Comprehensive Guide to 110cc ATV Repairs

Maintaining and servicing compact off-road vehicles is essential for ensuring their longevity and optimal performance. Understanding the intricacies of these machines can greatly enhance the ownership experience, allowing enthusiasts to tackle common issues and conduct routine check-ups with confidence. This guide aims to provide a comprehensive overview of the necessary procedures and techniques for keeping these vehicles in top shape.

Each section will delve into specific aspects of maintenance, offering practical insights and tips for troubleshooting common challenges. By familiarizing oneself with the inner workings of these vehicles, owners can make informed decisions regarding repairs and upgrades. This knowledge not only promotes safety but also enhances the overall enjoyment of the riding experience.

Whether you’re a seasoned rider or new to the world of off-road vehicles, having access to detailed instructions and guidance can be invaluable. The following information is designed to empower you, ensuring that your vehicle remains reliable and ready for adventure.

Understanding 110cc ATV Components

This section delves into the essential parts of a small four-wheeled vehicle designed for off-road adventures. Each element plays a crucial role in ensuring optimal performance, safety, and durability. A comprehensive grasp of these components enables enthusiasts and mechanics alike to troubleshoot issues effectively and enhance functionality.

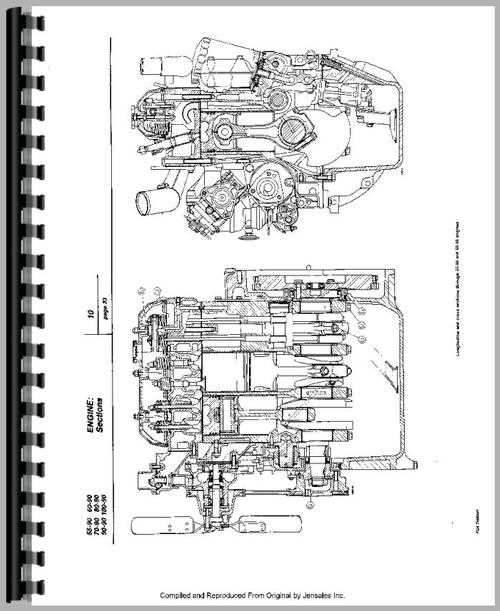

Engine: The heart of the vehicle, responsible for generating power and driving performance. Understanding its workings helps in diagnosing problems related to acceleration and efficiency.

Transmission: This system transmits power from the engine to the wheels. Familiarity with its mechanics can aid in addressing shifting issues and improving overall drive quality.

Suspension: This component absorbs shocks and maintains stability on uneven terrain. Knowledge of suspension types and adjustments can significantly enhance ride comfort and handling.

Brakes: Essential for safety, these systems allow for effective stopping power. Recognizing the types and maintenance needs is vital for ensuring reliable performance.

Wheels and Tires: These components provide traction and support. Understanding their specifications and maintenance requirements is crucial for optimizing grip and durability.

By familiarizing oneself with these fundamental parts, one can ensure the longevity and efficiency of the vehicle while enhancing the overall riding experience.

Common Issues and Troubleshooting

Maintaining a small off-road vehicle involves recognizing frequent problems that may arise during use. Understanding these issues is crucial for ensuring optimal performance and longevity. Below are some typical concerns along with troubleshooting steps to address them.

- Starting Difficulties:

If the engine fails to start, check the following:

- Battery charge and connections

- Fuel levels and quality

- Ignition system components

- Overheating:

Excessive heat can cause serious damage. To resolve this, consider:

- Inspecting coolant levels

- Checking for blockages in the cooling system

- Ensuring proper airflow around the engine

- Transmission Issues:

Difficulty in shifting gears can lead to performance loss. Troubleshoot by:

- Examining the clutch adjustment

- Inspecting fluid levels

- Looking for signs of wear on the transmission components

- Braking Problems:

Effective stopping power is essential for safety. To address braking issues, check:

- Brake fluid levels

- Brake pads for wear and tear

- The functionality of brake lines and hoses

By systematically addressing these common problems, you can enhance the reliability and performance of your vehicle, ensuring a smoother and safer ride.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. A well-equipped toolkit can significantly enhance your ability to diagnose issues and perform necessary fixes. Understanding which instruments to prioritize can save time and prevent frustration during the process.

Basic Hand Tools: A set of wrenches and screwdrivers is foundational for any task. These tools allow for adjustments and disassemblies, making it easier to access components that require attention.

