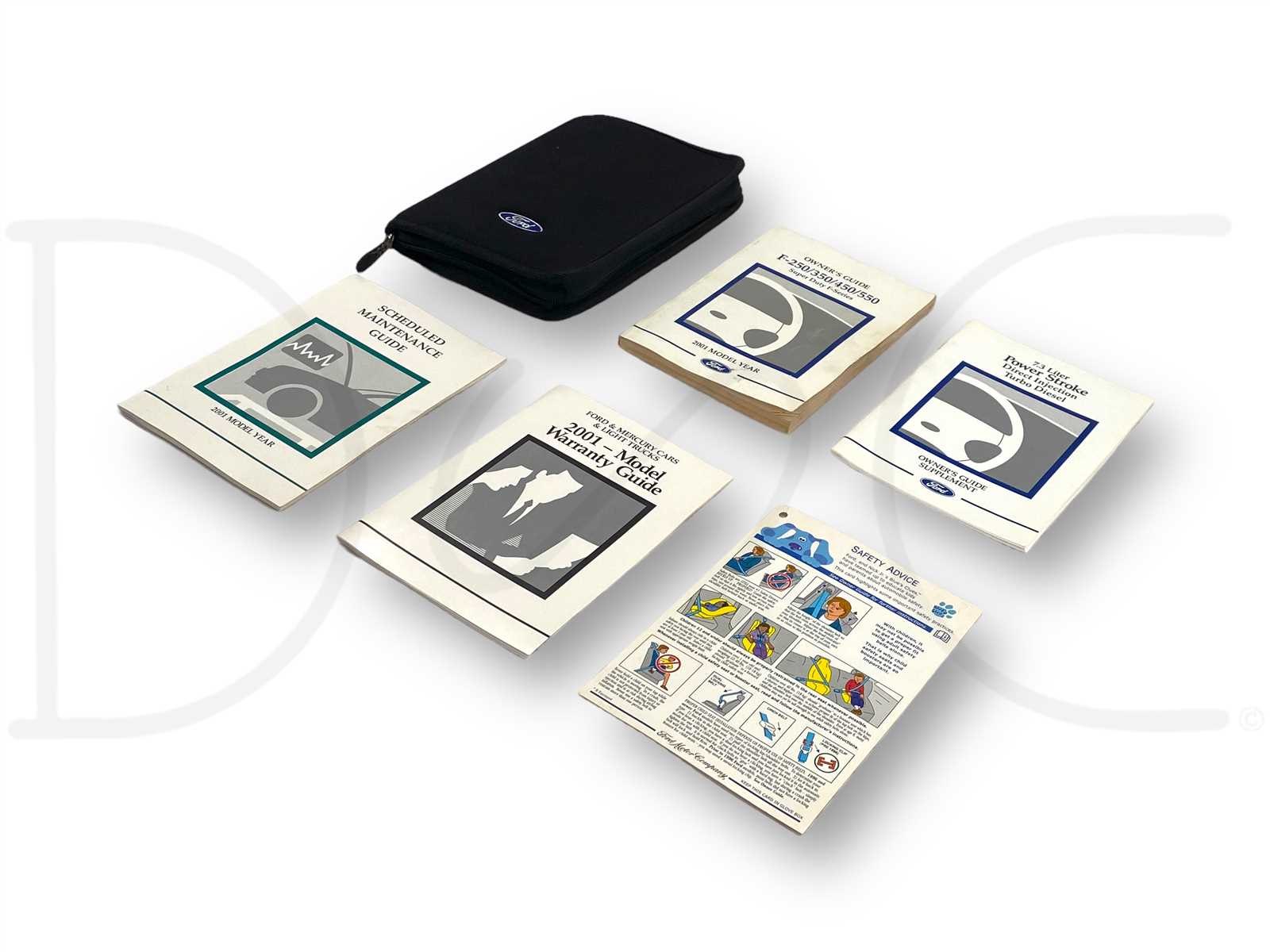

Comprehensive Guide for 2001 7.3 Powerstroke Repairs

This section provides essential insights into the upkeep of robust automotive engines. By understanding the intricacies of these power sources, enthusiasts and technicians alike can ensure optimal performance and longevity.

