Comprehensive Repair Guide for the 2002 GMC Sierra 1500

Owning a vehicle requires a solid understanding of its mechanics and regular upkeep to ensure optimal performance. This section aims to provide valuable insights and guidance on maintaining and troubleshooting various aspects of a specific truck model, helping owners maximize its longevity and efficiency.

By exploring detailed procedures and instructions, users will gain the knowledge necessary to address common issues and perform essential tasks. This resource serves as an indispensable tool for those seeking to enhance their skills and confidence in vehicle maintenance, empowering them to tackle challenges with ease.

Whether you are a seasoned enthusiast or a novice, the information presented here will aid in navigating the complexities of automotive care. Equip yourself with the expertise to keep your truck running smoothly and efficiently.

Overview of 2002 GMC Sierra 1500

This section provides a comprehensive look at a popular model known for its durability and versatility in the pickup truck segment. Recognized for its robust performance and comfort, this vehicle appeals to both work and leisure enthusiasts.

Key Features

- Powerful engine options for varied performance needs

- Spacious cabin designed for comfort and utility

- Advanced towing capabilities for hauling tasks

- Multiple trim levels offering a range of amenities

- Enhanced safety features to protect occupants

Specifications

- Engine Types: Choices include V6 and V8 configurations

- Transmission: Options range from manual to automatic

- Fuel Economy: Competitive ratings for its class

- Payload Capacity: Designed to handle heavy loads

- Interior Features: Includes modern entertainment and convenience options

Key Features and Specifications

This section highlights essential attributes and technical details of the vehicle, providing insights into its performance, design, and functionality. Understanding these characteristics is crucial for both current owners and potential buyers who seek to maximize their experience.

Equipped with a robust engine lineup, the truck offers a range of power options to suit various driving needs. The vehicle’s suspension system enhances stability and handling, ensuring a smooth ride on diverse terrains. Interior features prioritize comfort and convenience, with options for advanced infotainment systems and ergonomic seating.

Safety is a top priority, with multiple airbags and reinforced structures designed to protect occupants in the event of a collision. Additionally, the vehicle is engineered for durability, making it a reliable choice for both everyday use and heavy-duty tasks.

Overall, the combination of performance, comfort, and safety features makes this model a versatile choice for a wide array of driving situations.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle. Adhering to a structured timetable not only enhances reliability but also optimizes overall performance. This section outlines key maintenance practices to keep your automobile running smoothly.

Oil Changes: Frequent oil changes are crucial. It is recommended to change the oil every 3,000 to 5,000 miles or according to the manufacturer’s specifications. This helps maintain engine health and efficiency.

Tire Rotation: Rotating tires every 6,000 to 8,000 miles promotes even wear, extending their lifespan and improving handling. Check tire pressure monthly to ensure optimal performance.

Brake Inspection: Regular brake inspections should be performed to ensure safety. Checking brake pads, rotors, and fluid levels every 10,000 miles can prevent costly repairs.

Fluid Levels: Monitor and top off essential fluids such as coolant, transmission fluid, and brake fluid regularly. Keeping these levels in check is vital for vehicle functionality.

Battery Maintenance: Inspect the battery and connections for corrosion and ensure proper charge. It’s advisable to test the battery every six months to avoid unexpected failures.

Filter Replacements: Change air and fuel filters as recommended, typically every 15,000 to 30,000 miles. This ensures optimal engine performance and fuel efficiency.

By following this comprehensive schedule, vehicle owners can achieve reliable performance and prolong the lifespan of their automobile.

Common Issues and Solutions

This section highlights frequently encountered challenges faced by owners of a particular model and offers effective solutions to address them. Understanding these common problems can help in maintaining optimal performance and prolonging the lifespan of the vehicle.

-

Electrical System Failures:

Issues with the electrical components can lead to malfunctions. Symptoms may include dimming lights or malfunctioning gauges.

- Check the battery connections for corrosion.

- Inspect fuses and replace any that are blown.

- Test the alternator to ensure proper charging.

-

Engine Performance Problems:

Reduced power or strange noises may indicate engine issues. This could stem from various sources.

- Change the air filter to ensure optimal airflow.

- Examine the spark plugs and replace them if worn.

- Use a fuel system cleaner to remove deposits.

-

Transmission Difficulties:

Shifting problems or slipping gears can be frustrating. Regular maintenance can help mitigate these issues.

- Check the transmission fluid level and condition.

- Look for leaks in the transmission system.

