Nissan UD Truck Repair Guide

This section offers essential insights into the upkeep and troubleshooting of heavy-duty vehicles, ensuring optimal performance and longevity. Understanding the fundamental aspects of these machines is crucial for anyone responsible for their operation and care.

Comprehensive knowledge about various components and systems is vital for effective management. By following structured guidelines, operators can prevent potential issues and enhance efficiency. This guide serves as a valuable resource for users aiming to familiarize themselves with maintenance techniques and best practices.

By engaging with this information, individuals can develop skills that contribute to safer and more reliable vehicle performance. Practical advice and clear instructions empower users to tackle common challenges and foster a deeper understanding of their machinery.

This section provides a comprehensive understanding of how to effectively maintain a large commercial vehicle, ensuring its longevity and optimal performance. Regular upkeep is essential for preventing issues and enhancing reliability on the road.

Key maintenance practices include:

- Routine inspections of vital components

- Regular oil changes and fluid checks

- Tire maintenance and alignment

- Brake system evaluations

- Electrical system diagnostics

Implementing a systematic approach to these tasks can help identify potential problems early, thereby reducing downtime and repair costs. It’s advisable to follow the manufacturer’s guidelines to ensure all procedures are performed accurately and efficiently.

Understanding Common Truck Issues

Vehicles can experience a variety of challenges that affect their performance and reliability. Recognizing these common problems is essential for maintaining optimal functionality and ensuring safety on the road. Whether it’s engine performance, transmission difficulties, or electrical system malfunctions, being aware of potential issues can help in timely diagnosis and resolution.

One frequent concern involves engine irregularities, which may manifest as unusual noises, reduced power, or increased fuel consumption. These symptoms often signal the need for immediate attention to prevent further damage. Similarly, transmission complications can lead to shifting issues or slipping gears, hindering the overall driving experience.

Another area to monitor is the electrical system, where battery failures or wiring issues can cause starting difficulties and malfunctioning accessories. Regular checks of these components can prevent unexpected breakdowns and enhance the longevity of the vehicle.

By understanding these typical challenges, operators can better prepare for maintenance and address issues before they escalate, ensuring reliable performance over time.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and servicing. A well-stocked toolkit not only enhances efficiency but also ensures that tasks are completed safely and accurately. Understanding the essential instruments needed can significantly streamline the process, allowing for quicker and more reliable outcomes.

Basic Hand Tools

Fundamental implements such as wrenches, pliers, and screwdrivers are vital for any maintenance job. These tools enable users to perform a wide range of tasks, from tightening bolts to adjusting components. Investing in high-quality hand tools can make a substantial difference in both performance and durability.

Diagnostic Equipment

Advanced diagnostic tools are essential for identifying issues within various systems. These devices provide valuable insights into functionality and performance, helping technicians to pinpoint problems accurately. By utilizing such technology, one can ensure that all aspects of the machinery are functioning optimally.

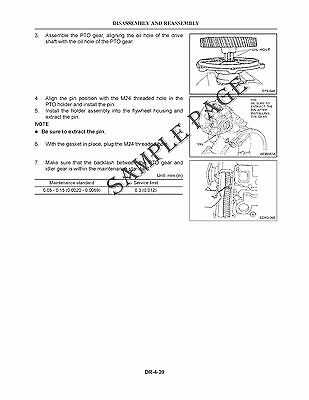

Step-by-Step Repair Techniques

This section outlines essential procedures for effectively addressing mechanical issues. By following a systematic approach, individuals can ensure proper diagnostics and solutions, leading to optimal performance.

The following table summarizes key techniques that can be applied during the maintenance process:

| Technique | Description | Tools Required |

|---|---|---|

| Diagnostic Assessment | Evaluate the system for potential faults using specialized equipment. | Multimeter, diagnostic scanner |

| Component Replacement | Remove and substitute faulty parts with high-quality alternatives. | Wrenches, screwdrivers, replacement components |

| System Calibration | Adjust settings to ensure all components work harmoniously. | Calibration tool, software |

| Performance Testing | Conduct tests to verify the effectiveness of repairs made. | Test gauges, performance analyzer |

Adhering to these methods will facilitate effective resolutions and prolong the lifespan of the equipment.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to established guidelines and practices not only protects the individual conducting the work but also enhances the overall efficiency of the procedure.

