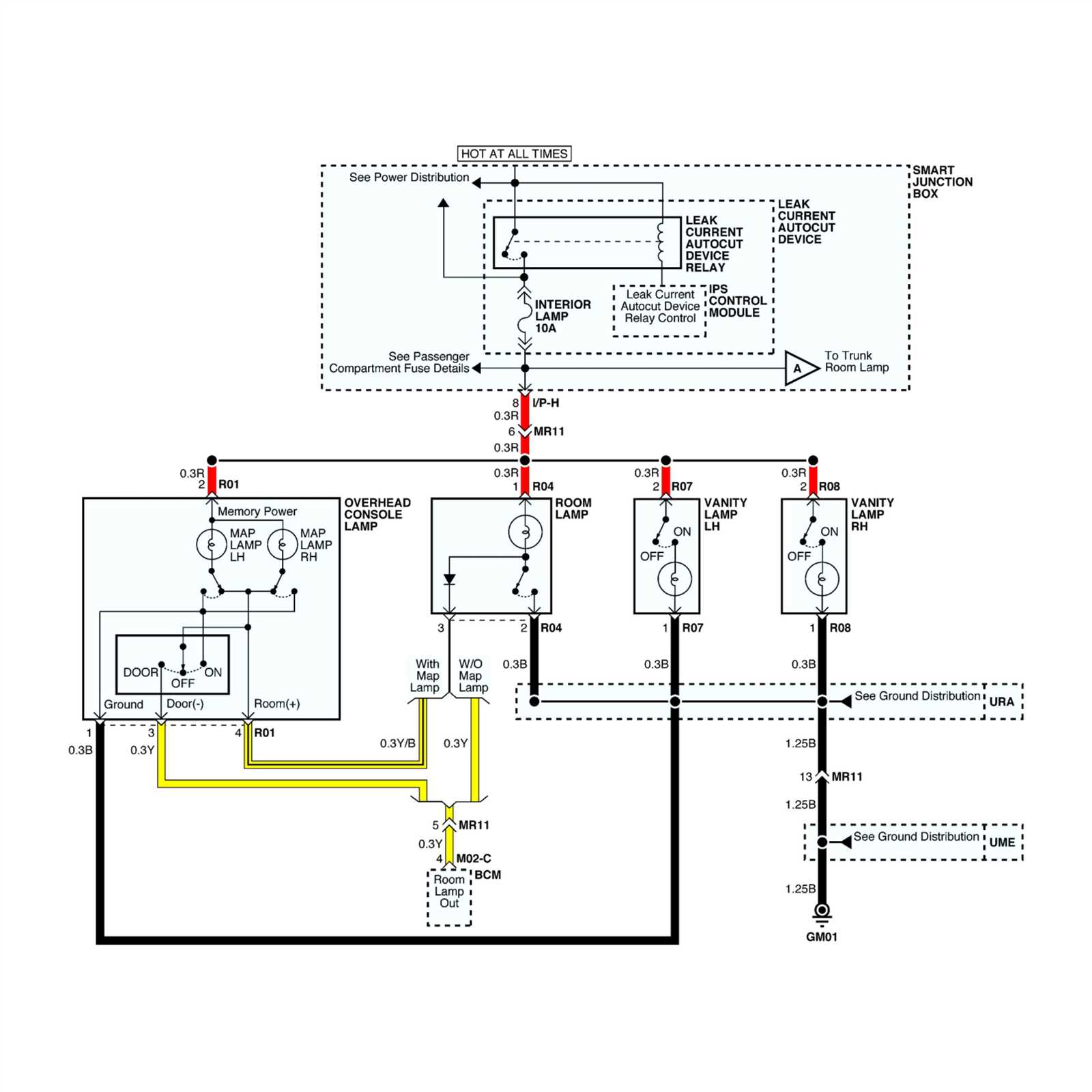

Electrical System Failures

One of the more prevalent problems involves the electrical components. Users have reported unexpected malfunctions in the lighting system and issues with dashboard indicators. These faults can lead to inconvenience and, in some cases, may compromise safety.

Transmission Concerns

Another common challenge relates to transmission performance. Drivers have experienced irregular shifting and delays during acceleration. Such issues can stem from various factors, including fluid levels and internal component wear, necessitating regular checks and potential interventions.

| Issue | Description | Potential Solution |

|---|---|---|

| Electrical Failures | Malfunctioning lights and dashboard indicators. | Inspect wiring and replace faulty components. |

| Transmission Irregularities | Delayed shifting and acceleration issues. | Check fluid levels and consider servicing the transmission. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise with your vehicle. Following these steps can help diagnose problems efficiently, ensuring a thorough examination before considering repairs or replacements.

