Comprehensive Guide to Mercedes W251 Repair

This section provides essential insights into the upkeep and troubleshooting of a specific vehicle model. Understanding the intricacies of automotive systems can greatly enhance performance and longevity.

Readers will find detailed information that addresses common challenges and solutions, making the process of maintaining the vehicle more accessible. By following these guidelines, one can ensure optimal functionality and safety.

Whether you’re a seasoned enthusiast or a newcomer, the knowledge shared here will equip you with the tools needed to tackle various tasks confidently. Familiarity with the vehicle’s components and their operation is crucial for effective maintenance.

Overview of Mercedes W251 Models

This section provides a comprehensive look at various models within the specific vehicle series. These automobiles are known for their distinct design, advanced technology, and luxurious features, making them popular choices among enthusiasts and everyday drivers alike.

Model Variants and Specifications

Each variant in this series offers unique specifications and capabilities tailored to different driving needs. From enhanced performance options to varied interior configurations, there is a model suitable for diverse preferences. Buyers can choose from various engine types, transmission options, and additional features that elevate the driving experience.

Notable Features

These vehicles are equipped with a range of innovative technologies aimed at improving safety, comfort, and convenience. Advanced infotainment systems, driver assistance features, and high-quality materials in the interior contribute to a refined atmosphere. The emphasis on craftsmanship and performance ensures a satisfying experience for drivers and passengers alike.

Common Issues in W251 Vehicles

Vehicles of this model series are known to encounter various challenges that can affect their performance and reliability. Understanding these typical problems can help owners maintain their vehicles more effectively and address issues promptly.

Frequent Problems

- Electrical system malfunctions, leading to issues with lights and accessories.

- Suspension wear, affecting ride quality and handling.

- Engine misfires, often resulting from ignition system failures.

- Transmission difficulties, including slipping or delayed shifting.

Preventive Measures

- Regular inspections of electrical components to identify and fix issues early.

- Routine maintenance of suspension parts to prolong their lifespan.

- Monitoring engine performance for signs of misfires and addressing them immediately.

- Ensuring timely fluid changes for optimal transmission functionality.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any vehicle. By adhering to a consistent maintenance schedule, owners can prevent common issues and enhance performance. Below are key strategies to promote durability and reliability over time.

Routine Inspections

Conducting frequent assessments of critical components can help identify wear and tear early. This proactive approach allows for timely interventions, reducing the risk of significant repairs down the line.

Fluid Checks

Maintaining optimal fluid levels is crucial for the smooth operation of various systems. Ensure that engine oil, coolant, brake fluid, and transmission fluid are regularly checked and replaced as needed.

| Component | Recommended Interval | Action |

|---|---|---|

| Engine Oil | Every 5,000 miles | Change oil and filter |

| Brake Fluid | Every 2 years | Flush and replace |

| Coolant | Every 30,000 miles | Check levels and condition |

| Transmission Fluid | Every 50,000 miles | Inspect and change if necessary |

Engine Repair Procedures Explained

This section outlines the essential steps involved in addressing engine issues. Understanding these procedures is vital for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the vehicle.

Key procedures include:

- Diagnosis of engine problems through systematic checks.

- Disassembly of engine components for thorough inspection.

- Replacement of worn or damaged parts.

- Reassembly of the engine, ensuring all components are correctly aligned.

- Testing for performance to confirm the effectiveness of repairs.

Additionally, it is important to follow manufacturer specifications for torque settings and assembly sequences to prevent future complications.

Routine maintenance tasks, such as oil changes and filter replacements, play a crucial role in preventing engine failure. Regular monitoring can help identify potential issues before they escalate.

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues related to the electrical components of your vehicle. Proper analysis can help identify the root causes of malfunctions, ensuring effective resolution.

Common Symptoms: Various signs may indicate electrical problems, such as malfunctioning lights, non-responsive accessories, or issues with starting the engine. Pay attention to these indicators as they can guide your troubleshooting process.

Diagnostic Steps: Begin with a visual inspection of wiring and connections for signs of wear or damage. Use a multimeter to check voltage levels and continuity in circuits. Identifying faulty components early can save time and resources.

