Comprehensive Guide to Repairing the 1994 Mazda B3000

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. This section aims to provide valuable insights and practical advice for individuals looking to enhance their automotive knowledge. Whether you’re a novice or an experienced enthusiast, understanding the intricacies of vehicle upkeep can save time and money.

By exploring detailed instructions and expert tips, readers can learn about various aspects of their vehicle’s functionality. From routine checks to complex troubleshooting, having access to a reliable resource is crucial for effective maintenance. The information provided will help demystify common challenges faced by vehicle owners, empowering them to take charge of their automotive care.

Equipped with the right knowledge, individuals can confidently address issues as they arise. This resource serves as a roadmap for successful maintenance practices, promoting a deeper understanding of automotive systems and components. Embrace the journey of learning and elevate your vehicle care skills.

Overview of the 1994 Mazda B3000

This section provides an insight into a mid-size pickup, known for its blend of utility and comfort. The vehicle has garnered attention for its reliable performance and well-thought-out features, making it a popular choice among enthusiasts and everyday users alike.

Key Features and Specifications

Equipped with a robust engine, this model delivers a commendable balance between power and efficiency. The design focuses on functionality, with ample cargo space and a comfortable interior layout. Advanced safety features for its time enhance the overall driving experience.

Performance and Handling

Known for its dependable handling, the vehicle performs well in various driving conditions. The suspension system contributes to a smooth ride, while the responsive steering ensures a confident driving experience. Overall, this pickup stands out as a versatile option for both work and leisure activities.

Common Issues and Solutions

Understanding typical challenges faced by vehicle owners can significantly enhance the experience of maintenance and troubleshooting. This section highlights frequent problems encountered with certain models and provides practical solutions to address them effectively.

Electrical System Malfunctions

One common issue involves electrical failures, such as intermittent power loss or malfunctioning components. Often, these problems stem from corroded connections or faulty wiring. Regularly inspecting and cleaning connectors can help maintain a reliable electrical system. Additionally, replacing damaged fuses and ensuring proper grounding can prevent further complications.

Engine Performance Problems

Another prevalent concern relates to engine performance, including rough idling or decreased power output. These symptoms may indicate issues with fuel delivery or ignition systems. Checking and replacing air filters, spark plugs, and fuel injectors can enhance engine efficiency. It’s also advisable to perform regular diagnostics to identify underlying issues promptly.