Focusing on various aspects of engine care, this guide delves into troubleshooting techniques, common issues, and necessary adjustments. Emphasizing proactive measures, readers will learn how to address potential challenges before they escalate.

Through a comprehensive exploration of components and systems, the aim is to equip users with the knowledge needed for effective maintenance practices. With detailed explanations and practical tips, this resource serves as a valuable tool for anyone looking to enhance their mechanical expertise.

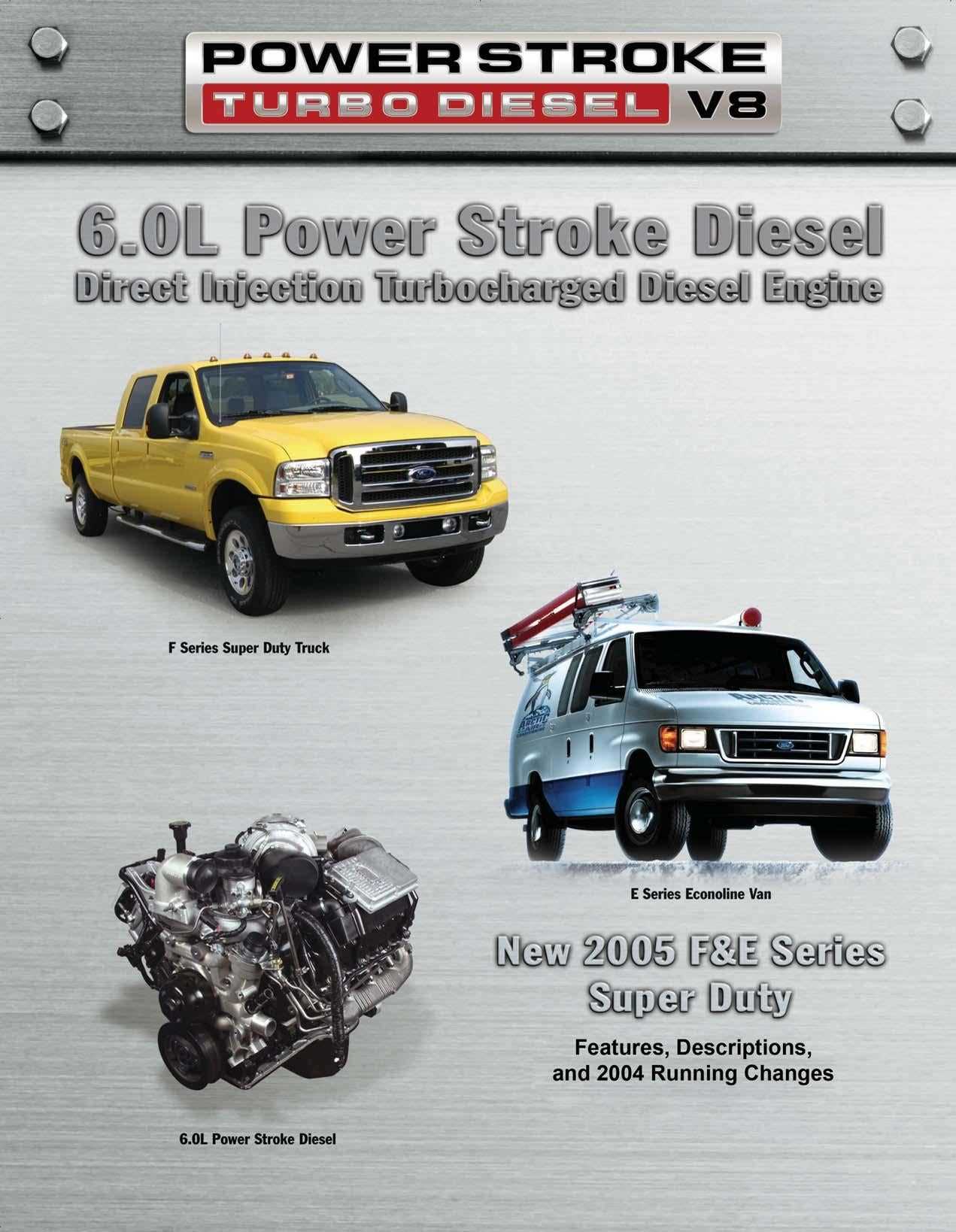

2001 7.3 Powerstroke Overview

This section provides an insight into a specific diesel engine model known for its reliability and performance. Designed to meet the demands of heavy-duty applications, this engine stands out in various settings due to its robust construction and advanced engineering.

Key Features

- High torque output for improved towing capacity

- Durable components designed for longevity

- Fuel efficiency that enhances operational cost savings

- Advanced cooling system for optimal performance

Applications

- Heavy-duty trucks

- Commercial vehicles

- Agricultural machinery

- Marine applications

Common Issues and Solutions

Many vehicle owners encounter various challenges during maintenance and operation. Understanding these common problems and their respective remedies can greatly enhance the ownership experience.

Engine Performance Problems: A frequent issue involves decreased power and responsiveness. This can often be traced back to fuel supply problems or air intake restrictions. Regularly checking filters and ensuring proper airflow can mitigate these concerns.

Starting Difficulties: Owners may experience trouble starting their vehicle, particularly in colder climates. Ensuring the battery is in good condition and that glow plugs are functioning properly can resolve these issues effectively.

Overheating: Another common concern is overheating, which can be caused by coolant leaks or malfunctioning thermostats. Regular inspection of the cooling system and timely replacement of worn components can prevent severe engine damage.