Professional Assistance: If issues persist after basic troubleshooting, consider consulting a specialist. Advanced diagnostic tools and expertise may be required for complex electrical failures.

Transmission Maintenance and Repair

Proper care and servicing of the transmission system are crucial for optimal vehicle performance. Regular checks and timely interventions can significantly extend the lifespan of this essential component.

Begin with routine fluid changes, as clean transmission fluid ensures smooth operation and reduces wear. It is also important to inspect the transmission filter, replacing it as needed to maintain efficiency. Listening for unusual noises during gear shifts can provide early warnings of potential issues.

If problems arise, diagnostics should be performed to identify the root cause. Common repairs may involve adjusting the linkage, replacing seals, or even overhauling the transmission assembly in severe cases. Adhering to a comprehensive maintenance schedule will help prevent costly repairs down the line.

Suspension System Components and Care

The suspension system plays a crucial role in ensuring vehicle stability and comfort during driving. Proper maintenance of these components is essential for optimal performance and safety.

- Shock Absorbers: These components dampen the impact from road irregularities, enhancing ride quality.

- Struts: Often integrated with the suspension system, struts provide structural support and help manage vehicle handling.

- Coil Springs: These elements absorb shock and maintain vehicle height, contributing to overall stability.

- Control Arms: Essential for connecting the suspension to the vehicle frame, control arms allow for controlled movement of the wheels.

Regular inspection and maintenance of these parts can prevent premature wear and enhance safety. Recommended care includes:

- Inspecting for leaks or damage in shock absorbers and struts.

- Checking the condition of springs for signs of sagging or cracks.

- Ensuring control arms are secure and free from excessive play.

- Revisiting alignment settings to maintain optimal handling and tire wear.

Addressing any issues promptly will prolong the lifespan of the suspension system and improve the overall driving experience.

Brake System Inspection Techniques

Regular evaluation of the braking system is crucial for ensuring vehicle safety and performance. Proper techniques help identify issues before they become significant problems, enhancing reliability and longevity.

Visual Inspection

Start with a thorough visual assessment of the brake components. Look for signs of wear, damage, or corrosion.

- Examine brake pads for thickness and uneven wear.

- Inspect rotors for grooves or scoring.

- Check brake lines for leaks or cracks.

Functional Testing

Conduct functional tests to ensure optimal performance of the braking system.

- Perform a brake pedal test for firmness.

- Test for noise during braking, indicating potential issues.

- Evaluate stopping distance under controlled conditions.

Bodywork and Paint Restoration Tips

Restoring the exterior of a vehicle involves careful attention to detail and a methodical approach. Whether addressing minor dents or faded paint, employing the right techniques can significantly enhance the appearance and longevity of the vehicle’s body.

Assessing Damage

Begin by thoroughly examining the surface for imperfections such as scratches, dents, or rust. Identifying the extent of the damage is crucial for planning the appropriate restoration steps. Utilize a cleaning solution to prepare the surface and reveal hidden issues.

Techniques for Restoration

For minor dents, consider using a hairdryer to heat the area followed by a cold treatment with ice to pop the dent out. For paint restoration, buffing with a polishing compound can revive dull surfaces. Always finish with a protective wax to shield the finish from environmental factors.

Choosing the Right Replacement Parts

Selecting appropriate components for your vehicle is crucial to ensure optimal performance and longevity. The quality of these parts directly impacts the reliability and safety of your automobile. Understanding the different options available can help you make informed decisions, ultimately enhancing your driving experience.

Types of Replacement Parts

There are primarily two categories of components: original equipment manufacturer (OEM) parts and aftermarket alternatives. OEM parts are produced by the same manufacturer as the vehicle, guaranteeing a perfect fit and compatibility. On the other hand, aftermarket parts are made by third-party companies and can vary in quality, performance, and price.

Evaluating Quality and Compatibility

When selecting a component, consider factors such as material quality, warranty, and user reviews. Researching compatibility with your specific model ensures the chosen part meets your vehicle’s requirements. Additionally, opting for reputable suppliers can provide peace of mind regarding the integrity and durability of the parts you select.

