2010 Mazda CX-7 Repair Manual Overview

Ensuring optimal performance of your vehicle requires a comprehensive understanding of its components and systems. This section provides valuable insights into the upkeep and diagnostics of a specific model from a renowned manufacturer, aiming to equip owners with the necessary knowledge for effective vehicle management.

By delving into the intricacies of the automotive systems, readers will gain a clearer perspective on how to maintain their vehicle’s reliability. From routine checks to more complex troubleshooting techniques, this guide emphasizes the importance of proper care and attention, empowering enthusiasts and everyday drivers alike.

Moreover, this resource serves as a crucial tool for identifying common issues and understanding the underlying mechanics. Equipped with this knowledge, vehicle owners can make informed decisions regarding maintenance and repairs, ensuring longevity and efficiency in their driving experience.

2010 Mazda CX-7 Overview

This section provides a comprehensive insight into a remarkable vehicle designed for versatility and performance. With a sleek design and robust features, it stands out in its class, appealing to those who seek a blend of style and practicality. Its innovative engineering offers both comfort and driving excitement, making it a popular choice among enthusiasts and families alike.

Key Features

The model showcases an array of features aimed at enhancing the driving experience. From advanced safety systems to modern entertainment options, it caters to various preferences and needs. The spacious interior provides ample room for passengers and cargo, ensuring comfort during long journeys.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Turbocharged Inline-4 |

| Horsepower | 244 hp |

| Transmission | 6-Speed Automatic |

| Fuel Economy | 20 MPG City / 28 MPG Highway |

| Seating Capacity | 5 Passengers |

Common Issues with the Mazda CX-7

The vehicle in question has garnered attention for several recurring complications that drivers may encounter. Understanding these frequent concerns can assist owners in maintaining optimal performance and ensuring a longer lifespan for their vehicle.

Engine and Performance Problems

One of the primary areas of concern involves the engine and overall performance. Owners have reported issues such as:

- Excessive oil consumption, leading to the need for more frequent oil top-ups.

- Turbocharger failure, which can result in decreased power and acceleration.

- Rough idling or stalling, often attributed to faulty sensors or fuel delivery problems.

Electrical System Failures

The electrical system is another aspect that has posed challenges for users. Common electrical issues include:

- Malfunctioning dashboard lights, which can hinder visibility of critical information.

- Problems with the power windows or locks, affecting convenience and security.

- Battery drain, often caused by parasitic draws from various electronic components.

Maintenance Tips for Your CX-7

Proper upkeep is essential for ensuring the longevity and performance of your vehicle. By adhering to regular servicing schedules and being attentive to specific aspects of your automobile, you can prevent issues before they arise and maintain optimal functionality. This guide offers practical suggestions to help you keep your car in top shape.

Regular Fluid Checks

Monitoring the various fluids in your vehicle is crucial. Regularly check the engine oil, coolant, brake fluid, and transmission fluid levels. Ensuring these fluids are at the proper levels helps maintain engine health and performance. Additionally, replacing fluids according to the manufacturer’s recommendations will prevent damage and enhance efficiency.

Tire Maintenance

Maintaining your tires is vital for safety and fuel efficiency. Regularly inspect tire pressure and tread depth. Properly inflated tires not only improve handling but also enhance fuel economy. Rotating your tires according to the service schedule promotes even wear and extends their lifespan, ensuring a smoother ride.

Understanding the Engine Specifications

When examining a vehicle’s powertrain, it is crucial to comprehend the characteristics and performance metrics that define its engine. This section will delve into the fundamental aspects that influence efficiency, power output, and overall driving experience.

Key Engine Features

- Engine Type: The arrangement of cylinders and the overall design greatly impact performance.

- Displacement: Refers to the total volume of all cylinders, affecting power and fuel efficiency.

- Fuel System: Determines how fuel is delivered to the engine, influencing efficiency and emissions.

- Compression Ratio: A critical factor that affects the engine’s efficiency and power output.

Performance Metrics

- Horsepower: Indicates the engine’s power, influencing acceleration and overall capability.

- Torque: Represents the twisting force produced, affecting towing capacity and driveability.

- Fuel Economy: Measures how efficiently the engine utilizes fuel, expressed in miles per gallon (MPG).

Understanding these specifications is essential for diagnosing issues, improving performance, and making informed decisions regarding modifications or maintenance.

