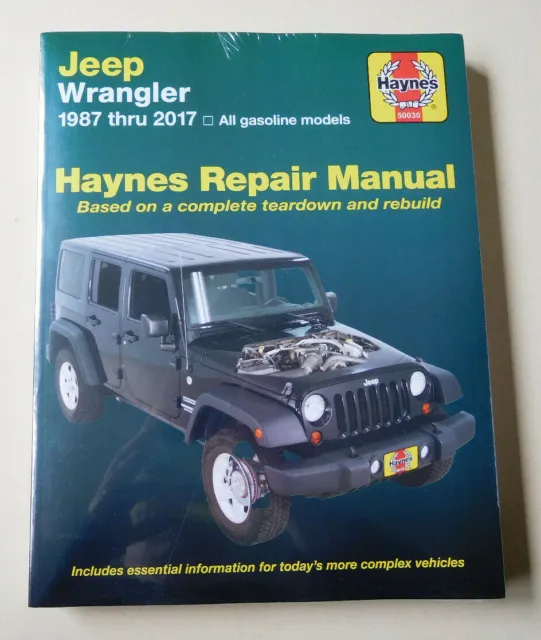

Comprehensive Guide to Jeep Wrangler JK Repairs

Maintaining an off-road vehicle can be both a rewarding and challenging endeavor. This section aims to provide essential insights and practical information tailored for enthusiasts and owners seeking to enhance their knowledge about vehicle upkeep. Whether it’s routine maintenance or troubleshooting complex issues, having access to the right information can significantly improve your experience.

In the world of rugged automotive care, understanding your vehicle’s systems is crucial. This guide encompasses detailed instructions, helpful tips, and systematic approaches to address common problems effectively. By following the outlined procedures, you can ensure optimal performance and longevity, allowing your vehicle to conquer any terrain with confidence.

Additionally, this resource emphasizes the importance of proper techniques and tools necessary for effective vehicle service. With a focus on both preventative measures and reactive solutions, this comprehensive guide serves as a vital reference for any off-road enthusiast aiming to keep their vehicle in peak condition.

Essential Tools for Jeep Maintenance

Proper upkeep of your vehicle requires a selection of fundamental implements to ensure efficiency and longevity. Having the right equipment at your disposal can make routine checks and repairs simpler and more effective, leading to a smoother driving experience.

Basic Tool Kit

A well-rounded toolkit is the cornerstone of any maintenance task. It should include a variety of hand tools, as well as some specialized equipment to tackle specific issues.

| Tool | Purpose |

|---|---|

| Socket Set | Used for tightening and loosening bolts and nuts. |

| Wrenches | Essential for adjusting fittings and hardware. |

| Screwdriver Set | Needed for various screws, both flat and Phillips head. |

| Pliers | Useful for gripping and bending wires and other materials. |

| Jack and Jack Stands | Important for lifting the vehicle safely for undercarriage access. |

Diagnostic Equipment

To efficiently identify problems, diagnostic tools play a crucial role. These devices help in monitoring performance and troubleshooting issues effectively.

| Tool | Purpose |

|---|---|

| OBD-II Scanner | Reads error codes from the vehicle’s computer system. |

| Multimeter | Measures voltage, current, and resistance in electrical systems. |

| Tire Pressure Gauge | Ensures proper inflation of tires for safety and performance. |

| Oil Filter Wrench | Facilitates easy removal of oil filters during changes. |

Common Issues with Jeep Wrangler JK

This section addresses frequent challenges encountered by owners of this popular off-road vehicle. Understanding these common concerns can aid in early detection and effective resolution, ensuring a smooth driving experience.

Mechanical Concerns

Various mechanical components may present issues over time, often related to wear and tear. These include the transmission, suspension system, and engine performance, which can lead to decreased reliability and efficiency.