Initial Assessment

- Begin by gathering necessary tools, such as a multimeter, socket set, and basic hand tools.

- Inspect the vehicle for visible signs of damage or wear, including leaks, cracks, or frayed wires.

- Check the dashboard for warning lights and note any error codes displayed.

Systematic Testing

- Start with the electrical system:

- Test the battery voltage to ensure it is within the normal range.

- Examine fuses and relays for integrity and functionality.

- Move on to the engine components:

- Check fluid levels, including oil, coolant, and transmission fluid.

- Perform a visual inspection of belts and hoses for wear.

- Evaluate the braking system:

- Inspect brake pads and rotors for thickness and condition.

- Test brake fluid for contamination and proper level.

By following this structured approach, you can effectively isolate issues and determine the necessary steps for resolution. Always prioritize safety and refer to relevant resources for detailed specifications and procedures when needed.

Tools Needed for Repairs

When undertaking maintenance on your vehicle, having the right instruments is essential for efficient and safe work. A well-equipped toolkit not only facilitates smoother processes but also enhances the overall experience of working on your automobile.

Basic hand tools, including wrenches, screwdrivers, and pliers, are fundamental for various tasks. A socket set allows for easier access to bolts and nuts in tight spaces. Additionally, specialized equipment, such as diagnostic scanners, can provide valuable insights into potential issues.

Safety gear, such as gloves and goggles, is vital to protect yourself while handling components. Lastly, having a reliable jack and stands is crucial for safely lifting the vehicle during any undercarriage work.

Engine Components and Their Functions

The internal combustion unit comprises various elements, each playing a vital role in the overall performance and efficiency of the system. Understanding these components and their specific tasks is essential for effective maintenance and troubleshooting.

Key Components Overview

Each element within the unit contributes uniquely to its operation, from generating power to managing exhaust emissions. Recognizing how these parts interact helps in diagnosing issues and optimizing performance.

Table of Engine Components

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports the engine components. |

| Pistons | Convert fuel combustion into mechanical energy. |

| Cylinder Head | Encloses the combustion chamber and contains intake/exhaust valves. |

| Crankshaft | Transforms linear motion of pistons into rotational motion. |

| Camshaft | Controls the opening and closing of valves at the right timing. |

| Intake Manifold | Distributes air and fuel mixture to the cylinders. |

| Exhaust Manifold | Channels exhaust gases away from the engine. |

Brake System Overview and Maintenance

The braking mechanism of a vehicle is essential for ensuring safety and control during operation. Understanding its components and functionality helps in maintaining optimal performance and preventing potential issues. Regular attention to this system can significantly enhance driving safety and prolong the life of critical components.

Key Components of the Brake System

The braking system consists of several vital elements, including brake pads, rotors, calipers, and brake fluid. Brake pads are designed to create friction against the rotors to slow down or stop the vehicle. Over time, these pads wear out and require replacement to ensure effective braking performance. Rotors, which the pads grip, also undergo wear and may need resurfacing or replacement. Additionally, calipers play a crucial role by housing the brake pads and applying pressure to them, enabling the necessary friction.

Maintenance Tips

To maintain the braking system, regular inspections are necessary. Checking brake fluid levels and quality should be a routine practice, as contaminated or low fluid can lead to system failure. Furthermore, inspecting pads and rotors for signs of wear or damage will help identify the need for replacement before issues escalate. Keeping the braking system clean and free of debris can also enhance its longevity and performance.

Electrical System Diagnostics Explained

The process of evaluating the electrical components of a vehicle plays a crucial role in maintaining optimal performance and reliability. Understanding how to assess and troubleshoot these systems can prevent minor issues from escalating into major problems. This section provides a comprehensive overview of the key concepts and methods involved in diagnosing electrical systems effectively.

Diagnosing electrical issues typically involves several steps, including visual inspections, testing of components, and the use of diagnostic tools. Here’s a breakdown of the primary components involved in this process:

| Component | Description |

|---|---|

| Batteries | Store electrical energy and supply power to the vehicle’s systems. |

| Alternators | Generate electricity while the engine is running, keeping the battery charged. |

| Fuses | Protect electrical circuits from overload by breaking the connection when necessary. |

| Wiring Harnesses | Facilitate the distribution of electrical power to various components throughout the vehicle. |

| Sensors | Monitor various parameters and send data to the vehicle’s control modules for processing. |

By systematically analyzing each of these components, technicians can identify faults and ensure that the electrical systems function as intended. Utilizing diagnostic equipment, such as multimeters and scan tools, further enhances the accuracy of the assessment and aids in pinpointing the source of any issues.

