Complete Guide to Repairing the 2005 Polaris Sportsman 700

When it comes to maintaining the performance and longevity of your all-terrain vehicle, having access to detailed instructions is crucial. Understanding the intricacies of your machine ensures that you can address various issues effectively, whether they pertain to the engine, transmission, or suspension systems. A thorough guide serves as a valuable resource for both novice enthusiasts and seasoned mechanics alike.

In this section, we will explore essential techniques and insights that can help you navigate common challenges faced by off-road enthusiasts. By utilizing a structured approach to troubleshooting and repairs, you can enhance your riding experience and prevent costly breakdowns. This comprehensive resource will empower you to take charge of your vehicle’s upkeep.

Additionally, familiarizing yourself with the key components and functions of your all-terrain vehicle allows for more informed decisions during maintenance tasks. From understanding the importance of regular inspections to knowing how to properly address wear and tear, this guide aims to equip you with the knowledge necessary for optimal performance.

Understanding the 2005 Polaris Sportsman 700

This section delves into the intricacies of a well-regarded all-terrain vehicle that combines power, durability, and versatility. Designed for both recreational and utilitarian purposes, this machine has garnered attention for its performance in various conditions. Understanding its features and capabilities can enhance the ownership experience and ensure optimal maintenance practices.

Key Features and Specifications

Familiarity with the fundamental attributes of this vehicle is essential for effective usage and upkeep. Below is a summary of its prominent characteristics:

| Feature | Specification |

|---|---|

| Engine Type | V-Twin |

| Cylinder Capacity | 700 cc |

| Transmission | Automatic |

| Drive Type | All-Wheel Drive |

| Fuel Capacity | 5.5 gallons |

Maintenance Considerations

Proper care is crucial for prolonging the lifespan and performance of this vehicle. Regular checks and services, such as oil changes and tire inspections, play a significant role in maintaining its reliability. Understanding common maintenance tasks can empower owners to take proactive steps in preserving their investment.

Common Issues with Sportsman 700

This section highlights frequent problems encountered with this specific off-road vehicle. Understanding these challenges can assist owners in troubleshooting and maintaining optimal performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Overheating | Often caused by coolant leaks or a malfunctioning radiator. | Check coolant levels and inspect the radiator for blockages. |

| Electrical Problems | Common issues include faulty wiring or dead batteries. | Inspect all connections and test the battery voltage. |

| Transmission Difficulties | Can manifest as slipping gears or difficulty shifting. | Check fluid levels and ensure proper maintenance of the gearbox. |

| Fuel System Clogs | Blockages in the fuel line can lead to poor engine performance. | Replace the fuel filter and clean the fuel lines. |

| Suspension Issues | Worn components may lead to a rough ride. | Inspect shocks and springs for wear and replace as necessary. |

Essential Tools for Repair

Having the right equipment is crucial for effectively addressing mechanical issues. A well-stocked toolkit not only enhances efficiency but also ensures that tasks are completed safely and accurately. Understanding which instruments are necessary can make the difference between a smooth workflow and unnecessary complications.

Basic Hand Tools are the foundation of any maintenance endeavor. These typically include wrenches, screwdrivers, and pliers, which are essential for loosening or tightening components. A multitool can be especially handy, providing multiple functionalities in a single device.

Power Tools can significantly speed up tasks. Drills, impact wrenches, and angle grinders are invaluable for more demanding jobs. Choosing the right power tool for the job can reduce effort and time.

Diagnostic Equipment plays a vital role in identifying issues accurately. Tools such as multimeters and diagnostic scanners provide insights into the functioning of various systems, helping to pinpoint problems without guesswork.

Lastly, Safety Gear should never be overlooked. Items like gloves, goggles, and ear protection are essential for ensuring personal safety while working. Prioritizing safety not only protects you but also fosters a more efficient work environment.

Engine Maintenance Tips and Tricks

Proper care of your engine is essential for longevity and optimal performance. Regular upkeep not only enhances efficiency but also prevents costly repairs down the line. By following a few key practices, you can ensure your machine operates smoothly for years to come.

Regular Oil Changes

Changing the oil at recommended intervals is crucial. Fresh oil lubricates moving parts, reducing wear and tear. Always check the owner’s guidelines for specific recommendations, and consider using high-quality lubricants for the best results.

Air Filter Care

A clean air filter is vital for optimal engine performance. It prevents dirt and debris from entering the engine, which can cause damage over time. Inspect and replace the air filter regularly to maintain airflow and efficiency.