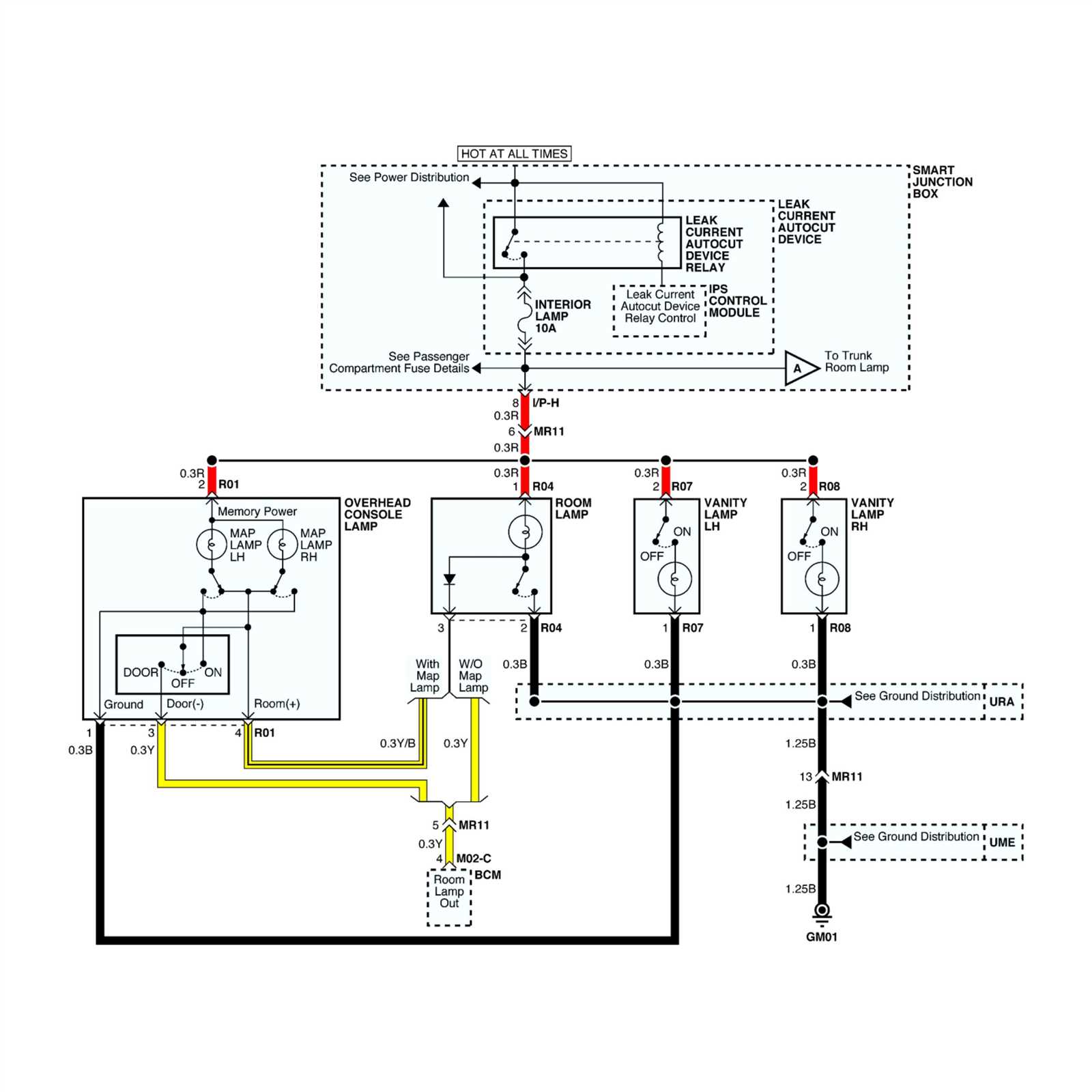

Electrical Problems

Electrical systems in these vehicles can sometimes malfunction, causing inconvenience for users. Common problems include battery drainage, faulty wiring, and issues with lighting systems. Regular checks can help mitigate these issues.

| Issue | Description | Possible Solution |

|---|---|---|

| Transmission Slippage | Difficulty in shifting gears, leading to erratic performance. | Check fluid levels and replace worn components. |

| Suspension Noise | Unusual sounds when driving over bumps, indicating worn bushings or shocks. | Inspect and replace damaged parts. |

| Battery Issues | Frequent battery failures, leading to starting problems. | Test battery health and inspect charging system. |

| Electrical Short Circuits | Inconsistent functioning of electrical accessories. | Check wiring connections and replace faulty components. |

