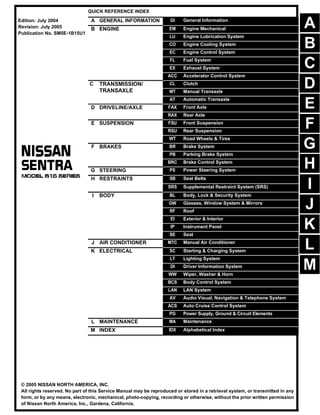

Comprehensive Guide to Repairing the 2005 Nissan Sentra

This section serves as a valuable resource for individuals seeking detailed information about vehicle upkeep. It aims to provide essential insights into troubleshooting, servicing, and enhancing the performance of specific automobile models. With a focus on practical applications, the guide offers step-by-step instructions that empower users to effectively manage their automotive needs.

Whether you’re a novice owner or an experienced enthusiast, having access to thorough guidance can significantly streamline the maintenance process. The content is designed to address common issues and preventative measures, ensuring that your vehicle remains in optimal condition. Understanding these aspects is crucial for ensuring longevity and reliability.

Throughout this resource, you’ll find pertinent advice on various components and systems, along with recommended procedures for addressing potential concerns. Engaging with this material will enhance your knowledge and confidence in handling your vehicle’s requirements, making it an indispensable tool for any car owner.

Nissan Sentra Maintenance Overview

Regular upkeep is essential for the longevity and performance of any vehicle. This section provides an outline of key practices that can enhance reliability and safety. By adhering to a structured maintenance schedule, owners can prevent potential issues and ensure optimal operation.

Key Maintenance Practices

- Engine Oil Change: Regularly replacing the lubricant helps maintain engine health.

- Fluid Checks: Periodically inspect and top off vital fluids, including coolant, brake fluid, and transmission fluid.

- Tire Care: Monitor tire pressure and tread depth to ensure proper handling and fuel efficiency.

- Brake System Inspection: Regular checks of the braking components are crucial for safety.

- Battery Maintenance: Clean terminals and check charge levels to prevent starting issues.

Recommended Schedule

- Every 3,000 to 5,000 miles: Change engine oil and filter.

- Every 6 months: Inspect tires, brakes, and fluid levels.

- Annually: Replace air filters and check battery health.

- Every 30,000 miles: Flush coolant and inspect the entire exhaust system.

Common Issues and Solutions

Vehicles often encounter a range of challenges that can affect their performance and reliability. Understanding these common problems and their potential fixes is essential for maintaining optimal functionality. This section explores prevalent concerns that owners may face, along with practical approaches to address them.

Electrical Problems

Issues related to the electrical system are frequently reported, including malfunctioning lights and starting difficulties. Checking the battery and fuses is a good starting point. Replacing worn-out components can often resolve these issues effectively.

Suspension Concerns

Wear and tear on suspension components can lead to a bumpy ride and handling difficulties. Inspecting struts, shocks, and bushings for damage can help identify the problem. Regular maintenance and timely replacements are crucial to ensuring a smooth driving experience.

Tools Required for Repairs

When addressing vehicle maintenance and troubleshooting, having the appropriate instruments is essential for effective work. The right tools ensure that tasks are completed efficiently and safely, minimizing the risk of damage and promoting optimal performance.

This section outlines the essential instruments that facilitate various tasks, from basic inspections to complex adjustments. Utilizing the correct tools not only simplifies the process but also enhances the overall quality of the work performed.

| Tool Type | Description |

|---|---|

| Wrenches | Used for loosening or tightening fasteners with various sizes and styles. |

| Screwdrivers | Essential for fastening and unfastening screws, available in various types. |

| Socket Set | Provides versatility in handling bolts and nuts in tight spaces. |

| Torque Wrench | Allows for precise tightening to manufacturer’s specifications. |

| Multimeter | Used for electrical diagnostics, measuring voltage, current, and resistance. |

| Jack and Stands | Necessary for lifting the vehicle safely for undercarriage work. |

| Pliers | Versatile tools for gripping, twisting, and cutting wire or small objects. |

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to addressing engine issues through a detailed, methodical process. By following each stage carefully, enthusiasts and technicians can restore functionality and enhance performance.

1. Diagnosis: Begin by identifying symptoms and performing a thorough examination. Check for unusual noises, leaks, or warning lights that may indicate underlying problems.

2. Disassembly: Carefully dismantle the components, labeling each part to ensure proper reassembly. Take note of any wear or damage that may require attention.

3. Inspection: Assess each component for integrity. Look for signs of wear, cracks, or corrosion that could affect performance. Replace any faulty parts as necessary.

4. Cleaning: Use appropriate cleaning solutions to remove carbon buildup and grime from surfaces. This step is crucial for ensuring optimal contact and function of all components.

5. Reassembly: Follow your labels and notes to reassemble the engine, ensuring that all parts are correctly aligned and secured. Double-check torque specifications for critical components.