Transmission and Drivetrain Overview

The transmission and drivetrain system plays a crucial role in the overall performance and efficiency of an all-terrain vehicle. This intricate assembly is responsible for transferring power from the engine to the wheels, enabling smooth acceleration and effective handling across various terrains. Understanding the components and their functions can significantly enhance maintenance and troubleshooting efforts.

Key Components

At the heart of the drivetrain are several essential components, including the gearbox, drive shafts, and differentials. The gearbox is designed to adjust the torque and speed, allowing for optimal performance depending on the riding conditions. Meanwhile, drive shafts connect the gearbox to the wheels, ensuring that power is efficiently delivered. The differential allows for variations in wheel speed during turns, which is critical for maintaining traction and stability.

Maintenance Considerations

Regular maintenance of the transmission and drivetrain is vital to prolonging the lifespan of these components. Routine checks should include fluid levels, wear and tear on belts and chains, and ensuring proper alignment. Addressing any issues promptly can prevent more significant problems and enhance the vehicle’s overall performance.

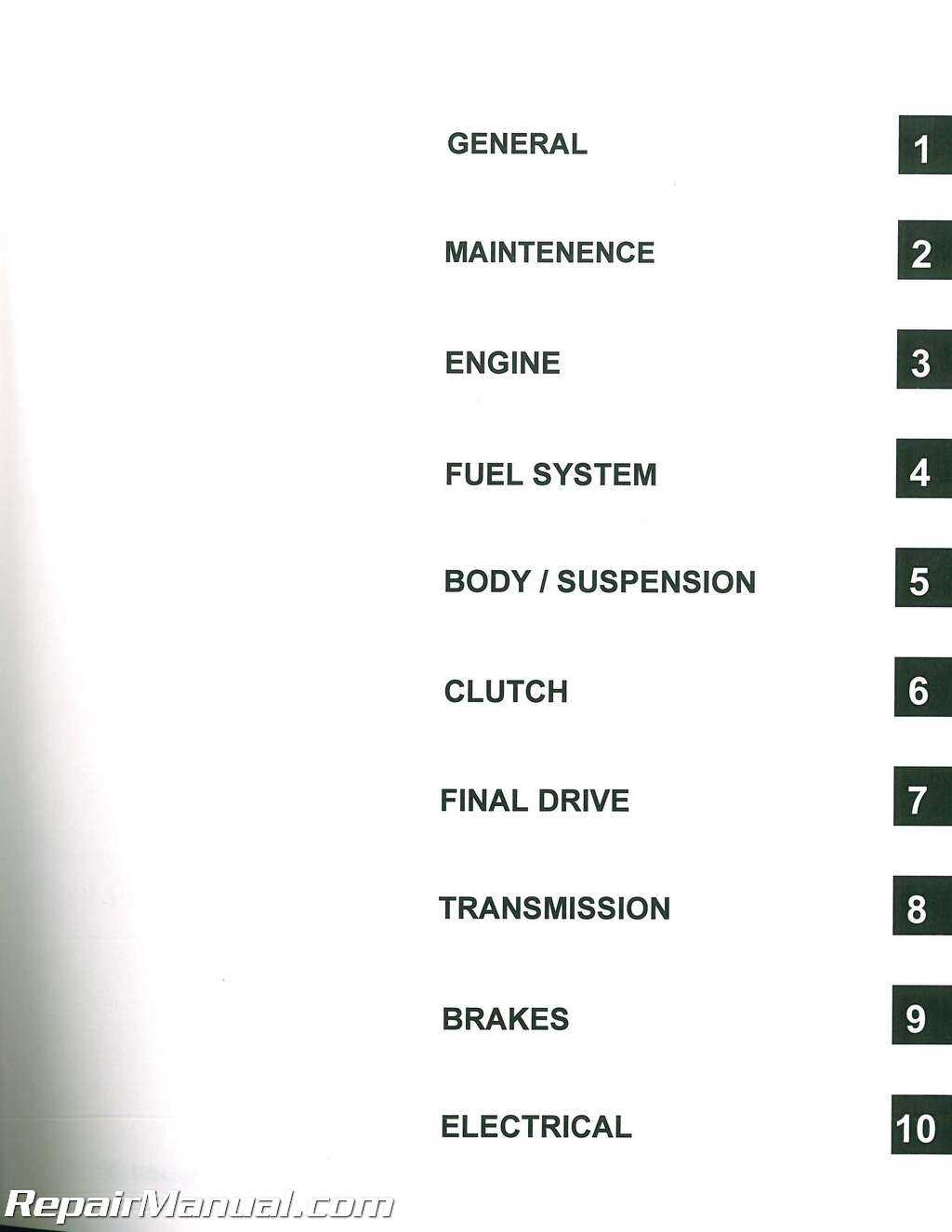

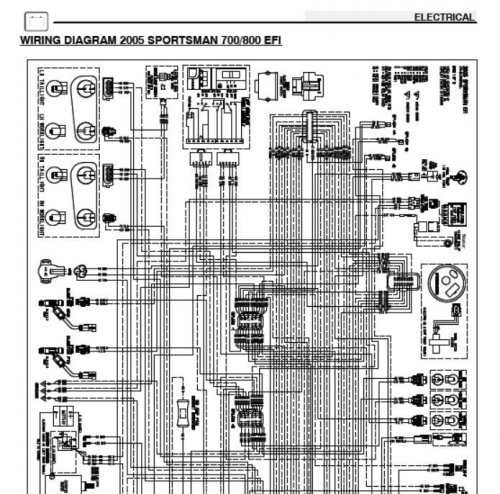

Electrical System Diagnostics Guide

This section focuses on the essential procedures for diagnosing electrical issues within an off-road vehicle. Understanding the electrical system’s components and their interactions is crucial for effective troubleshooting. Proper diagnosis ensures optimal performance and longevity of the vehicle.

To begin the diagnostic process, it is important to gather necessary tools and have a clear understanding of the electrical schematic. This guide outlines the common symptoms of electrical malfunctions and the corresponding steps for identification and resolution.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power to accessories | Blown fuse or faulty wiring | Inspect fuses and wiring connections; replace as needed. |

| Dim headlights | Weak battery or poor ground connection | Check battery voltage and ground points; clean or replace as required. |

| Intermittent starting issues | Starter relay failure or ignition switch problem | Test the starter relay and ignition switch; replace if faulty. |

| Electrical shorts | Damaged insulation or loose connections | Inspect wiring harness for damage; repair or replace as necessary. |

