Comprehensive Repair Manual for the 2004 Honda Accord

When it comes to maintaining a vehicle, having access to a detailed reference can make all the difference. This guide is designed to provide essential insights and instructions for troubleshooting, servicing, and enhancing the performance of your car. Whether you’re an experienced enthusiast or a novice looking to learn, this resource will equip you with the knowledge needed to ensure your vehicle operates smoothly.

Understanding the intricacies of your automobile is vital for effective upkeep. From routine checks to more complex repairs, knowing the specifics can save time and prevent costly mistakes. This compilation of information covers a wide range of topics, offering clarity on various components and systems that contribute to the overall functionality of your vehicle.

Equipped with step-by-step procedures and valuable tips, this guide empowers you to take control of your automotive care. Embrace the confidence to tackle challenges head-on, knowing you have a reliable source of information at your fingertips. Engage in the rewarding experience of self-service and become acquainted with the essential elements that keep your vehicle running at its best.

Essential Tools for Honda Accord Repairs

When tackling automotive maintenance and fixes, having the right equipment is crucial for achieving effective outcomes. This selection of essential instruments not only enhances the efficiency of tasks but also ensures safety and precision during work. Whether you are a novice enthusiast or a seasoned technician, understanding the necessary tools will prepare you for various mechanical challenges.

Socket Set: A comprehensive socket set is fundamental for loosening and tightening bolts and nuts. This kit typically includes both metric and standard sizes, allowing for versatility in handling different components.

Wrenches: A range of wrenches, including adjustable and combination types, is essential for accessing tight spaces and applying torque to fasteners securely.

Screwdriver Set: Various screwdrivers, including flathead and Phillips types, are necessary for managing screws of different sizes and shapes found throughout the vehicle.

Pliers: Needle-nose and regular pliers are vital for gripping, twisting, and cutting wires and other materials. They can also assist in holding small parts securely while working.

Jack and Jack Stands: A reliable jack is critical for lifting the vehicle, while jack stands provide stability and safety when working underneath. This combination is indispensable for many maintenance tasks.

Multimeter: This electronic tool is essential for diagnosing electrical issues. It helps measure voltage, current, and resistance, allowing for effective troubleshooting of the electrical system.

Oil Filter Wrench: An oil filter wrench simplifies the task of removing and replacing oil filters, making routine oil changes much easier.

Torque Wrench: Ensuring that bolts are tightened to the correct specifications is vital for safety and performance. A torque wrench provides the precision needed for this task.

Equipping yourself with these indispensable tools will enhance your capability to perform maintenance tasks with confidence and efficiency. Mastery of the appropriate equipment is a key step toward ensuring the longevity and performance of your vehicle.

Understanding Common Issues in 2004 Models

Many vehicles from this production year exhibit a range of challenges that owners should be aware of. Recognizing these typical problems can assist in proactive maintenance and enhance the overall driving experience. In this section, we will explore some of the frequent concerns that may arise, along with potential solutions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Transmission Slipping | Drivers may notice difficulties in gear shifting or unexpected changes in engine RPMs. | Regular fluid checks and timely replacement can mitigate this issue. Consulting a professional for diagnosis is advisable. |

| Brake Wear | Squeaking or grinding sounds while braking are common indicators of excessive wear. | Inspecting brake pads frequently and replacing them when necessary is essential for safety. |

| Electrical Problems | Issues such as flickering dashboard lights or malfunctioning accessories may arise. | Checking battery connections and fuses can resolve minor electrical faults; however, professional help may be needed for complex issues. |

| Suspension Noise | Unusual noises while driving over bumps can signal suspension wear. | Regular inspections of shock absorbers and struts can help identify and address problems before they escalate. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Following structured guidelines not only enhances reliability but also reduces the likelihood of unexpected issues. This section outlines systematic methods for routine care, enabling you to maintain your vehicle in peak condition.

1. Engine Oil Change

Changing the engine oil is vital for lubrication and preventing wear. Follow these steps:

- Gather necessary tools: oil filter wrench, socket set, and an oil catch pan.

- Warm up the engine slightly to thin the oil, then turn it off.

- Locate the oil drain plug underneath the vehicle and remove it.

