Comprehensive Repair Manual for 1997 Jeep Grand Cherokee

Maintaining an automobile from 1997 requires a blend of knowledge, patience, and access to the right resources. Owners of this model will find that understanding its unique features and common issues is essential for preserving performance and ensuring longevity. This guide aims to provide invaluable insights into troubleshooting and enhancing your vehicle’s functionality.

Empowerment through Knowledge is a key element in vehicle ownership. Familiarizing yourself with various components, systems, and maintenance practices can significantly impact your driving experience. This resource serves as a reference point, offering detailed instructions and helpful tips tailored to the intricacies of this particular model.

Additionally, preventative measures can save time and money in the long run. By proactively addressing minor concerns before they escalate, owners can maintain their vehicle’s reliability. The following sections will delve into essential procedures, ensuring that you are well-equipped to handle any challenges that may arise with your 1997 model.

Overview of the 97 Jeep Grand Cherokee

The 1997 model of this well-regarded SUV represents a significant evolution in the segment of mid-size vehicles. With a blend of ruggedness and comfort, it appeals to a wide range of drivers, from adventure seekers to those who prioritize daily usability. This vehicle combines advanced engineering with a robust design, catering to both on-road and off-road experiences.

Equipped with various powerful engine options, it offers a dynamic driving experience, while its spacious interior ensures comfort for all passengers. Safety features have been thoughtfully integrated, addressing the needs of families and individuals alike. Additionally, the innovative technology incorporated into its design reflects a commitment to modern standards, making it a practical choice for various lifestyles.

Overall, the 1997 iteration is a compelling choice that balances performance, reliability, and comfort, making it a noteworthy contender in its class.

Common Issues and Troubleshooting Tips

When maintaining a vehicle, it’s essential to be aware of frequent problems that can arise, along with effective strategies for resolving them. Understanding these common issues can save time, effort, and costs associated with repairs. This section provides insights into typical challenges faced by owners of older models and offers practical advice for troubleshooting.

| Issue | Description | Troubleshooting Tips |

|---|---|---|

| Engine Overheating | Excessive heat can lead to engine failure. | Check coolant levels, inspect the radiator for leaks, and ensure the thermostat is functioning correctly. |

| Electrical Problems | Faulty wiring or components can cause various issues. | Inspect fuses and wiring connections; consider using a multimeter to check voltage levels. |

| Transmission Slipping | Difficulty in shifting gears can indicate transmission issues. | Check fluid levels and condition; look for leaks and consider a transmission flush. |

| Brake Wear | Noisy or unresponsive brakes can pose safety risks. | Inspect brake pads and rotors; replace worn components and check brake fluid levels. |

| Suspension Noise | Unusual sounds while driving may suggest suspension problems. | Examine shocks, struts, and bushings for wear; listen for noise when hitting bumps. |

Essential Tools for Jeep Repairs

Maintaining a vehicle requires a set of fundamental instruments to ensure efficient and effective work. Whether tackling routine tasks or addressing more complex issues, having the right equipment can make a significant difference in the outcome. This section will explore the vital tools needed for various maintenance activities, allowing enthusiasts to approach their projects with confidence.

First and foremost, a quality socket set is indispensable. It enables easy access to nuts and bolts in tight spaces, facilitating quicker disassembly and assembly. Pairing this with a torque wrench ensures that all fasteners are tightened to the manufacturer’s specifications, which is crucial for safety and performance.

Another essential tool is the multimeter, which assists in diagnosing electrical problems. With this device, one can measure voltage, current, and resistance, helping to pinpoint issues in the electrical system. Alongside this, a basic set of pliers and wire cutters is necessary for handling various wiring tasks.

Furthermore, having a reliable jack and jack stands is vital for any undercarriage work. Safety is paramount, and these tools provide the necessary support when working underneath the vehicle. A creeper can also enhance comfort during such tasks, allowing for easy movement beneath the chassis.

