Comprehensive Guide to Repairing the 2007 Mercury Outboard

In the world of marine engines, understanding the intricacies of maintenance is crucial for ensuring optimal performance and longevity. This guide aims to provide invaluable insights into the nuances of upkeep, highlighting essential procedures and troubleshooting techniques. Whether you are a seasoned professional or a passionate hobbyist, having access to detailed information can significantly enhance your experience on the water.

Regular upkeep is not merely a suggestion; it is a necessity for anyone looking to keep their aquatic machinery in top shape. By familiarizing yourself with specific processes and best practices, you can avoid common pitfalls and minimize costly repairs. This guide will walk you through various components and offer practical advice tailored to your needs.

Furthermore, understanding the common challenges faced by enthusiasts can empower you to tackle issues head-on. Equipped with the right knowledge, you will be able to diagnose problems accurately and implement effective solutions. Dive into this resource to enrich your skills and boost your confidence in maintaining your marine engine.

Overview of Mercury Outboard Models

This section provides a comprehensive look at various models produced by a renowned marine engine manufacturer. Understanding these units is essential for enthusiasts and operators alike, as each design serves specific purposes and applications in the boating world.

Types of Engine Configurations

Different configurations play a crucial role in determining the performance and efficiency of marine propulsion systems. Options range from lightweight two-stroke designs, which are known for their speed and simplicity, to more robust four-stroke alternatives that offer enhanced fuel economy and reduced emissions. Each configuration caters to unique boating needs, whether for casual fishing trips or high-performance racing.

Features and Innovations

These power units incorporate various features aimed at improving usability and durability. Innovations such as advanced fuel injection systems, noise reduction technologies, and corrosion-resistant materials enhance the overall experience for users. Additionally, the integration of digital controls allows for greater precision in handling, making it easier for operators to manage their vessels effectively.

Common Issues with 2007 Models

Various challenges can arise with marine propulsion systems from this production year. Recognizing these frequent problems can help owners maintain optimal performance and extend the lifespan of their equipment.

- Fuel System Problems:

- Clogged fuel filters leading to reduced power.

- Issues with fuel lines causing leaks.

- Contaminated fuel affecting engine performance.

- Electrical Failures:

- Batteries not holding charge properly.

- Corrosion on terminals impacting connectivity.

- Faulty ignition systems preventing start-up.

- Cooling System Issues:

- Overheating due to blocked water passages.

- Pump malfunctions affecting water flow.

- Inadequate maintenance leading to scale build-up.

- Propulsion Difficulties:

- Worn propellers resulting in poor thrust.

- Transmission problems leading to gear shifting issues.

- Alignment issues causing vibrations during operation.

Understanding these common concerns allows for timely interventions and better overall functionality. Regular inspections and maintenance can mitigate these problems significantly.

Essential Tools for Repairs

When undertaking maintenance on marine engines, having the right equipment is crucial for effective troubleshooting and restoration. Proper tools not only facilitate the process but also ensure safety and efficiency. This section outlines the fundamental instruments every technician should possess to handle various tasks confidently.

Basic Tool Requirements

The following are the core tools necessary for any technician aiming to maintain or fix marine engines. These tools provide a solid foundation for most tasks and can be supplemented with specialized equipment as needed.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Wrenches | Essential for gripping and turning fasteners. |

| Screwdrivers | Necessary for assembling and disassembling components. |

| Torque Wrench | Ensures fasteners are tightened to the specified tension. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can enhance the repair process. These tools help address specific challenges that may arise during maintenance tasks.

| Tool | Purpose |

|---|---|

| Multimeter | Measures electrical voltage, current, and resistance. |

| Fuel Line Clamps | Helps in safely managing fuel lines during service. |

| Engine Hoist | Assists in lifting heavy components for access. |

| Propeller Puller | Facilitates the removal of propellers for inspection. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and performance of your marine engine. By following a systematic approach, you can effectively address common issues and enhance the overall functionality. This section outlines detailed procedures that guide you through various maintenance tasks, ensuring that your vessel remains in optimal condition.