- Allow the old oil to completely drain into the pan.

- Replace the oil filter, ensuring the rubber gasket is seated properly.

- Reinstall the drain plug and refill the engine with fresh oil.

- Start the engine and check for leaks around the filter and drain plug.

2. Tire Rotation

Rotating tires promotes even wear and extends their lifespan. Follow this process:

- Check the tire pressure and ensure all tires are inflated correctly.

- Use a jack to lift the vehicle and secure it with jack stands.

- Remove the lug nuts and take off the tires.

- Reinstall the tires in a different position according to the rotation pattern.

- Hand-tighten the lug nuts and lower the vehicle.

- Torque the lug nuts to the manufacturer’s specifications.

3. Brake Inspection

Ensuring your braking system functions properly is crucial for safety. Here’s how to inspect:

- Check the brake fluid level in the reservoir.

- Examine brake pads for wear; replace them if they are less than 3mm thick.

- Inspect rotors for scoring or uneven wear.

- Look for leaks in brake lines or around calipers.

- Test the brakes by pressing the pedal; it should feel firm.

4. Battery Maintenance

Maintaining the battery ensures reliable starts and electrical system functionality. Follow these steps:

- Check battery terminals for corrosion and clean them if necessary.

- Inspect the battery case for cracks or leaks.

- Test the battery voltage using a multimeter.

- If necessary, recharge the battery or replace it if it no longer holds a charge.

By adhering to these detailed maintenance procedures, you can enhance the reliability and efficiency of your vehicle. Regular checks not only ensure safety but also contribute to the overall driving experience.

Diagnosing Engine Performance Problems

Identifying issues related to engine efficiency is crucial for maintaining optimal vehicle functionality. By recognizing the symptoms and underlying causes, you can ensure a smoother driving experience and prolong the life of the powertrain. This section outlines common signs of performance troubles and methods for thorough evaluation.

Common Symptoms of Engine Performance Issues

- Poor acceleration

- Rough idling

- Decreased fuel efficiency

- Unusual noises during operation

- Check engine light activation

Steps for Diagnosing Performance Problems

- Conduct a visual inspection of the engine components.

- Utilize diagnostic tools to retrieve error codes.

- Examine the air intake and fuel delivery systems.

- Check ignition components and sensors for functionality.

- Test the exhaust system for blockages or leaks.

By systematically addressing these areas, you can effectively pinpoint performance challenges and take necessary corrective actions.

