Mazda B2000 Repair Guide and Maintenance Tips

Maintaining and understanding the mechanics of your vehicle is essential for ensuring its longevity and performance. Whether you’re dealing with small adjustments or more intricate technical challenges, a detailed guide can be an invaluable resource. This section provides key insights and step-by-step instructions to help you tackle common issues that may arise during the lifespan of your vehicle.

From identifying unusual noises to performing routine checks, knowing how to address potential problems can save time and prevent more significant breakdowns. This guide aims to offer practical advice for keeping your automobile in top condition, along with essential tips for troubleshooting more complex issues.

We will explore various techniques for diagnosing issues, explain the necessary tools for different tasks, and offer helpful solutions to ensure your vehicle remains reliable. By following this comprehensive approach, you’ll be equipped to handle the regular upkeep and any unexpected challenges you might encounter on the road.

Vehicle Maintenance Guide for Pickup Models

This section provides essential information about maintaining and servicing popular compact trucks. It covers critical systems and components that require routine attention to ensure optimal performance and longevity. Whether addressing mechanical or electrical issues, the guidelines here help ensure that any pickup stays in top shape for years to come.

Key Maintenance Areas

Regular inspections of engine components, fluid levels, and electrical systems are crucial for reliable operation. It is important to follow suggested intervals for checking and replacing parts like filters, belts, and spark plugs. Understanding these basic maintenance tasks can help avoid costly repairs in the future.

Service Intervals and Tips

Adhering to recommended service intervals is vital. This includes oil changes, brake checks, and tire rotations. Additionally, ensuring the cooling system functions properly can prevent overheating, while regular inspections of the suspension and exhaust systems maintain smooth operation.

Engine Troubleshooting Tips

When addressing engine issues, it’s essential to identify potential causes methodically. By following a structured approach, you can pinpoint malfunctions and ensure proper functioning without unnecessary repairs.

Below is a quick guide on common engine symptoms and their possible causes:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Dead battery, faulty ignition switch, or fuel delivery problems | Check battery connections, inspect ignition, and verify fuel pump operation |

| Rough idle | Vacuum leak, dirty fuel injectors, or worn spark plugs | Inspect hoses for leaks, clean injectors, and replace spark plugs if necessary |

| Overheating | Low coolant, malfunctioning thermostat, or clogged radiator | Top off coolant, test the thermostat, and ensure the radiator is clean |

| Excessive exhaust smoke | Oil leak, clogged air filter, or engine burning oil | Check for oil leaks, replace air filter, and monitor oil levels |

By paying attention to these symptoms and addressing them promptly, you can prevent more severe engine damage and ensure smoother operation.

How to Replace the Timing Belt

The process of changing the timing belt is essential to maintaining the smooth operation of an engine. Replacing this crucial component prevents potential damage to the engine’s internal parts, ensuring the system runs efficiently.

Step 1: Begin by disconnecting the negative battery cable. This ensures safety while working on the vehicle’s components.

Step 2: Remove any covers or protective panels blocking access to the belt. Depending on the model, this may include removing parts such as the fan or alternator.

Step 3: Carefully inspect the belt’s routing and use a wrench to release tension from the existing belt by adjusting the tensioner pulley.

Step 4: After the old belt is removed, compare it with the new one to confirm it’s the right size. Install the new belt, making sure the teeth align properly with the pulleys.

Step 5: Tighten the tensioner to ensure the belt is firmly in place, but avoid over-tightening as it can cause premature wear.

Step 6: Reassemble any parts that were removed and reconnect the battery. Start the engine to ensure the new belt is functioning correctly without any unusual sounds or movements.

Maintenance of the Fuel System

The fuel system plays a critical role in ensuring the efficient operation of any vehicle. Regular upkeep of this system helps to maintain optimal performance, prevents breakdowns, and extends the lifespan of the engine. Understanding the various components involved and keeping them in good working order is essential for smooth and reliable driving.

One of the key aspects of fuel system care is ensuring that the fuel filter remains clean and unblocked. A clogged filter can significantly reduce engine efficiency by restricting the flow of fuel. It’s advisable to check and replace the filter as part of routine maintenance.

Another important area to monitor is the fuel pump. This component is responsible for delivering the necessary amount of fuel to the engine. Any malfunction in the pump can lead to reduced power or even a complete engine failure. Regular inspection can help detect early signs of wear.

Lastly, keeping the fuel injectors clean is crucial for proper combustion. Dirty injectors can result in uneven fuel distribution, causing the engine to misfire or run inefficiently. Using fuel additives or having the injectors professionally cleaned can prevent buildup and ensure smooth engine operation.

Fixing Common Brake Issues

Brake problems can arise in any vehicle over time, affecting safety and driving experience. Identifying and addressing these issues early on ensures that your braking system functions properly and reduces the risk of more significant failures.

