Comprehensive Guide to Repairing the 2003 Mitsubishi Montero

This section offers essential insights into the upkeep and servicing of a specific vehicle model. Proper maintenance not only enhances performance but also extends the lifespan of the vehicle. Understanding key components and procedures is crucial for any owner looking to ensure their vehicle operates smoothly.

In this guide, readers will find detailed information regarding troubleshooting common issues, as well as preventative measures that can be taken. A comprehensive understanding of the various systems in the vehicle will empower owners to take informed actions, leading to better care and performance.

Additionally, the information provided will assist in recognizing when professional intervention is necessary. By familiarizing oneself with the intricacies of the vehicle, owners can enhance their confidence and capability in managing its maintenance.

Common Issues and Solutions

This section highlights frequent challenges encountered by vehicle owners and provides practical solutions to address them. Understanding these common problems can enhance the overall driving experience and extend the life of your vehicle.

Frequent Problems

- Engine performance issues

- Electrical system malfunctions

- Suspension noise

- Transmission difficulties

- Cooling system leaks

Possible Solutions

- Regularly check and replace air filters to ensure optimal engine performance.

- Inspect wiring and connections in the electrical system to identify any faults.

- Perform routine maintenance on suspension components to minimize noise.

- Flush and refill transmission fluid according to the manufacturer’s guidelines.

- Examine hoses and connections in the cooling system to prevent leaks.

Maintenance Schedule and Tips

Regular upkeep is essential for ensuring the longevity and performance of your vehicle. Adhering to a structured maintenance timetable not only enhances reliability but also prevents unexpected issues. Below is a guide to help you stay on track with essential servicing tasks.

Routine Maintenance Tasks

- Check and replace engine oil and filter every 5,000 to 7,500 miles.

- Inspect tire pressure and tread depth monthly; rotate tires every 6,000 miles.

- Examine brake fluid levels and brake pads every 10,000 miles.

- Replace air filter and cabin filter annually for optimal airflow.

- Inspect battery connections and clean terminals as needed.

Seasonal Maintenance Considerations

- Before winter, check antifreeze levels and inspect the heating system.

- In spring, assess the condition of wiper blades and replace if necessary.

- During summer, verify that the air conditioning system is functioning properly.

- Fall is a good time to check the vehicle’s lights and replace any burnt-out bulbs.

Staying proactive with these maintenance tips will ensure a safe and enjoyable driving experience. Consistent attention to these tasks can help you avoid more significant repairs in the future.

Tools Required for Repairs

When undertaking maintenance tasks on your vehicle, having the right instruments is crucial for ensuring efficient and effective work. This section outlines the essential equipment that can facilitate various repair activities, making the process smoother and more manageable.

Essential Hand Tools

Basic hand tools are the foundation of any repair project. These include items such as wrenches, screwdrivers, and pliers. A good set of these tools will allow you to tackle most common tasks without any hassle. Additionally, ratchet sets can be particularly useful for reaching tight spots.

Specialized Equipment

For more advanced repairs, specialized tools may be required. This could involve torque wrenches for precise tightening, compression testers for assessing engine performance, and code readers for diagnosing electronic issues. Investing in these tools can significantly enhance your repair capabilities and provide better outcomes.

Step-by-Step Brake Replacement Guide

Replacing the braking components of your vehicle is essential for maintaining optimal performance and safety. This guide provides a clear and concise approach to help you complete the task effectively.

1. Gather Necessary Tools and Parts: Before you start, ensure you have all required tools such as a jack, lug wrench, and socket set. Additionally, procure new brake pads and rotors suited for your vehicle.

2. Lift the Vehicle: Use the jack to elevate the car securely. Once lifted, place jack stands underneath for added safety while you work.

3. Remove the Wheel: With the lug wrench, loosen and remove the lug nuts to take off the wheel, granting you access to the braking system.

4. Take Off the Caliper: Unbolt the brake caliper using the socket set. Gently slide it off the rotor and support it using a hanger or a bungee cord to avoid stress on the brake line.

5. Replace the Pads: Remove the old brake pads from the caliper bracket. Insert the new pads, ensuring they are positioned correctly for optimal contact.

6. Reinstall the Caliper: Carefully place the caliper back over the new pads and tighten the bolts securely.

7. Put the Wheel Back On: Reattach the wheel and hand-tighten the lug nuts. Lower the vehicle to the ground, then use the lug wrench to securely fasten the nuts in a star pattern.