Transmission Troubleshooting Techniques

Addressing issues within the transmission system requires a systematic approach to identify and resolve potential faults. By employing various diagnostic methods, one can effectively pinpoint malfunctions that may lead to performance issues or failures in vehicle operation.

Initially, it’s essential to observe the vehicle’s behavior during operation. Any unusual sounds, shifting difficulties, or fluid leaks can indicate underlying problems. Recording these symptoms can help in the diagnostic process.

Common Symptoms and Possible Causes

| Symptom | Possible Cause |

|---|---|

| Slipping Gears | Worn clutch or low fluid levels |

| Delayed Engagement | Low fluid or internal wear |

| Fluid Leaks | Damaged seals or gaskets |

| Overheating | Insufficient fluid or clogged cooler |

Utilizing diagnostic tools such as a scan tool can provide valuable insights by reading error codes that indicate specific issues within the system. Regular maintenance, including fluid changes and filter replacements, is crucial in preventing transmission-related problems and ensuring longevity.

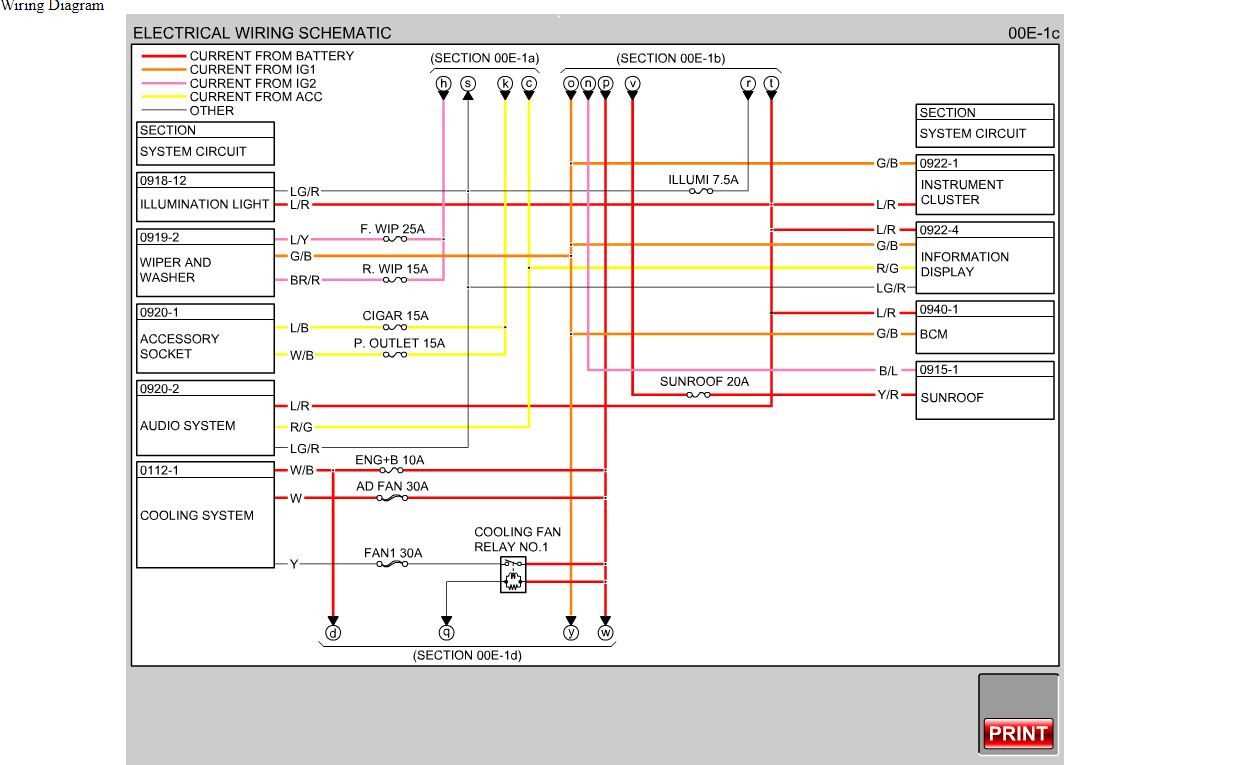

Electrical System Diagnostics Guide

Electrical issues can lead to various operational challenges, from minor inconveniences to significant malfunctions. This guide focuses on identifying and troubleshooting common electrical problems, assisting technicians in determining root causes efficiently. Understanding the basic components and their potential issues can prevent extensive damage and save time in the long run.