Specialized Equipment: Depending on the specific tasks, you might need items such as torque wrenches or socket sets. These tools help ensure that connections are secure and that parts are installed correctly, which is vital for performance and safety.

Diagnostic Tools: Incorporating diagnostic instruments can simplify troubleshooting. Devices such as multimeters or compression testers are invaluable for identifying electrical issues or assessing engine health.

Safety Gear: Never overlook the importance of safety equipment. Gloves, goggles, and appropriate clothing can protect you from potential hazards while working on machinery.

Equipping yourself with these essential tools not only streamlines the maintenance process but also fosters a more enjoyable and productive experience. Investing in quality equipment pays off in the long run, making repairs more manageable and efficient.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. This guide outlines a systematic approach to maintaining key components, helping you identify issues before they become significant problems. Following these steps will enhance reliability and safety during operation.

Routine Checks

Start with periodic inspections of the engine and its surrounding areas. Check for any signs of wear or damage, such as leaks or unusual noises. Ensure that the fuel system is clean, and replace filters as needed. Inspect the tires for proper inflation and tread wear, as these factors greatly influence handling and stability.

Fluid Maintenance

Keeping fluids at appropriate levels is crucial for functionality. Regularly check the oil, coolant, and brake fluid. Change the oil as per the manufacturer’s recommendations to maintain engine health. Ensure that the cooling system is free of debris, and the radiator is functioning efficiently to prevent overheating.

Engine Performance Enhancements

Boosting the efficiency and output of a small engine involves a range of modifications and upgrades that can significantly improve its overall functionality. By focusing on various components and tuning techniques, enthusiasts can achieve a more responsive and powerful experience.

One effective method is to upgrade the intake system, allowing for improved airflow. This can be accomplished by installing a high-performance air filter or modifying the intake manifold. Additionally, optimizing the exhaust system can enhance the expulsion of gases, further contributing to increased power and torque.

Tuning the engine’s carburetor or fuel injection system can also play a crucial role in achieving optimal performance. Adjustments to fuel mixtures can lead to better combustion efficiency, providing a noticeable increase in acceleration and throttle response.

Lastly, incorporating performance-enhancing components such as aftermarket ignition systems or lightweight flywheels can yield significant gains. These modifications not only improve performance but can also enhance the overall reliability and longevity of the engine.

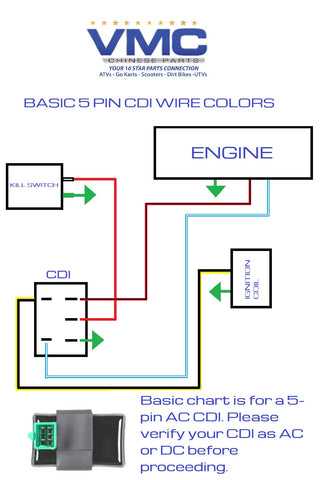

Electrical System Diagnostics

This section covers the essential processes involved in evaluating the electrical components of your vehicle. Proper diagnosis ensures that all parts function optimally and helps identify any issues that may arise during operation.

Common Symptoms of Electrical Issues

- Inconsistent starting behavior

- Dim or flickering lights

- Unresponsive electrical accessories

- Unexpected battery drain

Diagnostic Steps

- Begin with a visual inspection of wiring and connectors for signs of damage or corrosion.

- Utilize a multimeter to check voltage levels at various points in the system.

- Test the battery’s condition and charge status.

- Examine fuses and relays for continuity.

- Evaluate the performance of the alternator and starter motor if necessary.

Following these steps will help pinpoint electrical malfunctions, ensuring reliable performance and longevity of your machine.

Safety Protocols During Repairs

Ensuring a secure environment while conducting maintenance on motorized vehicles is crucial. Adhering to specific guidelines can prevent accidents and promote efficient work. This section outlines essential practices to enhance safety during servicing tasks.

Preparation Before Starting

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Gather all necessary tools and materials before beginning to minimize interruptions.

Conducting the Service

- Turn off the engine and disconnect the battery to prevent electrical hazards.

- Keep the area organized to avoid tripping hazards and misplacing tools.

- Utilize jacks or stands properly to stabilize the vehicle during work.

By following these safety measures, individuals can significantly reduce the risk of injury and ensure a smooth servicing process.

Replacing Tires and Suspension Parts

Maintaining the optimal performance of your all-terrain vehicle involves periodic checks and replacements of critical components. Among these, the wheels and suspension elements play a vital role in ensuring stability and comfort during rides. Addressing wear and tear in these areas not only enhances safety but also improves the overall riding experience.