1. Inspect the Fuel System: Begin by checking fuel lines and connections for any signs of wear or leaks. Clean or replace fuel filters as necessary to prevent clogging, which can lead to engine inefficiency.

2. Check the Cooling System: Ensure the water intake is clear and unobstructed. Flush the cooling system regularly to eliminate any debris or buildup that could impede performance. Replace worn impellers to maintain proper water flow.

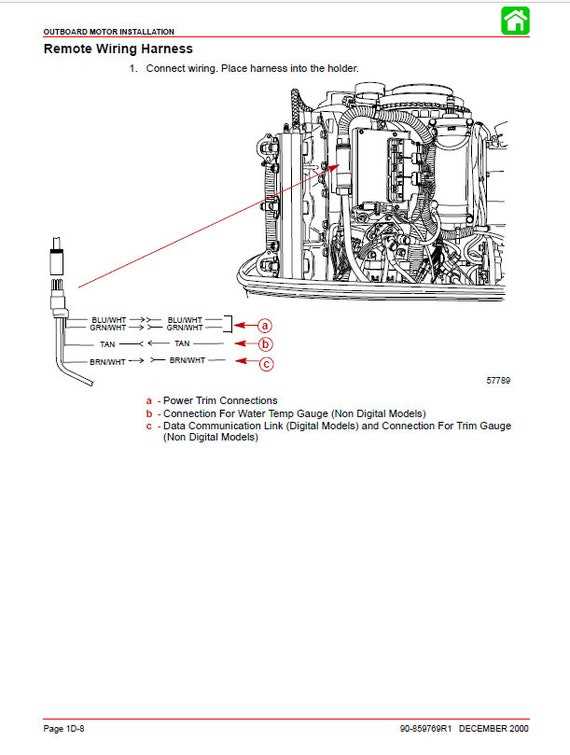

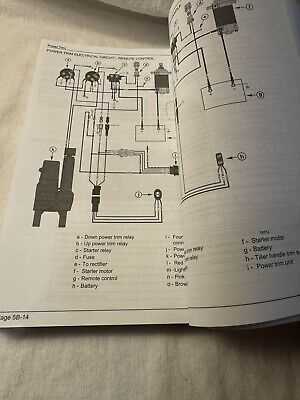

3. Examine Electrical Components: Inspect the battery for corrosion and ensure terminals are tight. Test the charging system and replace any faulty wiring or connectors. Keeping connections clean and secure is crucial for reliable operation.

4. Assess the Propeller: Remove the propeller and check for nicks or damage. Cleaning the propeller will also enhance efficiency. Reinstall it securely, ensuring that all components are in good condition.

5. Change the Lubricants: Regularly replace the engine oil and lubricants to reduce friction and prevent wear. Always use the recommended products for your specific engine model, and check the oil levels frequently.

6. Conduct a Visual Inspection: Periodically examine the exterior of the engine for signs of rust, cracks, or other damage. Address any issues promptly to avoid further complications.

By adhering to these outlined procedures, you can significantly improve the reliability and performance of your marine engine, ensuring that it operates smoothly for years to come.

Understanding Engine Components

Comprehending the various elements that make up an engine is essential for effective maintenance and troubleshooting. Each part plays a crucial role in ensuring optimal performance and longevity of the machinery. By familiarizing oneself with these components, one can better appreciate how they function together to create power and efficiency.

Main Parts of an Engine

- Crankshaft: Converts linear motion into rotational motion.

- Piston: Moves within the cylinder, compressing the fuel-air mixture.

- Cylinder: Houses the piston and is where combustion occurs.

- Camshaft: Controls the timing of valve openings and closings.

- Fuel System: Delivers fuel to the combustion chamber for ignition.

Additional Components

- Ignition System: Initiates combustion by creating a spark.

- Exhaust System: Expels waste gases produced during combustion.

- Cooling System: Regulates engine temperature to prevent overheating.

- Lubrication System: Reduces friction between moving parts and prolongs engine life.

