Polaris Ranger 2007 Repair Guide

The importance of understanding the upkeep of your all-terrain vehicle cannot be overstated. Proper maintenance ensures longevity, optimal performance, and safety on various terrains. This guide aims to provide essential insights and techniques for vehicle owners to effectively manage their machinery.

By delving into the intricacies of your vehicle’s components, you can identify common issues and address them proactively. This not only enhances the driving experience but also minimizes the risk of unexpected breakdowns. Equipped with the right knowledge, you can ensure that your vehicle remains in peak condition throughout its lifecycle.

Whether you are a novice or a seasoned enthusiast, familiarizing yourself with fundamental maintenance practices will empower you to take control of your vehicle’s care. With detailed instructions and tips, this guide serves as a valuable resource for all vehicle owners looking to enhance their understanding of maintenance protocols.

2007 Polaris Ranger Maintenance Overview

This section provides essential insights into the upkeep and care required for optimal performance and longevity of your all-terrain vehicle. Regular attention to maintenance tasks not only enhances functionality but also ensures safety and reliability during use.

Key Maintenance Tasks

- Regular fluid checks and changes

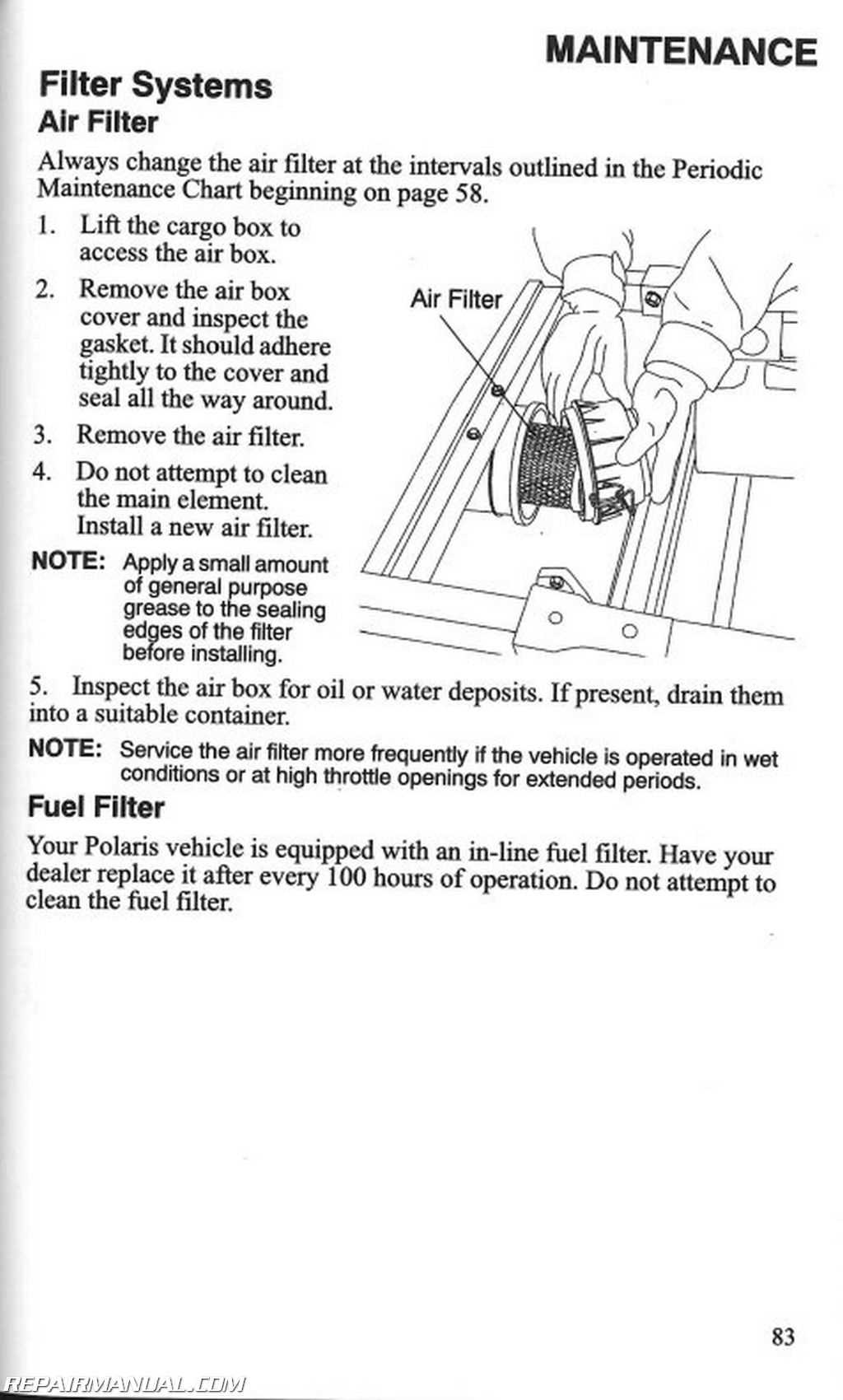

- Inspecting and replacing filters

- Tire maintenance, including pressure and tread depth checks

- Battery maintenance and inspection

- Brake system checks

Seasonal Care Tips

- Clean the exterior and undercarriage to remove debris and prevent corrosion.

- Check the lighting system for functionality.

- Examine the suspension system for wear and damage.

- Ensure all safety features are operational.

- Store the vehicle in a sheltered environment during off-seasons.

Understanding Your Ranger’s Components

The intricacies of your vehicle’s system are essential for optimal performance and longevity. Familiarizing yourself with the various elements allows for informed decisions during maintenance and troubleshooting. Each part plays a crucial role in the overall functionality.

Engine: The heart of your machine, responsible for generating power. Regular checks on this component can prevent potential issues that might hinder performance.

Transmission: This system transfers power from the engine to the wheels, ensuring smooth movement. Understanding its operation helps in recognizing signs of wear or malfunction.

Suspension: Vital for stability and comfort, this system absorbs shocks from uneven terrain. Proper maintenance ensures a smoother ride and better control.

