Mitsubishi Endeavor 2004 Repair Guide

Every vehicle owner understands the importance of regular upkeep to ensure optimal performance and longevity. This section serves as a valuable resource, offering insights into essential practices and troubleshooting techniques that can help maintain your vehicle in peak condition.

With a focus on various aspects of vehicle care, this guide will provide detailed instructions and helpful tips to address common challenges faced by drivers. By following the outlined procedures, individuals can enhance their understanding of how to effectively manage their automobile’s health.

Whether you are a seasoned enthusiast or a first-time owner, the information presented here aims to empower you with the knowledge needed to navigate maintenance tasks confidently. From routine checks to more complex adjustments, you will find practical advice designed to simplify the process.

Overview of the Mitsubishi Endeavor

This section provides a comprehensive look at a mid-size crossover vehicle designed to cater to the needs of families and individuals seeking a blend of comfort, utility, and performance. With its robust build and versatile features, this model has established itself as a reliable option in its category.

Key Features

- Spacious interior with flexible seating arrangements

- Ample cargo capacity for everyday use

- All-wheel drive system available for enhanced traction

- Modern infotainment options for connectivity and entertainment

Performance and Efficiency

The vehicle is equipped with a capable engine that strikes a balance between power and fuel efficiency. Its smooth handling and responsive steering contribute to an enjoyable driving experience, making it suitable for both city commutes and long-distance travels.

In summary, this model presents a well-rounded option for those in search of a practical and dependable vehicle, combining essential attributes for both daily use and adventure.

Key Features and Specifications

This section provides an overview of the primary attributes and technical details of the vehicle, showcasing its performance, design, and functionality. Understanding these aspects can assist in making informed decisions regarding maintenance and operation.

| Feature | Specification |

|---|---|

| Engine Type | V6, 3.8 liters |

| Horsepower | 210 hp |

| Transmission | 5-speed automatic |

| Fuel Economy (City) | 16 mpg |

| Fuel Economy (Highway) | 22 mpg |

| Seating Capacity | 5 passengers |

| Max Towing Capacity | 3,500 lbs |

| Standard Features | Alloy wheels, ABS, air conditioning |

Common Issues with the 2004 Model

This section addresses frequent challenges encountered with this particular vehicle. Owners often report specific problems that may affect performance, comfort, and safety. Understanding these issues can help in identifying potential concerns and implementing timely solutions.

Frequent Mechanical Concerns

- Transmission issues, including delayed shifting and slipping.

- Engine overheating, which may result from coolant leaks or thermostat failures.

- Brake system irregularities, such as squeaking noises or reduced responsiveness.

Electrical and Electronic Glitches

- Malfunctioning dashboard lights, leading to confusion regarding operational status.

- Problems with power windows and locks not responding as expected.

- Audio system failures, including issues with sound quality and connectivity.

Diagnostic Troubleshooting Techniques

Effective diagnostic strategies are essential for identifying and resolving issues in automotive systems. A systematic approach helps in pinpointing the root cause of malfunctions, ensuring that repairs are accurate and efficient. This section explores various methodologies that can be employed during the troubleshooting process.

Common Diagnostic Approaches

- Visual Inspection: Begin with a thorough examination of the vehicle’s components. Look for signs of wear, leaks, or damage.

- Data Analysis: Utilize diagnostic tools to retrieve error codes and monitor system performance in real time.

- Functional Testing: Conduct tests on individual systems to verify their operation. This may include checking sensors, actuators, and other components.

Step-by-Step Troubleshooting Process

- Gather Information: Collect details about the symptoms and any prior repairs that may relate to the current issue.

- Isolate the Problem: Use logical reasoning to narrow down the potential sources of the malfunction.

- Implement Solutions: Apply targeted fixes based on your findings, followed by re-evaluating the system’s functionality.

- Document Findings: Keep records of your diagnostic process and results for future reference.

Routine Maintenance Procedures Explained

Regular upkeep is essential for ensuring the longevity and efficiency of any vehicle. Implementing a series of systematic tasks can help prevent major issues, enhance performance, and promote safety on the road. This section outlines fundamental practices that should be followed to maintain optimal vehicle function.

Key Maintenance Tasks

The following table summarizes essential maintenance tasks along with their recommended frequency:

| Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Tire Rotation | Every 6,000 miles |

| Brake Inspection | Every 12,000 miles |

| Fluid Levels Check | Monthly |

| Air Filter Replacement | Every 15,000 miles |

Importance of Regular Checks

Consistently performing these tasks can significantly reduce the likelihood of unexpected breakdowns. Addressing minor concerns early on can save time and expenses in the long run, ensuring that the vehicle operates smoothly and reliably throughout its lifespan.