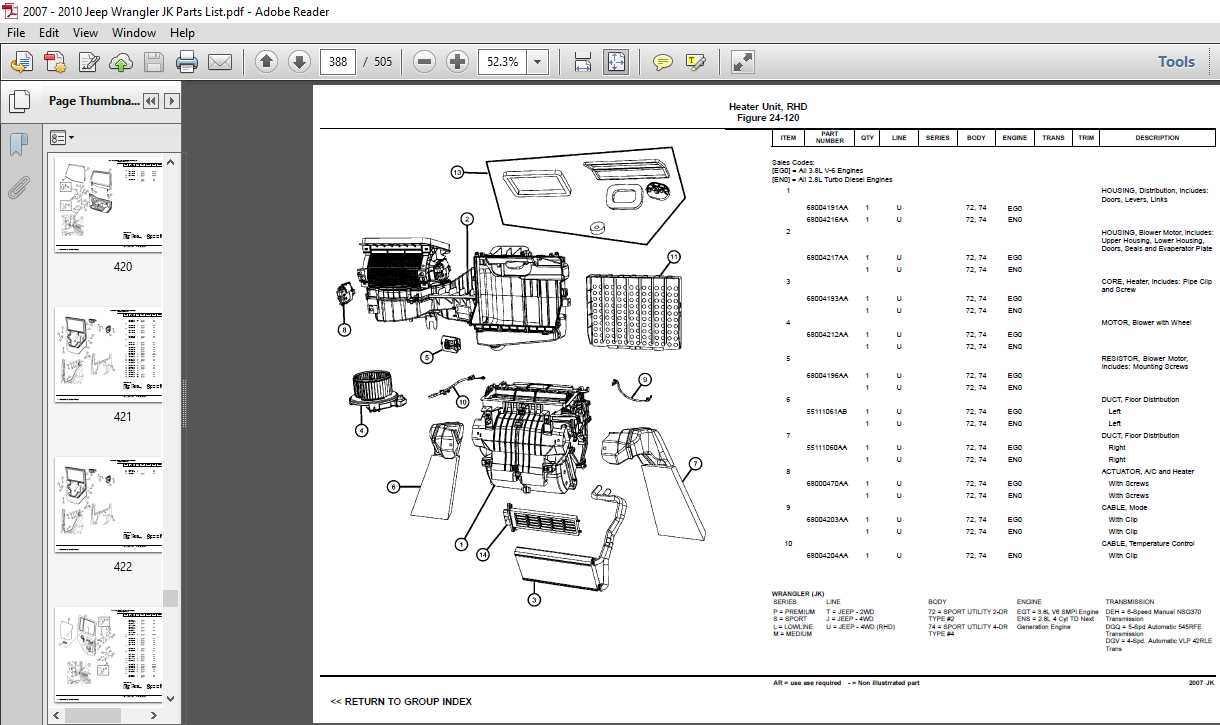

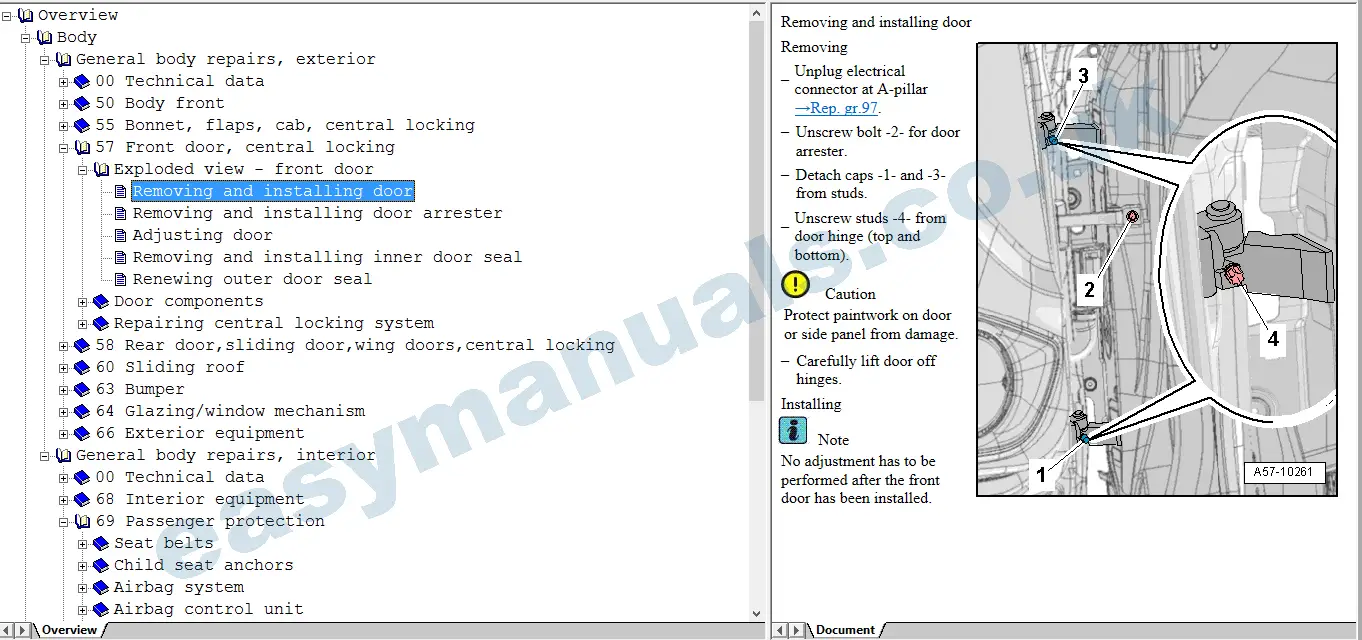

Step-by-Step Repair Procedures

This section outlines systematic techniques for addressing common issues that may arise with your vehicle. Following these detailed instructions will ensure that tasks are completed efficiently and correctly, ultimately enhancing the performance and longevity of the automobile.

Preparation for Maintenance

- Gather necessary tools and materials.

- Ensure a clean and organized workspace.

- Review the specific task requirements to understand the process.

Executing the Repair Process

- Begin by disconnecting the battery to ensure safety.

- Carefully remove any components obstructing access to the area requiring attention.

- Follow the specific instructions for the repair, ensuring all connections are secure.

- Reassemble any components in the reverse order of removal.

- Reconnect the battery and conduct a thorough test to verify functionality.

Understanding Electrical System Components

The electrical system in a vehicle plays a crucial role in ensuring its optimal performance. It consists of various elements that work together to power essential functions and facilitate communication between different systems. A comprehensive understanding of these components can greatly aid in maintenance and troubleshooting.

| Component | Function |

|---|---|

| Battery | Stores electrical energy to start the engine and power accessories. |

| Alternator | Generates electricity to recharge the battery and power electrical systems while the engine runs. |

| Fuses | Protect electrical circuits from overload by breaking the circuit when current exceeds safe levels. |

| Relays | Act as switches that control high-power devices using low-power signals. |

| Wiring Harness | Connects various electrical components, ensuring proper communication and power distribution. |

Fluid Change Recommendations and Intervals

Maintaining optimal performance in any vehicle necessitates regular updates to various fluids. Understanding the correct intervals for these changes is crucial for ensuring longevity and functionality. This section provides guidance on best practices for fluid maintenance.

Engine Oil

It is recommended to replace engine lubricant every 3,000 to 5,000 miles, depending on driving conditions and oil type. Regular checks can help prevent engine wear and enhance efficiency.

