Kia Sportage 2000 Repair Guide

Ensuring the longevity and optimal performance of your automobile requires a thorough understanding of its components and systems. This section serves as a valuable resource for individuals seeking detailed insights into the upkeep and troubleshooting of their vehicles. By following proper guidelines, owners can enhance the reliability and efficiency of their machinery.

In this guide, readers will find essential information that covers various aspects of vehicle servicing, including step-by-step procedures, diagnostic techniques, and preventative measures. Such knowledge empowers car owners to tackle common issues independently and make informed decisions regarding necessary repairs.

Utilizing this comprehensive resource, enthusiasts and everyday drivers alike can navigate the complexities of automotive care. With a focus on clarity and practicality, this section aims to demystify the intricacies of vehicle maintenance, enabling users to approach their automotive challenges with confidence.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. Proper tools not only make the job easier but also ensure that repairs are executed effectively, leading to enhanced performance and longevity of the vehicle. Below are some vital implements that should be part of every enthusiast’s toolkit.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flat-head and Phillips types are necessary for various fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Socket Set: Provides versatility for different nut sizes, making tasks quicker.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Oil Filter Wrench: Simplifies the removal of the oil filter during changes.

- Jack and Stands: Necessary for lifting the vehicle safely during underbody work.

- Diagnostic Scanner: Helps identify error codes and troubleshoot issues efficiently.

Common Issues in 2000 Models

The vehicles from this era often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems can help owners maintain their automobiles more effectively.

- Electrical Failures: Issues with wiring and electrical components are frequently reported, leading to problems with lights and other electronic systems.

- Transmission Concerns: Many owners experience difficulties with shifting gears, which may be attributed to fluid leaks or transmission wear.

- Engine Performance: Problems such as rough idling and decreased acceleration are common, often linked to fuel system blockages or sensor malfunctions.

- Suspension Wear: Components such as bushings and struts may wear out prematurely, resulting in a bumpy ride and handling issues.

- Cooling System Failures: Overheating due to coolant leaks or faulty thermostats is a prevalent concern, which can lead to severe engine damage if not addressed promptly.

By being aware of these potential issues, owners can take proactive measures to ensure their vehicles remain in good condition for years to come.

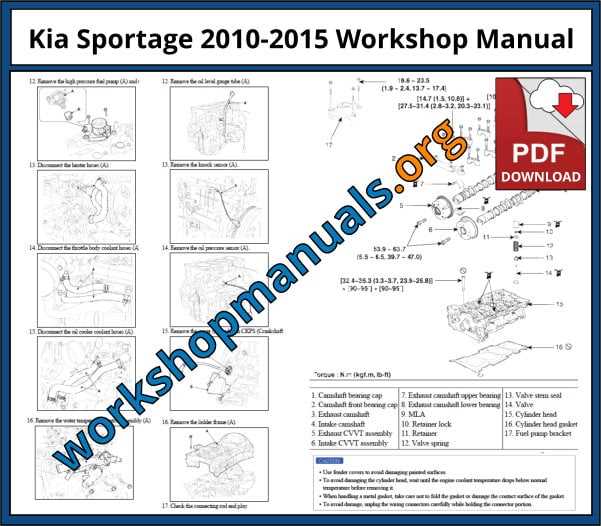

Engine Specifications and Troubleshooting

This section provides essential information regarding the performance and maintenance of the engine, along with common issues and their solutions. Understanding these specifications is vital for ensuring optimal functioning and longevity of the powertrain.

| Specification | Details |

|---|---|

| Engine Type | 4-Cylinder, DOHC |

| Displacement | 2.0 liters |

| Fuel System | Multi-Point Fuel Injection |

| Horsepower | 130 hp @ 6000 rpm |

| Torque | 135 lb-ft @ 4000 rpm |

Identifying and resolving engine problems requires a methodical approach. Regular checks can prevent major failures. Key symptoms include unusual noises, decreased power, and abnormal fluid leaks. Immediate attention to these indicators can lead to more straightforward and cost-effective solutions.

Transmission and Drivetrain Insights

This section delves into the essential components and functioning of the vehicle’s transmission and drivetrain systems. Understanding these elements is crucial for optimal performance, longevity, and addressing any potential issues that may arise during the vehicle’s lifecycle.

Key Components

The drivetrain is comprised of several vital parts that work in unison to ensure the vehicle operates smoothly. These include:

- Transmission: Responsible for transferring power from the engine to the wheels, allowing the vehicle to change speeds efficiently.