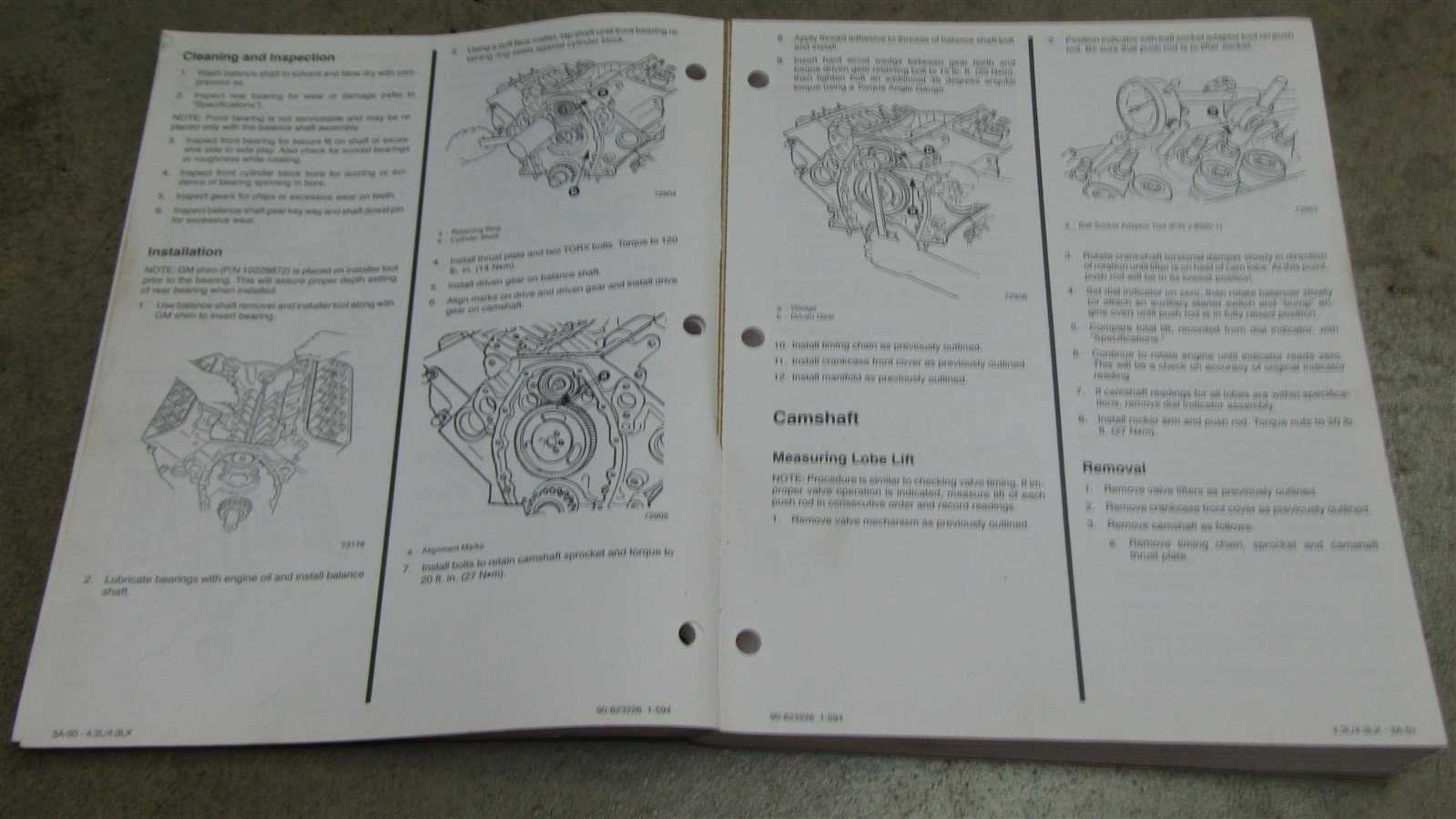

Engine Maintenance Tips

Regular upkeep of your vehicle’s power unit is essential for optimal performance and longevity. By following a few simple guidelines, you can ensure your engine runs smoothly and efficiently over time.

Routine Checks

- Inspect oil levels and quality regularly.

- Check coolant levels to prevent overheating.

