Comprehensive Guide to Repairing the Mercedes 240D

When it comes to the longevity and performance of your automobile, understanding the intricacies of its upkeep is essential. A well-structured resource can empower enthusiasts and professionals alike to tackle various challenges that may arise during ownership. This section aims to illuminate the fundamental aspects of automotive care, providing valuable insights and practical advice.

Every vehicle requires a unique approach to maintenance, tailored to its specific needs and characteristics. By exploring various components, from the engine to the electrical system, car owners can gain a deeper appreciation for their machinery. Knowledge is a powerful tool in ensuring optimal functionality and safety on the road.

In this comprehensive guide, readers will find detailed instructions and troubleshooting tips designed to assist in various scenarios. Whether you are a seasoned mechanic or a novice owner, this resource serves as an essential companion for anyone looking to enhance their understanding and skills in automotive maintenance.

Essential Tools for Mercedes 240D Repairs

When it comes to maintaining and fixing your vehicle, having the right equipment is crucial. A well-equipped toolbox can make all the difference, ensuring that tasks are completed efficiently and effectively. This section highlights the fundamental instruments needed for tackling various issues that may arise in your automotive journey.

First and foremost, a comprehensive set of hand tools is indispensable. This includes wrenches, sockets, and screwdrivers that are compatible with a variety of fasteners found in your vehicle. Additionally, pliers and wire cutters are essential for handling electrical components and other intricate tasks.

For those dealing with fluid changes or system checks, having specialized tools like oil filter wrenches and fluid extractors is beneficial. A jack and jack stands are necessary for safely elevating the vehicle, allowing access to the undercarriage for inspections and repairs.

Diagnostic equipment cannot be overlooked. A quality OBD-II scanner helps in identifying error codes, providing insights into performance issues that may need addressing. Having a multimeter on hand is also valuable for troubleshooting electrical systems.

Finally, safety gear such as gloves, goggles, and a sturdy work apron should not be forgotten. These items protect the mechanic while working, ensuring that maintenance tasks can be performed with both efficiency and safety in mind.

Common Issues with Mercedes 240D

Many enthusiasts of classic vehicles often encounter specific challenges that can arise from the unique engineering of these automobiles. Understanding these common problems can aid owners in maintaining optimal performance and prolonging the lifespan of their cherished rides.

Electrical System Glitches

One prevalent issue lies within the electrical components, which can lead to various malfunctions. Owners may experience problems such as dimming lights, faulty gauges, or starting difficulties. These symptoms often indicate issues with wiring or connectors that require careful inspection.

Engine Performance Concerns

Another area of concern is engine performance. Issues such as poor acceleration, unusual noises, or excessive smoke can signal underlying problems. Regular maintenance and timely diagnosis are essential to prevent further complications and ensure smooth operation.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Electrical Failure | Dimming lights, gauge malfunctions | Faulty wiring, corroded connectors |

| Engine Hesitation | Poor acceleration, unusual noises | Fuel delivery issues, air intake problems |

| Suspension Wear | Poor handling, uneven tire wear | Worn bushings, damaged shocks |

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential to ensure optimal performance and longevity. This section outlines a series of systematic procedures that will help maintain your automobile in peak condition. Following these steps will not only enhance reliability but also contribute to a smoother driving experience.

Essential Checks and Services

Performing routine inspections and services is key to preventing potential issues. Below is a summary of critical tasks that should be completed regularly:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace the engine oil and filter to ensure proper lubrication. |

| Tire Rotation | Every 6,000 miles | Switch the positions of the tires to promote even wear. |

| Brake Inspection | Every 10,000 miles | Check brake pads and discs for wear; replace if necessary. |

| Fluid Levels Check | Monthly | Inspect and top up fluids like coolant, brake fluid, and transmission fluid. |

| Battery Check | Every 6 months | Inspect battery terminals and charge status to ensure reliable starts. |

Seasonal Maintenance Tips

Adjusting your maintenance routine according to seasonal changes can further enhance vehicle performance. Consider the following recommendations:

- Before winter, inspect antifreeze levels and replace wiper blades.

- In spring, check air conditioning functionality and clean air filters.

- During summer, monitor tire pressure more frequently due to heat expansion.

- In fall, prepare for potential rain by ensuring brake performance is optimal.

Understanding the Engine Components

Grasping the intricacies of engine parts is crucial for anyone looking to maintain or enhance vehicle performance. Each component plays a specific role, contributing to the overall functionality and efficiency of the power unit. A thorough comprehension of these elements can lead to better decision-making regarding service and upgrades.

Key Engine Parts

- Engine Block: The core structure that houses the cylinders and supports various components.

- Cylinders: Spaces where the fuel-air mixture combusts to generate power.

- Pistons: Movable components within the cylinders that convert energy from combustion into mechanical motion.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, driving the vehicle’s wheels.

- Camshaft: Controls the timing of valve openings and closings, ensuring optimal airflow into and out of the cylinders.

Supporting Elements

- Fuel System: Delivers the necessary fuel to the engine for combustion.

- Ignition System: Provides the spark that ignites the fuel-air mixture in the cylinders.