Suspension and Steering Adjustments

This section focuses on optimizing the performance and handling of a vehicle through careful modifications and calibrations of the suspension and steering systems. Proper adjustments can enhance ride comfort, stability, and overall driving experience.

Key aspects to consider when making adjustments include:

- Alignment: Ensuring the wheels are properly aligned helps prevent uneven tire wear and improves handling.

- Ride Height: Adjusting the height of the suspension can affect the center of gravity and overall handling characteristics.

- Shock Absorber Settings: Fine-tuning the shock absorbers can lead to better control over bumps and road imperfections.

- Spring Tension: Adjusting the tension of the springs can influence ride quality and responsiveness.

Before making any adjustments, it is crucial to perform a thorough inspection of the suspension and steering components to identify any wear or damage that may affect performance.

- Check the tire pressure and condition.

- Inspect the steering linkage for any signs of play or damage.

- Evaluate the condition of shock absorbers and springs.

Following a systematic approach to adjustments will ensure enhanced handling, safety, and comfort for drivers and passengers alike.

Fluid Replacement Procedures

Proper maintenance of various liquids is essential for optimal performance and longevity of a vehicle. Regularly changing fluids ensures that all systems function smoothly and helps prevent costly repairs down the line. This section outlines the recommended practices for replacing key fluids in your vehicle.

Engine Oil Replacement

Engine oil is crucial for lubricating moving parts and preventing wear. Follow these steps for an effective replacement:

| Step | Action |

|---|---|

| 1 | Warm up the engine to thin the oil for easier drainage. |

| 2 | Lift the vehicle using a jack and secure it with stands. |

| 3 | Remove the drain plug and allow the old oil to completely drain. |

| 4 | Replace the oil filter to remove contaminants. |

| 5 | Refill with new oil as specified in the owner’s documentation. |

| 6 | Check the oil level using the dipstick and ensure it is within the recommended range. |

Transmission Fluid Change

Maintaining clean transmission fluid is vital for smooth shifting and overall performance. Follow these steps:

| Step | Action |

|---|---|

| 1 | Park the vehicle on a level surface and warm up the engine. |

| 2 | Locate the transmission fluid pan and drain plug. |

| 3 | Remove the drain plug and let the old fluid drain completely. |

| 4 | Replace the drain plug and refill with new transmission fluid through the dipstick tube. |

| 5 | Start the engine and cycle through the gears to circulate the new fluid. |

| 6 | Check the fluid level and add more if necessary. |

Safety Tips During Repairs

Engaging in maintenance and restoration tasks can be rewarding, but it is crucial to prioritize safety. Understanding potential hazards and implementing protective measures ensures a secure environment for both the individual and the vehicle. Here are essential guidelines to keep in mind during such undertakings.

Personal Protective Equipment

Wearing the right gear is vital when working on automotive tasks. This includes items that shield against injuries and enhance visibility. Below is a summary of recommended protective equipment:

| Equipment | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals |

| Gloves | Prevents cuts and chemical exposure |

| Steel-Toed Boots | Offers protection against heavy objects |

| High-Visibility Vest | Enhances visibility in low-light conditions |

Workspace Organization

A tidy workspace is essential for safety. Keeping tools organized and ensuring the area is free from clutter minimizes the risk of accidents. Consider implementing these practices:

- Store tools in designated areas after use.

- Keep the floor clean to prevent slips and falls.

- Ensure adequate lighting in the workspace.

Resources for Further Assistance

When seeking guidance for maintenance and troubleshooting, there are various sources that can provide valuable information. These resources can help enhance your understanding and ensure effective problem-solving for your vehicle.

Online Forums and Communities: Engaging with online platforms dedicated to automotive enthusiasts can be incredibly helpful. Members often share experiences, tips, and detailed solutions for common issues, creating a supportive environment for knowledge exchange.

Professional Workshops: Attending local workshops or classes led by skilled technicians can offer hands-on experience and insights into complex procedures. These sessions often cover a wide range of topics, enabling participants to gain practical skills and confidence.

Manufacturer’s Website: The official website of the vehicle’s manufacturer typically offers a wealth of information, including troubleshooting guides, FAQs, and contact details for customer support. Utilizing these resources can help you find specific details related to your vehicle’s systems.

Automotive Literature: Investing in books or subscription services that specialize in vehicle maintenance can provide comprehensive knowledge. These publications often include diagrams, step-by-step instructions, and tips from industry experts.