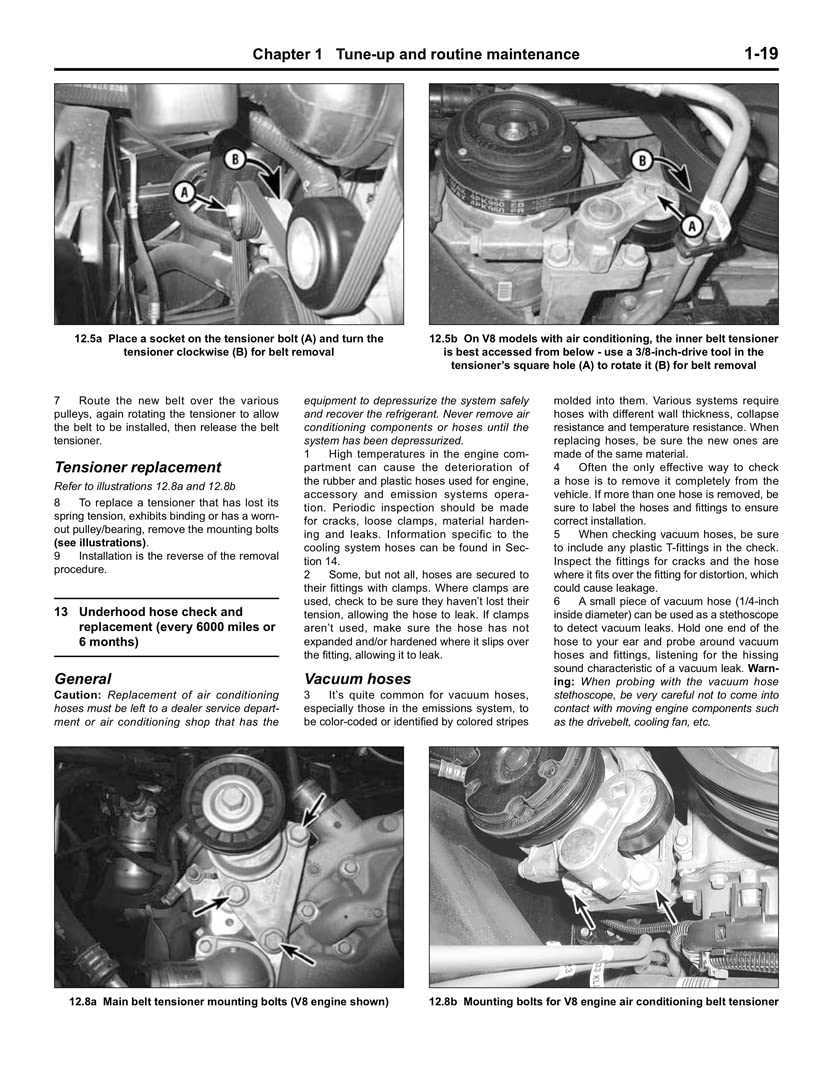

- Monitor the condition of belts and hoses for wear and tear.

Scheduled Maintenance

- Change the engine oil and filter as recommended.

- Replace air and fuel filters to maintain airflow and fuel efficiency.

- Keep spark plugs in good condition for effective ignition.

Following these practices can help extend the life of your engine and improve overall performance.

Transmission Troubleshooting Guide

This section aims to provide essential insights into identifying and resolving common issues related to the gear-shifting system. Effective diagnostics can prevent further complications and ensure optimal performance.

Common Symptoms of Transmission Issues

- Unresponsive or delayed shifting

- Strange noises during gear changes

- Fluid leaks underneath the vehicle

- Warning lights illuminated on the dashboard

Diagnostic Steps

- Check Fluid Levels: Ensure the transmission fluid is at the recommended level and appears clean.

- Inspect for Leaks: Look for signs of leaking fluid, which may indicate a faulty seal or gasket.

- Listen for Noises: Pay attention to any unusual sounds while the vehicle is in motion, as they may signal internal issues.

- Examine Electrical Connections: Ensure that all sensors and wiring related to the transmission are properly connected.

Brake System Inspection Procedures

Regular evaluation of the braking system is crucial for ensuring vehicle safety and performance. This process involves a series of steps designed to identify potential issues and maintain optimal functionality.

Follow these essential steps for thorough inspection:

- Visual Inspection:

- Check for any visible leaks around brake lines and calipers.

- Inspect brake pads for wear; replace if they are below the recommended thickness.

- Examine rotors for signs of scoring or warping.

- Fluid Level Check:

- Ensure brake fluid reservoir is filled to the recommended level.

- Inspect fluid condition; it should be clear and free of debris.

- Function Test:

- Press the brake pedal to assess responsiveness; it should feel firm.

- Perform a test drive to evaluate braking performance, paying attention to any unusual noises.

By adhering to these procedures, one can ensure that the braking system remains effective and reliable, contributing to overall vehicle safety.

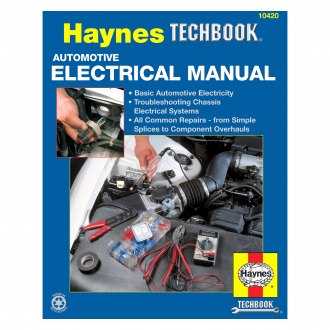

Electrical System Diagnostics

Effective evaluation of an automobile’s electrical components is crucial for maintaining optimal performance. This section explores the methods and tools necessary for troubleshooting and diagnosing common electrical issues that can affect vehicle operation. Understanding these systems can help identify faults before they lead to more significant problems.