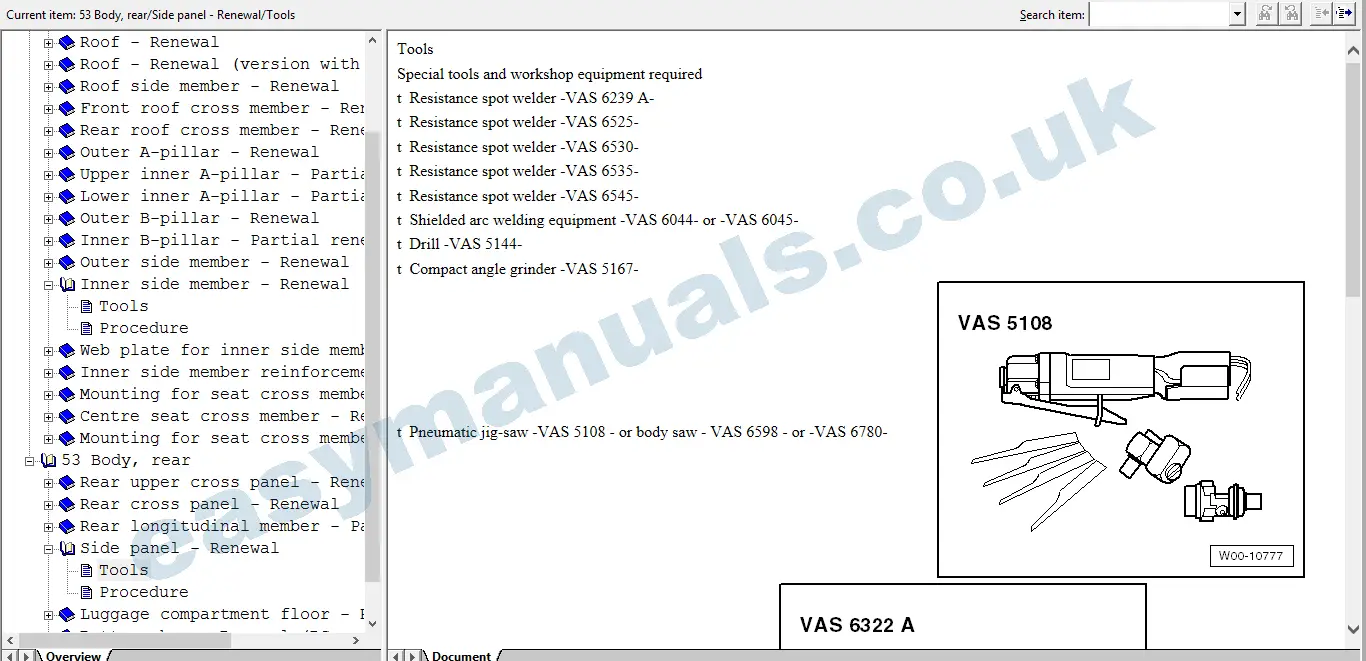

Tools Needed for W251 Repairs

Having the right equipment is essential for effective maintenance and troubleshooting. Proper tools not only ensure efficiency but also help prevent damage during the process.

Here are some fundamental instruments you will need:

- Socket Set: Various sizes to fit different bolts.

- Wrenches: Both adjustable and fixed for various tasks.

- Screwdriver Set: Includes flathead and Phillips for different screws.

- Pliers: Useful for gripping and twisting tasks.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Multimeter: Essential for electrical diagnostics.

- Jack and Jack Stands: For safely lifting the vehicle.

Additionally, having a comprehensive repair guide can enhance your understanding of the specific requirements for different tasks.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both the technician and the vehicle. Proper precautions help minimize the risk of accidents and enhance the overall efficiency of the work process.

Always wear appropriate protective gear, including gloves, safety glasses, and steel-toed boots. This equipment provides essential protection against potential hazards, such as sharp objects, chemicals, or heavy components.

Before starting any work, make sure to disconnect the battery to prevent electrical shocks or short circuits. Additionally, use wheel chocks to secure the vehicle and prevent it from rolling during maintenance. Familiarize yourself with the vehicle’s layout and potential risks, ensuring that the workspace is well-lit and organized to reduce the likelihood of accidents.