- Cooling System: Regulates engine temperature to prevent overheating.

- Exhaust System: Channels exhaust gases away from the engine, reducing emissions and noise.

By familiarizing oneself with these components and their interactions, individuals can better appreciate the complexity of automotive engineering and the importance of proper maintenance.

How to Troubleshoot Electrical Problems

Addressing issues related to the electrical system in your vehicle can often seem daunting. However, with a systematic approach, you can identify and resolve these complications efficiently. This guide will provide you with essential steps to diagnose and fix common electrical faults, ensuring your automobile remains in optimal condition.

1. Gather Tools and Resources

Before starting, assemble the necessary tools, including a multimeter, basic hand tools, and wiring diagrams. Having these at hand will facilitate the troubleshooting process and allow for accurate measurements and tests.

2. Check the Battery

The battery is the heart of the electrical system. Begin by inspecting its connections for corrosion or looseness. Use a multimeter to measure the voltage; a fully charged battery should read around 12.6 volts. If the voltage is low, consider recharging or replacing the battery.

3. Inspect Fuses and Relays

Fuses and relays protect the electrical circuits from overloads. Locate the fuse box and examine each fuse for damage. Replace any that are blown. Additionally, test relays using a multimeter or by swapping them with similar components to ensure they are functioning correctly.

4. Examine Wiring and Connectors

Look for any visible damage to wiring, such as fraying or exposed conductors. Check connectors for corrosion or looseness, as these can interrupt the flow of electricity. Repair or replace any damaged components as needed.

5. Test Electrical Components

Identify the specific electrical components that may be malfunctioning. Using a multimeter, check for proper voltage and continuity in switches, lights, and other devices. Compare your findings against the specifications in the wiring diagrams to determine if any parts require replacement.

6. Consult Professional Assistance

If you are unable to identify the problem, it may be wise to seek help from a qualified technician. They possess the expertise and tools necessary to diagnose complex electrical issues that may be beyond the scope of home troubleshooting.

By following these steps, you can systematically address electrical problems and maintain the reliability of your vehicle’s systems.

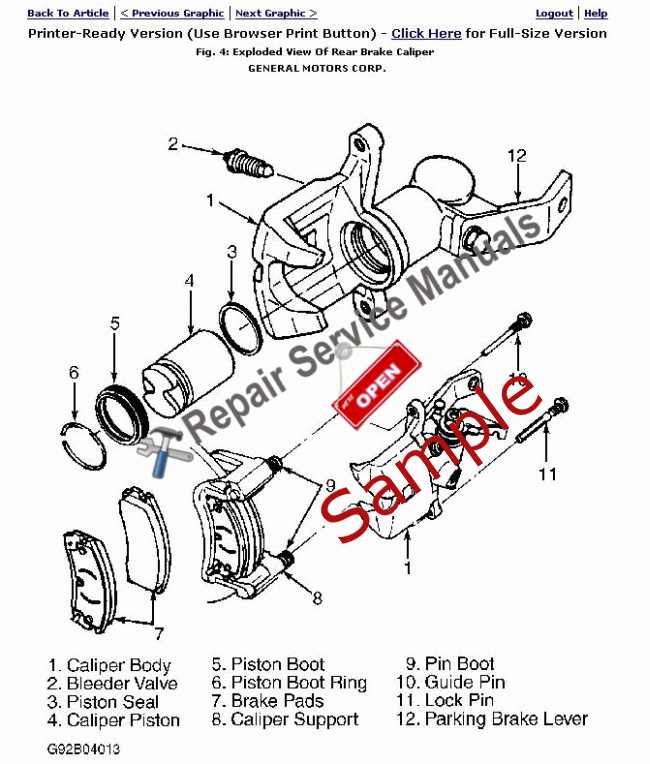

Brake System Inspection and Repair

The braking system is a crucial component of any vehicle, ensuring safety and control while driving. Regular examination and maintenance of this system are vital to prevent failures and enhance performance. This section delves into the essential aspects of evaluating and fixing the braking mechanism to ensure optimal functionality.

Inspection Procedures

Begin by visually assessing the components of the braking system, including the pads, rotors, and calipers. Look for signs of wear such as uneven surfaces or excessive thickness reduction. Listening for unusual sounds during braking can also indicate potential issues. Pay attention to any vibrations felt through the brake pedal, as this may suggest rotor problems.

Maintenance and Repair Techniques

Once inspection is complete, proceed with necessary adjustments or replacements. Replacing worn brake pads is crucial for maintaining stopping power. Ensure that the rotors are also checked; resurfacing or replacing them might be necessary if they are beyond acceptable limits. Bleeding the brake lines is essential to remove air bubbles that can compromise braking efficiency. Following proper guidelines during this process will ensure the system remains responsive and reliable.

Replacing the Fuel Filter Safely

Changing the fuel filter is a crucial task for maintaining optimal engine performance and ensuring fuel efficiency. This process requires careful handling to avoid spills and potential hazards. Proper preparation and adherence to safety protocols are essential for a smooth replacement.

Before starting, gather the necessary tools and materials, including a new filter, wrenches, and rags. It’s advisable to work in a well-ventilated area and wear protective gloves and eyewear to safeguard against fuel exposure. Ensure the engine is cool to prevent burns and avoid ignition sources nearby.

