Nissan Altima 1999 Repair Guide

Proper upkeep of an automobile ensures its longevity and enhances its performance over time. A well-maintained vehicle can serve its owner reliably, making regular care crucial. This section provides essential insights for understanding your car’s needs and managing basic tasks to keep it in optimal condition.

From addressing frequent issues to routine check-ups, this guide offers step-by-step instructions for various maintenance activities. You’ll find methods to handle common challenges and practical advice to simplify your car upkeep. Designed for both beginners and experienced owners, these tips empower anyone looking to understand and maintain their vehicle better.

Efficiently managing upkeep can improve your vehicle’s functionality and prevent unexpected issues. By following these guidelines, you can handle essential tasks confidently, enhancing your experience on the road and extending the life of your car.

99 Nissan Altima Repair Guide

Maintaining an older vehicle requires both attention to detail and a solid understanding of its unique mechanics. For this particular model, understanding key aspects like engine efficiency, brake responsiveness, and electrical components can go a long way toward enhancing performance and extending longevity. This guide highlights essential maintenance practices, focusing on typical wear points and areas that may benefit from regular adjustments or replacements.

With the right approach to servicing, drivers can address common issues effectively. Routine checks, including fluid levels, tire alignment, and battery health, ensure that each system functions optimally. By following a consistent upkeep schedule, it’s easier to prevent costly repairs and keep the car in reliable condition over time.

Engine Maintenance Tips for Altima

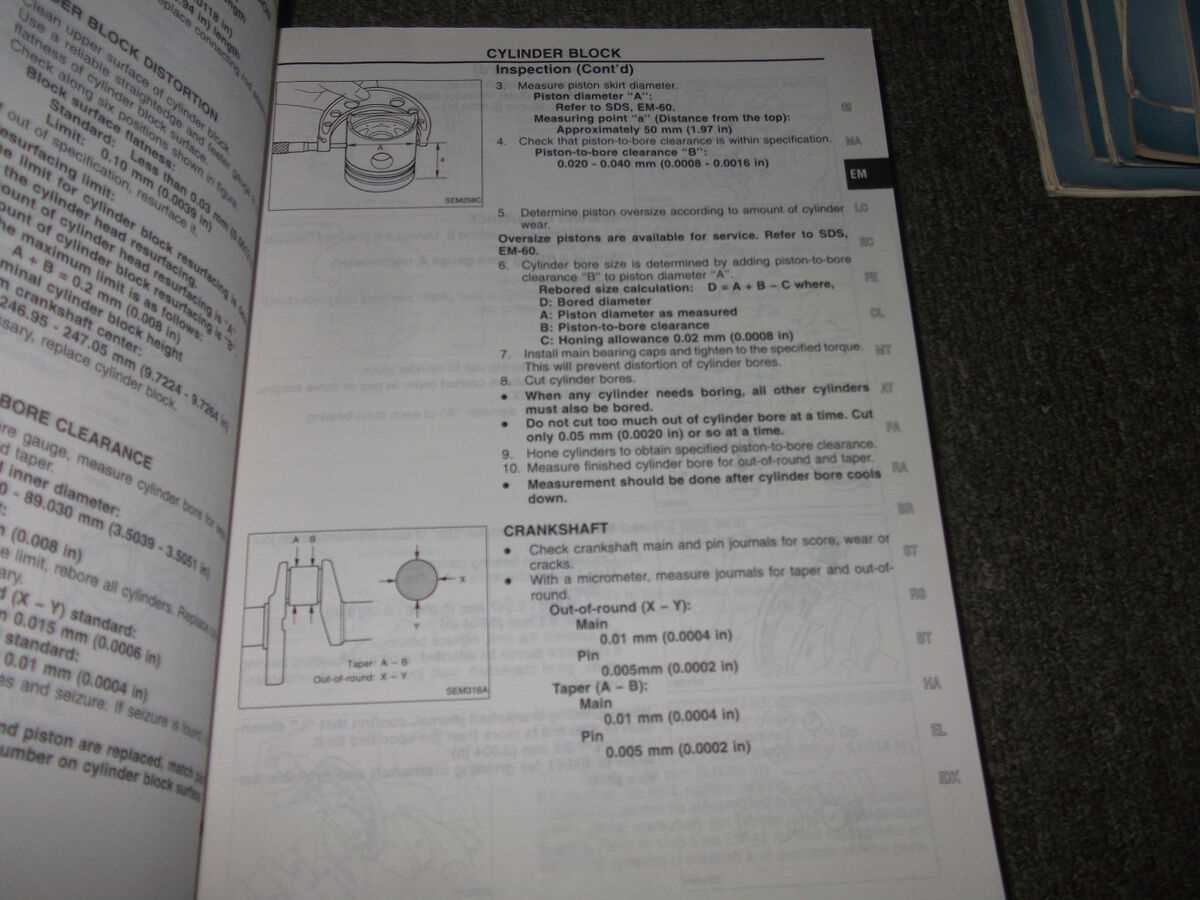

Regular engine upkeep is essential for preserving vehicle performance and extending engine life. A few simple yet effective routines can keep your engine running smoothly and prevent future issues. This section highlights fundamental tips for routine maintenance that enhance efficiency and prevent common wear.

