Comprehensive Guide to Repairing the 1997 7.3 Powerstroke

This section provides essential information for enthusiasts and professionals alike, focusing on the upkeep and troubleshooting of a popular diesel engine model. Understanding the intricacies of such a powerhouse is crucial for optimal performance and longevity.

By delving into specific procedures and insights, users will gain the knowledge needed to navigate various challenges that may arise during operation. This resource is designed to empower individuals with the tools and techniques necessary for effective diagnostics and maintenance.

Whether you are a seasoned mechanic or a novice eager to learn, this guide offers a wealth of practical advice and step-by-step instructions. Equip yourself with the understanding to ensure reliability and efficiency in your vehicle’s performance.

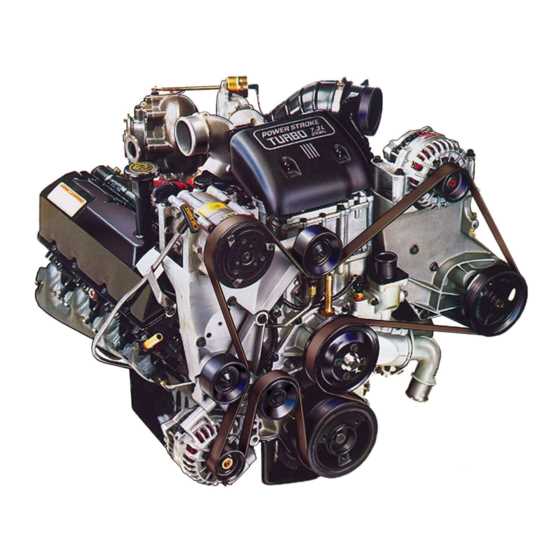

Overview of the 7.3 Powerstroke

This section provides an in-depth look at a highly regarded diesel engine known for its reliability and performance. Often favored in heavy-duty applications, this engine has become a benchmark for durability and efficiency. Its robust design and engineering have made it a popular choice among enthusiasts and professionals alike.

The engine features advanced technologies that enhance its functionality while maintaining fuel efficiency. Understanding the core components and their roles is crucial for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Fuel Injection System | Utilizes high-pressure injectors for optimal combustion efficiency. |

| Turbocharger | Enhances power output by forcing more air into the combustion chamber. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Exhaust System | Facilitates the safe expulsion of exhaust gases while minimizing emissions. |

Grasping the functionalities of these elements can significantly improve performance and longevity. Regular inspection and upkeep are essential to ensure this powerhouse remains in peak condition.

Essential Tools for Repairs

When embarking on maintenance or restoration tasks, having the right instruments at your disposal is crucial for achieving effective results. A well-equipped toolkit can significantly enhance efficiency and precision during the process.

Basic Hand Tools: Every project begins with fundamental hand tools such as wrenches, screwdrivers, and pliers. These items are indispensable for loosening or tightening components and can tackle a wide range of tasks.

Diagnostic Equipment: To identify issues accurately, employing diagnostic tools is essential. OBD-II scanners can provide valuable insights into system performance, helping to pinpoint malfunctioning parts.

Specialized Instruments: Depending on the nature of the job, specialized tools may be necessary. For instance, torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, while compression gauges can assess engine health.

Safety Gear: Always prioritize safety by using protective equipment. Items such as gloves, safety glasses, and steel-toed boots protect against injuries and enhance confidence while working.

Investing in these essential tools not only streamlines the repair process but also fosters a successful outcome, ultimately leading to improved performance and longevity of the vehicle.

Common Issues and Troubleshooting

Identifying and addressing frequent challenges can significantly enhance the performance and longevity of your vehicle’s engine. This section outlines typical problems encountered during operation and provides guidance on effective solutions.

One prevalent issue is the difficulty in starting the engine, often linked to battery failure or faulty glow plugs. Ensuring that the battery is adequately charged and the glow plugs are functioning properly can resolve this complication.

Another common concern is a decrease in fuel efficiency. This may stem from clogged fuel filters or injector malfunctions. Regular maintenance and timely replacement of filters can help maintain optimal fuel flow and engine efficiency.

Additionally, strange noises during operation may indicate mechanical problems. Listening for unusual sounds can aid in diagnosing issues such as worn bearings or misaligned components. Prompt attention to these symptoms can prevent more extensive damage.

Lastly, overheating is a critical issue that requires immediate action. Monitoring coolant levels and ensuring the radiator is clear of debris can help maintain appropriate temperature levels and prevent engine damage.

Step-by-Step Repair Procedures

This section outlines the essential processes for addressing common issues encountered in a specific diesel engine model. By following these detailed instructions, you can effectively troubleshoot and rectify various components, ensuring optimal performance.

1. Initial Assessment: Begin by inspecting the vehicle for any visible signs of damage or wear. Check fluid levels, hoses, and electrical connections. Document any irregularities that may require attention.

2. Gather Tools and Materials: Ensure you have all necessary tools at hand, including wrenches, sockets, and diagnostic equipment. Having the right supplies will streamline the process and minimize delays.

