Comprehensive Guide to Repairing the 2003 4Runner

Maintaining your vehicle is essential to ensuring its longevity and performance. Understanding how to address issues early and perform routine check-ups can save time, money, and avoid potential inconveniences. This guide provides an extensive overview of methods for diagnosing and resolving common concerns that can arise over time, empowering owners to handle various tasks with confidence and efficiency.

In this resource, you’ll discover step-by-step instructions, essential insights, and valuable tips tailored to various aspects of vehicle upkeep. From understanding core systems to tackling specific challenges, each section is designed to build your knowledge and skill set. Regular upkeep, knowing what to look for, and understanding specific systems in detail can transform the experience of vehicle ownership, keeping your machine in optimal condition and maximizing its lifespan.

Whether you’re addressing basic care or tackling more complex issues, this guide aims to be an invaluable companion. By gaining insight into every aspect of vehicle function, you’ll be better equipped to handle unexpected situations, ensuring that each journey is as smooth and secure as possible. Explore these pages to equip yourself with a wealth of practical knowledge, elevating your confidence and ability to handle a wide range of upkeep scenarios.

Essential Guide for 2003 4Runner Maintenance

Regular upkeep is the cornerstone of ensuring both the longevity and reliability of your vehicle. Consistent attention to the key systems under the hood and throughout the vehicle can prevent costly repairs and extend its performance. Understanding the essential aspects of maintenance will help owners achieve a smoother driving experience, optimal efficiency, and peace of mind on the road.

Fluid Checks and Changes are vital for engine health. Monitor engine oil, coolant, brake, and transmission fluids at recommended intervals, ensuring levels are within specified ranges. Fresh, clean fluids reduce wear and prevent damage to key engine components.

Tire Care goes beyond routine pressure checks. Rotate tires periodically to promote even wear, which can improve traction and handling. Checking for signs of misalignment, like uneven wear, can prevent further damage and maintain safe driving dynamics.

Braking System upkeep is essential for safety. Inspect brake pads and rotors for wear, as worn components can significantly reduce braking efficiency. Replacing parts at the first signs of wear helps ensure consistent stopping power, even in emergency situations.

Battery Health plays a major role in vehicle reliability. Clean the terminals and check for corrosion periodically. A healthy battery, along with secure connections, ensures dependable starts and supports the operation of essential electronics.

Filter Replacements are easy yet impactful. Engine and cabin air filters, along with fuel filters, should be replaced as needed to improve performance, reduce emissions, and enhance interior air quality. A clean air intake promotes efficient combustion and contributes to fuel economy.

Following these basic upkeep principles can make a noticeable difference in the overall condition and lifespan of your vehicle. Prioritizing these maintenance steps

Inspecting Key Vehicle Components

Ensuring the functionality and safety of a vehicle involves a thorough check of essential components. Regular assessments can help detect early signs of wear or potential issues, promoting both optimal performance and long-term durability. Familiarity with each part’s purpose and condition allows for timely maintenance that keeps the vehicle reliable on the road.

Engine and Fluids: Inspect the engine for any visible signs of leaks or unusual wear. Ensure all fluid levels, including oil, coolant, brake, and transmission fluids, are within recommended levels. Checking these fluids helps prevent overheating and keeps internal parts lubricated and functioning smoothly.

Brakes and Suspension: Examine brake pads, rotors, and calipers for signs of wear or corrosion. Test suspension components by checking for unusual sounds or a loose feel when handling the vehicle. Worn brakes or suspension parts can impact safety, making early detection essential.

Battery and Electrical System: Check the battery terminals for corrosion and ensure the battery holds a proper charge. Inspect connections, lights, and other electrical features to confirm reliable operation. Proper function of the electrical system ensures all safety and convenience features perform correctly.

Tires and Wheels: Review tire tread depth, inflation levels, and inspect for any punctures or uneven wear. Properly balanced and inflated tires enhance vehicle handling and extend tire lifespan. Don’t overlook the wheel alignment, as it affects overall stability and tire longevity.