Transmission Issues: Shifting problems can arise, often linked to low fluid levels or dirty transmission fluid. Regular maintenance, including fluid changes, can help maintain smooth operation.

Electrical System Malfunctions: Electrical issues, such as flickering lights or failure to start, may stem from corroded connections or a failing alternator. Routine checks of electrical connections and components can enhance reliability.

Essential Tools for Repairs

When tackling maintenance tasks on your vehicle, having the right equipment is crucial for achieving optimal results. The appropriate instruments not only enhance efficiency but also ensure that the job is done correctly and safely. Below are key categories of tools that every enthusiast should consider for effective upkeep.

Hand Tools are fundamental in any workshop. Wrenches, screwdrivers, and pliers are essential for loosening and tightening various components. It’s advisable to invest in a comprehensive set that includes both metric and standard sizes to accommodate different fittings.

Power Tools can significantly expedite the process of disassembly and assembly. An electric drill, impact wrench, and air compressor are valuable additions that can make tough jobs easier and more efficient. Ensure you select tools with appropriate torque settings to prevent damage.

Diagnostic Equipment is increasingly important in modern maintenance. A quality scanner can help identify issues quickly by reading error codes and providing insights into the vehicle’s systems. This tool is essential for troubleshooting and ensuring that repairs address the root causes of problems.

Safety Gear should never be overlooked. Wearing gloves, goggles, and hearing protection ensures personal safety while working. Having a first aid kit on hand is also advisable in case of any unforeseen accidents.

By equipping yourself with these essential tools, you can enhance your repair experience and achieve satisfactory results, ensuring that your vehicle remains in optimal condition.