Essential Fluid Types and Levels

Maintaining the correct types and levels of fluids is crucial for the optimal performance and longevity of your vehicle. Regular checks and timely replacements help ensure smooth operation and prevent potential issues. Understanding the different fluids and their specific roles will assist in effective vehicle care.

| Fluid Type | Purpose | Recommended Level |

|---|---|---|

| Engine Oil | Lubricates engine components, reducing friction and wear. | Check every 3,000-5,000 miles. |

| Coolant | Regulates engine temperature and prevents overheating. | Maintain between minimum and maximum marks. |

| Transmission Fluid | Facilitates smooth gear shifts and lubricates transmission parts. | Inspect regularly; levels should be within the dipstick range. |

| Brake Fluid | Transmits force from the brake pedal to the brake components. | Keep above the minimum line in the reservoir. |

| Power Steering Fluid | Aids in steering system operation, providing necessary assistance. | Check levels in the reservoir periodically. |

Ensuring that all fluid levels are within the recommended ranges is essential for maintaining vehicle functionality and safety. Regular inspections will help identify any leaks or deterioration early, allowing for prompt action and avoiding larger issues down the line.

Step-by-Step Repair Instructions

This section provides detailed guidance for performing maintenance and troubleshooting procedures on your vehicle. Following these systematic steps will ensure effective resolution of issues while enhancing overall functionality.

Preparation

- Gather all necessary tools and equipment.

- Ensure the vehicle is parked on a flat surface.

- Disconnect the battery to prevent electrical hazards.

Procedure

- Inspect the area requiring attention for any visible damage or wear.

- Follow the specific sequence for disassembly, if applicable:

- Remove any coverings or shields.

- Unfasten screws and bolts methodically.

- Keep track of all parts removed for reassembly.

Tools Required for Common Repairs

When performing maintenance tasks or troubleshooting issues with your vehicle, having the right tools on hand is essential. This section outlines the necessary equipment that can facilitate various tasks, ensuring efficient and effective work.

- Socket Set: A comprehensive socket set is crucial for loosening and tightening fasteners.

- Wrenches: Both open-end and adjustable wrenches allow for versatile use on different sizes of nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Screwdrivers: A variety of flathead and Phillips screwdrivers are necessary for working with different types of screws.

- Pliers: Needle-nose and regular pliers help grip, twist, and cut wires and other materials.

- Jack and Jack Stands: A hydraulic jack is essential for lifting the vehicle safely, while jack stands provide stability during work underneath.

- Oil Filter Wrench: This specialized tool simplifies the removal of oil filters during maintenance tasks.

Having these tools readily available will enhance your ability to perform various tasks efficiently and with confidence.

Understanding the Electrical System

The electrical system of a vehicle plays a crucial role in ensuring its overall functionality and performance. This intricate network comprises various components that work in harmony to power critical systems, manage energy distribution, and enhance driving comfort and safety. Grasping the fundamentals of this system can empower owners to troubleshoot issues and maintain optimal performance.

Key Components

The electrical architecture consists of several essential parts that contribute to the vehicle’s operation. Understanding these components can aid in identifying potential problems and implementing effective solutions.

| Component | Function |

|---|---|

| Battery | Stores electrical energy and provides power for starting the engine and operating accessories. |

| Alternator | Generates electrical power while the engine is running, recharging the battery and supplying power to the electrical systems. |

| Fuses | Protect electrical circuits from overloads by breaking the circuit when excessive current flows. |

| Wiring Harness | Connects various electrical components, facilitating communication and power distribution. |

Troubleshooting Tips

When facing electrical issues, a systematic approach can help in diagnosing and resolving the problem. Checking the battery condition, inspecting fuses for any signs of damage, and ensuring all connections are secure can often lead to quick fixes. Regular maintenance of the electrical system is essential to prevent unexpected failures and ensure reliable operation.