Lastly, a well-stocked toolbox with various wrenches, screwdrivers, and specialty tools tailored for specific components will streamline the process. By equipping oneself with these instruments, any vehicle owner can effectively manage maintenance and minor issues, ensuring longevity and performance.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any vehicle. A well-structured maintenance plan not only enhances performance but also reduces the likelihood of unexpected breakdowns. Adhering to specific intervals for inspections and service tasks can lead to smoother operation and increased reliability over time.

For optimal functionality, it is advisable to follow a routine that includes checking fluid levels, inspecting brakes, and examining tire conditions at least once a month. Additionally, an oil change should be performed every 3,000 to 5,000 miles, depending on driving habits and conditions. Air filters and fuel filters should also be replaced regularly to maintain engine health.

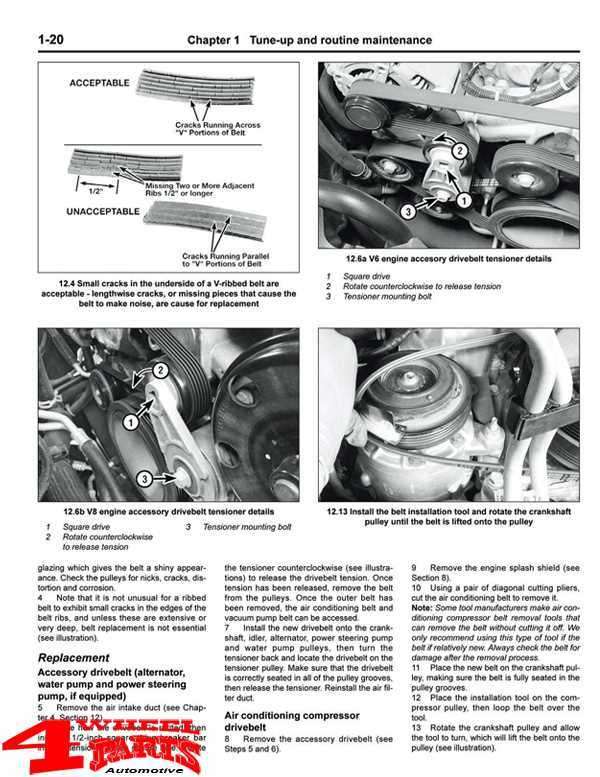

Every 15,000 miles, it is beneficial to inspect the entire exhaust system for leaks and damages. Brake pads and rotors should be assessed at the same interval, ensuring safety and effective stopping power. Every 30,000 miles, consider a more thorough inspection of belts and hoses, as wear can lead to significant issues if neglected.

For long-term care, a full service, including transmission fluid replacement and coolant system flush, is recommended every 60,000 miles. This comprehensive approach will not only keep performance at its peak but also preserve the vehicle’s value and efficiency over time.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing various maintenance tasks and fixes on your vehicle. Each procedure is broken down into clear steps to ensure that even those with limited experience can successfully complete the work. By following these detailed instructions, you can enhance the longevity and performance of your automobile.

Essential Tools Required

Before starting any procedure, gather the necessary tools to ensure a smooth workflow. Below is a list of essential instruments you’ll need:

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Removing and securing screws |

| Jack and Stands | Lifting the vehicle safely |

| Multimeter | Testing electrical systems |

| Oil Filter Wrench | Changing the oil filter |

Basic Maintenance Steps

Performing routine checks is vital to ensure optimal operation. Here’s a straightforward outline to follow:

- Check fluid levels (oil, coolant, brake fluid).

- Inspect belts and hoses for wear or damage.

- Replace air and cabin filters as needed.

- Examine tire pressure and tread depth.

- Test battery condition and connections.