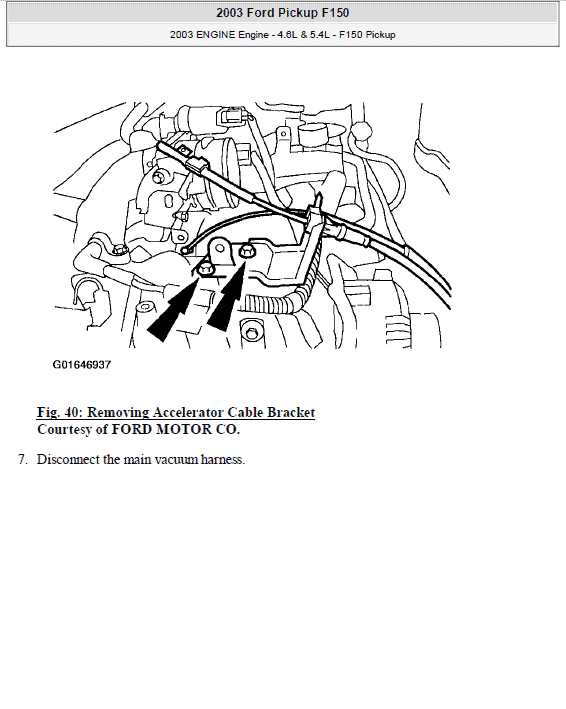

Engine Maintenance Procedures

Proper care and upkeep of an internal combustion unit are essential for optimal performance and longevity. Regular maintenance helps in identifying potential issues before they escalate, ensuring that the system operates smoothly and efficiently.

Routine Maintenance Tasks

- Check and replace the oil at recommended intervals to ensure proper lubrication.

- Inspect the air filter regularly and replace it when necessary to maintain airflow.

- Monitor coolant levels and check for leaks to prevent overheating.

- Examine belts and hoses for wear and replace them as needed.

Inspection Procedures

- Conduct a visual inspection of the engine compartment for any signs of leaks or damage.

- Use diagnostic tools to monitor engine performance and detect any error codes.

- Perform compression tests to assess the condition of the cylinders.

Fuel System Troubleshooting Tips

When dealing with fuel delivery issues in diesel engines, understanding the common symptoms and their potential causes is crucial for effective diagnosis. This section offers valuable insights into troubleshooting various aspects of the fuel system to ensure optimal performance.

Start by checking the fuel supply. Insufficient fuel flow can lead to a range of problems, including stalling and poor acceleration. Inspect the fuel tank for contamination, and ensure that the fuel lines are free from blockages. Additionally, verify that the fuel filter is clean and functioning properly.

| Symptoms | Potential Causes | Recommended Actions |

|---|---|---|

| Engine won’t start | No fuel delivery, clogged filter | Check fuel lines and replace the filter |

| Rough idling | Air in the fuel system, dirty injectors | Bleed air and clean injectors |

| Poor acceleration | Weak fuel pump, contaminated fuel | Test pump pressure and inspect fuel quality |

Regular maintenance of the fuel system components can prevent many issues from arising. Keep an eye on fuel quality and change filters as recommended to maintain performance and reliability.