1. Tire Replacement: Regular inspection of tires is essential. Look for signs of damage such as cracks, bulges, or uneven wear. To replace tires, start by lifting the vehicle securely, then remove the lug nuts using a wrench. Once the tire is off, check the rim for any corrosion or damage. Install the new tire by aligning it with the rim, securing it with the lug nuts, and ensuring they are tightened to the manufacturer’s specifications.

2. Suspension Component Replacement: The suspension system absorbs shocks and maintains control. Inspect parts like shocks, struts, and springs for leaks or excessive wear. When replacing suspension components, begin by safely lifting the vehicle and removing the wheel for better access. Detach the old part using appropriate tools, then install the new component, ensuring proper alignment and secure connections. Regular maintenance of these parts is crucial for a smooth and stable ride.

Fuel System Care and Upgrades

Maintaining and enhancing the fuel delivery mechanism is crucial for optimal performance and longevity of your vehicle. Regular attention to this system ensures smooth operation and can significantly improve efficiency. Upgrades can also provide better fuel management and responsiveness, making every ride more enjoyable.

Routine Maintenance Tips

To keep the fuel delivery system in top condition, consider the following practices:

| Task | Frequency | Description |

|---|---|---|

| Inspect Fuel Lines | Monthly | Check for cracks or leaks that may affect fuel flow. |

| Clean Fuel Filter | Every 6 Months | Replace or clean the filter to prevent clogging and ensure proper fuel delivery. |

| Test Fuel Pump | Annually | Check the functionality of the pump to maintain adequate pressure. |

Performance Enhancements

For those looking to elevate their vehicle’s performance, several upgrades are available:

- Install a high-flow fuel filter for better filtration and flow rate.

- Upgrade the fuel pump for increased pressure and efficiency.

- Consider tuning the carburetor for improved air-fuel mixture and throttle response.

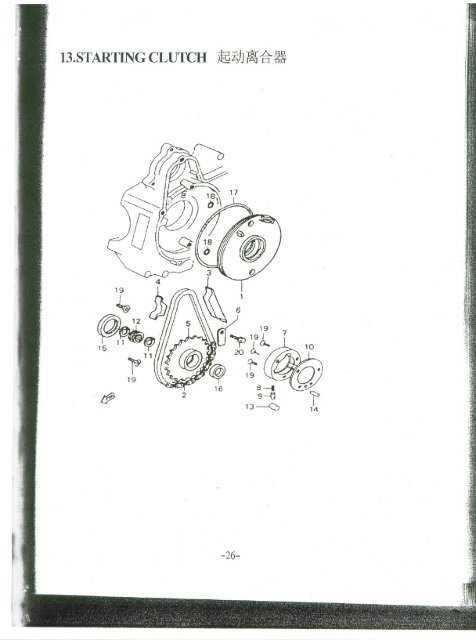

Handling Transmission Problems

Issues within the transmission system can significantly impact the performance of your vehicle, leading to a frustrating experience for the operator. Understanding common symptoms and identifying potential causes is crucial for effective troubleshooting and maintenance. By taking a systematic approach, you can address these challenges and restore optimal functionality.

Common Symptoms

Typical signs of transmission trouble include unusual noises, difficulty in shifting gears, or unresponsive acceleration. These indicators may stem from various factors, such as fluid leaks, worn components, or improper adjustments. Regularly monitoring the performance can help catch these issues early, preventing further damage.

Troubleshooting Steps

Begin by inspecting the fluid levels and condition; low or contaminated fluid can lead to operational failures. Next, check for any visible leaks around the transmission casing. If the symptoms persist, it may be necessary to examine internal components or consult a professional for a thorough assessment. Addressing problems promptly will enhance the longevity of the system and ensure smooth operation.

Best Practices for Long-Term Care

Maintaining the longevity of your vehicle requires a proactive approach to upkeep and vigilance regarding its condition. By implementing a series of effective strategies, you can ensure optimal performance and reduce the likelihood of costly repairs down the line.

Routine Maintenance

- Conduct regular inspections to identify any wear and tear.

- Change the oil and fluids at recommended intervals.

- Check and maintain tire pressure to enhance safety and efficiency.

- Inspect the brakes and replace components as necessary.

Proper Storage

- Store the vehicle in a dry, sheltered environment to prevent rust and degradation.

- Use a cover to protect against dust and UV damage when not in use.

- Ensure the fuel system is stabilized to prevent issues with stale fuel.

By following these best practices, you can significantly extend the lifespan of your vehicle while enhancing its performance and reliability.