Check Oil Levels Regularly

Maintaining proper oil levels is crucial for engine lubrication, helping to reduce friction between moving parts. Make it a habit to check oil levels frequently and replace oil according to the recommended schedule. Fresh oil protects engine components from heat and wear, prolonging the engine’s longevity.

Inspect and Replace Air Filters

An engine’s air filter keeps dust and debris from entering the system. Over time, filters can clog, reducing airflow and affecting performance. Replacing air filters as needed ensures your engine breathes freely, promoting better fuel efficiency and a cleaner burn.

Following these simple steps can help your vehicle’s engine maintain optimal performance and provide a smoother driving experience over time. Consistency in maintenance habits is the key to long-term reliability.

Transmission Troubleshooting and Solutions

Transmission issues can arise from various sources, affecting performance and efficiency. Proper diagnosis and attention to potential signs of wear or malfunction can prevent major problems and prolong the lifespan of the vehicle’s transmission system.

Here are some common transmission problems along with suggested solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Slipping Gears | Low fluid levels, worn clutches, or electronic issues | Check and refill fluid, inspect clutches, and reset electronic controls if necessary |

| Delayed Engagement | Cold temperatures, worn seals, or clogged filters | Warm up engine, replace seals, and clean or change filters |

| Strange Noises | Faulty bearings, lack of lubrication, or component damage | Inspect bearings, ensure proper fluid levels, and replace damaged parts |

| Fluid Leaks | Damaged seals, loose connections, or cracks in the transmission case | Replace seals, tighten connections, and repair or replace the case as needed |

Regular maintenance and timely troubleshooting of transmission problems can prevent costly repairs and ensure smoother, more reliable driving. If uncertain about an issue, consulting a specialist is advisable to avoid further complications.

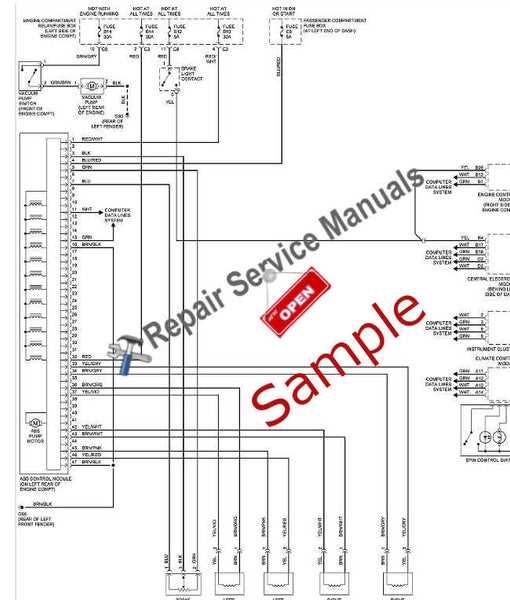

Electrical System Diagnostics

The electrical system in any vehicle is complex and responsible for powering various critical components, from the ignition to the lighting and even the entertainment system. Effective troubleshooting in this area can help identify issues that impact performance, efficiency, and safety. Understanding the electrical layout and following logical steps can simplify the diagnostic process and aid in maintaining overall vehicle reliability.

Basic Troubleshooting Steps

Start by checking battery voltage and ensuring all connections are clean and tight. Low or inconsistent voltage often leads to unexpected electrical failures. Next, examine the fuse box for any blown fuses or visible damage, as these could indicate overloads in specific circuits. Testing each fuse with a multimeter can quickly reveal problem areas without disassembling major components.

Inspecting the Wiring and Connectors

Over time, wiring and connectors can suffer from wear, leading to poor connectivity and shorts. Examine all accessible wiring for signs of fraying, corrosion, or loose connections. Pay particular attention to high-wear areas and ensure connectors are fully seated. For accurate readings, using a continuity tester can help pinpoint broken circuits within a harness, ensuring a thorough inspection.