Electrical System: Comprising the battery, wiring, and various components, this system is crucial for starting and operating accessories. A thorough understanding aids in identifying electrical issues quickly.

Incorporating knowledge of these elements empowers you to maintain your vehicle effectively, enhancing its reliability and efficiency.

Common Issues and Troubleshooting Tips

Understanding frequent complications that may arise with utility vehicles can greatly enhance the overall experience for users. This section aims to provide insights into typical problems and effective solutions to ensure optimal functionality.

Starting Difficulties: One of the most common issues encountered is trouble starting the vehicle. This can often be traced back to a weak battery or poor electrical connections. Regularly checking and maintaining battery health can prevent such occurrences.

Engine Performance: Users may experience a lack of power or irregular engine behavior. This can result from fuel quality issues or clogged filters. It is advisable to use high-quality fuel and perform regular filter replacements to maintain smooth operation.

Steering Problems: Difficulty in steering may signal underlying mechanical issues. Inspecting the steering components for wear and ensuring proper lubrication can resolve these concerns effectively.

Brake System: A decrease in braking efficiency is a critical safety concern. Regular inspections of brake pads and fluid levels are essential. If any irregularities are detected, addressing them promptly can prevent accidents.

By staying aware of these common issues and applying the recommended troubleshooting tips, users can ensure their utility vehicles remain in excellent working condition.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and fixing tasks. A well-equipped workspace enhances efficiency and ensures that issues can be addressed promptly. Understanding which instruments are necessary can save time and prevent complications during the process.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for most tasks. They allow for the assembly and disassembly of various components with ease. Additionally, having a set of sockets can help access hard-to-reach areas, making it easier to tackle intricate jobs.

Power tools like drills and impact wrenches can significantly speed up work, particularly for tasks that require more force or precision. Furthermore, safety equipment such as gloves and goggles is essential to protect yourself while working, ensuring that repairs are completed without injury.

Lastly, having a reliable diagnostic tool can assist in identifying problems quickly. This technology provides valuable insights, helping to determine the necessary steps for effective solutions. Investing in these essential tools will greatly enhance the ability to maintain and service your vehicle efficiently.