Transmission Fluid

For smooth shifting and operational integrity, consider changing transmission fluid every 30,000 to 60,000 miles. Keeping this fluid fresh will contribute to better transmission health and performance.

Following these guidelines will help ensure that the vehicle operates smoothly and efficiently over its lifespan.

Tire Care and Replacement Tips

Proper maintenance of tires is essential for ensuring vehicle safety and performance. Regular checks and timely replacements can prevent accidents and enhance driving comfort. This section covers best practices for tire upkeep and guidance on when to change them.

Regular Inspection

Frequent examinations help identify issues before they escalate. Look for signs of wear, such as uneven tread patterns, cracks, or bulges. Ensuring proper inflation is equally vital, as under-inflated or over-inflated tires can affect handling and fuel efficiency.

When to Replace Tires

Knowing when to replace tires can save you from potential hazards. Consider factors such as tread depth, age, and any visible damage. A tire with a tread depth below 2/32 of an inch should be replaced immediately.

| Indicator | Action |

|---|---|

| Tread Depth | Replace if below 2/32 inches |

| Age | Replace if older than 6 years |

| Visible Damage | Replace if cracks or bulges are present |

Upgrading Suspension for Better Performance

Enhancing the suspension system can significantly improve a vehicle’s handling, ride comfort, and overall driving experience. By selecting appropriate components, drivers can achieve better stability, increased ground clearance, and superior responsiveness, especially on rugged terrains.

One of the primary upgrades involves replacing stock shock absorbers with high-performance variants. Quality shocks not only provide better damping but also enhance the vehicle’s ability to absorb impacts from uneven surfaces. Additionally, installing a lift kit can offer more ground clearance, allowing for larger tires and improved off-road capability.

Upgrading to heavy-duty springs is another essential step. These springs can support additional weight and resist sagging over time, ensuring consistent performance even under demanding conditions. Furthermore, considering adjustable suspension systems can provide versatility, enabling drivers to fine-tune their setup based on specific driving needs.