- Driveshaft: A rotating shaft that transmits torque from the transmission to the differential, enabling power delivery to the wheels.

- Differential: A mechanical component that allows the wheels to rotate at different speeds, especially important during turns.

- Axles: Connect the differential to the wheels, supporting the vehicle’s weight while facilitating rotation.

Common Issues and Maintenance

Regular maintenance of the transmission and drivetrain is essential to avoid significant problems. Here are some common issues and tips for upkeep:

- Fluid Checks: Ensure transmission fluid is at the proper level and in good condition, as it lubricates and cools the system.

- Leaks: Look for signs of fluid leaks under the vehicle, which can indicate a failing seal or gasket.

- Strange Noises: Pay attention to any unusual sounds during operation, as they may signal mechanical issues.

- Performance Changes: Noticeable changes in shifting or acceleration may require immediate attention to prevent further damage.

Brake System Components Explained

The braking system is crucial for ensuring vehicle safety and performance. It consists of various components that work together to slow down or stop the vehicle effectively. Understanding these parts can help in maintaining and diagnosing any issues that may arise during operation.

| Component | Description |

|---|---|

| Brake Pads | Friction materials that press against the brake rotor to create the necessary stopping power. |

| Brake Rotors | Disc-shaped components that provide a surface for the brake pads to clamp onto, converting kinetic energy into thermal energy. |

| Calipers | Devices that house the brake pads and use hydraulic pressure to push the pads against the rotors. |

| Brake Lines | Hoses that transfer hydraulic fluid from the master cylinder to the calipers. |

| Master Cylinder | The central component that generates hydraulic pressure within the braking system when the brake pedal is pressed. |

Electrical System Diagnostics

Diagnosing issues within an electrical framework is crucial for ensuring optimal performance and reliability of the vehicle. This process involves a systematic approach to identify malfunctions, assess the functionality of various components, and verify that electrical systems operate within specified parameters. Proper diagnosis can save time and resources while enhancing overall vehicle safety and efficiency.

Common Electrical Issues

Various problems can arise within the electrical system, including faulty wiring, malfunctioning sensors, and degraded connections. Understanding these common issues helps in troubleshooting effectively. Symptoms may range from flickering lights to complete failure of electrical components, indicating underlying problems that require immediate attention.

Diagnostic Tools and Techniques

Utilizing specialized diagnostic equipment is essential for accurate analysis. Tools such as multimeters and oscilloscopes aid in measuring voltage, current, and resistance, providing valuable data for evaluating the condition of electrical circuits. Visual inspections and component testing are also integral parts of the diagnostic process, allowing technicians to pinpoint defects and ensure all systems function correctly.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle performance. These adjustments ensure a smooth ride, enhance handling, and prolong the lifespan of various components. Addressing any misalignment or wear can prevent uneven tire wear and improve overall safety.

Alignment Procedures

To achieve correct alignment, start by checking the angles of the wheels. Camber, caster, and toe should be within manufacturer specifications. Adjustments can be made using specialized tools to ensure that the wheels are perpendicular to the ground and parallel to each other.

Steering System Calibration

In addition to alignment, the steering system may require calibration to maintain responsiveness. Inspect the steering components for wear or damage, and adjust as needed. Ensuring that the steering linkage is properly set will enhance the driving experience and improve maneuverability.

Cooling System Maintenance Tips

The proper upkeep of a vehicle’s cooling system is essential for optimal performance and longevity. Regular attention to this system helps prevent overheating and ensures that the engine operates at the correct temperature. Here are some effective strategies to maintain this crucial component.

Regular Inspection

Conducting frequent inspections can help identify potential issues before they escalate. Look for signs of leaks, corrosion, or worn hoses. Regularly checking coolant levels is vital to ensure the system functions effectively.