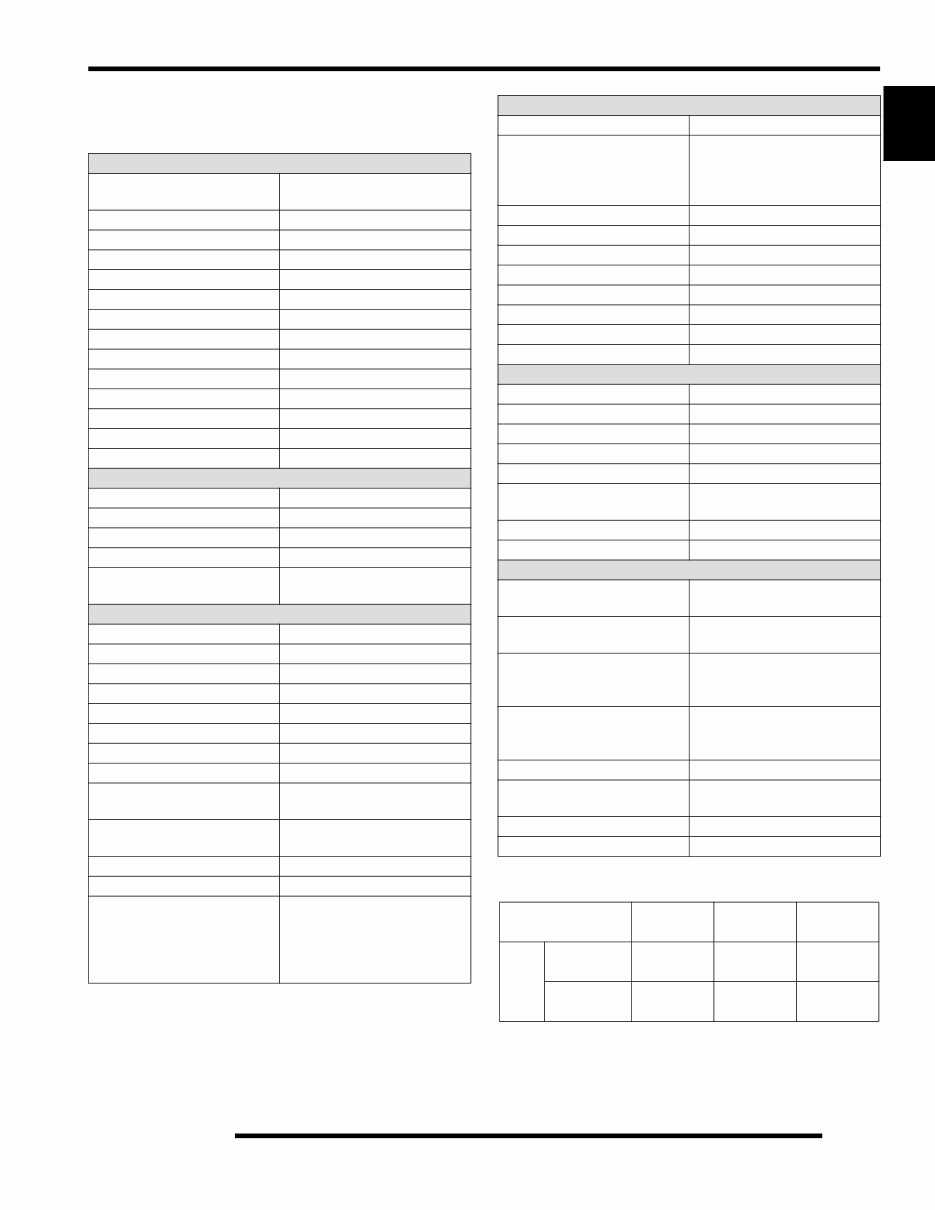

Fluid Maintenance and Replacement Guidelines

Proper upkeep of various fluids is essential for optimal performance and longevity of your vehicle. Regular checks and timely replacements help ensure that the systems operate smoothly and prevent potential damage.

Engine Oil: Regularly monitor the oil level and quality. Change the oil based on the manufacturer’s recommendations or whenever it appears dark and gritty. Use the appropriate viscosity for your engine to maintain efficiency.

Coolant: Check the coolant level frequently to avoid overheating. Replace it as needed, typically every two years, to prevent corrosion and scale buildup within the cooling system.

Transmission Fluid: Inspect the transmission fluid regularly for discoloration and odor. Change it according to the suggested intervals to maintain smooth shifting and avoid costly repairs.

Brake Fluid: Ensure brake fluid is at the correct level and replace it every couple of years to maintain braking efficiency and safety.

Fuel System: Use high-quality fuel and consider periodic fuel system cleaning to prevent injector clogs and maintain optimal engine performance.

Electrical System Diagnostics

This section focuses on the analysis and troubleshooting of the electrical framework, essential for maintaining optimal performance. Understanding the functionality and interconnections of various components can help identify potential issues before they escalate.