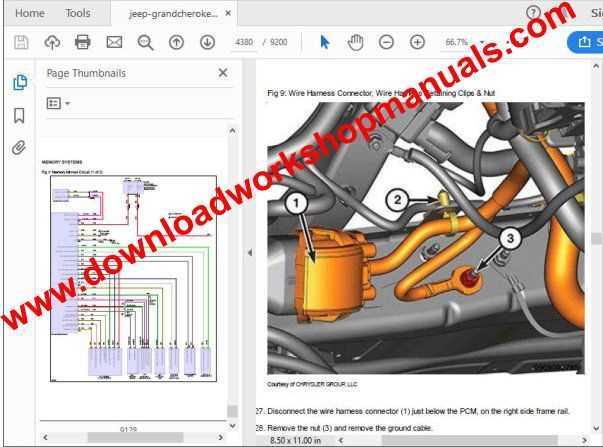

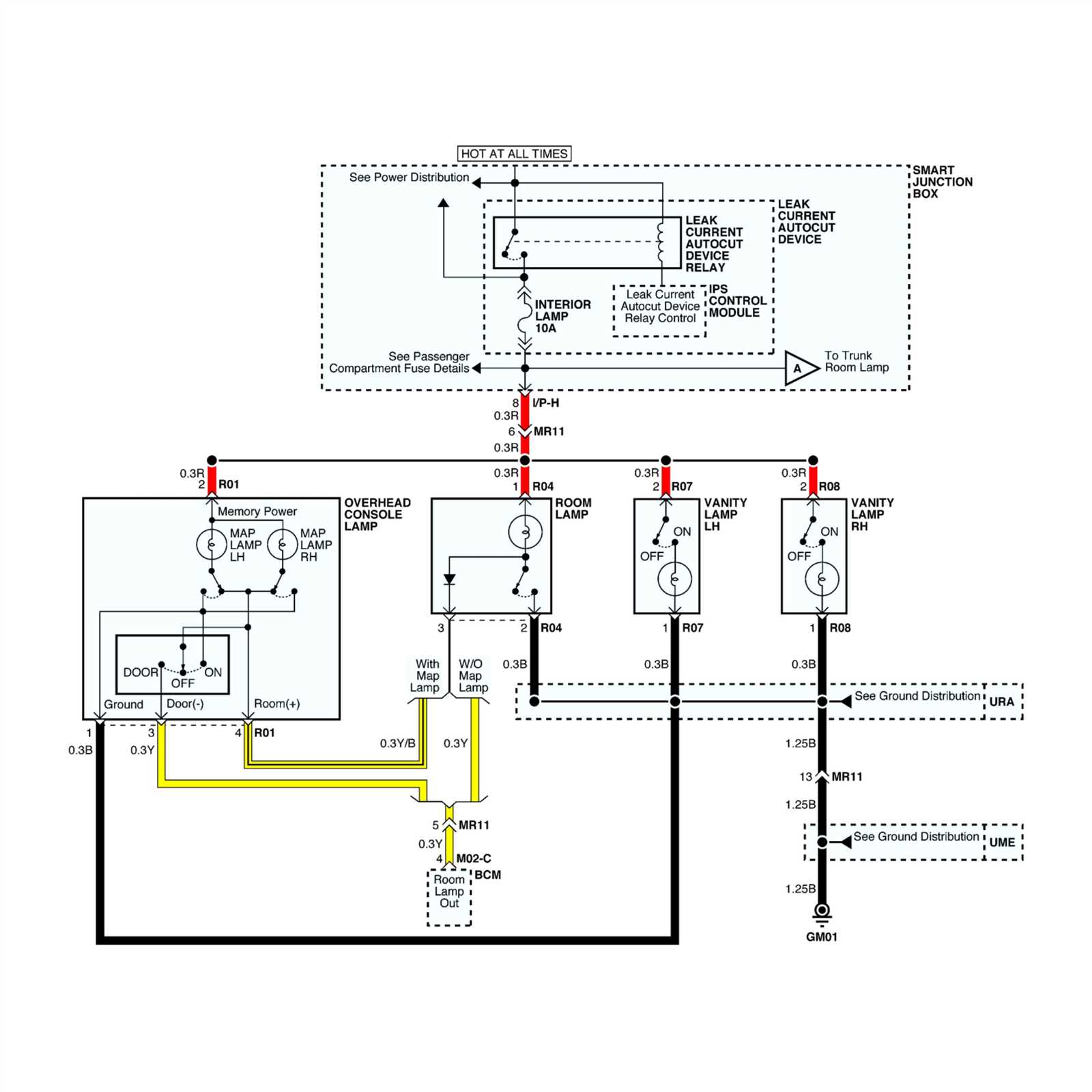

Electrical Systems and Diagnostics

The electrical systems in vehicles are integral to their operation, controlling everything from ignition to lighting. Understanding how to diagnose and troubleshoot these systems is essential for maintaining optimal performance and ensuring safety. This section provides insights into common electrical components, their functions, and methods for effective diagnostics.

Common Electrical Components

Modern vehicles are equipped with a variety of electrical components that work together seamlessly. Key elements include the battery, alternator, fuses, and wiring harnesses. Each component plays a vital role in the overall functioning of the electrical system:

- Battery: Supplies the necessary power to start the engine and operate electrical accessories.

- Alternator: Charges the battery while the engine runs, ensuring a steady supply of electrical energy.

- Fuses: Protect circuits from overload by breaking the connection when excessive current flows.

- Wiring Harness: Connects various electrical components, allowing for communication and power distribution.