Personal Protective Equipment

Utilizing appropriate personal protective gear is essential. This includes wearing gloves, goggles, and sturdy footwear to safeguard against potential hazards. Additionally, high-visibility clothing can be beneficial in low-light conditions, ensuring that the technician is easily seen.

Work Environment Considerations

Maintaining a clean and organized workspace is vital. Clutter can lead to slips and falls, so it is advisable to keep tools and materials in designated areas. Furthermore, ensuring proper ventilation when working with chemicals or fuels is necessary to minimize inhalation risks. Always be aware of your surroundings to prevent accidents.

Engine Troubleshooting Tips

Identifying and resolving issues with your vehicle’s powertrain is crucial for optimal performance. By following a systematic approach, you can diagnose problems effectively and implement necessary solutions.

Common Symptoms to Watch For

- Unusual noises during operation

- Decreased power output

- Inconsistent starting

- Excessive exhaust smoke

- Engine overheating

Basic Diagnostic Steps

- Inspect fluid levels and quality.

- Check for leaks around seals and hoses.

- Examine the condition of belts and filters.

- Run a diagnostic scan to check for error codes.

- Perform a visual inspection of electrical connections.

Transmission System Diagnostics

Understanding the functionality of the transmission system is crucial for ensuring optimal performance in heavy vehicles. This section focuses on the diagnostic processes that help identify issues within this critical component, allowing for timely intervention and maintenance.

Initial Assessment involves observing the behavior of the vehicle during operation. Signs such as unusual noises, delayed shifting, or fluid leaks can indicate underlying problems. It’s essential to monitor these symptoms closely to determine the next steps in the diagnostic procedure.

Utilizing specialized diagnostic tools is a vital part of the evaluation process. These devices can read error codes from the vehicle’s onboard computer, providing valuable insights into potential malfunctions. By interpreting these codes accurately, technicians can pinpoint specific areas of concern.

Furthermore, a thorough examination of the fluid condition is necessary. The transmission fluid should be clean and at the proper level. Contaminated or low fluid can lead to inadequate lubrication and overheating, resulting in severe damage if not addressed promptly.

Finally, conducting a functional test helps confirm the overall performance of the transmission system. This test simulates various driving conditions to evaluate the responsiveness and efficiency of gear shifts. Through systematic diagnostics, maintenance personnel can ensure the longevity and reliability of the transmission system.

Electrical System Maintenance Guide

Maintaining the electrical components of your vehicle is essential for ensuring optimal performance and longevity. Proper care and regular checks can prevent issues that may lead to unexpected breakdowns or malfunctions.

Regular Inspection Practices

Routine inspections are critical for identifying potential problems before they escalate. Consider the following steps:

- Check all wiring for signs of wear or damage.

- Ensure all connections are secure and free from corrosion.

- Inspect the battery for leaks and check the fluid levels.

- Test the functionality of all electrical components, including lights and gauges.

Maintenance Tips

Incorporate these maintenance tips into your regular vehicle care routine:

- Clean battery terminals to prevent corrosion buildup.

- Replace any worn-out fuses to ensure proper circuit protection.

- Use protective sprays on electrical connections to resist moisture.

- Schedule professional inspections periodically for comprehensive assessments.

Brake System Repair Procedures

This section outlines the essential steps required for addressing issues related to the braking mechanism of heavy vehicles. Proper maintenance and timely interventions are crucial for ensuring optimal performance and safety.

Inspection and Diagnosis

Before proceeding with any corrective actions, a thorough examination of the braking components is necessary. Follow these steps:

- Check for fluid leaks in the brake lines.