Common Issues and Symptoms

Various problems may arise within the electrical system, such as inconsistent power delivery, malfunctioning indicators, or battery drainage. Recognizing these signs early can lead to effective resolutions and prevent further complications.

Diagnostic Procedures

Utilizing diagnostic tools and following systematic testing protocols are crucial in assessing the integrity of the electrical components. Begin by checking the battery and connections, then proceed to evaluate the wiring and circuit integrity for any anomalies.

Suspension and Steering Adjustments

This section focuses on the modifications and fine-tuning necessary for the suspension and steering systems of utility vehicles. Proper adjustments ensure optimal handling, comfort, and performance on various terrains.

Importance of Proper Alignment

Correct alignment of the steering components is crucial for maintaining stability and control. Misalignment can lead to uneven tire wear and affect handling. Regular checks are recommended to avoid these issues.

Adjusting Suspension Settings

Modifying the suspension settings can enhance the vehicle’s ability to absorb shocks and improve ride quality. Adjustments can be made based on load requirements and driving conditions.

| Adjustment Type | Description | Recommended Frequency |

|---|---|---|

| Alignment Check | Ensures wheels are parallel and positioned correctly. | Every 3,000 miles |

| Shock Absorber Adjustment | Tweaks the stiffness of the shock absorbers for varied loads. | As needed |

| Spring Preload Setting | Adjusts the initial tension on the springs to match weight. | Every 6 months |