Cooling System Care and Repair

The cooling system is essential to maintaining optimal engine performance and preventing overheating. Regular attention to this system can help ensure steady temperatures and extend engine life, particularly during demanding driving conditions. Proper care includes inspection, maintenance, and timely adjustments to preserve efficient cooling.

| Component | Care Tips | Replacement Interval |

|---|---|---|

| Radiator | Check for any leaks or damage; flush coolant annually. | Every 5 years |

| Thermostat | Inspect functionality to ensure it opens and closes properly. | As needed, generally every 3-5 years |

| Coolant | Top off regularly and replace according to vehicle guidelines. | Every 2 years |

| Water Pump | Inspect for leaks or unusual noises. | Every 4-5 years |

In addition to routine checks, cleaning the radiator and verifying coolant levels can support reliable temperature control. A well-maintained cooling system minimizes the risk of heat-related issues and promotes engine durability.

Brake Inspection and Replacement Steps

Regular examination and replacement of braking components are essential for maintaining vehicle safety and performance. This section outlines the procedures for assessing and changing brake parts to ensure optimal functionality. Following these guidelines will help you identify issues early and execute the necessary maintenance efficiently.

Before starting, gather the required tools and materials, including a jack, lug wrench, brake cleaner, new brake pads, and any additional parts as needed. Always ensure that the vehicle is on a level surface and securely supported before working on the braking system.

| Step | Description |

|---|---|

| 1 | Lift the vehicle and remove the wheel to access the braking assembly. |

| 2 | Inspect the brake pads for wear; replace them if they are below the recommended thickness. |

| 3 | Check the brake rotors for damage or warping; resurfacing or replacing may be necessary. |

| 4 | Clean the braking surfaces and components with brake cleaner to remove dust and debris. |

| 5 | Install new brake pads, ensuring proper alignment and fit. |

| 6 | Reassemble the wheel and lower the vehicle, then perform a test of the braking system. |

Suspension System Maintenance Guide

The suspension system plays a vital role in ensuring a smooth and stable driving experience. Regular upkeep of this crucial component enhances vehicle performance and safety. This guide outlines essential maintenance practices to keep your suspension in optimal condition.

Routine inspections are crucial to detect potential issues early. Look for signs of wear such as leaks, cracks, or abnormal noises. Ensuring proper alignment and tire pressure is also important for extending the life of your suspension components.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for visible wear or damage on suspension parts. |

| Lubrication | Every 6 months | Apply lubricant to moving parts to reduce friction. |

| Shock Absorber Replacement | Every 50,000 miles | Replace worn shock absorbers for improved handling. |

| Alignment Check | Yearly | Ensure proper wheel alignment to prevent uneven tire wear. |

| Tire Rotation | Every 5,000 miles | Rotate tires to promote even wear and extend their lifespan. |

By following these maintenance guidelines, you can ensure that your vehicle’s suspension system remains effective, providing a comfortable ride and enhancing overall safety on the road.

Fuel System Troubleshooting Techniques

Effective troubleshooting of the fuel system is essential for ensuring optimal engine performance. This section outlines various methods and approaches to diagnose and resolve issues related to fuel delivery, quality, and pressure. By following these techniques, you can identify potential problems and apply appropriate solutions.

Here are some common techniques to troubleshoot fuel system issues:

- Check Fuel Quality: Inspect the fuel for contaminants or degradation. Poor fuel quality can lead to engine performance problems.

- Examine Fuel Lines: Look for leaks, cracks, or blockages in the fuel lines. Any damage can impede fuel flow and affect performance.

- Test Fuel Pressure: Use a pressure gauge to measure the fuel pressure at the injector rail. Ensure it meets the manufacturer’s specifications.

- Inspect Fuel Filter: A clogged filter can restrict fuel flow. Replace the filter if it appears dirty or has not been changed in a while.

- Evaluate Fuel Pump Functionality: Listen for the sound of the pump when the ignition is turned on. If there’s no sound, the pump may be malfunctioning.

- Examine Injectors: Check for proper operation of the fuel injectors. Clean or replace them if they are clogged or not functioning correctly.

By systematically applying these troubleshooting techniques, you can effectively diagnose fuel system issues and restore proper functionality to the engine.

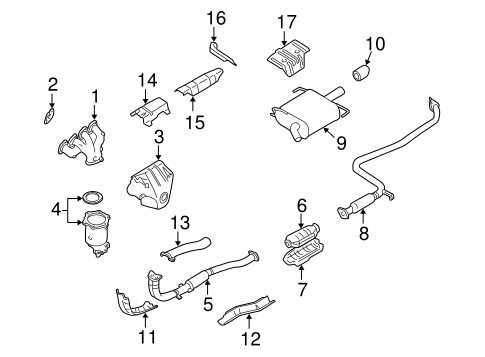

Exhaust System Repair Tips

Maintaining an efficient exhaust setup is crucial for optimal vehicle performance. Regular attention to this system can prevent issues related to emissions and engine efficiency. Here are some valuable suggestions to help you ensure your exhaust system functions smoothly.