3. Disassembly: Carefully remove the components that need service. Keep track of all bolts and pieces, using labeled containers to avoid confusion during reassembly.

4. Component Inspection: Thoroughly examine each part for signs of wear or damage. Replace any faulty items with high-quality replacements to maintain reliability.

5. Reassembly: Follow the reverse order of disassembly, ensuring each component is properly aligned and secured. Refer to manufacturer specifications for torque settings and other requirements.

6. Final Testing: After reassembly, conduct a series of tests to confirm that everything functions correctly. Monitor engine performance, check for leaks, and ensure all systems are operational.

By adhering to these procedures, you can effectively manage maintenance and repairs, prolonging the life of your vehicle.

Maintenance Tips for Longevity

Ensuring the long-term performance of your vehicle requires consistent care and attention. By implementing regular maintenance practices, you can significantly extend its lifespan and enhance reliability. Here are essential guidelines to keep your engine in optimal condition.

Regular Fluid Checks

- Monitor engine oil levels and change it according to the manufacturer’s recommendations.

- Inspect coolant levels regularly to prevent overheating.

- Check transmission fluid for proper operation and smooth shifting.

Routine Inspections

- Examine filters for dirt and debris; replace them as needed.

- Inspect belts and hoses for wear, cracking, or fraying.

- Keep an eye on brake systems and tires for any signs of damage or wear.

By following these practices, you can help ensure that your vehicle remains efficient and dependable for years to come.

Understanding Engine Components

Every engine consists of a variety of essential parts that work in harmony to ensure optimal performance. Familiarity with these components is crucial for diagnosing issues and executing effective maintenance strategies. Each element plays a specific role in the overall operation, contributing to the power and efficiency of the engine.

Core Elements: At the heart of the engine lies the cylinder block, which houses the cylinders where fuel and air mix for combustion. Attached to this are the cylinder heads, which contain the intake and exhaust valves. These parts are vital for regulating airflow and maintaining the engine’s rhythm.

Moving Parts: The crankshaft transforms linear motion from the pistons into rotational force, powering the vehicle. Coupled with the camshaft, these components synchronize timing to ensure precise opening and closing of the valves, optimizing the combustion process.

Auxiliary Components: Supporting elements like the oil pump and water pump are crucial for maintaining lubrication and cooling, preventing overheating and wear. The fuel system also plays a significant role, delivering the necessary fuel to keep the engine running smoothly.

By understanding these fundamental parts and their interactions, one can gain deeper insights into the functionality of the engine and enhance troubleshooting efforts, leading to improved performance and longevity.