6. Testing: After reassembly, conduct tests to confirm that the engine operates smoothly. Monitor for any irregularities and make adjustments as needed to achieve peak performance.

7. Final Inspection: Once tests are complete, perform a final check of all connections and fluid levels. Ensure everything is in order before closing the hood.

Transmission Troubleshooting Techniques

Effective diagnostic practices are crucial when addressing issues related to a vehicle’s shifting mechanism. Understanding common problems and employing systematic methods can greatly enhance the chances of accurate identification and resolution.

Common Symptoms of Transmission Issues

- Delayed engagement when shifting gears

- Unusual noises during operation

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

Step-by-Step Diagnostic Process

- Begin with a visual inspection for leaks or damage.

- Check fluid levels and quality, ensuring they meet the manufacturer’s specifications.

- Connect a diagnostic tool to read any trouble codes from the vehicle’s onboard computer.

- Test drive the vehicle to replicate the symptoms and observe behavior during shifting.

- Consult technical resources or databases for specific troubleshooting guidance related to the identified issues.

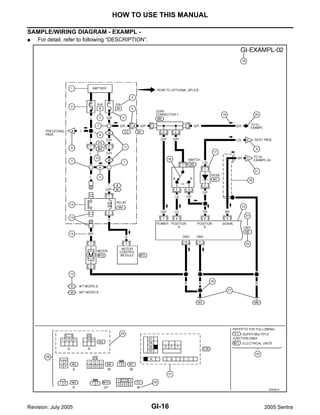

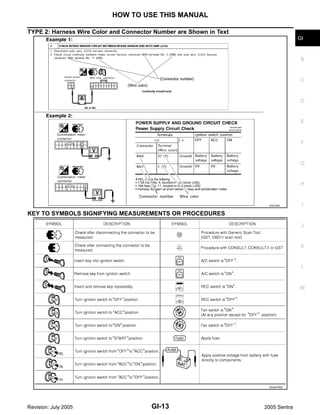

Electrical System Diagnostics

The functionality of an automobile’s electrical framework is crucial for its overall performance. Effective troubleshooting methods are essential for identifying and rectifying issues that may arise within this complex network. Understanding how to assess various components will enable you to maintain optimal operation and safety.

Common Symptoms of Electrical Issues

Several indicators can signify problems within the electrical system. Recognizing these symptoms early can prevent further complications and costly repairs.

| Symptom | Possible Cause |

|---|---|

| Dim or flickering lights | Weak battery or faulty alternator |

| Dead battery | Corroded terminals or parasitic drain |

| Malfunctioning electrical accessories | Wiring issues or blown fuses |

Diagnostic Steps

Following a systematic approach to diagnosing electrical problems can lead to effective solutions. Begin by inspecting visible components for damage and ensuring connections are secure. Utilize diagnostic tools to check for error codes, which can provide insights into the underlying issues.

Brake System Inspection Procedures

The assessment of the braking mechanism is essential for ensuring optimal vehicle performance and safety. Regular checks can prevent potential issues and enhance reliability. This section outlines the necessary steps to evaluate the brake assembly effectively.

Visual Inspection

Begin with a thorough visual examination of the brake components. Look for the following:

- Leaks in brake lines or around the calipers

- Worn or damaged brake pads

- Corrosion or rust on rotors and drums

- Loose or missing hardware

Functional Tests

After the visual check, proceed with functional assessments to ensure proper operation:

- Press the brake pedal and observe the response; it should feel firm.

- Test the braking effectiveness by driving at a low speed and applying brakes gradually.

- Check for any unusual noises, such as grinding or squeaking, during braking.

Following these procedures will help maintain the integrity of the braking system and promote safe driving conditions.

Suspension and Steering Adjustments

This section addresses the critical aspects of modifying the suspension and steering systems for optimal performance and handling. Proper alignment and adjustment are essential to ensure a smooth driving experience, enhancing both comfort and safety on the road.

To achieve the desired outcomes, it is vital to regularly check the suspension components for wear and tear. Components such as shocks, struts, and springs must be evaluated to determine if adjustments or replacements are necessary. Fine-tuning these elements can significantly affect the vehicle’s ride quality and stability.

Moreover, the steering system should be assessed for proper alignment. Misalignment can lead to uneven tire wear and compromised handling. Adjusting the steering angle and ensuring that the steering components are in optimal condition can enhance the driver’s control and responsiveness.

Ultimately, maintaining the integrity of these systems through regular checks and adjustments can extend the lifespan of the vehicle and provide a safer, more enjoyable driving experience.

Cooling System Maintenance Tips

Ensuring the longevity and efficiency of your vehicle’s cooling system is crucial for optimal performance. Regular upkeep helps prevent overheating and extends the life of the engine. Here are some essential practices to maintain this vital component.

- Regular Fluid Checks: Consistently monitor coolant levels and top up as necessary to avoid engine overheating.

- Inspect for Leaks: Look for any signs of leakage around hoses and connections. Promptly address any issues to prevent fluid loss.