Understanding these fundamental elements provides a foundation for recognizing issues and implementing effective solutions, ultimately enhancing the overall functionality of the engine.

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues within the electrical framework of your vessel’s propulsion system. Understanding the components and their functions is crucial for identifying and resolving malfunctions effectively.

1. Identifying Symptoms: Begin by observing any irregularities during operation. Common indicators include failure to start, flickering lights, or unusual sounds. Take note of these signs, as they can guide your troubleshooting process.

2. Inspecting Connections: A frequent cause of electrical problems is loose or corroded connections. Examine all wiring and terminals for signs of wear or damage. Ensure that all connections are secure and free from corrosion, as this can greatly affect performance.

3. Testing Components: Utilize a multimeter to check the voltage and continuity of critical parts such as the battery, ignition system, and fuses. Ensure that readings fall within the specified ranges, as deviations can indicate faults that need addressing.

4. Reviewing the Battery: The power source is often at the heart of electrical issues. Confirm that the battery is fully charged and in good condition. A weak or failing battery can lead to a host of problems, including difficulty starting and erratic performance.

5. Analyzing the Circuitry: If issues persist, delve deeper into the circuit layout. Trace wiring paths and consult the electrical schematics to pinpoint any discrepancies or potential short circuits. This systematic approach will help you isolate the source of the malfunction.

6. Seeking Professional Help: If troubleshooting does not resolve the issues, consider consulting a professional. Experienced technicians can provide insights and repairs that may be beyond DIY capabilities, ensuring your system is safe and reliable.

By following this guide, you will enhance your ability to diagnose and rectify electrical challenges, contributing to the overall reliability and performance of your vessel.

Fuel System Care and Repair

Maintaining the fuel system is essential for ensuring optimal performance and longevity of your marine engine. A well-functioning fuel delivery system guarantees that the engine receives the right amount of fuel, minimizing issues related to combustion and overall efficiency. Regular checks and maintenance can help prevent common problems that may arise due to neglect.

Here are key areas to focus on for effective fuel system maintenance:

- Fuel Quality: Always use high-quality fuel. Contaminated or old fuel can lead to performance issues.

- Filters: Regularly inspect and replace fuel filters to prevent blockages and ensure smooth fuel flow.

- Lines and Hoses: Check for cracks, leaks, or wear in fuel lines and hoses, replacing them as necessary to prevent leaks.

- Pump Functionality: Test the fuel pump to ensure it is functioning correctly, as a malfunction can impede fuel delivery.

Following these practices can significantly enhance the reliability and efficiency of your engine. In addition to routine checks, consider the following steps for thorough care:

- Drain and replace stale fuel to avoid clogs and ensure optimal combustion.

- Inspect all connections for tightness and security, preventing air leaks that can affect performance.

- Monitor engine performance regularly for any signs of fuel-related issues, addressing them promptly.

- Consult with professionals for any complex issues beyond basic maintenance.

By staying proactive with these tasks, you can ensure a reliable fuel system that supports the overall efficiency and functionality of your marine engine.

Cooling System Functionality Explained

The cooling system plays a crucial role in maintaining optimal operating temperatures for marine engines. Its primary function is to regulate heat, ensuring that the engine performs efficiently and does not overheat. This process is vital for the longevity of the engine and the overall performance of the vessel.

A typical cooling system utilizes a combination of water and coolant to absorb heat generated during combustion. The heat is then transferred away from the engine components, allowing them to function within a safe temperature range. In many designs, water is drawn from the surrounding environment and circulated through the engine, where it absorbs excess heat before being expelled.

Key components of this system include the water pump, thermostat, and heat exchanger. The water pump is responsible for drawing water into the system, while the thermostat regulates the flow based on the engine’s temperature. The heat exchanger facilitates the transfer of heat from the engine to the coolant, preventing overheating.

Maintenance of the cooling system is essential for optimal performance. Regular checks for leaks, blockages, and the condition of the coolant can prevent significant issues down the line. Keeping the cooling system in good working order not only enhances engine efficiency but also prolongs its lifespan.