By following these guidelines and systematically addressing each symptom, one can effectively diagnose and remedy electrical issues, leading to a smoother and more reliable riding experience.

Suspension and Steering Repairs

The performance and safety of an all-terrain vehicle heavily rely on its suspension and steering systems. Proper maintenance of these components is essential for a smooth ride and optimal handling. This section will delve into common issues that can arise in these areas and provide guidance on troubleshooting and resolving them effectively.

Common Suspension Issues

Suspension problems can manifest as excessive bouncing, uneven tire wear, or abnormal noises during operation. Regularly inspecting shock absorbers, springs, and bushings for signs of wear can help identify issues early. Replacing worn components is crucial for maintaining stability and comfort on rough terrains.

Steering System Maintenance

A well-functioning steering mechanism is vital for maneuverability and control. Symptoms of steering troubles may include looseness, difficulty in turning, or unusual vibrations. Checking the steering linkage and fluid levels, along with tightening any loose connections, ensures responsive handling. Addressing these issues promptly can enhance overall driving experience.

Brake System Maintenance Steps

Proper upkeep of the braking mechanism is crucial for ensuring safe and efficient operation. Regular checks and maintenance help in identifying potential issues before they escalate, thereby enhancing overall performance and longevity.

The following steps outline essential maintenance practices for the brake system:

- Inspection of Brake Pads:

- Check for wear and tear.

- Replace pads that show significant thinning.

- Ensure even wear across all pads.

- Fluid Check:

- Inspect brake fluid levels regularly.

- Top up with the recommended fluid type if necessary.

- Replace fluid if it appears contaminated or discolored.

- Brake Lines Examination:

- Look for cracks, leaks, or damage in the lines.

- Ensure all connections are secure.

- Testing the Braking Response:

- Perform a visual inspection of the entire system.

- Test the brakes at low speed for responsiveness.

- Listen for unusual noises during operation.

- Adjustment of Brake Components:

- Ensure that calipers are aligned properly.

- Adjust the tension of cables, if applicable.

Following these steps will contribute to a reliable and efficient brake system, enhancing safety during operation.