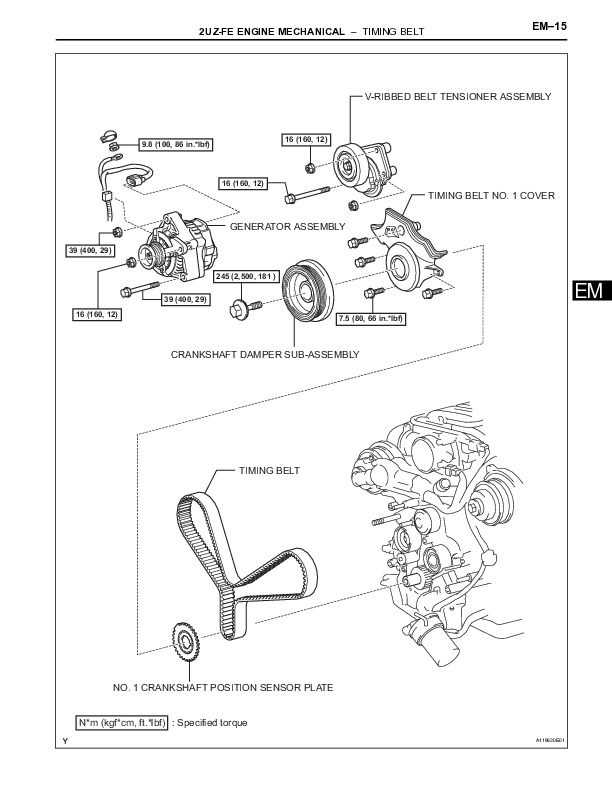

Belts and Hoses: Check all belts for signs of cracking,

Steps to Diagnose Engine Issues

Identifying engine problems can help detect underlying mechanical or electrical faults early, ensuring smoother operation and longevity. The following steps guide you through examining potential engine issues in a structured manner.

- Initial Visual Inspection

- Check for any visible leaks under the vehicle, such as oil or coolant spots.

- Inspect hoses and belts for wear, cracks, or other visible signs of deterioration.

- Look over the battery and connections to ensure there is no corrosion or looseness.

- Listen for Unusual Sounds

- Start the engine and listen for any knocking, rattling, or hissing sounds that could signal component issues.

- Identify the specific area the sound is coming from to narrow down possible causes, like belts, valves, or exhaust components.

- Check Warning Indicators

- Observe the dashboard for any illuminated warning lights such as the check engine light or temperature gauge.

- If any indicators are active, use a diagnostic tool to retrieve error codes that can help pinpoint issues.

- Test Engine Performance

- Monitor acceleration and note any unusual hesitations or lack of power.

- Observe if the engine stalls or misfires, which may indicate problems with the fuel system or ignition components.

- Analyze Exhaust Emissions

- Examine the

Transmission Troubleshooting and Solutions

Transmission issues can present a range of symptoms, from unusual noises and shifting difficulties to fluid leaks and overheating. Identifying these issues early helps ensure smoother driving and extends the vehicle’s lifespan. Here, we explore common signs of transmission problems and practical solutions for addressing them.

Symptom Possible Cause Solution Unusual noises (grinding or whining) Low transmission fluid or worn internal components Check fluid levels, top up or replace if necessary; inspect internal parts if noise persists Difficulty in shifting gears Faulty clutch, worn synchronizers, or low fluid Adjust or replace clutch; inspect synchronizers; ensure fluid is at the recommended level Slipping gears Damaged or worn clutch or bands; low transmission fluid Inspect and replace clutch or bands; refill or replace fluid Fluid leaks Worn seals or damaged transmission pan Brake System Check and Repair Tips

The brake system is crucial for vehicle safety, and keeping it in optimal condition ensures reliable performance. Regular inspection and proper maintenance of the system’s components can prevent potential issues, enhancing control and safety. Here’s a guide on essential steps to check and maintain the braking components effectively.

- Inspect Brake Pads and Rotors: Examine the thickness of the pads and look for any unusual wear on the rotors. Uneven or worn-out pads indicate the need for replacement, while damaged rotors may require resurfacing or replacement.