- Inspect the condition of brake pads and shoes for wear.

- Examine rotors and drums for scoring or damage.

- Assess the functionality of the master cylinder and brake booster.

Repair and Replacement Steps

Once the inspection is complete, follow these procedures for repair or replacement:

- If brake pads or shoes are worn, replace them with new components.

- Resurface or replace rotors and drums if damaged.

- Repair any leaks in the brake lines by replacing damaged sections.

- Bleed the braking system to remove air and ensure proper fluid flow.

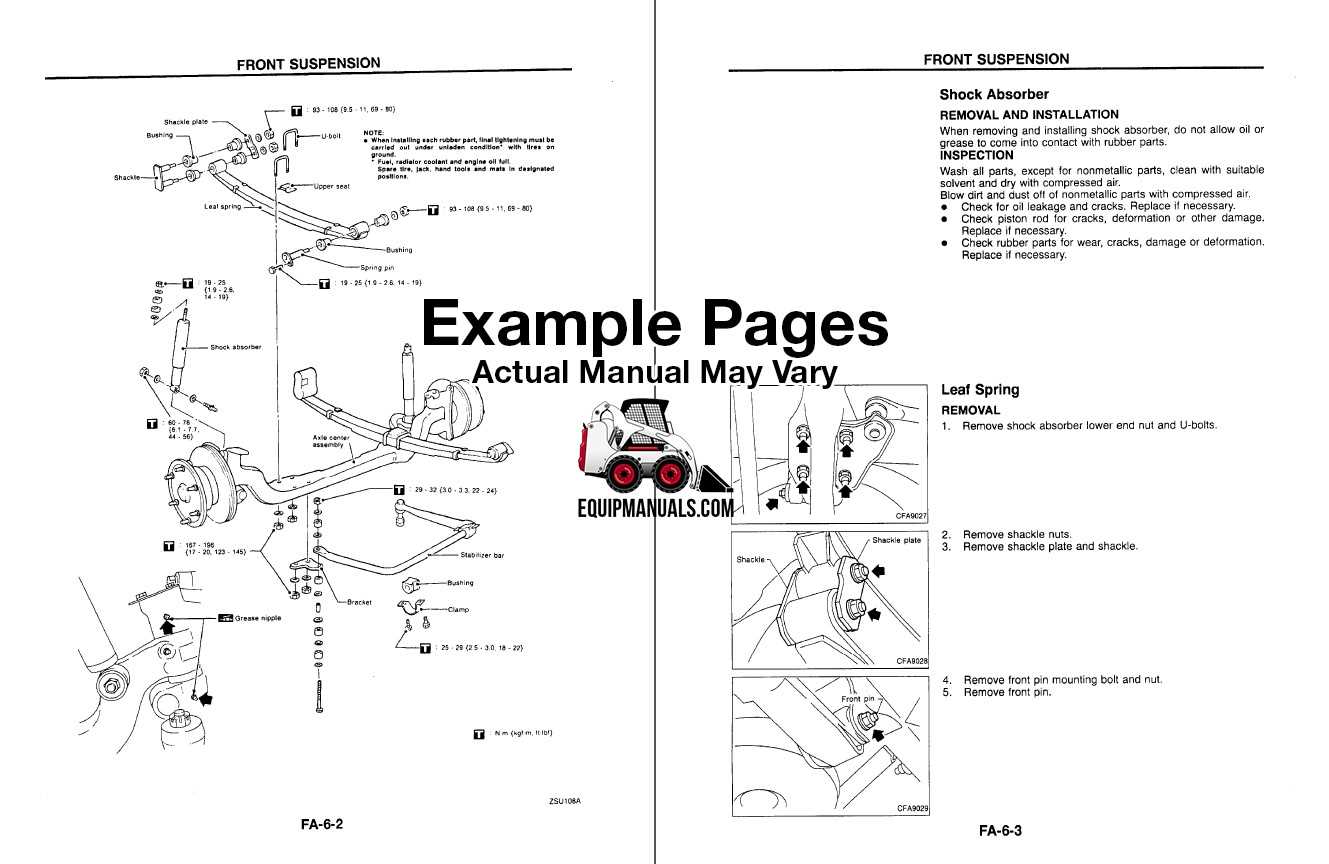

Suspension and Steering Adjustments

Proper alignment and calibration of the vehicle’s suspension and steering systems are essential for optimal performance and safety. This section delves into the necessary procedures and considerations for fine-tuning these components, ensuring a smooth and controlled driving experience.