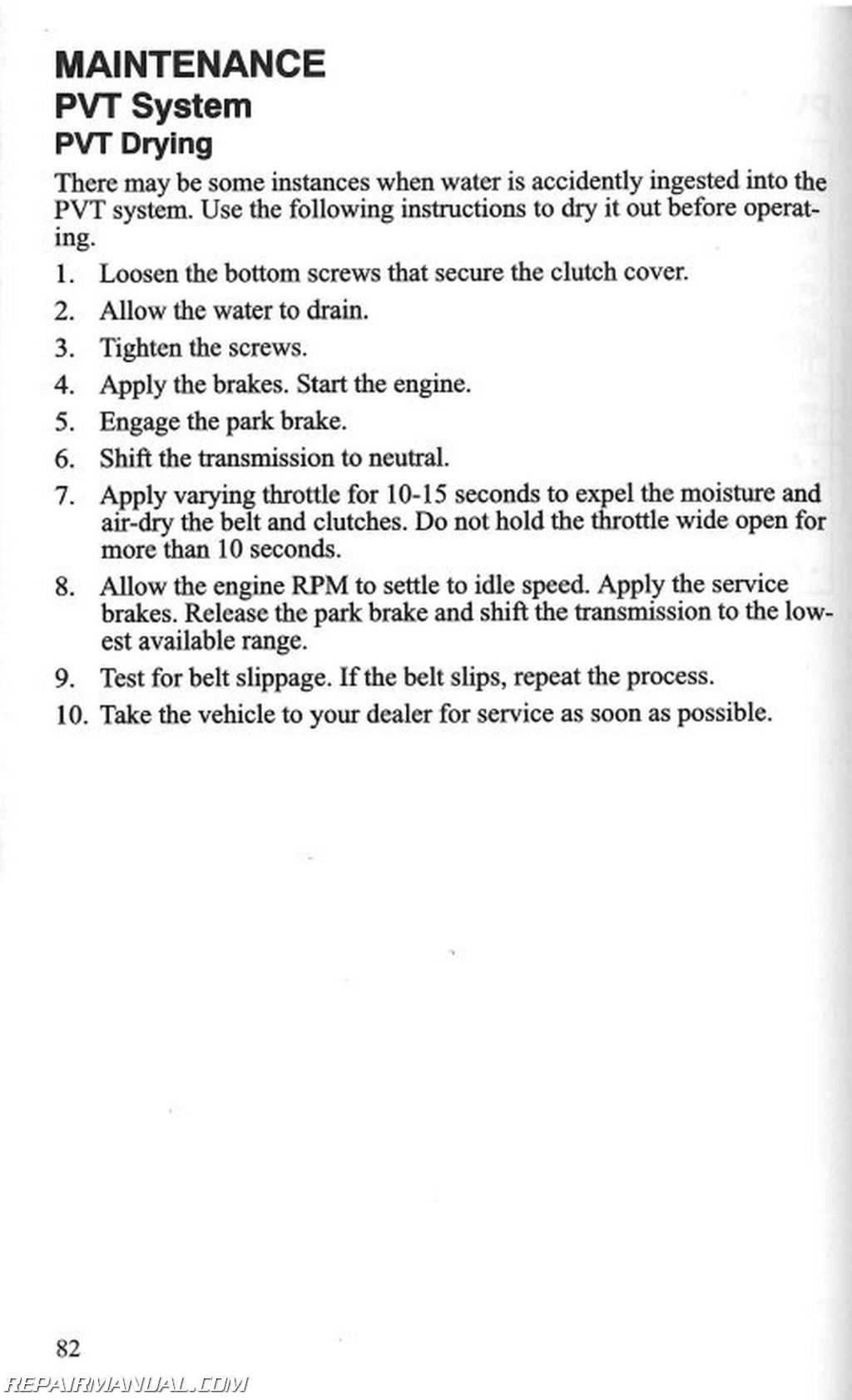

Brake System Inspection Procedures

Regular evaluation of the braking mechanism is essential for ensuring optimal performance and safety. Proper procedures help identify potential issues before they escalate, contributing to a reliable driving experience.

Begin by visually examining the brake components for signs of wear or damage. Check for fluid leaks around the lines and fittings, as well as inspecting the condition of the brake pads or shoes. Ensure that the rotors or drums are not excessively worn and that their surfaces are smooth.

Next, assess the brake fluid level in the reservoir. Low fluid levels may indicate a leak or wear in the braking components. If the fluid appears contaminated, it should be replaced. Additionally, examine the brake lines for any signs of cracking or corrosion.

Perform a functional test by pressing the brake pedal to evaluate its responsiveness. A spongy or unresponsive pedal may suggest air in the lines or worn components that require attention. Ensure that the brake system engages effectively and that there are no unusual noises during operation.

Finally, consult the specific guidelines for adjusting and servicing the braking system. Following the recommended practices ensures that all components are functioning correctly and contributes to the longevity of the system.