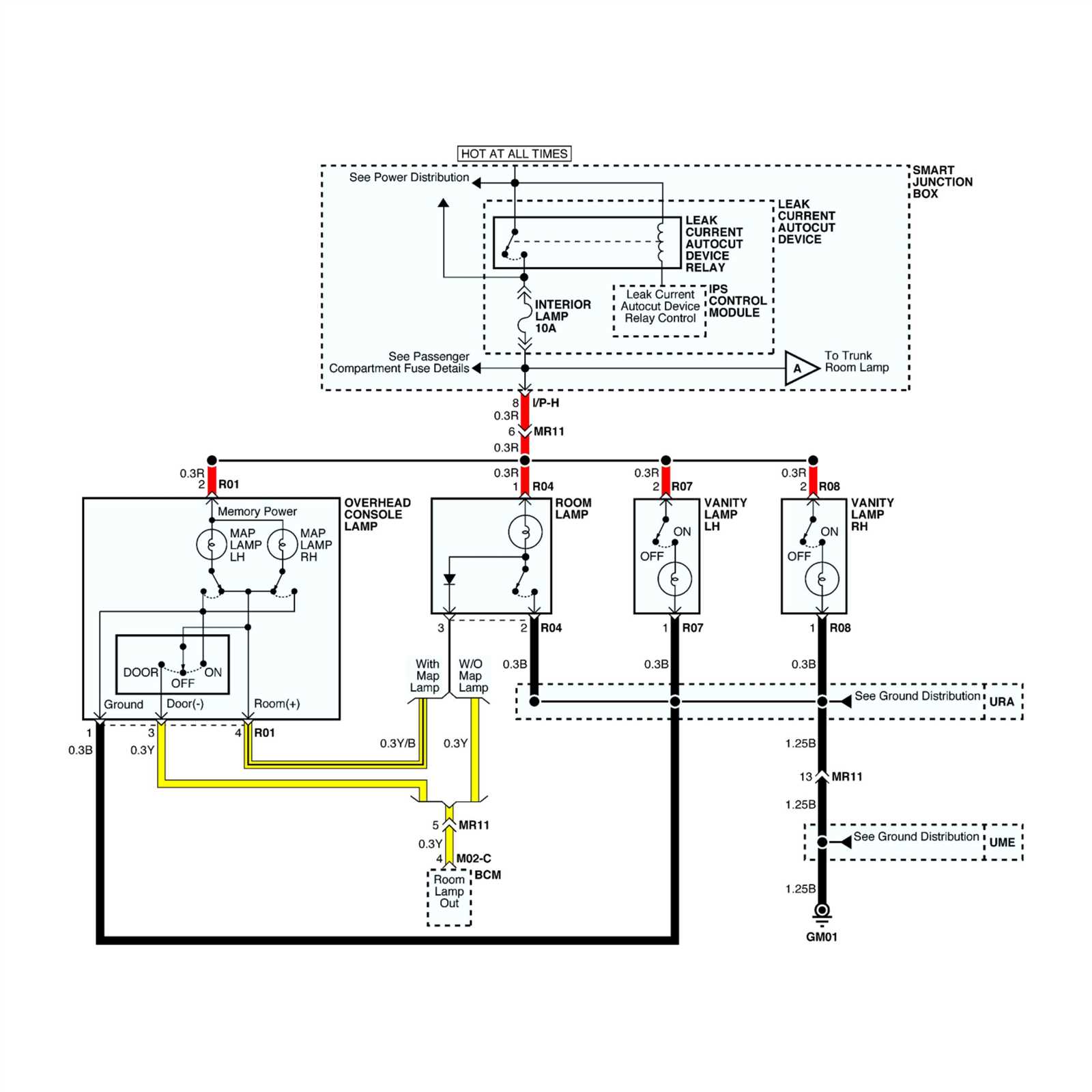

Electrical Components and Diagnosis

This section focuses on the essential electrical parts of the system and the methods to troubleshoot common issues. Understanding these elements is crucial for effective maintenance and repair.

Key electrical components include:

- Batteries

- Alternator

- Starter motor

- Wiring harnesses

- Relays and fuses

To diagnose electrical problems, follow these steps:

- Inspect the battery condition and connections.

- Check for voltage output from the alternator.

- Test the starter motor functionality.

- Examine wiring for any signs of damage or wear.

- Use a multimeter to measure voltage and continuity in circuits.

By following these guidelines, you can effectively identify and address electrical issues, ensuring optimal performance of the system.

Transmission Repair Techniques

This section explores effective methods for addressing issues related to the gear-shifting mechanism in vehicles. Mastery of these techniques is essential for maintaining optimal performance and longevity of the drivetrain components.

Common Issues and Solutions

Identifying frequent problems, such as slipping gears or harsh shifting, is the first step in the process. Utilizing diagnostic tools can aid in pinpointing the root cause, enabling a more focused approach to restoration.

Rebuilding and Adjustments

Reconstructing the transmission involves replacing worn-out components and fine-tuning adjustments to ensure seamless operation. Proper alignment and lubrication play crucial roles in achieving a fully functional system.

Cooling System Maintenance Steps

Maintaining the cooling system is essential for ensuring optimal engine performance and longevity. Regular checks and servicing can prevent overheating and other related issues, which can lead to costly repairs. Here are key steps to keep your cooling system in excellent condition.