Common Symptoms and Troubleshooting Steps

Drivers may encounter various signs indicating electrical system malfunctions, such as flickering lights or difficulty starting the engine. Initial steps include checking the battery’s condition, inspecting fuses for continuity, and ensuring proper connections at terminals. A thorough examination of wiring for wear or damage is essential, as compromised insulation can lead to short circuits or intermittent failures.

Diagnostic Tools and Techniques

Utilizing diagnostic tools can significantly enhance troubleshooting efficiency. A multimeter is invaluable for measuring voltage, current, and resistance within circuits. Additionally, specialized scan tools can provide error codes related to the electrical system, aiding in pinpointing specific issues. Regular use of these methods can prevent costly repairs and extend the lifespan of electrical components.

Cooling System Repair Techniques

The effective maintenance of a vehicle’s thermal management system is crucial for optimal performance and longevity. Addressing issues within this system not only prevents overheating but also enhances overall efficiency. Various methods can be employed to diagnose and resolve common problems.

Inspection and Diagnostics: Regular checks of hoses, clamps, and connections can reveal potential leaks or weaknesses. Utilizing a pressure test can help identify faulty components by simulating operating conditions.

Fluid Replacement: Over time, the coolant may become contaminated or lose its effectiveness. Flushing the system and replacing old fluid with a fresh mixture ensures proper heat transfer and prevents corrosion.

Component Replacement: If issues persist, specific parts such as the thermostat, radiator, or water pump may need replacement. Selecting high-quality components will contribute to a more reliable system and reduce the likelihood of future problems.

System Bleeding: After any service, it’s essential to remove air pockets from the system. This process, known as bleeding, allows for efficient circulation and prevents overheating due to trapped air.

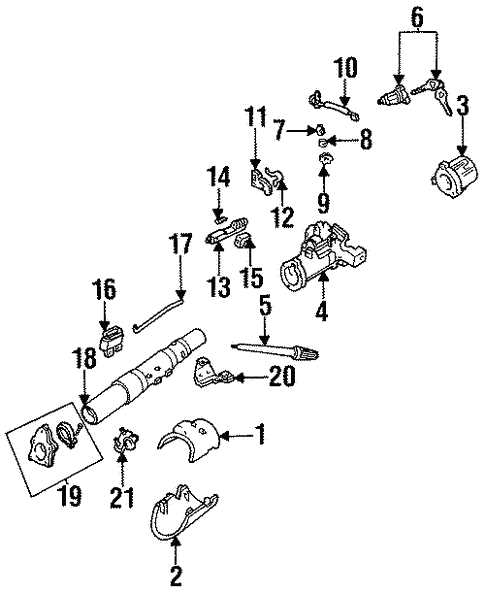

Suspension and Steering Care

Maintaining the suspension and steering system is essential for ensuring optimal vehicle performance and safety. Regular attention to these components can enhance handling, improve ride quality, and prolong the lifespan of crucial parts.

To achieve effective maintenance, consider the following key aspects:

- Regular Inspections: Periodically check the suspension components for signs of wear, such as leaks in shock absorbers and loose connections.

- Wheel Alignment: Ensure proper alignment to prevent uneven tire wear and enhance handling capabilities.

- Fluid Levels: Monitor and maintain appropriate levels of steering fluid to ensure smooth operation.

- Tire Maintenance: Regularly inspect tires for proper inflation, tread depth, and alignment to promote stability and control.

Following these practices can lead to improved vehicle responsiveness and a more enjoyable driving experience. Proper care also helps avoid costly repairs in the long run.

Bodywork and Frame Considerations

Addressing the structure and exterior elements of a vehicle is crucial for both aesthetics and functionality. Ensuring the integrity of the body and frame plays a significant role in performance, safety, and longevity. This section delves into essential aspects of maintaining and repairing these components.