Identifying Symptoms of Electrical Issues

Early detection is crucial in avoiding further complications. Signs of electrical system issues often include irregular lighting, intermittent power loss, or unresponsive sensors. Noticing these symptoms early allows for targeted inspections of likely problem areas, such as wiring connections, grounding points, and individual system components. A thorough initial assessment can streamline the diagnostic process significantly.

Common Electrical Components and Diagnostic Methods

Each electrical component may require a specific approach for testing and verification. Below is a table detailing common components and methods for diagnostic checks:

| Component | Symptom | Diagnostic Method |

|---|---|---|

| Battery | Frequent power drops, dim lighting | Test voltage with a multimeter; check for corrosion on terminals |

| Alternator | Power fades, warning lights | Measure output voltage; inspect belt condition |

| Wiring | Intermittent power, unresponsive sensors | Visual inspection for wear; continuity testing |

| Fuses and Relays | Single component failure, power interruption | Check fuse box for blown fuses; test relay functionality |

Using this structured approach to inspect each component can help identify the underlying cause of electrical issues efficiently. With the right tools and techniques, technicians can address issues promptly, ensuring reliable performance of all systems.

Suspension and Steering Repair Methods

The suspension and steering systems are critical for stability, control, and comfort during vehicle operation. Regular checks and adjustments ensure that these components perform optimally, especially under varying road conditions and loads. This section provides an overview of recommended techniques for maintaining and restoring the integrity of the vehicle’s handling dynamics.

Basic Components and Inspection

Key elements in the suspension and steering systems include shock absorbers, control arms, tie rods, and ball joints. Routine inspection of these parts helps detect early signs of wear or damage. Some areas to assess include:

- Checking for leaks or wear on shocks and struts.

- Inspecting control arms for bends or cracks.

- Examining tie rods and ball joints for play or looseness.

- Observing bushings for signs of aging or cracking.

Alignment and Balancing

Wheel alignment and tire balancing directly influence the steering response and reduce tire wear. Proper alignment ensures the wheels are positioned correctly, reducing strain on steering and suspension. Common steps include:

- Adjusting camber, caster, and toe angles to match specifications.

- Balancing wheels to prevent vibrations at higher speeds.

- Rotating tires to even out wear patterns.

Shock Absorber and Strut Replacement

Shock absorbers and struts play a significant role in handling and comfort. Replacing worn shocks can restore damping capability and reduce excessive body movement. The replacement process involves:

- Loosening and removing old shock or strut mounts.

- Securing new shocks or struts in place, ensuring proper alignment.

- Tightening all mounting bolts to secure new parts effectively.

Steering Linkage Repair

Steering linkage connects the steering wheel to the wheels, and any play or damage can reduce steering precision. Key steps include:

- Inspecting linkages for looseness or wear.

- Replacing worn tie rod ends to restore direct handling.

- Reassembling and ensuring correct torque on all linkage fasteners.

By following these guidelines, maintaining a balanced and responsive driving experience is achievable, enhancing both safety and comfort on the road.

Brake System Maintenance and Repair

Regular upkeep of the braking components is essential to ensure both performance and safety during driving. A well-maintained system provides responsive braking, which is crucial for handling and avoiding potential hazards on the road.

Inspecting Brake Pads and Rotors

Brake pads and rotors are critical elements that experience significant wear with regular use. To prevent issues, it’s important to inspect these parts periodically. Pads should be checked for thickness, and any signs of glazing or excessive wear indicate the need for replacement. Rotors should be examined for grooves, cracks, or rust. A clean, smooth surface on the rotor is essential for effective contact with the pads, contributing to stable braking.

Checking Brake Fluid and Lines

Maintaining proper fluid levels and ensuring that the brake lines are intact is equally important. Over time, brake fluid can absorb moisture, reducing its effectiveness and potentially leading to corrosion within the lines. Regular fluid checks and replacements help keep the system in top condition. Also, inspect brake lines for leaks or cracks, as these can compromise the pressure and reduce braking efficiency.

Tip: Always use the recommended type of brake fluid and follow the suggested replacement intervals to maximize system longevity.