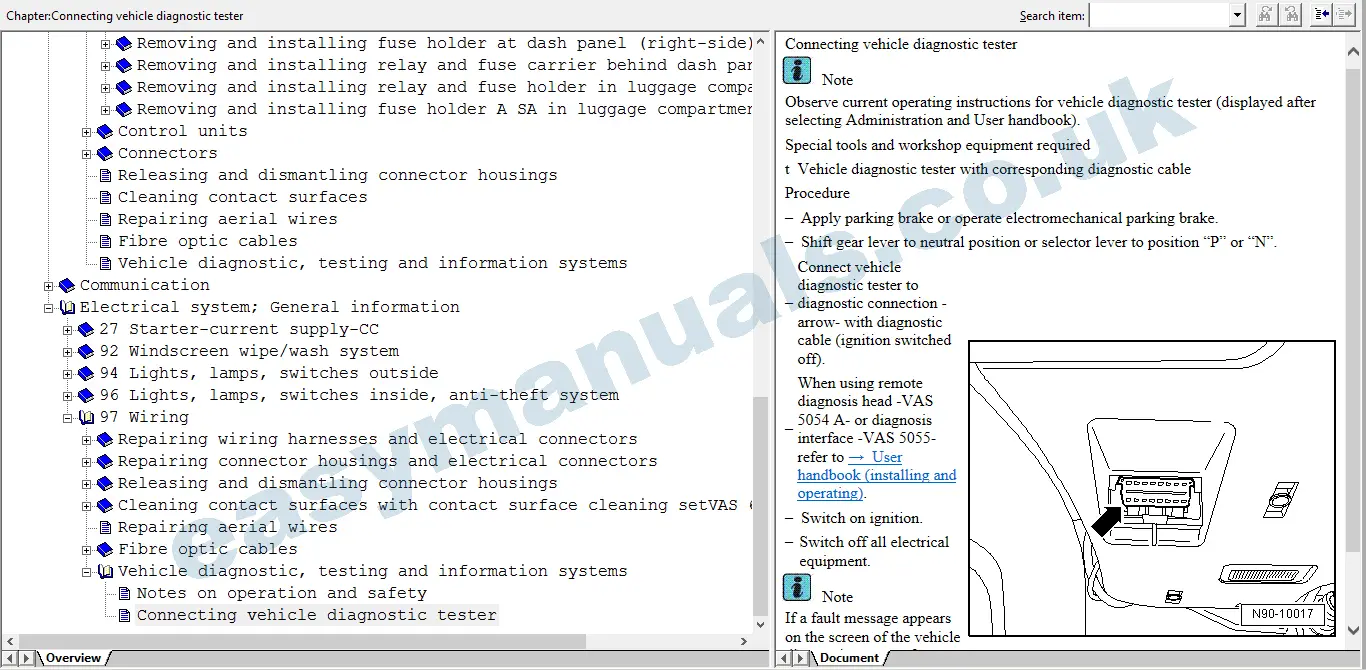

Electrical System Diagnostics

Understanding the intricacies of a vehicle’s electrical framework is crucial for effective troubleshooting and maintenance. This section delves into the fundamental practices for assessing electrical components, ensuring optimal functionality and reliability. By employing systematic diagnostic techniques, technicians can swiftly identify issues and implement corrective measures.

Key Diagnostic Tools

Utilizing the right instruments is essential for accurate assessments. Multimeters, oscilloscopes, and specialized diagnostic scanners enable technicians to monitor voltage levels, continuity, and signal integrity across various circuits. Multimeters are particularly valuable for measuring electrical parameters, while oscilloscopes provide insights into waveform characteristics, helping to pinpoint irregularities.

Troubleshooting Procedures

Establishing a methodical approach to troubleshooting enhances efficiency. Start by reviewing wiring diagrams to understand circuit layouts. Next, perform visual inspections to detect any obvious signs of wear, corrosion, or damage. Documenting findings throughout the process aids in tracking progress and ensures that no steps are overlooked. Following this, apply the appropriate diagnostic tools to test individual components, confirming their functionality or identifying failures that require replacement.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel system is essential for optimal engine performance and longevity. Regular attention to various components ensures efficiency and reduces the likelihood of malfunctions.

Inspect Fuel Filters: Regularly check and replace fuel filters to prevent contaminants from entering the system. A clogged filter can restrict fuel flow and affect performance.

Monitor Fuel Quality: Use high-quality fuel to avoid issues such as sediment build-up or injector fouling. Contaminated fuel can lead to significant operational problems.

Check Fuel Lines: Examine all fuel lines for signs of wear, leaks, or damage. Promptly replace any compromised sections to maintain system integrity and prevent fuel loss.

Clean Injectors: Periodically clean fuel injectors to ensure proper atomization and distribution of fuel. This practice enhances combustion efficiency and overall engine response.

Inspect the Fuel Pump: Regularly evaluate the fuel pump for proper operation and pressure. A failing pump can lead to inadequate fuel delivery, impacting engine performance.

Maintain Fuel Tank: Keep the fuel tank clean and free of debris. Sediment accumulation can obstruct fuel flow and lead to other complications within the system.

Adhering to these maintenance practices can significantly enhance the reliability and efficiency of the fuel system, ultimately prolonging the life of the engine.

Upgrading Performance Parts

Enhancing the capabilities of your vehicle can significantly improve its efficiency, power output, and overall driving experience. By selecting the right components, you can ensure your engine operates at peak performance while also prolonging its lifespan. This section will explore various aftermarket options available for enhancing engine performance and efficiency.

When considering upgrades, it’s essential to assess the current setup and determine which parts will provide the most benefit. Below is a table summarizing some popular performance enhancements along with their benefits:

| Component | Description | Benefits |

|---|---|---|

| Cold Air Intake | Improves airflow to the engine. | Increased horsepower and throttle response. |

| Performance Exhaust System | Enhances exhaust flow and reduces backpressure. | Boosts power and provides a more aggressive sound. |

| High-Performance Turbocharger | Increases air compression into the engine. | Significantly improves power output and torque. |

| ECU Tuning | Adjusts engine parameters for optimal performance. | Enhances fuel efficiency and horsepower. |

| Intercooler Upgrade | Cools the air entering the engine. | Improves engine efficiency and prevents overheating. |

Investing in these components can lead to a remarkable transformation in vehicle performance, allowing you to achieve a more enjoyable and powerful driving experience. Prioritizing quality and compatibility will ensure the upgrades deliver the desired results while maintaining reliability.

Safety Precautions During Repairs

When undertaking maintenance tasks on any vehicle, adhering to proper safety measures is essential to ensure the well-being of both the technician and the equipment. These guidelines are designed to minimize risks and create a safe working environment.

Firstly, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and a dust mask. This gear helps protect against hazardous substances and potential injuries from sharp objects or hot surfaces.

Secondly, ensure that the workspace is well-ventilated. Proper airflow is crucial, especially when dealing with chemicals or fumes that may be released during maintenance procedures. If necessary, use fans or open windows to improve air circulation.

Additionally, familiarize yourself with the specific tools and equipment before use. Understanding how to operate machinery correctly reduces the likelihood of accidents. Always inspect tools for damage and ensure they are in good working condition.

Finally, maintain a clean and organized workspace. Clutter can lead to accidents, so keep tools and materials in designated areas. This practice not only enhances safety but also improves efficiency during the task.