Start by locating the fuel filter, which is typically situated along the fuel line. Relieve the fuel system pressure by removing the fuel pump fuse and running the engine until it stalls. Once the pressure is released, you can proceed to disconnect the fuel lines. Use caution, as residual fuel may still be present.

After disconnecting the lines, carefully remove the old filter, taking note of its orientation for proper installation of the new one. Install the new filter in the same direction as the previous one, ensuring a secure fit. Reconnect the fuel lines and replace the fuel pump fuse.

Finally, turn the ignition to the “on” position without starting the engine to prime the fuel system. Check for leaks around the connections before starting the engine. Following these steps will help ensure a safe and effective fuel filter replacement.

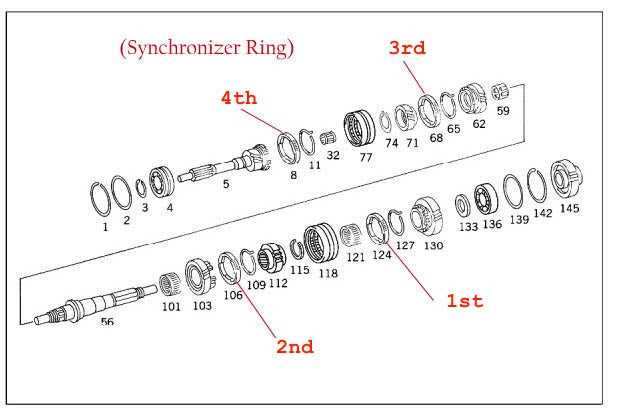

Guidelines for Transmission Maintenance

Proper upkeep of the transmission system is crucial for ensuring the longevity and efficiency of your vehicle. Regular attention to this component can prevent costly repairs and enhance overall performance. By following a few essential practices, you can maintain optimal functioning and avoid common pitfalls associated with transmission neglect.

Regular Fluid Checks

Monitoring the transmission fluid level and condition is essential. Low fluid levels can lead to overheating and increased wear on internal components. It’s important to check the fluid regularly, ensuring it is at the correct level and free of contaminants. If the fluid appears dark or has a burnt smell, it may be time for a replacement.

Scheduled Maintenance Intervals

Adhering to a maintenance schedule is vital for the health of the transmission. This includes regular servicing as outlined in your vehicle’s guidelines. Routine inspections can identify potential issues early, allowing for timely interventions. Additionally, replacing the filter at recommended intervals helps to keep the fluid clean and reduces wear on the transmission parts.

Tips for Bodywork Restoration

Restoring the exterior of a vehicle can be a rewarding endeavor, enhancing both aesthetics and value. This process involves careful attention to detail, as well as an understanding of materials and techniques that can help achieve a flawless finish.

Assess the Damage: Begin by thoroughly examining the body for dents, rust, and paint imperfections. Identifying the extent of the damage will help you determine the necessary steps and materials needed for effective restoration.

Gather the Right Tools: Equip yourself with a variety of tools, including sanders, paint sprayers, and body fillers. Having the right equipment at hand will streamline the process and improve the final outcome.

Preparation is Key: Before applying any new paint or filler, ensure that the surface is clean and free from debris. Properly sanding the area will promote better adhesion and a smoother finish.

Choose Quality Materials: Invest in high-quality paints and fillers. While cheaper options may save money initially, they often result in poor durability and appearance over time.

Work in Sections: Tackle one area at a time to maintain focus and achieve precision. This approach minimizes the risk of overlooking details and allows for thorough inspection before moving on.

Finishing Touches: After applying paint, consider adding a clear coat for added protection and shine. This final layer can significantly enhance the overall look and longevity of your work.

Regular Maintenance: Once the restoration is complete, regular upkeep is essential. Washing, waxing, and addressing any new damage promptly will help maintain the exterior in excellent condition.

Finding Reliable Replacement Parts

When it comes to maintaining an automobile, sourcing dependable components is essential for ensuring optimal performance and longevity. Whether you’re replacing worn-out pieces or upgrading certain features, identifying high-quality alternatives can significantly affect the vehicle’s reliability and functionality.

First and foremost, it is crucial to research trusted suppliers that specialize in automotive parts. Look for businesses with a solid reputation, positive customer reviews, and a history of delivering genuine products. Online marketplaces can be helpful, but always verify the credibility of the seller before making a purchase.

Additionally, consider the option of OEM (Original Equipment Manufacturer) parts. These components are designed to match the specifications of the original pieces, ensuring a perfect fit and maintaining the vehicle’s integrity. While they may be pricier, the investment often pays off in terms of durability and performance.

Another valuable resource is local auto salvage yards, where you can find used parts that are still in excellent condition. This can be a cost-effective solution, but it’s important to inspect the items thoroughly and confirm their functionality before proceeding with a purchase.

Finally, don’t hesitate to seek advice from automotive forums or communities. Enthusiasts often share their experiences and recommendations, helping you navigate the options available and make informed choices. Building a network of knowledgeable contacts can be an invaluable asset in your search for reliable components.