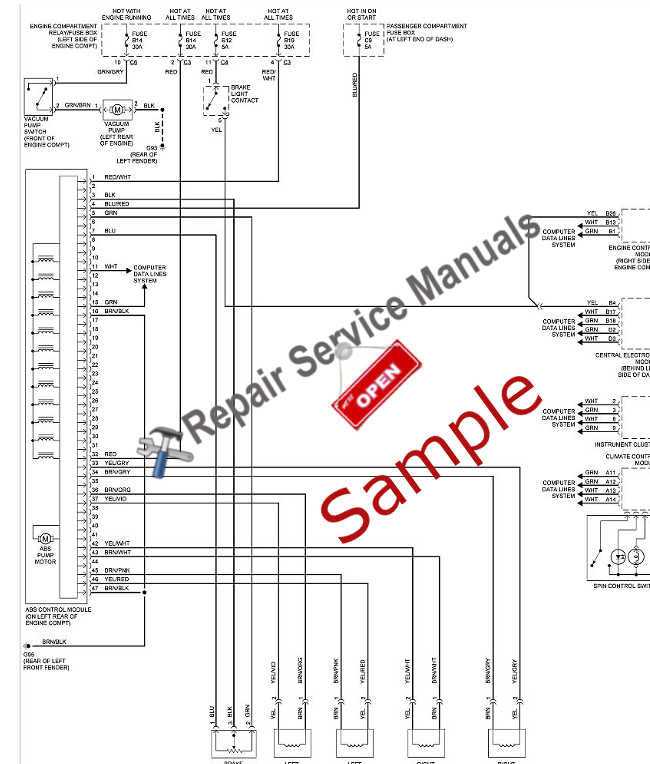

Wiring Diagrams and Component Locations

This section provides essential information regarding electrical schematics and the positioning of various elements within the vehicle’s system. Understanding these diagrams is crucial for diagnosing and troubleshooting issues effectively.

Understanding Electrical Schematics

Electrical schematics are visual representations that illustrate the connections and pathways of electrical components. They are invaluable tools for identifying potential issues and understanding how different parts interact within the system. By studying these diagrams, one can gain insights into the electrical layout, helping to pinpoint areas that may require attention.

Component Positioning

Knowing the precise locations of components is vital for efficient repairs and maintenance. Each element within the vehicle serves a specific function, and their arrangement can significantly impact the overall performance. Familiarity with these locations aids in quick access and reduces the time spent on diagnostics and repairs.

Suspension and Steering System Insights

The suspension and steering components play a crucial role in vehicle dynamics, influencing ride comfort and handling characteristics. Understanding the intricacies of these systems can greatly enhance driving experience and safety.

Key Components of the Suspension System

The suspension system comprises several key elements that work together to absorb shocks from the road and maintain tire contact. This includes springs, dampers, and control arms. Springs support the vehicle’s weight and allow for vertical movement, while dampers control the oscillation of springs, providing stability. Control arms connect the wheel assemblies to the vehicle frame, allowing for proper wheel alignment and movement.

Importance of the Steering Mechanism

The steering mechanism is essential for guiding the vehicle. It translates driver input into directional changes, enhancing maneuverability. A well-functioning steering system consists of the steering wheel, column, and rack, along with various linkages. Regular maintenance of these components ensures precise handling and prevents issues such as uneven tire wear or steering instability.

Brake System Maintenance Tips

Regular upkeep of the braking mechanism is crucial for ensuring safety and optimal performance. Attention to this system not only enhances driving experience but also extends the lifespan of components. Following some basic guidelines can significantly reduce wear and prevent potential issues.

Routine Inspections

Frequent checks are essential. Inspect brake pads for wear and ensure they meet the required thickness. Additionally, examine brake fluid levels and look for signs of contamination. A timely evaluation can help catch problems before they escalate.

Proper Cleaning

Keeping the braking system clean is vital for its efficiency. Debris and dust can accumulate over time, leading to decreased performance. Regularly clean the calipers and rotors, ensuring that all parts are free from obstruction. This simple task can help maintain the responsiveness of the brakes.

Engine Performance and Optimization

This section explores methods to enhance engine efficiency and overall functionality. By focusing on various tuning techniques and maintenance practices, you can achieve better power output and fuel economy, ensuring a smoother driving experience.

Key Factors Affecting Performance

Several elements contribute to engine optimization. These include air intake systems, fuel delivery, ignition timing, and exhaust flow. Each component plays a crucial role in the overall performance of the engine.

Maintenance Practices

Regular upkeep is essential for optimal engine function. Simple measures such as timely oil changes, air filter replacements, and checking spark plugs can significantly impact performance levels.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Improves lubrication and reduces wear |

| Air Filter Replacement | Every 15,000 miles | Enhances airflow and engine efficiency |

| Spark Plug Check | Every 30,000 miles | Ensures proper ignition and fuel combustion |