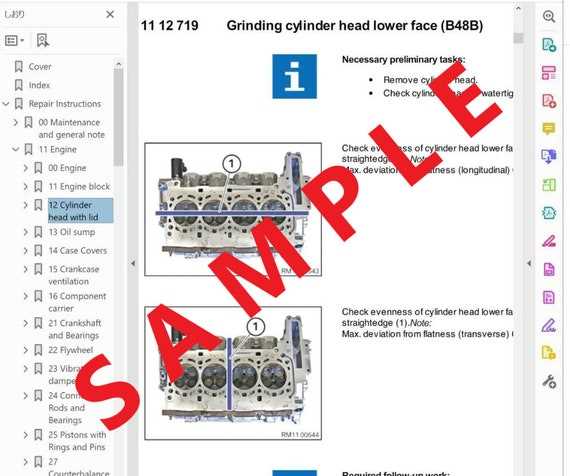

Diagnostic Techniques for Engine Problems

Identifying issues within an engine requires a systematic approach that encompasses various methodologies. These techniques assist in pinpointing malfunctions and optimizing performance, ensuring reliable operation. A thorough understanding of symptoms and possible causes is essential for effective diagnosis.

Common Symptoms to Observe

- Unusual noises, such as knocking or tapping

- Decreased power or acceleration

- Excessive exhaust smoke or unusual colors

- Increased fuel consumption

- Warning lights illuminating on the dashboard

Methods for Troubleshooting

- Visual Inspection: Begin with a thorough examination of the engine compartment for obvious signs of wear, leaks, or damaged components.

- Diagnostic Tools: Utilize OBD-II scanners to retrieve error codes that can guide the troubleshooting process.

- Test Drive: Assess vehicle performance under various conditions to gather data on symptoms experienced during operation.

- Component Testing: Check individual parts, such as spark plugs and sensors, to ensure they are functioning correctly.

- Fluid Analysis: Examine engine oils and coolant for contamination or degradation that could indicate deeper issues.

By applying these techniques, one can systematically address and resolve engine-related complications, enhancing overall functionality and longevity.

Body Repairs and Painting Techniques

Ensuring the integrity and aesthetics of a vehicle’s exterior involves a variety of methods and strategies. Understanding the fundamentals of addressing surface damage and applying protective finishes is essential for maintaining both functionality and visual appeal.

Essential Steps for Surface Restoration

- Assess the extent of the damage to determine the appropriate repair technique.

- Clean the affected area thoroughly to remove dirt and debris.

- Use body filler to fill in dents and scratches, ensuring a smooth finish.

- Sand the repaired surface to create an even texture and prepare for painting.

Painting Techniques for a Professional Finish

- Choose high-quality paint suited for the vehicle’s exterior conditions.

- Apply a primer coat to enhance adhesion and durability.

- Use even strokes while spraying or rolling the paint to avoid runs and drips.

- Allow adequate drying time between coats to achieve optimal results.

Safety Protocols During Repairs

Ensuring a secure environment while conducting maintenance work is paramount. Adopting appropriate safety measures minimizes risks and promotes a smooth workflow. Every individual involved should be well-informed and equipped to handle potential hazards, thus fostering a culture of safety and preparedness.

Personal Protective Equipment

Utilizing the right personal protective gear is essential. Items such as gloves, goggles, and ear protection shield individuals from injuries that can occur from tools and hazardous materials. Always ensure that your equipment fits correctly and is in good condition before starting any task.

Workspace Organization

A well-organized workspace reduces the likelihood of accidents. Keep tools and materials neatly arranged, and ensure that walkways are clear of obstructions. Properly storing hazardous substances and disposing of waste materials responsibly enhances safety and efficiency.

Maintaining Off-Road Capabilities

Ensuring optimal performance in rugged environments requires a comprehensive approach to upkeep and enhancement. Proper attention to various components and systems can significantly improve overall functionality when traversing challenging terrains.

Here are key areas to focus on for maintaining off-road efficiency:

- Tire Management: Regularly inspect tire pressure and tread depth. Consider using specialized tires designed for off-road conditions.

- Suspension Checks: Maintain the suspension system to absorb shocks and provide stability. Replace worn-out parts promptly.

- Fluid Levels: Ensure all essential fluids, including engine oil, transmission fluid, and differential oil, are at appropriate levels and free of contaminants.

- Brake System: Inspect brakes frequently, as off-road driving can wear them down faster. Replace pads and rotors as needed.

- Electrical Systems: Check the battery and wiring for any signs of corrosion or damage. Ensure all lights and signals are functioning correctly.

Adhering to these maintenance practices will help retain the capability to navigate diverse landscapes while enhancing safety and performance.