Regular Inspections

- Check coolant levels regularly and top up as needed.

- Inspect hoses for signs of wear, leaks, or cracks.

- Examine the radiator for any debris or blockages.

Flushing the Cooling System

- Drain the old coolant from the system.

- Flush the system with clean water to remove any deposits.

- Refill with the appropriate coolant mixture, ensuring proper ratios.

Oil Change Best Practices

Regularly replacing the lubricant in your vehicle is crucial for maintaining optimal performance and longevity. Following effective techniques during this process ensures that the engine remains well-lubricated, reducing wear and preventing potential issues.

Essential Steps for an Effective Oil Change

To achieve the best results, adhere to the following steps:

- Gather necessary tools and materials.

- Warm up the engine slightly to thin the oil.

- Drain old lubricant completely before refilling.

- Replace the filter to maintain cleanliness.

- Use the recommended type and grade of lubricant.

Recommended Maintenance Schedule

Following a regular schedule for changing the lubricant can greatly enhance vehicle reliability. Below is a table outlining a suggested interval based on driving conditions:

| Driving Condition | Recommended Interval |

|---|---|

| Normal Conditions | Every 5,000 to 7,500 miles |

| Towing or Heavy Load | Every 3,000 to 5,000 miles |

| Extreme Temperatures | Every 4,000 to 6,000 miles |

Exhaust System Inspection Guidelines

Regular examination of the exhaust framework is crucial for maintaining vehicle performance and emissions compliance. A thorough assessment can help identify issues that may lead to reduced efficiency or environmental impact.

Visual Inspection

Begin with a detailed visual assessment of the exhaust components. Look for signs of wear, rust, or any physical damage. Ensure that all connections are secure and free from leaks. Pay special attention to areas around joints and welds, as these are common points for failure.

Functional Checks

After the visual inspection, conduct functional tests to assess the system’s performance. Start the engine and listen for unusual noises, which may indicate leaks or blockages. Additionally, check for excessive smoke, which can signify underlying problems within the exhaust setup.

Proper maintenance and timely inspections can extend the life of the exhaust system and enhance overall vehicle efficiency. Regular attention to these guidelines ensures optimal operation and compliance with emissions standards.

Body and Frame Repairs

Maintaining the integrity of the outer structure and supporting framework is crucial for vehicle longevity and safety. Proper attention to these components ensures optimal performance and prevents future complications.

When addressing issues related to the outer shell, it is essential to inspect for any signs of damage, such as dents, rust, or misalignment. Prompt action can prevent further deterioration and enhance aesthetic appeal. Techniques like panel replacement or straightening may be necessary for effective restoration.

In the case of the frame, ensuring structural soundness is paramount. Regular assessments can help identify weaknesses that could compromise overall stability. Techniques such as welding or reinforcement are commonly employed to rectify any issues, maintaining the vehicle’s safety and functionality.

Ultimately, thorough understanding and careful execution of these procedures will contribute to a reliable and enduring vehicle. Consistent maintenance practices are key to ensuring that both the body and frame remain in excellent condition over time.

Preventive Measures for Longevity

Ensuring the durability of a vehicle involves a combination of regular maintenance and mindful practices. Adopting a proactive approach can significantly enhance performance and extend the lifespan of the engine. Simple measures can prevent extensive damage and costly repairs.

| Measure | Description |

|---|---|

| Regular Oil Changes | Consistent oil changes are crucial for engine health, preventing sludge buildup and ensuring proper lubrication. |

| Fluid Checks | Monitoring all fluid levels, including coolant and transmission fluid, helps maintain optimal performance and avoid overheating. |

| Air Filter Maintenance | Replacing the air filter regularly ensures clean airflow, improving fuel efficiency and engine performance. |

| Inspection of Belts and Hoses | Regularly checking belts and hoses for wear can prevent breakdowns and costly repairs caused by failures. |

| Tire Care | Maintaining proper tire pressure and alignment contributes to better handling and fuel efficiency. |