Common Issues and Solutions

Various challenges can arise concerning the body and frame. Rust, dents, and misalignments are frequent concerns that may compromise the vehicle’s appearance and structural soundness. Identifying these issues early can prevent further damage and costly repairs.

Preventive Measures

Regular maintenance is key to preserving the condition of the exterior and framework. Cleaning, sealing, and applying protective coatings can extend the life of these components. Additionally, proper storage and handling can mitigate risks associated with environmental factors.

| Issue | Solution |

|---|---|

| Rust Formation | Use rust inhibitors and regular inspections |

| Dents and Scratches | Utilize paintless dent repair techniques |

| Frame Misalignment | Professional alignment services and adjustments |

Exhaust System Repair Guidelines

Addressing issues within the exhaust assembly is crucial for maintaining optimal vehicle performance and ensuring compliance with environmental standards. This section outlines essential practices for effectively diagnosing and remedying complications within the exhaust framework.

Key considerations include:

- Regular inspections for leaks or damage.

- Identifying unusual sounds during operation.

- Checking for rust or corrosion on components.

When undertaking modifications or replacements, follow these steps:

- Gather necessary tools, such as wrenches, clamps, and safety equipment.

- Lift the vehicle securely to access the exhaust system.

- Detach any sections needing replacement with caution.

- Install new components, ensuring all connections are tight and secure.

- Test for leaks after reassembly by running the engine and checking for any unusual emissions or sounds.

Following these guidelines will help ensure a safe and effective overhaul of the exhaust system, enhancing overall vehicle functionality.

Regular Service Schedule Recommendations

Maintaining optimal performance and longevity of your vehicle requires adhering to a structured maintenance timeline. Regular servicing ensures that all critical systems function efficiently and any potential issues are addressed promptly. Following these recommendations can enhance reliability and safety while driving.

Oil Change and Fluid Checks

It is essential to replace the engine lubricant every 3,000 to 5,000 miles, depending on driving conditions. Regularly checking other fluids, such as coolant, brake fluid, and transmission fluid, is also crucial. Keeping these levels at their recommended capacities helps prevent overheating and ensures smooth operation.

Filter Replacements

Changing air and fuel filters every 15,000 miles will improve engine efficiency and performance. A clean air filter allows for better airflow, while a fresh fuel filter ensures that contaminants do not reach the engine. Regular replacements contribute to a healthier operating environment.

Parts Replacement Best Practices

When it comes to maintaining vehicle performance, effective component replacement plays a crucial role. Ensuring that parts are installed correctly can enhance longevity and functionality. Adopting best practices during this process not only prevents future issues but also promotes overall safety on the road.

Quality Over Cost

Choosing high-quality replacements is essential. While it may be tempting to opt for cheaper alternatives, inferior parts can lead to premature failure and increased maintenance costs in the long run. Always prioritize reputable brands and verify the specifications to ensure compatibility with the vehicle.

Proper Tools and Techniques

Using the right tools is vital for effective installation. Each component may require specific equipment for a secure fit. Additionally, following the manufacturer’s guidelines or trusted resources can help avoid common mistakes. This diligence ensures that each part functions as intended, contributing to the vehicle’s optimal performance.

Tools and Equipment Needed

Having the right instruments and apparatus is essential for effective maintenance and troubleshooting of your vehicle. Properly chosen tools can significantly simplify tasks, enhance efficiency, and ensure safety during any project.

Below is a list of essential items you will require:

- Basic Hand Tools:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Ratchet set with sockets

- Specialty Tools:

- Torque wrench

- OBD-II scanner for diagnostics

- Brake caliper tool

- Oil filter wrench

- Safety Equipment:

- Safety glasses

- Gloves (mechanic’s and nitrile)

- Ear protection (if necessary)

- Maintenance Supplies:

- Engine oil

- Coolant

- Brake fluid

- Various filters (oil, air, fuel)

Equipping yourself with these tools will facilitate a more seamless and effective approach to handling maintenance tasks and resolving issues. Prioritizing quality and reliability in your selection will also contribute to better outcomes in your endeavors.