Diagnostic Techniques

To effectively troubleshoot electrical issues, several techniques can be employed. Using a multimeter is one of the most common methods to measure voltage, current, and resistance:

- Visual Inspection: Look for damaged wires, corrosion, or loose connections that may disrupt the flow of electricity.

- Testing Components: Isolate and test individual parts using a multimeter to determine functionality.

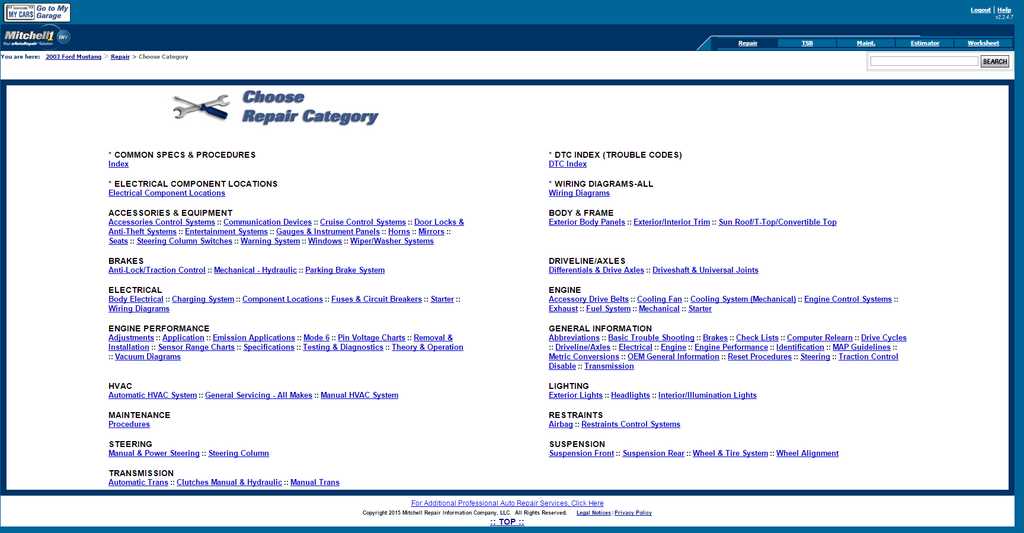

- Scan Tools: Utilize diagnostic tools to read error codes from the vehicle’s computer, pinpointing specific issues within the electrical system.

Understanding these systems and employing proper diagnostic techniques can lead to quicker resolutions and enhanced reliability for any vehicle.

Understanding the Engine Components

Familiarity with the various parts of an engine is crucial for any enthusiast or technician. Each component plays a vital role in ensuring that the power unit operates smoothly and efficiently. Recognizing these parts not only aids in maintenance but also enhances the ability to diagnose issues when they arise.