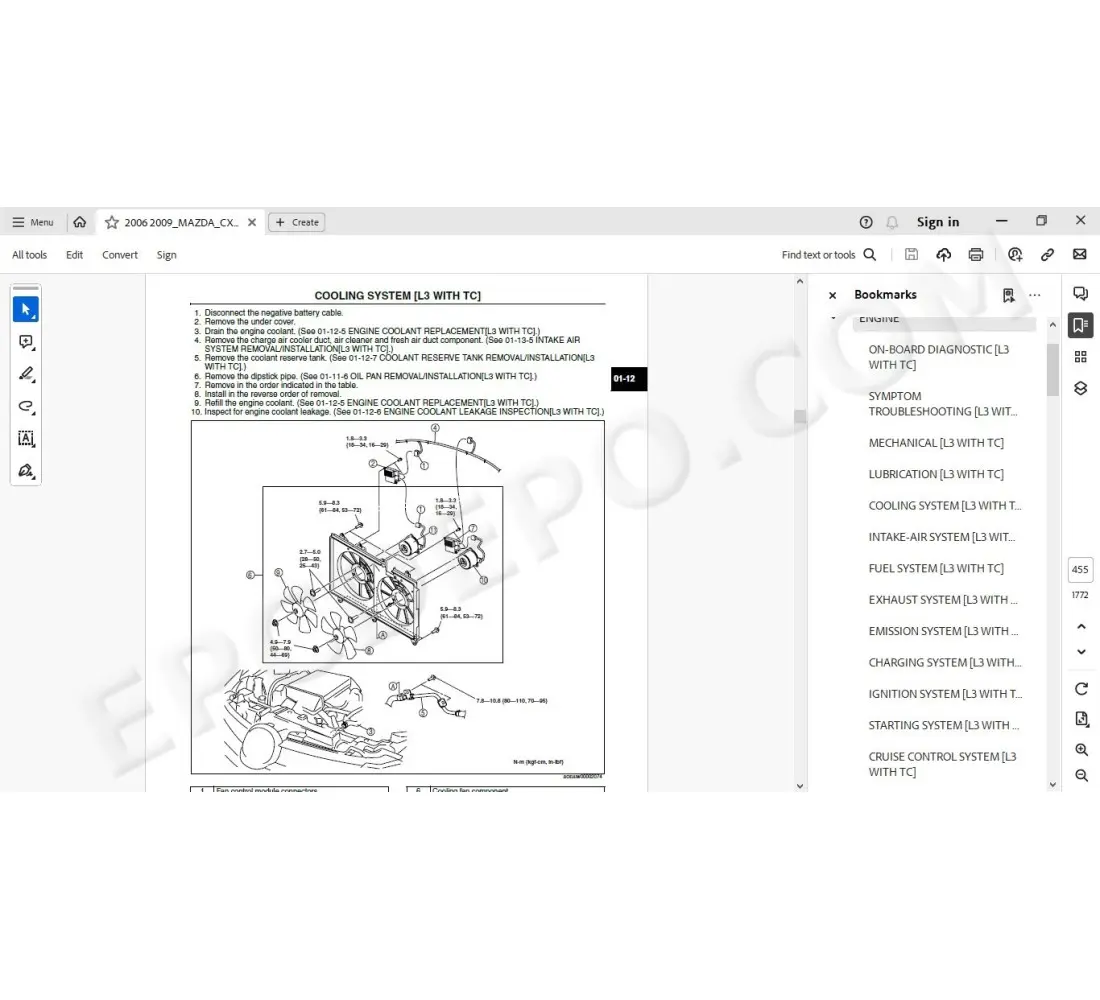

Cooling System Insights and Solutions

The cooling system plays a crucial role in maintaining optimal engine temperature, preventing overheating, and ensuring smooth vehicle performance. It operates by circulating coolant through the engine and radiator, dissipating excessive heat to maintain a balanced temperature range. This process is essential for both engine efficiency and longevity, as overheating can cause significant engine damage and reduce overall performance.

Key components in the system include the radiator, thermostat, water pump, and hoses, each designed to facilitate fluid movement and heat transfer. Regular checks and timely maintenance of these parts help sustain effective cooling and prevent potential issues, such as leaks or clogs, that can compromise the system. Periodic inspection for worn hoses, checking coolant levels, and ensuring proper thermostat operation are proactive measures that can significantly reduce the risk of overheating.

Common cooling system issues often arise from factors such as coolant leaks, thermostat malfunctions, or blockages in the radiator. Detecting early signs of trouble, like unusual temperature gauge fluctuations or visible coolant puddles, can prevent costly repairs. Regular flushing of the cooling system helps eliminate contaminants, ensuring cleaner coolant flow and enhancing heat dissipation capabilities. Keeping up with these preventive practices will ensure that the system operates efficiently, supporting both performance and durability.