- Have the transmission serviced if problems persist.

-

Suspension and Steering Concerns:

Unusual noises or difficulty steering can signal suspension issues. Addressing these promptly can prevent further damage.

- Inspect shock absorbers for leaks or wear.

- Check the alignment to ensure proper handling.

- Replace worn-out bushings or bearings.

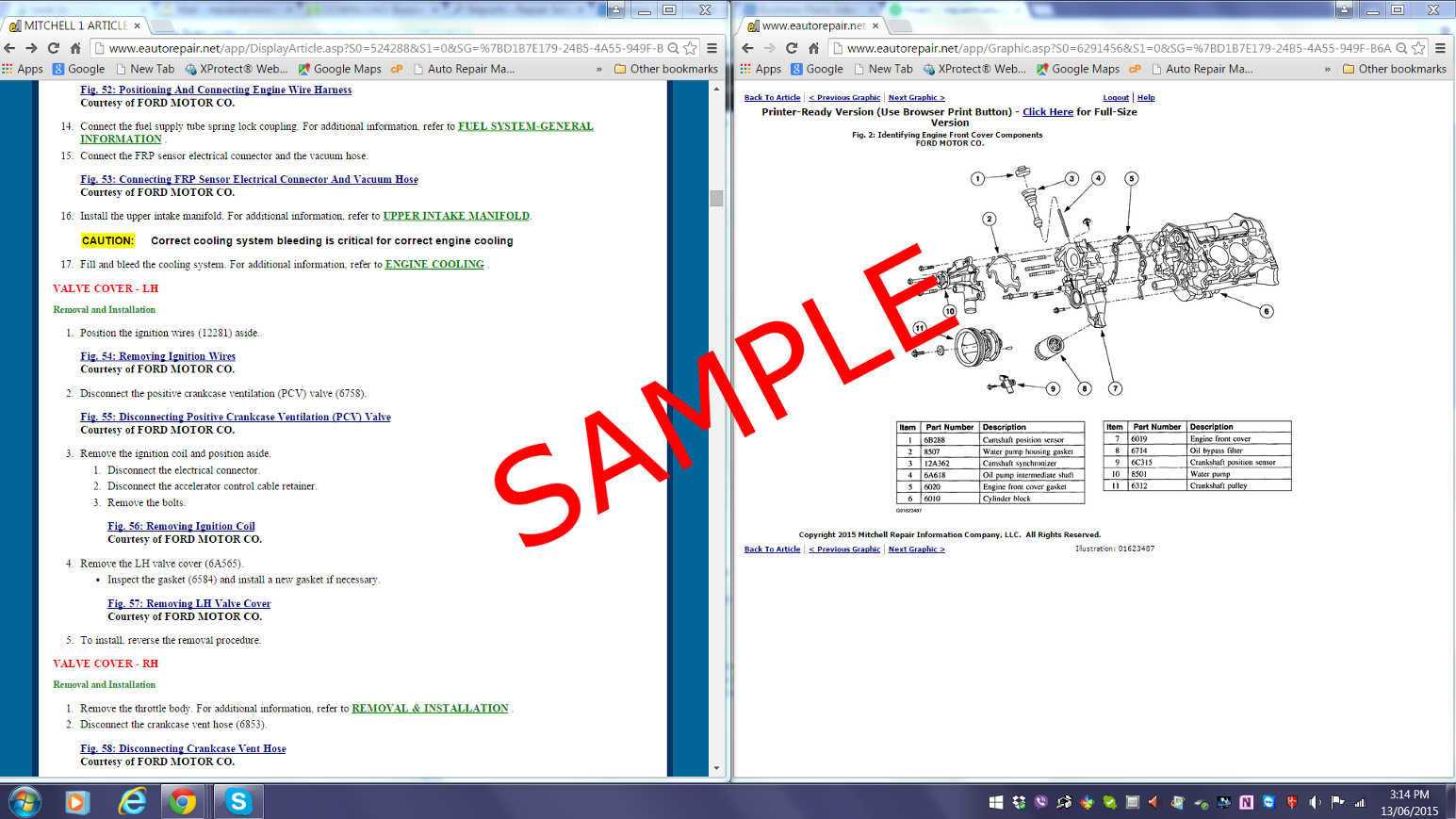

Step-by-Step Repair Procedures

This section provides detailed guidance on the processes required to address various issues encountered in a vehicle. Following a structured approach ensures that tasks are completed effectively and efficiently, reducing the likelihood of errors.