- Flush the System: Perform a complete coolant flush at recommended intervals to remove contaminants and prevent buildup.

- Check the Thermostat: Ensure the thermostat is functioning correctly to regulate the flow of coolant effectively.

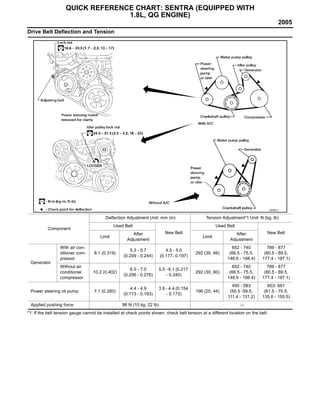

- Examine Hoses and Belts: Regularly inspect hoses and belts for wear and tear, replacing them as needed to maintain system integrity.

By following these maintenance tips, you can ensure that your vehicle’s cooling apparatus operates efficiently, reducing the risk of potential issues in the future.

Fuel System Cleaning Methods

Maintaining optimal performance of a vehicle’s fuel delivery system is essential for efficiency and longevity. Various techniques can be employed to remove contaminants and deposits, ensuring that the components operate smoothly and effectively. Regular cleaning helps to restore proper function and can prevent future issues.

| Method | Description | Advantages |

|---|---|---|

| Fuel Injector Cleaning | Utilizing specialized cleaning solutions to remove carbon build-up from fuel injectors. | Enhances fuel atomization and engine performance. |

| Intake Manifold Cleaning | Removing deposits from the intake manifold using solvents or mechanical methods. | Improves airflow and combustion efficiency. |

| Fuel Tank Cleaning | Flushing the fuel tank to eliminate sediment and contaminants. | Prevents clogging and prolongs fuel system life. |

| Professional Cleaning Services | Hiring a service that utilizes advanced techniques for comprehensive cleaning. | Ensures thoroughness and effectiveness, often with warranty options. |

Safety Features and Their Maintenance

Ensuring the effectiveness of safety elements in vehicles is crucial for both driver and passenger protection. Regular checks and upkeep of these components play a significant role in preventing accidents and enhancing overall road safety. This section focuses on key aspects of maintaining essential safety systems.

One of the primary systems to monitor is the braking mechanism. Regular inspection of brake pads, rotors, and fluid levels ensures that the stopping power remains reliable. Any signs of wear or reduced performance should be addressed immediately to maintain optimal function.

Another vital feature is the airbag system. This requires periodic evaluations to confirm that all sensors and modules are functioning correctly. It is essential to ensure that the airbags deploy as intended in the event of a collision.

Furthermore, the effectiveness of seatbelts cannot be overlooked. They should be checked for any fraying, buckling, or mechanical issues. Keeping these restraints in good condition is vital for passenger safety during any journey.

Lastly, maintaining the stability control and traction systems enhances a vehicle’s handling characteristics. Regular diagnostics can identify any faults in these systems, helping to ensure they perform well under various driving conditions.

Regular Service Intervals Explained

Maintaining a vehicle’s optimal performance requires adhering to scheduled maintenance timelines. These intervals ensure that all components function efficiently and help prevent potential issues that could lead to costly repairs.

Understanding the key service milestones is essential for any vehicle owner. Here are some of the common intervals you should be aware of:

- Oil Changes: Typically recommended every 3,000 to 5,000 miles, depending on the type of oil used.

- Filter Replacements: Air and cabin filters should generally be replaced every 15,000 to 30,000 miles.

- Tire Rotation: It is advisable to rotate tires every 5,000 to 7,500 miles to promote even wear.

- Brake Inspection: Brakes should be examined at least once a year or whenever you notice a change in performance.

- Fluid Checks: Regular checks on coolant, transmission fluid, and brake fluid are crucial to ensure proper levels and condition.

Following these guidelines helps prolong the lifespan of your vehicle and enhances safety on the road. It’s essential to consult your vehicle’s specifications for any specific recommendations.

Resources for Further Assistance

When faced with challenges related to vehicle maintenance and troubleshooting, various resources can provide invaluable support. These materials are designed to enhance understanding and facilitate the resolution of common issues, ensuring a smoother experience for both novice and experienced individuals.

Online forums and communities offer a platform for sharing experiences and solutions. Engaging with fellow enthusiasts can lead to practical advice and insights that are often not found in traditional literature. Additionally, many websites specialize in automotive guides, providing detailed instructions and diagrams that cater to a wide range of vehicle models.

For those seeking a more personalized approach, local mechanics or specialized workshops can be excellent resources. These professionals possess hands-on experience and can provide tailored assistance based on individual needs. Furthermore, manufacturer support lines can offer direct help for specific inquiries, ensuring that you receive accurate information and guidance.

Lastly, video tutorials on platforms like YouTube can be particularly helpful. Visual aids can simplify complex procedures and demonstrate techniques that may be difficult to grasp through text alone. Utilizing these resources will empower you to tackle automotive challenges with greater confidence.