8. Test the Brakes: Before taking the vehicle for a drive, pump the brake pedal several times to ensure proper engagement of the new components. Check for any unusual sounds or issues.

Following these steps will help ensure a successful replacement of your vehicle’s braking system, contributing to a safer driving experience.

Engine Troubleshooting Techniques

Identifying issues within the engine system is crucial for maintaining optimal performance and longevity. Effective diagnostics can prevent minor problems from escalating into major failures. This section will explore various strategies and methods to systematically address engine-related concerns.

Understanding Symptoms is the first step in troubleshooting. Carefully observing and noting any unusual sounds, vibrations, or changes in performance can provide valuable clues. Pay attention to indicators such as decreased power, poor fuel efficiency, or irregular idling.

Next, Conducting Visual Inspections is essential. Begin by examining the engine compartment for visible signs of wear or damage, such as leaks, frayed wires, or loose connections. Checking fluid levels and quality can also highlight potential issues.

Finally, Utilizing Diagnostic Tools enhances the troubleshooting process. Employing devices like scan tools can help retrieve error codes from the engine control unit, guiding you toward specific problems. This data can significantly streamline repairs and ensure accurate resolutions.

Transmission Repair Insights

Understanding the intricacies of vehicle drivetrain components is essential for ensuring optimal performance. This section delves into common issues, maintenance practices, and troubleshooting techniques that are crucial for longevity and reliability.

Common Challenges: Various factors can contribute to transmission difficulties, including fluid quality, wear and tear on internal components, and electronic malfunctions. Regular inspections can help identify early signs of trouble, allowing for proactive measures.

Maintenance Tips: Routine fluid changes and system checks are vital in maintaining a smooth operation. Using the correct lubricant and adhering to service intervals can significantly extend the life of transmission elements.

Troubleshooting Techniques: Diagnosing issues often requires a methodical approach. Listening for unusual noises, monitoring shifting behavior, and checking for warning lights are key steps. Utilizing diagnostic tools can further assist in pinpointing specific faults.