Adjustment Procedures

To achieve the desired handling characteristics, it is crucial to follow specific guidelines for adjusting the suspension and steering. Begin by checking the camber, caster, and toe angles, as these factors significantly influence tire wear and steering response. Utilize appropriate tools and equipment for accurate measurements, and make adjustments as needed to restore proper alignment.

Regular Maintenance

Regular inspections of the suspension and steering systems help identify wear and tear early. Pay close attention to components such as shock absorbers, tie rods, and ball joints. Ensuring these parts are in good condition not only enhances safety but also prolongs the lifespan of the vehicle.

Regular Service Interval Importance

Maintaining optimal performance and longevity of vehicles requires adhering to scheduled maintenance intervals. These check-ups are crucial in identifying potential issues before they escalate, ensuring smooth operation and enhancing safety.

Benefits of Regular Maintenance

Consistent servicing leads to numerous advantages. It not only improves efficiency but also helps in reducing unexpected breakdowns. Regular checks contribute to better fuel economy and can significantly lower long-term repair costs.

Recommended Service Schedule

| Service Type | Frequency | Details |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace engine oil and filter to maintain lubrication and engine health. |

| Tire Inspection | Monthly | Check tire pressure and tread depth for optimal handling and safety. |

| Brake Inspection | Every 10,000 miles | Examine brake pads and discs to ensure effective stopping power. |

| Fluid Check | Every 3 months | Inspect coolant, transmission fluid, and brake fluid levels to prevent overheating and failures. |

Identifying Fluid Leaks and Solutions

Detecting leaks in a vehicle’s systems is crucial for maintaining optimal performance and safety. Understanding the origin of these leaks can help in preventing further damage and ensuring efficient operation. Various types of fluids may escape from different components, each indicating a specific issue that needs addressing.

| Fluid Type | Leak Source | Possible Solutions |

|---|---|---|

| Engine Oil | Oil pan or gasket | Inspect and replace gaskets; tighten oil pan bolts. |

| Coolant | Radiator or hoses | Check for cracks; replace damaged hoses or radiator. |

| Transmission Fluid | Transmission pan | Tighten bolts; replace pan gasket if necessary. |

| Brake Fluid | Brake lines or master cylinder | Inspect for leaks; replace faulty components. |

| Power Steering Fluid | Power steering pump or hoses | Replace damaged hoses or pump; ensure tight connections. |

Regular inspections and prompt action can significantly reduce the risk of severe mechanical issues. Addressing leaks as soon as they are identified will help maintain the vehicle’s longevity and reliability.

Owner’s Role in Vehicle Longevity

The responsibility of maintaining a vehicle’s lifespan significantly lies with its owner. Proper care and attention to various aspects of maintenance can lead to improved performance and durability over time.

Regular Inspections are essential for identifying potential issues before they escalate. Owners should make it a habit to routinely check fluid levels, tire pressure, and other critical components. By being proactive, minor problems can be resolved swiftly, preventing costly repairs down the line.

Adhering to Maintenance Schedules provided by the manufacturer is another key factor. These schedules outline important services such as oil changes, filter replacements, and brake inspections. Following these guidelines helps ensure that the vehicle operates efficiently and safely.

Additionally, driving habits play a crucial role in a vehicle’s longevity. Gentle acceleration, maintaining appropriate speeds, and avoiding abrupt stops can minimize wear and tear on various systems. By adopting mindful driving practices, owners can extend the lifespan of their vehicles significantly.