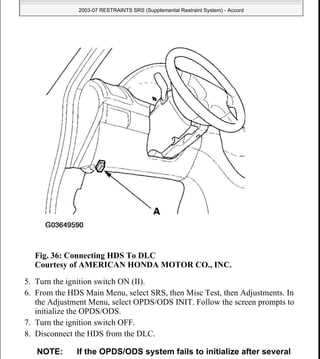

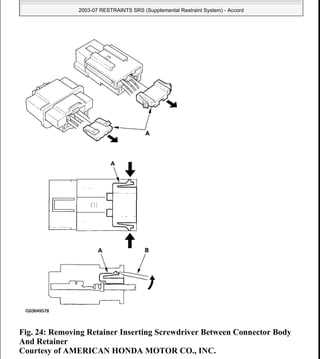

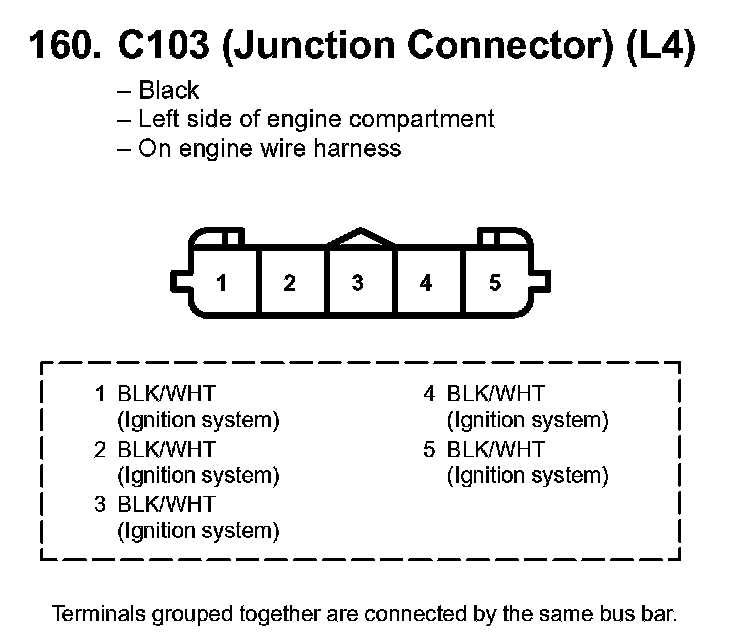

Electrical System Troubleshooting Guide

The electrical system of a vehicle is crucial for its overall functionality, encompassing various components that work in harmony. When issues arise, diagnosing the underlying problems can seem daunting. This guide aims to provide a systematic approach to identifying and resolving common electrical faults, enabling a smoother troubleshooting experience.

Initial Checks: Start by inspecting the battery connections and terminals for corrosion or looseness. A clean and secure connection is vital for optimal performance. Verify that the battery is adequately charged and free of any signs of damage.

Fuses and Relays: A blown fuse or faulty relay can disrupt the flow of electricity. Check the fuse box for any blown fuses and replace them with the correct amperage. Additionally, test relays for proper operation to ensure that electrical circuits are receiving the necessary power.

Wiring Inspection: Examine wiring for any signs of wear, fraying, or damage. Pay special attention to areas that may be subject to excessive movement or exposure to heat. Repair or replace any compromised wiring to restore electrical integrity.

Testing Components: Utilize a multimeter to measure voltage and resistance across various components. This tool is essential for diagnosing issues with switches, sensors, and other critical parts of the electrical system. Ensure that readings are within the manufacturer’s specifications for proper functionality.

Ground Connections: Poor ground connections can lead to a myriad of electrical issues. Ensure that all ground points are clean, tight, and free of corrosion. Establishing a solid ground is fundamental to the system’s performance.

Conclusion: By following this guide, you can effectively troubleshoot electrical system issues. Remember, systematic diagnosis and attention to detail are key in resolving problems and maintaining the vehicle’s electrical integrity.

Brake System Inspection and Repair

Ensuring optimal performance of the braking system is crucial for vehicle safety and longevity. Regular evaluations can prevent potential hazards and extend the lifespan of components. This section outlines the necessary steps and considerations for thoroughly assessing and addressing issues within the braking mechanism.

Visual Examination

The initial stage in the evaluation process involves a meticulous visual inspection of the braking components. Look for signs of wear, such as unevenly worn pads, cracked rotors, or leaking fluid. Pay attention to the condition of the brake lines and connections, as corrosion or damage can significantly impair functionality. Identifying these issues early can save time and resources in the long run.

Functional Testing

After the visual assessment, it is essential to conduct functional tests. This includes checking the responsiveness of the pedal and the overall effectiveness of braking. Listen for any unusual noises during operation, which may indicate underlying problems. Additionally, ensure that the brake fluid level is adequate and that the fluid is free of contaminants. Regular maintenance not only enhances safety but also promotes a smoother driving experience.

Suspension and Steering Adjustments

The proper alignment and adjustment of the suspension and steering systems are crucial for optimal vehicle handling, comfort, and safety. Ensuring these components function harmoniously not only enhances driving performance but also prolongs the lifespan of related parts.

Regular checks and adjustments can significantly improve ride quality and responsiveness. Here are key areas to focus on:

- Alignment: Misalignment can cause uneven tire wear and affect steering precision.

- Camber Angle: Adjusting this angle ensures that the tires make optimal contact with the road surface.

- Toe Settings: Proper toe adjustments can enhance stability and cornering performance.

- Ride Height: Modifying the vehicle’s height can influence handling characteristics and overall balance.

When addressing steering issues, consider the following:

- Steering Rack Inspection: Check for wear and proper lubrication to maintain smooth operation.

- Power Steering Fluid Levels: Ensure that fluid is at the correct level to prevent steering difficulties.

- Joint and Linkage Condition: Examine all connecting parts for wear or damage that could impact steering accuracy.