One common issue is squeaking or grinding sounds when applying the brakes. This often indicates worn brake pads that need replacement. Delaying this can lead to damage to the rotors, which will be more expensive to fix.

Another frequent problem is a soft or spongy brake pedal. This typically points to air in the brake lines or a need for brake fluid replacement. In more serious cases, it could signal a failing master cylinder, which would require immediate attention.

If the vehicle pulls to one side during braking, it could be due to uneven brake pad wear or a malfunctioning caliper. Inspecting the components and replacing worn or defective parts will restore balanced braking performance.

Finally, if you notice vibrations when braking, this is often due to warped rotors. Resurfacing or replacing the rotors can resolve this issue and improve braking smoothness.

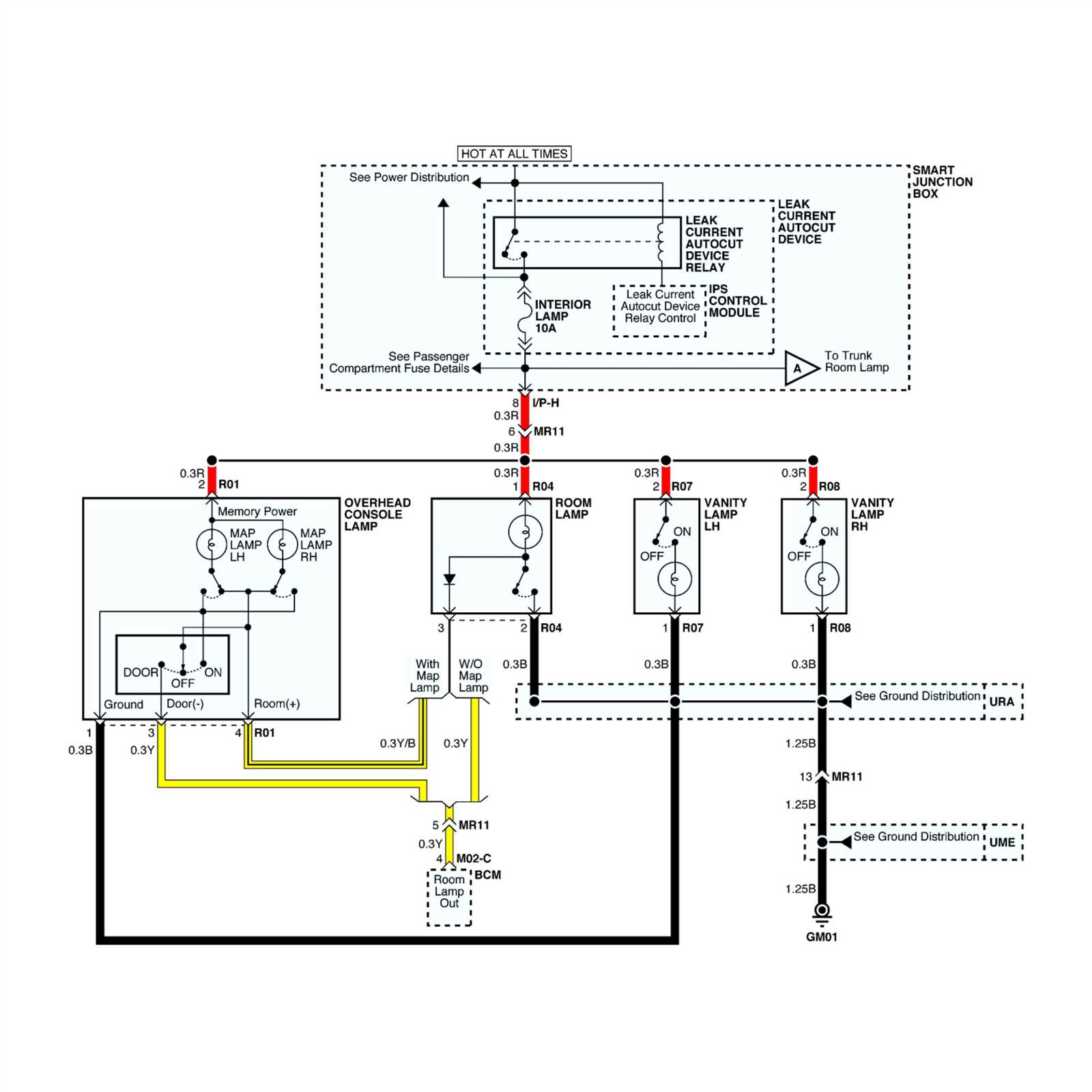

Guide to Electrical Wiring Repairs

Electrical systems are vital components of any vehicle, ensuring that everything functions smoothly and efficiently. Properly addressing wiring issues is crucial for maintaining optimal performance and preventing further complications. This section provides a comprehensive overview of how to approach electrical repairs, focusing on common problems and solutions.