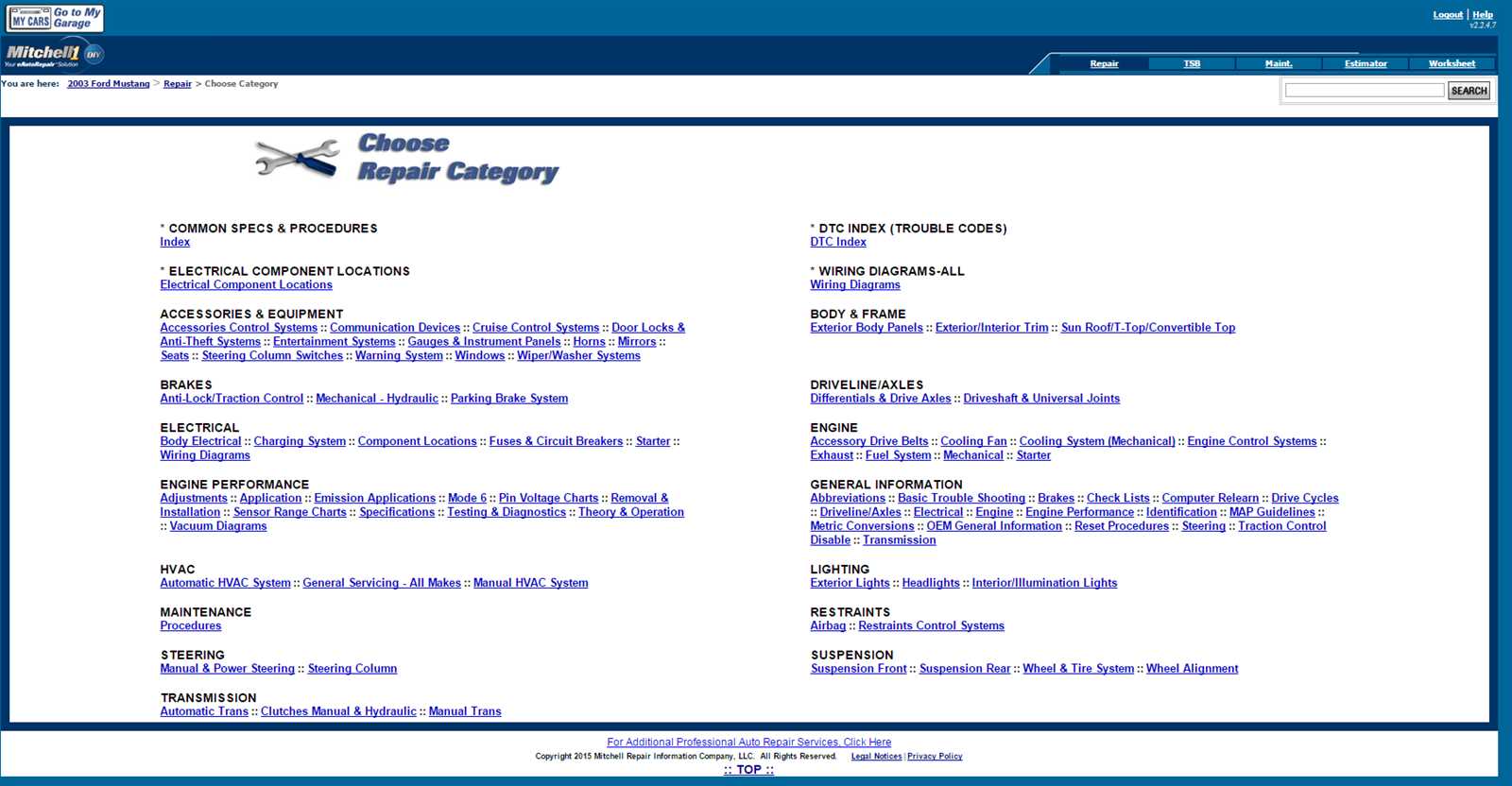

Electrical System Diagnostics

The effective diagnosis of the electrical system in vehicles is crucial for ensuring optimal performance and reliability. This process involves identifying potential issues within various components, from wiring and connections to electronic control units. By employing systematic approaches, technicians can accurately pinpoint malfunctions and implement appropriate solutions.

A comprehensive diagnostic procedure typically includes visual inspections, continuity tests, and the use of specialized diagnostic tools. These methods help to assess the condition of wiring harnesses, fuses, and battery connections, as well as the functionality of sensors and actuators.

| Component | Common Issues | Diagnostic Method |

|---|---|---|

| Wiring Harness | Fraying, corrosion | Visual inspection, continuity testing |

| Battery | Weak charge, leakage | Voltage test, load test |

| Sensors | Faulty readings | OBD-II scanner analysis |

| Fuses | Blown fuses | Visual inspection |

Implementing these diagnostic steps can significantly enhance the troubleshooting process, allowing for timely repairs and improved vehicle functionality. Regular checks and maintenance of the electrical system not only prolong the lifespan of components but also contribute to overall vehicle safety.

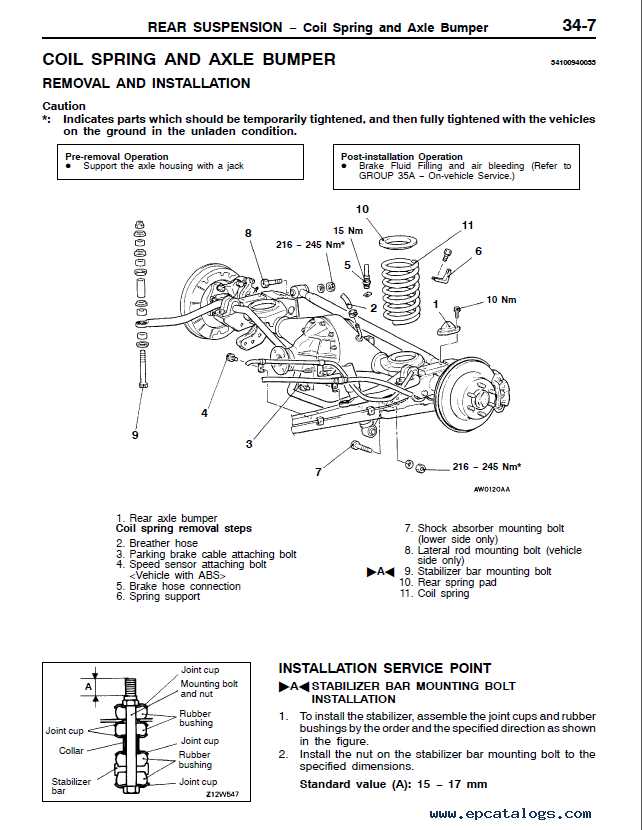

Suspension System Overview

The suspension system is a crucial component of any vehicle, designed to enhance ride comfort and stability. It plays a vital role in absorbing shocks from the road, ensuring that the vehicle remains in contact with the surface for improved handling and safety.