Key Engine Parts

- Engine Block: The main structure housing most engine components, providing support and stability.

- Pistons: Move up and down within the cylinders, converting fuel combustion into mechanical energy.

- Cylinders: The chambers where combustion occurs; they are essential for the engine’s power generation.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, powering the drivetrain.

- Camshaft: Controls the opening and closing of the intake and exhaust valves, regulating airflow in and out of the engine.

Supporting Systems

- Fuel System: Delivers the necessary fuel to the engine for combustion.

- Ignition System: Initiates the combustion process by igniting the air-fuel mixture.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and damage.

- Lubrication System: Ensures smooth operation by reducing friction between moving parts.

Understanding these components and their functions is essential for anyone involved in automotive maintenance or repair. Knowledge of how they work together enhances troubleshooting skills and promotes effective upkeep of the power unit.

Transmission Problems and Solutions

When it comes to vehicle performance, transmission issues can be particularly frustrating for drivers. These problems can manifest in various ways, including slipping gears, delayed engagement, or unusual noises. Identifying and addressing these concerns promptly is crucial to maintaining optimal functionality and prolonging the lifespan of the drivetrain.

Common Symptoms of Transmission Issues

Drivers may experience several indicators that point to transmission troubles. For instance, if the vehicle struggles to shift smoothly or exhibits a jerking sensation during gear changes, it could suggest internal malfunctions. Additionally, fluid leaks under the vehicle are a clear sign that attention is needed. Paying close attention to warning lights on the dashboard can also provide valuable information regarding potential failures.

Potential Solutions and Maintenance Tips

Addressing transmission problems often involves a series of systematic steps. First, checking the fluid level and quality is essential; low or contaminated fluid can lead to significant performance issues. If the fluid appears burnt or contains debris, a replacement may be necessary. Regular maintenance, including fluid changes and inspections, can help prevent many common complications. In cases of severe damage, professional assistance may be required to assess and perform necessary repairs or replacements.

Suspension and Steering Adjustments

The proper alignment and adjustment of the suspension and steering components are crucial for ensuring optimal performance and safety in any vehicle. These systems work in harmony to provide stability, comfort, and control, making it essential to address any irregularities or wear promptly. Regular maintenance and timely adjustments can greatly enhance driving experience and prolong the lifespan of various parts.

Suspension adjustments primarily focus on the height and stiffness of the system, affecting how the vehicle handles various terrains. If the ride height is uneven, it may lead to compromised handling and uneven tire wear. Ensuring that springs and shock absorbers are in good condition is vital, as they absorb impacts and maintain contact with the road surface. Regular checks for leaks or damage can prevent more extensive issues down the line.

Steering alignment is equally important, as it influences how the vehicle responds to driver inputs. Misalignment can result from hitting potholes or general wear and tear. Adjusting the camber, caster, and toe angles ensures that the wheels point in the correct direction, enhancing steering precision and overall stability. It’s advisable to have these angles checked periodically, especially after significant driving events.

Resources for DIY Enthusiasts

For those who enjoy hands-on projects, finding reliable resources is crucial. Whether you’re tackling a maintenance task or a more complex upgrade, having access to the right information can make the process smoother and more enjoyable.

- Online Forums: Engaging with communities dedicated to automotive projects can provide insights, tips, and solutions to common challenges.

- Video Tutorials: Platforms like YouTube host a plethora of step-by-step guides that can visually assist you in various tasks.

- Specialized Websites: Numerous sites offer detailed articles, diagrams, and user-generated content tailored for enthusiasts of different skill levels.

- Workshops and Classes: Local automotive shops and community colleges often provide classes for hands-on learning, fostering skills and confidence.

- Books and Publications: Investing in comprehensive guides can serve as a valuable reference, offering in-depth knowledge and techniques.

Utilizing these resources can empower enthusiasts to tackle projects effectively, ensuring a rewarding experience in automotive care and enhancement.