- Preparation:

- Gather necessary tools and materials.

- Review any applicable service bulletins or guidelines.

- Ensure the vehicle is on a flat surface and properly secured.

- Assessment:

- Identify the symptoms and the areas requiring attention.

- Perform a visual inspection to locate any obvious issues.

- Document findings for reference during the procedure.

- Dismantling:

- Carefully remove any components that obstruct access to the area of concern.

- Label all parts and fasteners for reassembly.

- Take note of any special instructions for removing parts.

- Repair:

- Address the identified issue following specific instructions.

- Replace any damaged or worn components as necessary.

- Utilize appropriate lubricants or sealants when reassembling.

- Reassembly:

- Reinstall all removed components in the reverse order of disassembly.

- Ensure all fasteners are torqued to the specified settings.

- Double-check the alignment and fit of all parts.

- Testing:

- Start the vehicle and monitor for any unusual sounds or behaviors.

- Perform a test drive to verify that the issue has been resolved.

- Recheck fluid levels and inspect for leaks.

Following these systematic procedures can help ensure a thorough and effective approach to vehicle maintenance and troubleshooting.

Engine Diagnostics and Troubleshooting

Effective engine diagnostics is crucial for maintaining vehicle performance and longevity. Understanding the various components and systems allows for early identification of potential issues, facilitating timely interventions.

Common symptoms that may indicate engine problems include:

- Decreased power or acceleration

- Unusual noises or vibrations

- Increased fuel consumption

- Illuminated warning lights on the dashboard

To accurately diagnose engine issues, follow these steps:

- Visual Inspection: Examine the engine bay for obvious signs of wear or damage.

- Check Fluid Levels: Ensure that oil, coolant, and other vital fluids are at appropriate levels.

- Scan for Codes: Utilize an OBD-II scanner to retrieve diagnostic trouble codes (DTCs) for further analysis.

- Conduct Performance Tests: Measure engine performance under various conditions to identify anomalies.

Regular maintenance and attentive observation can prevent minor issues from escalating into major repairs, ensuring a smooth and efficient operation.

Electrical System and Wiring Diagrams

The electrical framework in a vehicle plays a crucial role in ensuring optimal performance and functionality. Understanding the intricate network of wiring and components is essential for troubleshooting and maintenance. This section delves into the essential elements of the electrical system, highlighting the significance of accurate wiring diagrams for effective diagnostics and repairs.

Key components of the electrical system include:

- Battery

- Alternator

- Starter motor

- Fuses and relays

- Wiring harnesses

Wiring diagrams serve as invaluable tools for technicians and enthusiasts alike. They provide a visual representation of the electrical connections and pathways, facilitating a deeper understanding of the system’s layout. When working on electrical issues, referring to these diagrams can help in:

- Identifying faulty components

- Tracing electrical circuits

- Ensuring correct connections

- Preventing potential short circuits

Moreover, a thorough knowledge of the electrical system enhances the ability to make informed decisions during repairs. Familiarity with specific connections, such as those related to the ignition system and lighting, is vital for maintaining the overall integrity of the vehicle’s operation.

Transmission Repair and Service Guide

This section provides essential information for the maintenance and servicing of the vehicle’s transmission system. Understanding the components and their functions is crucial for ensuring optimal performance and longevity.

Regular inspections and timely interventions can prevent major issues and enhance driving experience. The following guidelines will assist in maintaining the transmission effectively.

| Task | Description | Frequency |

|---|---|---|

| Fluid Check | Inspect the transmission fluid level and condition; top off or replace if necessary. | Monthly |

| Filter Replacement | Change the transmission filter to ensure clean fluid flow and proper functioning. | Every 30,000 miles |

| Fluid Change | Replace old transmission fluid to maintain optimal performance and prevent overheating. | Every 50,000 miles |

| Seal Inspection | Examine seals for leaks; replace any damaged seals to prevent fluid loss. | Annually |

By following these guidelines, you can ensure that the transmission remains in excellent working condition, thereby enhancing the overall reliability of your vehicle.

Suspension and Steering Maintenance Tips

Proper care of your vehicle’s suspension and steering systems is essential for ensuring a smooth and safe driving experience. Regular maintenance helps prevent issues that can lead to costly repairs and compromised safety. Here are some essential tips to keep these critical components in optimal condition.

Inspect Components Regularly: Regularly check key parts such as shock absorbers, struts, and control arms for wear and damage. Look for signs of leakage or rust, which may indicate the need for replacement.