Key Functions: This system serves multiple purposes, including supporting the vehicle’s weight, maintaining tire contact with the ground, and providing stability during turns and stops. By effectively managing the forces encountered while driving, it contributes to a smoother experience for passengers and helps protect the vehicle from excessive wear.

Components: A typical suspension system consists of various elements such as springs, shock absorbers, and control arms. Each component works in harmony to provide optimal performance, allowing the vehicle to adapt to different road conditions and driving styles.

Body and Frame Repair Procedures

This section outlines essential methods for addressing structural and outer shell issues in vehicles. Proper techniques are crucial for restoring integrity and safety, ensuring that the chassis and bodywork meet the necessary standards.

Begin by assessing the extent of damage to the outer shell and frame. Visual inspections should be complemented by measurements to confirm alignment and identify any deformations. Using specialized tools, such as frame straighteners, can help in realigning the structure effectively.

When repairing the outer panels, consider the materials involved. Techniques may vary between steel and aluminum, requiring distinct approaches for welding or adhesive bonding. Ensure that all repair methods comply with industry standards to maintain safety and durability.

Additionally, it’s important to address any corrosion or rust that may compromise the integrity of the vehicle’s structure. Employing rust treatment solutions and protective coatings can enhance longevity and performance.

After completing the repairs, a thorough inspection is essential to confirm that all components function as intended. Final adjustments should be made to ensure that doors, hoods, and other movable parts align properly, providing a seamless operation and aesthetic appeal.

Interior Components Maintenance

Regular upkeep of interior elements is crucial for ensuring comfort and functionality within the vehicle. This section focuses on essential practices to keep the cabin in optimal condition, enhancing both aesthetic appeal and user experience.

Cleaning Upholstery and Surfaces

To maintain the cleanliness and longevity of fabrics and surfaces, it is important to use appropriate cleaning agents. Vacuuming seats and carpets regularly will prevent dirt buildup. For stains, a gentle upholstery cleaner should be applied according to the manufacturer’s instructions to avoid damage.

Inspecting Dashboard and Controls

Routine inspections of the dashboard and control systems are necessary to ensure all components are functioning correctly. Look for any signs of wear or damage, and clean the surfaces with a damp cloth to remove dust and grime, enhancing visibility and ease of use.

Maintaining Climate Control System

The efficiency of the climate control system can significantly impact comfort levels. Periodic checks of air filters and ventilation systems will help ensure optimal airflow. Replace filters as recommended to maintain a clean and pleasant cabin environment.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when conducting maintenance on vehicles. Adhering to specific safety measures not only protects the technician but also prevents potential harm to the vehicle and surrounding areas. Following these guidelines promotes a safer working atmosphere.

Essential Safety Measures

Before starting any service work, it is vital to prepare adequately. This includes wearing appropriate personal protective equipment and ensuring the workspace is clear of hazards. Additionally, keeping necessary tools and materials organized can greatly enhance efficiency and safety.

Tool and Equipment Safety

Utilizing the correct tools for each task is imperative. Inspect all equipment before use to ensure they are in proper working condition. If any tool appears damaged or malfunctioning, it should be repaired or replaced immediately to avoid accidents.

| Precaution | Description |

|---|---|

| Personal Protective Gear | Wear gloves, goggles, and masks to protect against chemicals and debris. |

| Ventilation | Ensure proper airflow to prevent inhalation of fumes or harmful vapors. |

| Emergency Procedures | Familiarize yourself with emergency protocols and the location of first aid kits. |

| Work Environment | Keep the workspace well-lit and organized to minimize risks of tripping or accidents. |

Resources for Parts and Support

When it comes to maintaining and enhancing your vehicle, accessing reliable components and expert assistance is crucial. Numerous platforms and outlets provide a range of options to ensure that you can find the necessary parts, whether for routine upkeep or specific repairs.

Online Marketplaces: Websites such as eBay and Amazon offer a vast selection of automotive components. You can often find both new and used parts, catering to various budgets and preferences.

Local Auto Parts Stores: Establishments like AutoZone and O’Reilly Auto Parts have physical locations where you can consult with knowledgeable staff. They can help you identify the right components and may also provide installation advice.

Specialized Forums and Communities: Engaging with online communities can be an invaluable resource. Many enthusiasts share insights, recommendations, and sometimes even links to reputable suppliers.

Service Centers: Authorized service centers provide professional support. They typically use high-quality parts and have trained technicians who are familiar with the specific needs of your vehicle.

Utilizing these resources can greatly assist in ensuring that your vehicle remains in optimal condition, enhancing both performance and longevity.