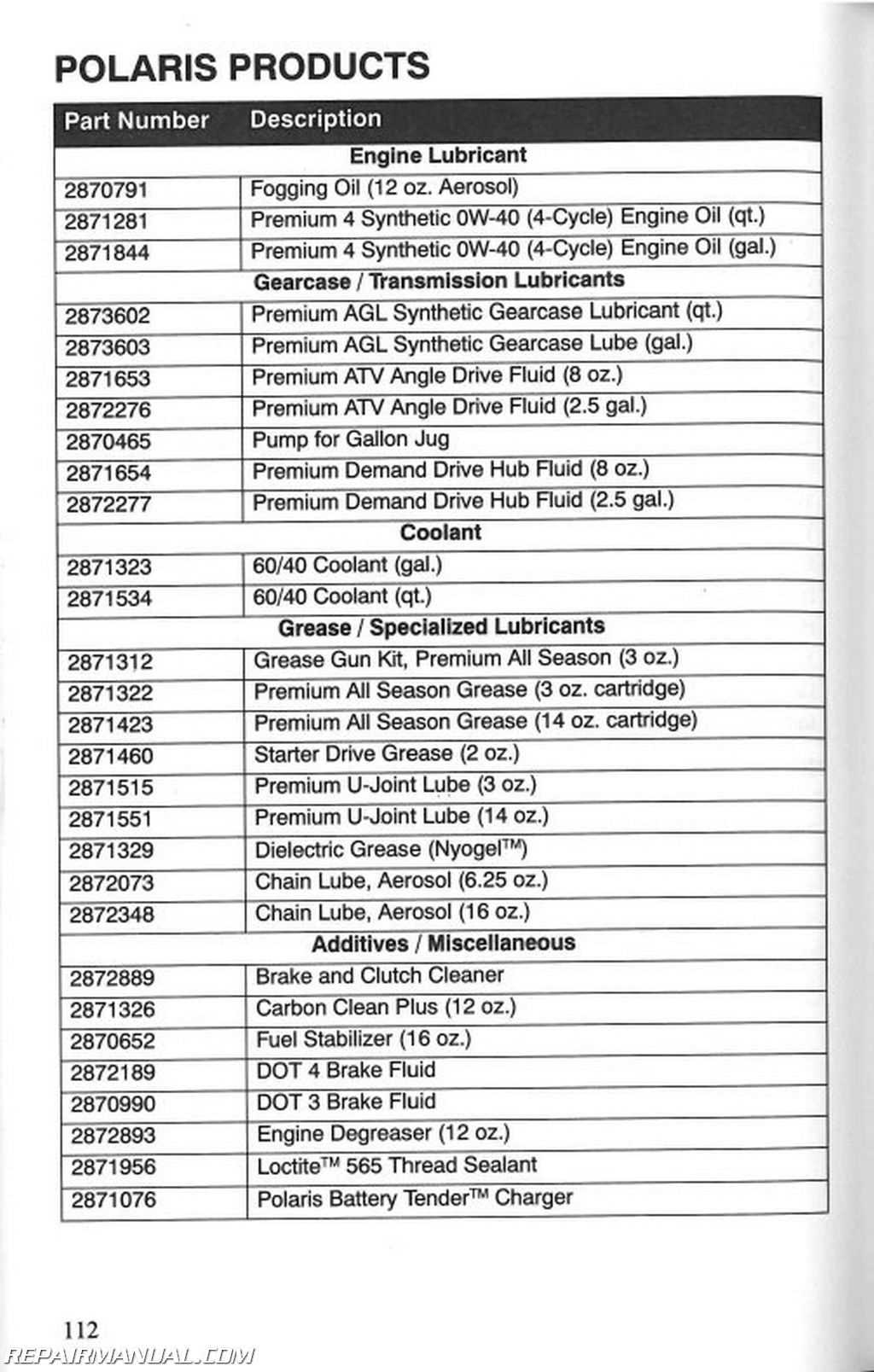

Engine Performance Enhancements

Improving engine efficiency and power output can significantly enhance overall vehicle performance. Various modifications can be implemented to achieve better acceleration, responsiveness, and fuel efficiency. Below are some common enhancements that can be considered to optimize engine capabilities.

| Enhancement | Description |

|---|---|

| Cold Air Intake | Installing a cold air intake system allows the engine to draw in cooler, denser air, leading to improved combustion and increased power. |

| Performance Exhaust | A high-flow exhaust system reduces back pressure, allowing for better exhaust gas evacuation and improved engine breathing. |

| Tuning | Reprogramming the engine control unit (ECU) can optimize fuel maps and ignition timing for enhanced performance and efficiency. |

| High-Performance Spark Plugs | Upgrading to high-performance spark plugs can improve ignition efficiency and enhance engine responsiveness. |

| Fuel System Upgrade | Enhancing the fuel delivery system with larger injectors or a performance fuel pump can provide the necessary fuel for increased power demands. |

Tire Care and Replacement Advice

Maintaining the quality and condition of your vehicle’s tires is crucial for optimal performance and safety. Proper care not only extends the life of the tires but also enhances overall driving experience. Below are essential guidelines to ensure your tires remain in excellent shape.

Routine Maintenance Tips

- Regularly check tire pressure to ensure it matches the manufacturer’s recommendations.

- Inspect tread depth to monitor wear and ensure sufficient traction.

- Look for signs of damage, such as cuts, bulges, or punctures.

- Rotate tires periodically to promote even wear.

- Keep tires clean and free from debris that can cause damage.

When to Replace Tires

Knowing when to replace your tires is essential for safety. Consider the following signs:

- Worn tread that reaches the wear indicators.

- Visible cracks or damage on the tire surface.

- Frequent loss of air pressure.

- Vibration or noise during driving that indicates imbalance.