By focusing on these adjustments, drivers can ensure a smoother, safer driving experience while enhancing the longevity of their vehicle’s systems.

Transmission Fluid Change Instructions

Regular maintenance of your vehicle’s transmission system is crucial for optimal performance and longevity. One essential aspect of this upkeep is the periodic replacement of the transmission fluid. This procedure helps ensure smooth shifting and prevents potential damage to the transmission components.

Follow these steps to effectively change the transmission fluid:

| Step | Instructions |

|---|---|

| 1 | Gather necessary tools and materials, including new fluid, a funnel, a wrench, a drain pan, and a filter if required. |

| 2 | Start the engine and let it warm up for a few minutes to allow the fluid to circulate. |

| 3 | Turn off the engine and securely lift the vehicle using jack stands. |

| 4 | Locate the transmission drain plug and carefully remove it to let the old fluid drain into the pan. |

| 5 | Replace the drain plug once all fluid has drained and tighten it to the manufacturer’s specifications. |

| 6 | If applicable, replace the transmission filter following the specific instructions for your vehicle. |

| 7 | Using a funnel, refill the transmission with the new fluid through the dipstick tube. |

| 8 | Start the engine and let it run for a few minutes, then check the fluid level using the dipstick. Add more fluid if necessary. |

| 9 | Lower the vehicle and take it for a short drive to ensure the fluid circulates properly. Check for leaks afterwards. |

Following these steps will help maintain the efficiency of your transmission system, enhancing the overall driving experience.

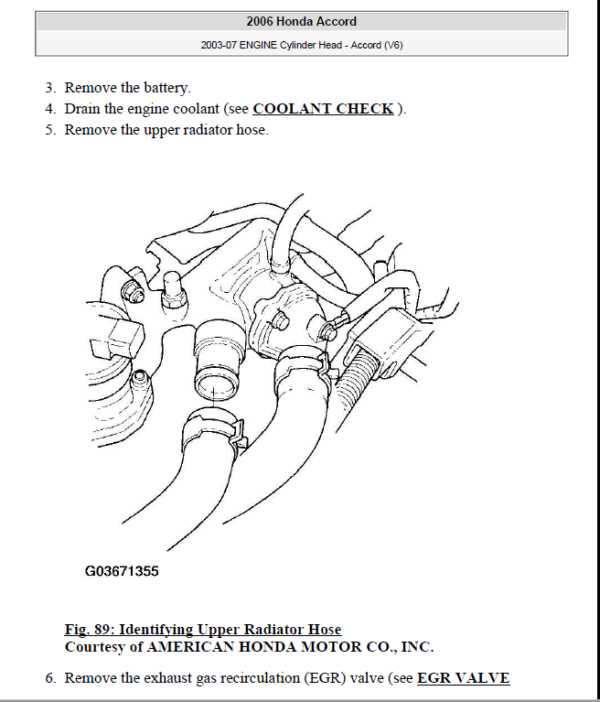

Cooling System Maintenance Tips

Proper upkeep of your vehicle’s cooling system is essential for ensuring optimal performance and longevity. Regular maintenance can prevent overheating, enhance efficiency, and protect your engine from potential damage. Here are some valuable tips to keep your cooling system in excellent condition.

Regular Inspections

Conduct routine checks on your cooling system to identify any potential issues before they escalate. Focus on the following:

- Examine hoses for signs of wear, leaks, or cracks.

- Check the radiator for any blockages or corrosion.

- Inspect the water pump for leaks or unusual noises.

Flushing and Replacing Coolant

Maintaining the correct coolant levels is crucial for your engine’s health. Consider the following steps:

- Flush the cooling system every two years to remove any accumulated debris.

- Replace the coolant with the appropriate type recommended for your vehicle.

- Monitor coolant levels regularly and top off as needed.

By adhering to these guidelines, you can ensure your vehicle’s cooling system operates smoothly, reducing the risk of overheating and promoting overall engine efficiency.

Replacing Timing Belt: A Guide

The timing belt is a crucial component of an engine’s internal workings, ensuring that the camshaft and crankshaft are synchronized. Replacing this belt is essential for maintaining optimal engine performance and preventing potential damage. This guide outlines the steps required to complete this task effectively, emphasizing the importance of following proper procedures and safety measures.