- Check Brake Fluid Levels: Monitor fluid levels regularly, ensuring they remain between the minimum and maximum marks. Low levels could indicate a leak, which needs to be addressed to maintain effective braking performance.

- Examine Brake Lines and Hoses: Visually inspect lines and hoses for any signs of cracks, leaks, or other damage. Well-maintained lines ensure efficient hydraulic pressure transfer, essential for brake function.

- Test Brake Pedal Responsiveness: Press down on the pedal to gauge its firmness and response. A soft or spongy pedal feel may indicate air in the brake lines, requiring a bleeding procedure to restore proper function.

- Assess Parking Brake Function: Engage and release the parking brake, observing its grip and release efficiency. Adjustments or repairs may be needed if it does not hold the vehicle securely or disengage smoothly.

- Start with a visual inspection of brake components.

- Check fluid levels, topping o

Understanding Suspension and Alignment Care

The proper maintenance of a vehicle’s suspension and alignment system is essential for ensuring a smooth and safe driving experience. These components work together to provide stability, comfort, and control, significantly impacting handling and tire wear. Regular attention to these systems can prevent long-term damage and enhance overall performance.

Suspension systems consist of various parts, including springs, shock absorbers, and control arms, all designed to absorb shocks from the road and maintain tire contact. Over time, wear and tear can lead to decreased effectiveness, resulting in a bumpy ride and reduced handling capabilities. Inspecting and replacing worn components is crucial to maintain optimal performance.

Alignment refers to the adjustment of the wheels relative to the vehicle’s body and to each other. Proper alignment ensures that tires wear evenly and that the vehicle handles predictably. Misalignment can result from hitting potholes or curbs and can lead to premature tire wear, steering issues, and reduced fuel efficiency. Regular checks and adjustments help maintain proper alignment, improving safety and extending the life of tires.

Both suspension and alignment care require periodic inspections, ideally at regular intervals or when changes in handling are noted. Paying attention to these systems can lead to a more enjoyable driving experience, enhancing safety and prolonging the life of key components.

Electrical System Overview and Fixes

The electrical system in vehicles plays a crucial role in ensuring proper functionality and safety. It encompasses a variety of components that work together to power the engine, lights, and essential accessories. Understanding the intricacies of this system can help in diagnosing issues effectively and implementing necessary repairs.

Common components of the electrical system include:

- Batteries

- Alternators

- Fuses and relays

- Wiring harnesses

- Control modules

When problems arise within the electrical system, several symptoms may manifest:

- Difficulty starting the vehicle

- Flickering or dimming lights

- Non-functional accessories

- Warning lights on the dashboard

To troubleshoot these issues, consider the following steps:

- Inspect the battery: Ensure terminals are clean and connections are secure.

- Test the alternator: Check output voltage to confirm it is charging the battery adequately.

- Examine fuses and relays: Replace any blown fuses and test relays for proper operation.

- Check wiring harnesses: Look for signs of wear, fraying, or corrosion.

- Utilize diagnostic tools: Scan for error codes that can provide insights into control module issues.

By understanding the electrical system and following these troubleshooting steps, vehicle owners can address many common issues efficiently. Regular maintenance and prompt attention to any anomalies can significantly enhance the longevity and reliability of the electrical components.

Cooling System Maintenance Essentials

Proper upkeep of the cooling apparatus is crucial for ensuring optimal engine performance and longevity. Regular attention to this system prevents overheating and promotes efficient temperature regulation. Essential practices include monitoring fluid levels, checking for leaks, and ensuring that all components are functioning correctly.

One fundamental aspect of maintenance involves inspecting the coolant. Maintaining the appropriate fluid level is vital, as insufficient coolant can lead to overheating and potential engine damage. It is also important to replace the coolant at recommended intervals to avoid contamination and to ensure that it retains its effectiveness in heat transfer.

Additionally, the condition of hoses and clamps should be routinely assessed. Signs of wear, such as cracks or bulges, may indicate the need for replacement to prevent leaks. Furthermore, ensuring that the radiator and cooling fans are clean and operational is essential for optimal airflow and heat dissipation.