- Visual Inspection: Regularly check for signs of rust, damage, or leaks in the exhaust components. Look for black soot around joints, which may indicate a leak.

- Check Mountings: Ensure that all hangers and mounts are secure. Loose connections can lead to rattling noises and misalignment.

- Listen for Unusual Sounds: Pay attention to any unusual noises while driving. Loud rumbling or hissing may signal an issue within the exhaust system.

- Examine Gaskets: Inspect gaskets for wear and tear. Replacing old or damaged gaskets can prevent exhaust leaks and improve performance.

- Clear Blockages: Ensure that the exhaust pipes are free of blockages. A clogged system can lead to increased back pressure and reduced engine efficiency.

By following these tips, you can maintain a healthy exhaust system, contributing to better overall vehicle performance and longevity.

Interior Component Fixes and Upgrades

Enhancing the interior of a vehicle can significantly improve both aesthetics and functionality. This section focuses on various modifications and repairs that can revitalize your car’s cabin, ensuring a comfortable and appealing driving experience. From replacing worn-out materials to upgrading technology, these improvements can breathe new life into your ride.

Common Upgrades

- Installing new seat covers for a fresh look.

- Upgrading the audio system for better sound quality.

- Adding ambient lighting to enhance the atmosphere.

- Replacing the steering wheel for improved grip and style.

Essential Repairs

- Fixing dashboard cracks to prevent further damage.

- Repairing window mechanisms for smooth operation.

- Addressing any issues with climate control for comfort.

- Restoring or replacing floor mats for cleanliness and protection.

Exterior Body Repair Essentials

Understanding the fundamental aspects of external vehicle restoration is crucial for maintaining aesthetics and functionality. This section highlights essential procedures and techniques to address common issues that may affect the outer shell of your vehicle, ensuring both appearance and durability are preserved.

Common Issues and Solutions

- Dents and Dings: Minor surface imperfections can often be remedied through techniques such as paintless dent removal, which restores the original shape without damaging the finish.

- Scratches: Shallow scratches can typically be addressed using polishing compounds, while deeper scratches may require touch-up paint or clear coat application.

- Rust: Prevention is key; however, if rust develops, it’s essential to sand down the affected area and apply rust-inhibiting primer before repainting.

Tools Required

- Dent puller

- Polishing machine

- Touch-up paint kit

- Sandpaper (various grits)

- Rust treatment products

By equipping yourself with the right tools and knowledge, you can effectively maintain and restore the external features of your vehicle, enhancing its overall appeal and longevity.

Common Sensor Issues and Fixes

Sensors play a crucial role in modern vehicles, providing essential data for various systems to function effectively. However, these components can sometimes fail or produce inaccurate readings, leading to performance issues. Understanding common sensor-related problems can help drivers identify symptoms early and seek appropriate solutions.

Faulty Oxygen Sensors

One of the prevalent issues is related to oxygen sensors, which monitor the air-fuel mixture in the engine. If these sensors malfunction, it can result in poor fuel efficiency and increased emissions. Signs of a faulty oxygen sensor include a drop in mileage, engine hesitation, and the illumination of the check engine light. Replacing the sensor usually resolves the issue.

Malfunctioning Mass Airflow Sensors

The mass airflow sensor measures the amount of air entering the engine. A malfunction here can cause erratic engine performance, including stalling and rough idling. Drivers may notice a significant loss of power or acceleration issues. Cleaning the sensor can sometimes restore its functionality, but replacement may be necessary for severe cases.

Regular Maintenance Checklist

Routine upkeep is essential for ensuring the longevity and reliability of your vehicle. By following a systematic checklist, you can keep your automobile in optimal condition and prevent potential issues from arising.

- Engine Oil Change: Replace every 5,000 to 7,500 miles to maintain engine efficiency.

- Fluid Levels: Regularly check and top off fluids, including coolant, brake, and power steering fluids.

- Tire Inspection: Examine tire pressure and tread depth monthly, and rotate tires every 6,000 miles.

- Brake System Check: Inspect brake pads and rotors for wear every 10,000 miles.

- Battery Maintenance: Clean terminals and ensure connections are secure; check battery life annually.

- Air Filter Replacement: Change the air filter every 15,000 to 30,000 miles for optimal airflow.

- Belts and Hoses: Inspect for cracks or wear during each service; replace as needed.

- Wiper Blades: Replace blades every 6 to 12 months to maintain visibility in adverse weather.

Implementing this checklist can greatly enhance performance and safety. Regular inspections help identify minor issues before they escalate into costly repairs.