Propeller and Gearbox Maintenance

Ensuring the longevity and efficiency of your vessel’s propulsion system relies heavily on proper upkeep of critical components. Regular attention to the propeller and gearbox can prevent costly repairs and enhance performance, allowing for a smoother and more reliable experience on the water.

Propeller Care

The propeller plays a vital role in generating thrust, making its maintenance essential. Regular inspections for signs of wear, damage, or corrosion can help identify issues early. Additionally, cleaning the propeller after use, especially in saltwater environments, can prevent buildup and extend its lifespan.

Gearbox Inspection

The gearbox is responsible for transferring power from the engine to the propeller. Regular checks for oil levels, leaks, and wear can ensure optimal function. It’s crucial to follow manufacturer recommendations for fluid changes to maintain the system’s integrity.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Propeller | Every Use | Look for nicks, bends, or corrosion. |

| Clean Propeller | After Each Use | Especially in saltwater. |

| Check Gearbox Oil Level | Monthly | Top off if low; replace if dirty. |

| Inspect Gearbox for Leaks | Monthly | Address leaks immediately. |

Using the Repair Manual Effectively

Maximizing the utility of a technical guide involves understanding its structure and utilizing its resources to address issues efficiently. Familiarity with the content layout enhances the troubleshooting process, allowing for quicker identification of problems and appropriate solutions.

Understanding the Layout

A comprehensive guide typically includes sections that cover specifications, troubleshooting steps, and maintenance tips. Knowing where to find specific information is crucial for a smooth experience. Start by familiarizing yourself with the table of contents and index, which can save valuable time during diagnostics.

Utilizing Resources

Make the most of illustrations and diagrams provided in the documentation. Visual aids can clarify complex instructions and enhance comprehension. Additionally, take notes on your findings and modifications as you work, which will facilitate future reference and ongoing maintenance.

| Section | Description |

|---|---|

| Specifications | Details about technical parameters and performance standards. |

| Troubleshooting | Step-by-step guidance for diagnosing common issues. |

| Maintenance | Recommendations for routine care and upkeep to ensure longevity. |

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance is crucial for both personal well-being and the integrity of the equipment. Adopting proper safety measures helps prevent accidents and injuries, allowing for a more efficient and effective workflow. This section highlights essential precautions to consider before and during any servicing tasks.

Proper Gear and Equipment

Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear. This not only safeguards against potential hazards but also enhances your ability to work with tools and materials safely. Additionally, ensure that all equipment used is in good condition and suitable for the tasks at hand.

Work Environment Considerations

Maintain a clean and organized workspace to minimize the risk of accidents. Remove any unnecessary items that could obstruct movement or become tripping hazards. Good lighting is essential; ensure your area is well-lit to clearly see what you are working on. Lastly, always be mindful of your surroundings, particularly when using power tools or handling heavy components.

Where to Find Replacement Parts

Locating components for your marine engine can seem daunting, but with the right resources, it becomes a straightforward task. Various options exist to help you secure the necessary items for maintenance or upgrades, ensuring your vessel remains in optimal condition.

Consider exploring the following avenues to find quality parts:

| Source | Description |

|---|---|

| Authorized Dealers | Official dealerships often carry a wide range of genuine components. They can provide expertise and support tailored to your specific engine model. |

| Online Retailers | Numerous e-commerce platforms specialize in marine parts, offering convenience and competitive pricing. Be sure to verify the seller’s reputation. |

| Local Marine Stores | Brick-and-mortar shops can be a valuable resource. They may have parts in stock and offer personalized service. |

| Salvage Yards | For budget-friendly options, consider checking out salvage yards. They often have used parts that are still in good condition. |

| Online Marketplaces | Platforms like eBay or Craigslist can connect you with individual sellers. However, exercise caution and verify the condition of parts before purchase. |

Utilizing these resources will help you find the necessary components to keep your marine engine running smoothly and efficiently.