Cleaning and Lubrication Techniques

Maintaining optimal performance of your all-terrain vehicle requires regular cleaning and proper lubrication. These practices not only enhance the longevity of components but also ensure smooth operation under various conditions. This section explores effective methods and best practices for keeping your machine in peak condition.

Essential Cleaning Methods

Regular cleaning helps remove dirt, mud, and debris that can accumulate during rides. It is crucial to focus on key areas that are prone to dirt buildup.

| Area to Clean | Recommended Method | Frequency |

|---|---|---|

| Frame | Use a pressure washer or hose with mild soap | After each ride |

| Air Filter | Remove and clean with compressed air or replace | Every 10 hours of operation |

| Wheels | Brush with soap and water, rinse thoroughly | Every ride |

| Underbody | Scrape off mud and rinse | Weekly or after heavy use |

Effective Lubrication Practices

Proper lubrication is vital for reducing friction and wear on moving parts. Selecting the right type of lubricant and applying it correctly can significantly enhance the vehicle’s performance.

| Component | Type of Lubricant | Application Method |

|---|---|---|

| Chain | Chain oil or spray lubricant | Apply evenly along the length |

| Bearings | Grease suitable for high pressure | Inject using a grease gun |

| Cables | Light oil | Drip along the cable length |

| Suspension components | Silicone-based spray | Spray evenly to protect against moisture |

By implementing these cleaning and lubrication techniques, you can ensure that your vehicle remains reliable and performs at its best in any terrain.

Parts Replacement Recommendations

Maintaining optimal performance and longevity of your vehicle involves timely replacement of essential components. This section provides guidelines for identifying and substituting parts that may exhibit wear or damage. Adhering to these suggestions will enhance functionality and ensure a smoother riding experience.

Key Components to Monitor

- Filters: Regularly inspect air and oil filters for clogs or dirt buildup.

- Belts: Check drive belts for signs of cracking or fraying.

- Fluids: Ensure that all fluid levels, including engine oil and coolant, are topped up and free from contamination.

- Brake Pads: Monitor the thickness of brake pads and replace them as needed to maintain stopping power.

Replacement Best Practices

- Consult the manufacturer’s specifications for compatible parts to ensure proper fit and function.

- Utilize high-quality replacement components to avoid premature failure.

- Perform replacements in pairs when applicable, such as shocks or brake pads, for balanced performance.

- Document any changes made, including dates and parts used, to maintain a comprehensive service history.

Safety Precautions for DIY Repairs

Engaging in maintenance and troubleshooting tasks can be rewarding, but it is essential to prioritize safety throughout the process. Proper precautions not only protect the individual performing the work but also ensure that the equipment remains in optimal condition. Understanding potential hazards and taking proactive steps can significantly reduce the risk of accidents or injuries.

Before starting any hands-on project, it is crucial to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to safeguard against sharp edges, hot surfaces, or flying debris. Additionally, ensuring that the workspace is clean and well-lit can help prevent trips and falls, making the environment safer for any tasks at hand.

Moreover, it is advisable to familiarize oneself with the equipment before diving into repairs. Consulting relevant guides or resources can provide valuable insights into the specific components and potential risks involved. Always make sure to have the necessary tools readily available and in good condition, as using faulty equipment can lead to unintended consequences.

Finally, working in a well-ventilated area is paramount, especially when dealing with chemicals or substances that may emit fumes. Taking breaks and staying hydrated are also important to maintain focus and prevent fatigue. By adhering to these guidelines, individuals can enhance their safety while effectively addressing maintenance needs.

Where to Find Repair Manuals

Locating comprehensive guides for maintenance and troubleshooting can significantly enhance your experience with your vehicle. These resources are essential for anyone looking to perform their own service or address specific issues effectively.

There are several reliable avenues to explore when seeking these valuable documents:

| Source | Description |

|---|---|

| Manufacturer’s Website | Often, the original equipment maker provides downloadable documents or links to online resources for their products. |

| Online Retailers | Many e-commerce platforms offer printed or digital versions of these resources, allowing for quick purchase and access. |

| Automotive Forums | Dedicated communities frequently share links or upload copies of these documents, providing invaluable peer support. |

| Local Dealerships | Authorized dealers often have physical copies or can order specific documents on request, ensuring authenticity. |

| Library Resources | Many public libraries maintain archives of automotive literature that can be accessed for free. |

Exploring these options can lead you to the necessary documentation, ensuring you have the information required for effective maintenance and repairs.