When dealing with electrical wiring, it’s important to follow systematic steps to ensure safety and effectiveness:

- Identify the Issue: Begin by diagnosing the problem. Common signs include flickering lights, malfunctioning accessories, or blown fuses.

- Gather Necessary Tools: Equip yourself with essential tools such as wire strippers, multimeters, and electrical tape.

- Inspect Wiring: Examine the wiring for visible damage, such as frayed insulation or loose connections.

- Test Circuits: Use a multimeter to check for continuity and voltage levels in the affected circuits.

- Make Repairs: Depending on the diagnosis, repairs may involve reattaching loose connections, replacing damaged wires, or securing grounding points.

After completing the repairs, it’s crucial to test the electrical system to ensure everything operates correctly. Pay attention to any unusual behaviors and verify that all components function as intended.

Regular maintenance and inspections of electrical systems can help prevent future issues. Keep an eye out for any signs of wear and tear, and address them promptly to ensure longevity and reliability.

Suspension System Maintenance

The suspension system is crucial for ensuring a smooth and stable ride. Regular upkeep of this system not only enhances comfort but also prolongs the lifespan of various components. Proper maintenance involves routine inspections and addressing any issues promptly to maintain optimal performance.

Key areas to focus on during maintenance include the inspection of shock absorbers, springs, and control arms. Identifying wear and tear early can prevent more severe problems in the future. Always refer to the manufacturer’s recommendations for specific maintenance intervals and procedures.

| Component | Maintenance Tips |

|---|---|

| Shock Absorbers | Check for leaks and test performance. Replace if worn. |

| Springs | Inspect for cracks and deformation. Ensure they are properly seated. |

| Control Arms | Examine bushings and joints for wear. Lubricate as needed. |

| Alignment | Regularly check wheel alignment to prevent uneven tire wear. |

By adhering to a consistent maintenance routine, vehicle owners can ensure their suspension system remains in excellent condition, leading to improved handling and safety on the road.

Cooling System Inspection and Repairs

The cooling system plays a vital role in maintaining the optimal operating temperature of the engine. Regular examination and maintenance are crucial to prevent overheating and ensure the longevity of the engine. This section outlines the essential steps for evaluating and addressing issues within this system.

Begin by conducting a thorough inspection of the cooling components:

- Radiator: Check for any signs of leaks, corrosion, or blockages that could impede airflow.

- Hoses: Inspect all hoses for cracks, bulges, or wear. Ensure they are securely connected.

- Water Pump: Examine the water pump for leaks or unusual noises, which could indicate a malfunction.

- Thermostat: Test the thermostat to confirm it opens and closes at the correct temperature.

- Coolant Level: Ensure the coolant level is adequate and the fluid is clean and free of contaminants.

If any issues are detected during the inspection, consider the following repair options:

- Replacing Hoses: If hoses show signs of deterioration, replace them with high-quality, compatible parts.

- Radiator Flush: Perform a coolant flush to remove debris and deposits that may affect performance.

- Water Pump Replacement: If the water pump is faulty, replace it to restore proper circulation.

- Thermostat Replacement: A malfunctioning thermostat should be replaced to maintain the correct operating temperature.

- Coolant Top-Up: Regularly check and top up the coolant as necessary to maintain optimal levels.

Following these guidelines will help ensure that the cooling system operates efficiently, preventing potential engine damage due to overheating.

Transmission Fluid Replacement Guide

Maintaining the proper condition of the fluid within your vehicle’s transmission system is essential for optimal performance and longevity. This guide provides a comprehensive approach to replacing the transmission fluid, ensuring smooth gear shifts and preventing potential damage to critical components.

Step 1: Gather Necessary Tools

Step 2: Prepare the Vehicle

Park the vehicle on a level surface and engage the parking brake. It is advisable to allow the engine to cool down before proceeding. If necessary, raise the vehicle using jack stands to access the transmission pan easily.

Step 3: Drain the Old Fluid

Locate the transmission pan and remove the drain plug. Allow the old fluid to drain completely into the pan. This step may take several minutes, so be patient to ensure all fluid is removed.

Step 4: Replace the Filter

If your transmission has a filter, now is the time to replace it. Remove the old filter and install the new one according to the manufacturer’s instructions, ensuring a secure fit to avoid leaks.

Step 5: Refill with New Fluid

Using a fluid pump, refill the transmission with the new fluid through the designated fill tube. Be cautious not to overfill; consult the vehicle’s specifications for the correct fluid level.

Step 6: Check for Leaks

Start the engine and allow it to run for a few minutes while checking for leaks around the transmission pan and drain plug. If any leaks are detected, address them promptly to avoid further complications.