Interior Components: Repairing Damage

The interior of a vehicle often shows signs of wear over time, with various materials like upholstery, trim, and dashboard surfaces being prone to scratches, scuffs, and other forms of deterioration. Addressing these imperfections not only enhances the aesthetic appeal but also contributes to maintaining the overall value and comfort of the car’s cabin. Knowing how to handle minor damage can make a significant difference in prolonging the lifespan of these interior components.

Upholstery and Seat Restoration

Upholstered seats can accumulate stains, tears, or discoloration, which require different methods depending on the material. For fabric seats, stains are often managed with specialized cleaning agents and gentle scrubbing, while more stubborn spots might need steam cleaning. Leather surfaces, on the other hand, benefit from conditioning treatments that replenish natural oils and repair minor cracks. In cases of more extensive damage, applying a leather repair kit with color-matching compounds can effectively mask scuffs and scratches, restoring a seamless look to the seats.

Dashboard and Trim Repairs

Dashboards and trims are exposed to sunlight and temperature variations, leading to fading or cracking over time. To fix scratches or minor cracks, plastic fillers or vinyl repair solutions provide effective coverage. Application involves cleaning the area thoroughly, applying the filler or repair compound, and then sanding for a smooth finish. In addition, applying a UV-protective coating can help prevent future damage by shielding these surfaces from sun exposure. For areas with intricate trim, touch-up paint or adhesive vinyl wraps can enhance appearance and protect against further wear.

By using these restoration techniques, interior surfaces regain a refreshed look, contributing to a more enjoyable driving experience and an extended lifespan for the vehicle’s cabin materials.

Using Diagnostic Tools Effectively

Diagnostic tools provide valuable insights into a vehicle’s performance, enabling efficient troubleshooting by detecting errors and anomalies within various systems. To maximize the accuracy and benefit of these tools, understanding how to use them properly is crucial. This section highlights best practices for leveraging diagnostic tools to enhance overall vehicle maintenance.

When starting diagnostics, it’s essential to ensure that tools are properly calibrated and compatible with the vehicle’s systems. This prevents misinterpretation of data and ensures more reliable readings. Below are key steps for using diagnostic equipment effectively:

- Prepare the Vehicle: Before connecting, ensure the vehicle is in a safe state, with the engine off if required by the tool. Check the tool’s manual for specific connection steps.

- Identify and Connect Properly: Locate the diagnostic port and securely attach the tool to avoid connection errors. A firm, accurate connection prevents interruptions in data transmission.

- Run Preliminary Scans: Begin with general scans to identify potential issues across major systems. Review all displayed codes and take notes on any recurring alerts.

- Analyze Error Codes: Each code offers insights into particular issues. Use the device’s reference materials or an online database to interpret these codes accurately.

- Use Additional Testing: For unclear or vague codes, utilize further tests like sensor monitoring and system-specific scans to pinpoint the underlying causes.

Finally, regularly update diagnostic tools to ensure they recognize the latest error codes and system changes. Proper use and regular updates ensure that diagnostic equipment remains effective, aiding in quick, accurate vehicle analysis and problem resolution.

Resources for Further Learning

To gain deeper insights into vehicle maintenance and diagnostics, there are a variety of valuable resources available. By leveraging both digital and physical materials, enthusiasts and professionals alike can expand their technical knowledge and stay current on best practices.

Online Platforms

- Automotive Forums: Discussion forums offer direct access to community knowledge, allowing users to exchange tips, troubleshooting steps, and experiences with similar models.

- Technical Blogs: Blogs run by mechanics or automotive experts often provide tutorials, detailed guides, and video walkthroughs on various systems and components.

- Video Tutorials: Platforms with video content allow for hands-on demonstrations, ideal for visual learners. These tutorials often cover everything from basic upkeep to more complex repairs.

Printed Guides and Manuals

- Service Books: Professionally published service books are a solid resource for in-depth technical specifications, procedures, and diagrams. They often cover a broad range of years and models.

- Workshop Manuals: These detailed guides focus on both common and advanced maintenance tasks, suited for those looking to handle more technical projects.

- Manufacturer Publications: Publications directly from the manufacturer offer official guidance and recommended practices, typically addressing model-specific intricacies.

By exploring these resources, users can significantly improve their maintenance skills, building confidence in handling a wide range of tasks.