Check Alignment and Tire Pressure: Maintaining proper wheel alignment not only improves handling but also prolongs tire life. Ensure that tire pressure is within the recommended range to enhance stability and performance.

Lubricate Moving Parts: Apply appropriate lubricants to joints and bushings to reduce friction and prevent premature wear. Keeping these parts well-lubricated ensures smoother operation and enhances longevity.

Monitor Steering Fluid Levels: Regularly check the steering fluid reservoir and top it off as needed. Low fluid levels can lead to steering difficulties and may indicate leaks that require attention.

Perform Professional Inspections: Schedule periodic inspections with a qualified technician. Professional assessments can identify hidden issues and provide peace of mind, ensuring your vehicle remains safe and responsive on the road.

Brake System Inspection and Repair

Ensuring the effectiveness of the braking mechanism is crucial for vehicle safety and performance. This section provides essential guidance for evaluating and addressing potential issues within the braking system, focusing on key components that contribute to its overall functionality.

Begin the assessment by examining the brake pads for wear and tear. Worn pads can significantly reduce stopping power and may lead to further damage if not addressed promptly. Check for uneven wear, which can indicate issues with alignment or the caliper.

Next, inspect the brake rotors for any signs of damage, such as scoring or warping. Smooth, undamaged rotors are essential for effective braking performance. If the surface is compromised, consider machining or replacing the rotors to restore functionality.

Additionally, evaluate the brake fluid for contamination and ensure that it meets the manufacturer’s specifications. Low or dirty fluid can impair braking efficiency. Replace the fluid if it appears discolored or if the level is below the recommended mark.

Finally, examine the entire braking system for leaks and loose connections. Addressing any leaks immediately can prevent further damage and maintain optimal braking performance. Regular maintenance and timely interventions are key to ensuring a safe driving experience.

Bodywork and Paint Touch-Up Techniques

Maintaining the exterior of a vehicle is crucial for both aesthetic appeal and long-term durability. Proper techniques for addressing minor damages, such as scratches and dents, can significantly enhance the overall appearance. This section explores effective methods for touch-ups and repairs that can be performed at home or in a workshop setting.

Assessing Damage

Before initiating any restoration process, it’s essential to thoroughly evaluate the extent of the damage. Identifying whether a scratch is superficial or a deeper gouge will determine the required approach. For minor imperfections, a simple touch-up may suffice, while significant dents may need more intensive repair work.

Touch-Up Process

Once the damage is assessed, gather the necessary materials, including color-matched paint, applicators, and sanding tools. Begin by cleaning the area to remove dirt and debris. Apply the paint in thin layers, allowing each coat to dry completely. For optimal results, consider finishing with a clear coat to protect the new paint and achieve a seamless blend with the surrounding surface. Regular maintenance of the vehicle’s exterior will prolong its life and keep it looking sharp.

Interior Repairs and Upgrades

This section focuses on enhancing the cabin space, addressing common issues, and implementing modifications that improve both functionality and aesthetics. From fixing minor wear and tear to adding modern features, there are numerous ways to elevate the interior experience.

Common Interior Issues

- Worn upholstery and carpets

- Deteriorating dashboard components

- Faulty electrical systems

- Damaged trim and panels

Upgrade Options

- Replace or reupholster seats for a fresh look.

- Install sound-deadening material for a quieter ride.

- Upgrade the audio system for enhanced sound quality.

- Add modern connectivity options, such as USB ports.

By addressing existing issues and considering upgrades, the cabin can be transformed into a more comfortable and enjoyable space for all passengers.

Tools and Equipment for Repairs

Having the right instruments and gear is crucial for effectively addressing any maintenance tasks on your vehicle. The proper tools not only facilitate smoother processes but also enhance safety and accuracy while working on various components. This section outlines essential items that every technician should have at their disposal to ensure successful outcomes.

Essential Hand Tools

Basic hand tools are fundamental for most tasks. Items such as wrenches, sockets, and screwdrivers are necessary for disassembling and reassembling parts. Adjustable wrenches provide versatility, allowing you to tackle fasteners of different sizes, while torque wrenches ensure that components are tightened to the manufacturer’s specifications, preventing potential damage.

Diagnostic Equipment

In addition to hand tools, diagnostic devices play a vital role in identifying issues. OBD-II scanners are indispensable for reading error codes and monitoring vehicle systems, enabling quick troubleshooting. Furthermore, multimeters assist in testing electrical systems, helping to pinpoint faults in wiring and components efficiently.