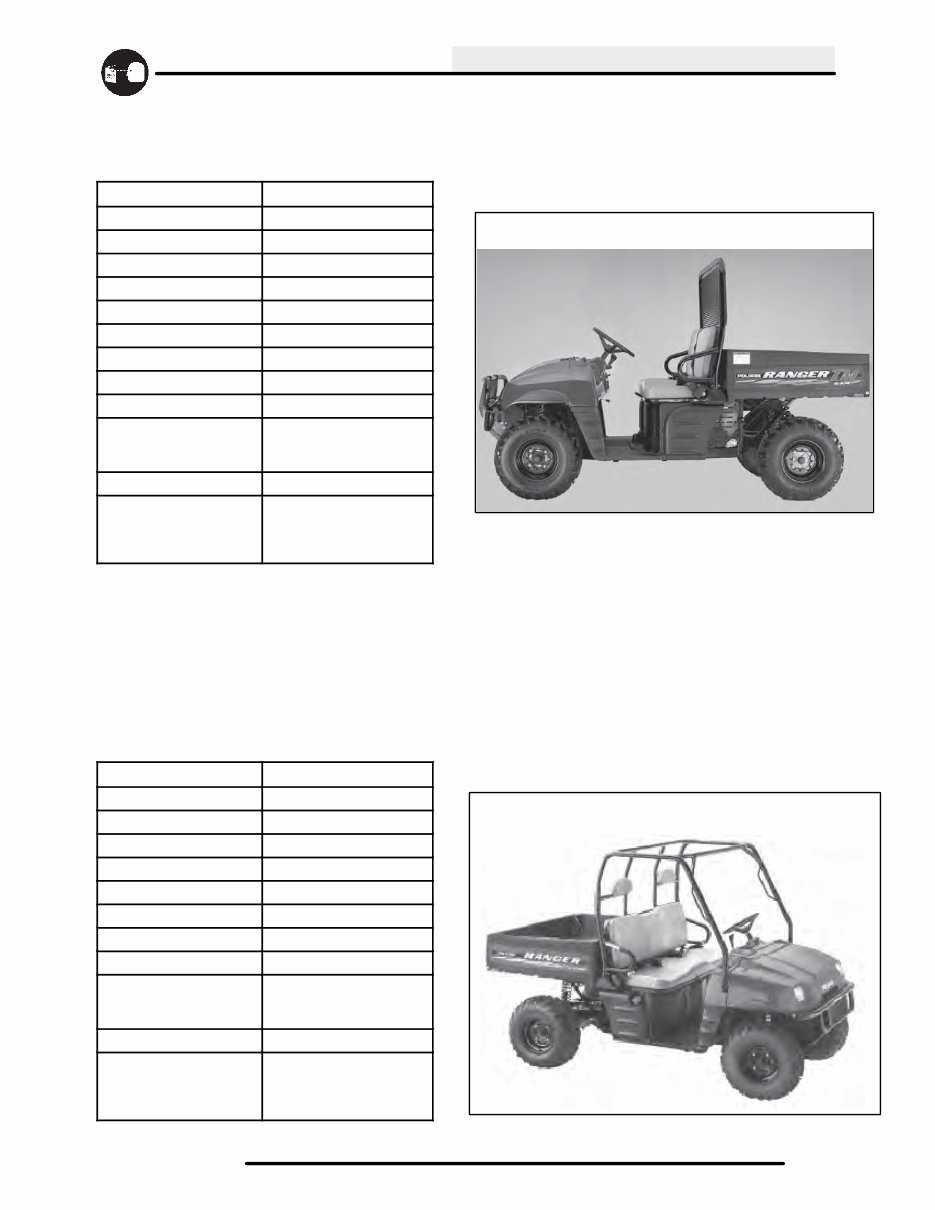

Safety Features and Compliance Checks

This section focuses on the essential safety mechanisms and the importance of regulatory adherence in off-road vehicles. Ensuring that these vehicles are equipped with the right safety features not only enhances user protection but also guarantees compliance with industry standards and regulations.

Essential Safety Mechanisms

Key safety elements include roll bars, seat belts, and proper lighting. These components are designed to minimize risks during operation and improve visibility. Regular inspections of these features ensure they are functioning correctly, providing peace of mind to users.

Importance of Compliance Checks

Routine compliance checks are crucial for maintaining vehicle safety and performance. Adhering to established guidelines helps identify potential hazards and ensures that all safety features meet the necessary standards. This proactive approach is vital for both the operator’s safety and the longevity of the vehicle.

Preparing for Seasonal Storage

Proper preparation for seasonal storage is essential to ensure the longevity and optimal performance of your vehicle. Taking the right steps will protect it from environmental factors and mechanical issues during the off-season.

Steps to Follow

Begin by cleaning the exterior and interior thoroughly, removing dirt and debris. Next, change the fluids, including oil and fuel, to prevent contaminants from causing damage. Consider adding a fuel stabilizer to keep the fuel system in good condition.

Final Checks

Inspect the battery and ensure it is fully charged. Disconnect it if possible to prevent drainage. Lastly, cover your vehicle with a breathable cover to protect it from dust and moisture while allowing ventilation.