Finally, flushing the cooling system periodically helps remove debris and contaminants, maintaining the efficiency of the entire setup. By adhering to these essential maintenance tasks, vehicle owners can ensure the reliability and performance of their cooling system over time.

Fuel System Checks for Optimal Performance

Maintaining an efficient fuel system is essential for reliable vehicle operation and energy efficiency. Regular evaluations of this system help ensure that fuel reaches the engine effectively, providing stable performance and preventing potential issues.

Inspect Fuel Lines and Connections: Carefully check fuel lines and connections for signs of wear, cracks, or leaks. Damaged lines can disrupt fuel delivery, impacting the engine’s power output and potentially leading to costly repairs.

Test Fuel Pump Pressure: Accurate fuel pressure is crucial for engine responsiveness. Using a pressure gauge, measure the pump’s output to ensure it aligns with recommended values. Low pressure may indicate a weakened pump, while high pressure could suggest a clogged fuel return line.

Check Fuel Filter Condition: The fuel filter removes impurities before fuel reaches the engine. Over time, it can become clogged, reducing fuel flow and straining the pump. Replacing the filter periodically improves fuel quality, enhancing overall engine performance.

Evaluate Fuel Injectors: Fuel injectors play a key role in atomizing fuel for optimal combustion. Inspect injectors for signs of clogging, such as uneven idling or poor acceleration. Professional cleaning or replacement can restore fuel efficiency and power output.

Consistent fuel system maintenance significantly impacts engine health, ensuring the vehicle runs smoothly while maximizing fuel efficiency. Addressing these components regularly will not only improve performance but also extend the system’s longevity.

Body and Frame Rust Prevention

Maintaining the structural integrity of a vehicle involves safeguarding it from environmental elements that can cause deterioration over time. One of the primary concerns for any vehicle owner is protecting the body and frame from corrosion. Preventative measures help extend the lifespan of the vehicle, enhancing its durability and overall reliability.

Regular Cleaning and Inspection is essential for rust prevention. Dirt, salt, and moisture can accumulate on the underbody and various components, creating the perfect conditions for rust to develop. Regularly washing the underside, especially after driving on salted roads or through mud, helps minimize the risk of corrosion.

Applying protective coatings to vulnerable areas is another highly effective method. Specialized sprays, wax-based products, or sealants can create a barrier, shielding the metal surfaces from moisture. Additionally, applying rust-resistant paint or primer to areas that frequently come into contact with water or debris can offer long-term protection.

Drainage Maintenance is often overlooked but crucial. Ensuring that all drainage points, especially in doors and rocker panels, are clear can prevent water accumulation. Blocked drains can trap moisture, leading to hidden rust spots that may spread unnoticed over time.

For vehicles in areas with high humidity or road salt, scheduling periodic rust inspections is advisable. Professionals can apply rustproofing treatments or identify early signs of rust in hard-to-see areas, allowing timely action before corrosion affects critical components. Following these preventive practices can significantly reduce the likelihood of rust, ensuring the vehicle’s frame and body remain sound for years.

Recommended Tools for DIY Repairs

Having the right tools on hand can make all the difference in the ease and efficiency of any home project. Essential equipment not only simplifies tasks but also ensures a safer and more organized approach to hands-on maintenance and adjustments.

- Socket Set: A good-quality socket set with a range of sizes will be invaluable for handling various nuts and bolts. Look for one that includes both standard and deep sockets for flexibility.

- Wrenches: Combination wrenches in both metric and standard sizes are ideal. A ratcheting wrench set can further streamline the process, providing efficiency in tight spaces.

- Screwdrivers: Invest in a set that covers both flathead and Phillips types. Precision screwdrivers are also useful for accessing smaller screws and intricate components.

- Pliers: A variety of pliers, such as needle-nose, slip-joint, and locking pliers, will help with gripping, bending, and cutting tasks as needed.

- Torque Wrench: For tasks requiring specific force, a torque wrench is essential to prevent over-tightening and ensure secure fastening.

- Jack and Stands: When working beneath any structure, using a reliable jack with sturdy stands provides the necessary stability for safe access.

- Examine the