Coolant Replacement Schedule

Changing the coolant at recommended intervals is critical to maintaining the integrity of the cooling system. Over time, coolant can become contaminated and lose its effectiveness. Refer to the vehicle’s guidelines for the appropriate replacement schedule.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and clamps | Every 3 months | Replace any that are cracked or loose |

| Check coolant level | Monthly | Add if low; ensure no leaks |

| Flush cooling system | Every 2 years | Helps remove deposits and contaminants |

| Replace thermostat | As needed | Symptoms include overheating or poor temperature regulation |

Interior Features and Repairs

The comfort and functionality of a vehicle’s interior significantly enhance the overall driving experience. Understanding the components and systems within the cabin is essential for maintenance and addressing any issues that may arise. This section will provide insights into the key elements found inside the vehicle and guidance on troubleshooting common problems.

| Feature | Description | Common Issues | Basic Repair Tips |

|---|---|---|---|

| Dashboard | Houses instruments and controls, providing essential information. | Flickering lights, warning indicators. | Check fuses and connections; replace faulty bulbs. |

| Seating | Designed for comfort with various adjustments available. | Torn upholstery, malfunctioning adjusters. | Use upholstery repair kits; lubricate moving parts. |

| Audio System | Enables entertainment through music and communication. | No sound, static interference. | Inspect wiring and connections; reset the system. |

| Climate Control | Regulates temperature and air quality within the cabin. | Inadequate heating/cooling, strange noises. | Check refrigerant levels; clean filters and vents. |

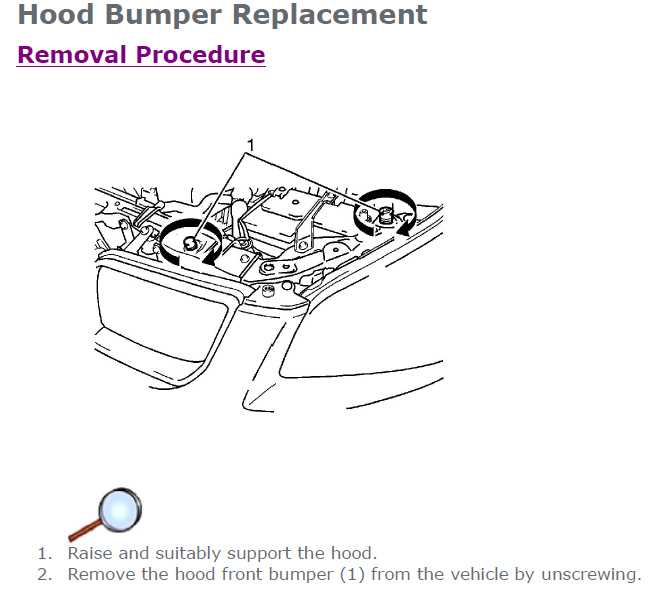

Exterior Care and Bodywork

The maintenance of a vehicle’s exterior is essential for preserving its appearance and longevity. Regular cleaning and protection not only enhance aesthetic appeal but also safeguard the bodywork from environmental elements that can lead to deterioration. This section delves into effective strategies for caring for the outer surfaces of your vehicle, ensuring it remains in prime condition.

Routine Cleaning Practices

To maintain the exterior’s shine, it is important to wash the vehicle regularly. Utilize a gentle automotive soap and a soft sponge to avoid scratches. Pay special attention to areas where dirt and grime tend to accumulate, such as the wheel wells and undercarriage. Rinse thoroughly to remove any soap residue, and dry with a microfiber towel to prevent water spots.

Protection and Restoration

Applying a quality wax or sealant can significantly protect the paintwork from harmful UV rays and contaminants. This protective layer helps to repel water and dirt, making future cleanings easier. For scratches and imperfections, consider using touch-up paint or a specialized compound to restore the original finish. Regularly inspecting the bodywork for chips and rust is crucial to addressing issues before they escalate.

Service Intervals and Recommendations

Regular maintenance is essential for ensuring optimal performance and longevity of your vehicle. Following a structured schedule for servicing various components not only enhances safety but also prevents costly repairs down the line. This section outlines the recommended intervals for routine checks and services to keep your automobile running smoothly.

Maintenance Schedule

It is advisable to adhere to a maintenance timetable that includes oil changes, filter replacements, and inspections of critical systems such as brakes and tires. Typically, oil changes should occur every 3,000 to 5,000 miles, while other components may require inspection at longer intervals, such as every 15,000 or 30,000 miles. Regularly monitoring fluid levels and replacing worn parts can greatly contribute to the overall health of your vehicle.

Additional Recommendations

In addition to following the maintenance schedule, drivers should remain attentive to any unusual sounds or performance issues. Addressing concerns promptly can prevent minor problems from escalating. Seasonal checks, especially before extreme weather changes, are also beneficial. Ensuring that your vehicle is ready for the conditions can enhance both safety and comfort on the road.