Regular maintenance of the transmission fluid not only enhances performance but also extends the lifespan of the transmission system. Following these steps will help ensure a successful fluid replacement process.

Restoring the Exhaust System

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. Over time, it may suffer from wear and tear due to exposure to heat, moisture, and corrosive elements. Restoring this component involves a careful assessment of its condition, identification of any damage, and implementing appropriate repairs or replacements to ensure optimal functionality.

Begin the process by inspecting the entire exhaust assembly, including the pipes, muffler, and catalytic converter. Look for signs of rust, leaks, or cracks that could affect performance. Replacing damaged sections with high-quality parts is essential for maintaining proper exhaust flow and reducing noise levels.

In addition, consider cleaning the system to remove any accumulated soot or debris, which can hinder efficiency. Using specialized cleaners can help restore the internal surfaces, improving exhaust gas flow. Furthermore, ensuring all connections are secure and free of leaks will contribute to the overall health of the exhaust system.

Finally, regular maintenance checks will help prolong the lifespan of the exhaust system, allowing for early detection of issues and timely interventions. By taking these steps, you can ensure a reliable and efficient exhaust system that supports the vehicle’s performance.

How to Align the Wheels

Proper wheel alignment is crucial for the optimal performance of a vehicle. It ensures that the wheels are set to the correct angle, improving handling and extending tire life. Misalignment can lead to uneven tire wear and affect steering response, making regular checks essential for any vehicle owner.

Here are the steps to achieve accurate wheel alignment:

- Check Tire Pressure: Ensure all tires are inflated to the manufacturer’s recommended pressure. Proper inflation is vital for accurate alignment.

- Inspect Suspension Components: Examine the suspension system for any worn or damaged parts, including bushings, ball joints, and tie rods. Replace any faulty components before proceeding.

- Perform the Alignment: Use an alignment tool or take the vehicle to a professional service. If doing it at home, follow these steps:

- Front Alignment: Adjust the camber, caster, and toe angles according to specifications.

- Rear Alignment: Set the rear wheel angles as needed, ensuring they match the front settings where applicable.

Regularly aligning the wheels can enhance vehicle safety and performance, leading to a smoother driving experience and increased fuel efficiency.

Replacing the Clutch on Mazda B2000

Changing the clutch in a vehicle is a crucial maintenance task that ensures optimal performance and driving experience. This procedure involves removing the old unit and installing a new one, allowing for smoother gear transitions and improved power delivery from the engine to the transmission.

Before starting the replacement process, it’s important to gather all necessary tools and materials:

- Jack and jack stands

- Wrenches and sockets

- Screwdrivers

- Clutch alignment tool

- New clutch kit

- Transmission fluid

Follow these steps to successfully replace the clutch:

- Preparation: Park the vehicle on a level surface, engage the parking brake, and disconnect the battery.

- Raise the Vehicle: Use a jack to lift the vehicle and secure it with jack stands for safety.

- Remove the Transmission: Unbolt the transmission from the engine, taking care to support it properly as you do so.

- Take Out the Old Clutch: Remove the pressure plate and old clutch disc, making note of their orientation.

- Install the New Clutch: Position the new clutch disc using an alignment tool and attach the pressure plate securely.

- Reassemble: Carefully reattach the transmission to the engine, ensuring all bolts are tightened to the manufacturer’s specifications.

- Lower the Vehicle: Remove the jack stands and lower the vehicle back to the ground.

- Reconnect the Battery: Reconnect the battery and test the clutch by engaging the gears.

Following these instructions will help ensure a successful clutch replacement, enhancing the overall functionality of the vehicle.

Understanding Mazda B2000’s Fuse Box

The fuse box plays a crucial role in the electrical system of your vehicle, acting as the central hub that protects circuits from overloads. By housing fuses, it safeguards various components and systems, ensuring that everything operates smoothly. Familiarizing yourself with this element can greatly enhance your ability to troubleshoot and maintain your automobile.

Typically located under the dashboard or in the engine compartment, this assembly contains multiple fuses, each responsible for a specific function. In case of electrical issues, checking the status of these fuses is one of the first steps to diagnosing problems. A blown fuse can indicate a fault in the associated circuit, and replacing it is often a straightforward solution.

Understanding the layout and labeling of the fuse box is essential. Each fuse should be marked with its corresponding function, making it easier to identify which one may need attention. Regular inspection and timely replacement of blown fuses can prevent more significant electrical failures and keep your vehicle running optimally.

Additionally, having a comprehensive understanding of this component allows for proactive maintenance. Knowing the ratings and specifications of each fuse can help in selecting the right replacements and avoiding potential hazards. Thus, being informed about this integral part of your automobile is beneficial for ensuring its longevity and reliability.