Before beginning the replacement process, it’s vital to gather the necessary tools and materials. This includes a socket set, torque wrench, timing belt kit, and any additional components that may require replacement during the procedure, such as tensioners and water pumps. Below is a table summarizing the tools and components needed:

| Tools/Components | Description |

|---|---|

| Socket Set | Various sizes for removing engine components. |

| Torque Wrench | To ensure bolts are tightened to the manufacturer’s specifications. |

| Timing Belt Kit | Includes the timing belt and necessary tensioners. |

| Coolant | To refill the cooling system if the water pump is replaced. |

Following the assembly of the necessary tools, the next step involves disconnecting the battery and removing any components obstructing access to the timing belt cover. This may include the air intake, belts, and other parts depending on the specific engine layout. Once access is secured, remove the timing belt cover and inspect the existing belt for signs of wear or damage.

Afterward, align the engine’s timing marks to ensure proper synchronization. Carefully remove the old timing belt, taking note of its routing path. Install the new belt following the manufacturer’s specifications and double-check that all components are aligned correctly. Finally, reassemble the components in the reverse order of disassembly, ensuring that everything is securely fastened.

In conclusion, replacing the timing belt is a fundamental maintenance task that can significantly affect engine performance and longevity. By adhering to this guide and taking the necessary precautions, you can successfully complete the process and keep your vehicle running smoothly.

Resources for Finding OEM Parts

When it comes to maintaining your vehicle, sourcing original equipment manufacturer (OEM) components is crucial for ensuring quality and compatibility. Accessing these parts can significantly enhance the performance and longevity of your automobile. Below are various avenues to explore when searching for reliable OEM parts.

Online Marketplaces

Digital platforms provide a convenient way to locate OEM parts. Here are some popular options:

- Amazon – A vast selection of automotive components with user reviews.

- eBay – An auction site where you can find new and used parts from various sellers.

- RockAuto – A dedicated automotive parts website offering a wide array of OEM options.

Manufacturer Websites

Directly visiting the websites of car manufacturers can yield valuable resources:

- Official brand sites often have sections for parts and accessories.

- Many manufacturers provide online catalogs that allow you to search by model and year.

- Some brands offer exclusive online promotions for OEM components.

By utilizing these resources, vehicle owners can effectively source the necessary OEM parts to keep their automobiles running smoothly.

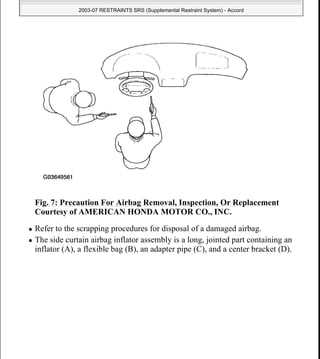

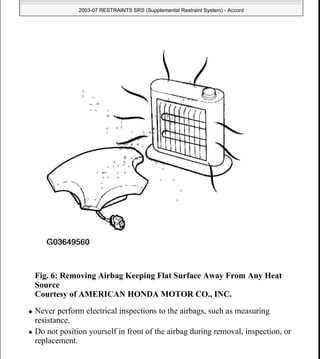

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both personal safety and effective outcomes. Adhering to specific guidelines can prevent accidents and injuries, fostering a more efficient working atmosphere. This section outlines essential safety measures that should be observed whenever engaging in vehicle service procedures.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital. This includes gloves to shield hands from chemicals and sharp objects, safety goggles to protect eyes from debris, and sturdy footwear to minimize foot injuries. Additionally, employing ear protection is advisable when working with loud machinery. By equipping oneself with the right gear, risks can be significantly reduced.

Proper Workspace Management

Maintaining an organized and clutter-free workspace is essential for safety. Tools should be stored in designated areas to prevent tripping hazards. Ensuring adequate lighting will help in identifying potential dangers and enhance focus during intricate tasks. Furthermore, keeping flammable materials away from heat sources is critical to avoid fire hazards. A well-managed environment contributes to safer practices and improved efficiency.